ALKALINE HYDROLYSIS OF EXPLOSIVES by Catherine Elizabeth VanEngelen

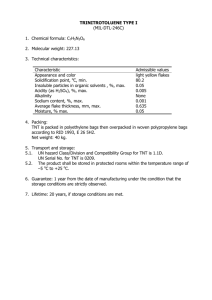

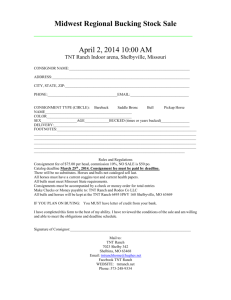

advertisement