RISK ASSESSMENT OF PLANT-BASED PHARMACEUTICALS AND BIOLOGICS by

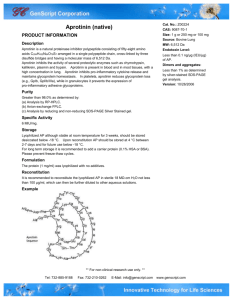

advertisement