1

advertisement

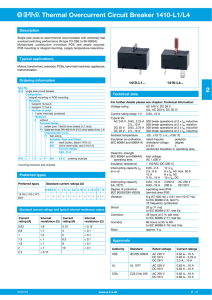

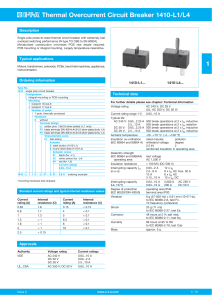

Thermal Overcurrent Circuit Breaker 1410-L/-G... Description Single pole press-to-reset thermal circuit breaker with extremely fast overload switching performance (R-type TO CBE to EN 60934). Single hole threadneck, PCB or integral mounting with a choice of designs. Miniaturized construction minimizes PCB real estate required. Type 1410-L2 and 1410-G1 versions feature changeover contacts suitable for providing status output signals. Largely temperature-insensitive. 1 Typical applications Motors, transformers, solenoids, PCBs, hand-held machines, appliances, instrumentation. Ordering information L 1 1 0 - L1 1410-L2... F1 - S 01 - 0.8 A ordering example Voltage rating Current rating range 1-2 Auxiliary circuit 1-3 Typical life Ambient temperature Insulation co-ordination (IEC 60664 and 60664A) Dielectric strength (IEC 60664 and 60664A) operating area Insulation resistance Interrupting capacity Icn (o-o-o) Interrupting capacity (UL 1077) Degree of protection (IEC 60529/DIN 40050) Vibration Shock Standard current ratings and typical internal resistance values Corrosion Current rating (A) 0.63 Internal resistance (Ω) 1.8 Current rating (A) 3.15 Internal resistance (Ω) < 0.12 Humidity Mass 0.8 1.7 4 < 0.1 1 1.3 4.5 < 0.1 1.25 <1 5 < 0.1 1.5 <1 6.3 < 0.1 1.8 <1 8 < 0.1 2 <1 10 < 0.1 2.5 < 0.15 All dimensions without tolerances are for reference only. In the interest of improved design, performance and cost effectiveness the right to make changes in these specifications without notice is reserved.Product markings may not be exactly as the ordering codes. Errors and omissions excepted. Issue D 1410-G1... Technical data Type No. 1410 single pole circuit breaker Configuration L PCB mounting G threadneck panel mounting Mounting 1 threadneck 3/8-27 UNS-2A (1410-G) 1 PCB 16.3x4.6 grid (1410-L) .642 x .181 2 PCB 10.15x7.6 grid (1410-L) .400 x .299 Number of poles 1 1 pole, thermally protected Hardware 0 without 1 with hex nut and knurled nut (1410-G only) bulk shipped Terminal design L1 solder pins 1.8x0.8 silver-plated (-L1 only) L2 solder pins 1x0.8 silver-plated (-L2 and -G1 only) P2 blade terminals A2.8-0.8 (QC .110) silver-plated (-G1 only) Characteristic curve F1 fast acting Actuator S manual re-set Actuator colour 01 black (for -G1.. and -L1..) 02 white (for -L2..) Current ratings 0.63 ... 10 A 1410- 1410-L1... ☎ AC 240 V; DC 28 V (AC 250 V; DC 50 V UL/CSA) 0.63...10 A 0.2 x IN max. 1 A, AC 250 V style -L2 and -G1 only 300 operations at 2 x IN (-L2...) 500 operations at 2 x IN (-L1../-G1..) -20...+100 °C (-4...+212 °F) Rated impulse Pollution withstand voltage degree 2.5 kV 2 reinforced insulation in operating area Test voltage AC 1,500 V > 100 MΩ (DC 500 V) 0.63...2 A 12 x IN 2.5 ...8 A 8 x IN, AC max. 50 A 10 A 6 x IN, AC 3.15...10 A 10 x IN, DC 0.63...10 A 2,000 A AC 250 V 0.63...10 A 200 A DC 50 V operating area IP 40 terminal area IP 00 8 g (57-500 Hz) ±0.61 mm (10-57 Hz), to IEC 60068-2-6, Test Fc, 10 frequency cycles/axis 20 g (11 ms) to IEC 60068-2-27, test Ea 48 hours at 5 % salt mist, to IEC 60068-2-11, test Ka 96 hours at 95 % RH to IEC 60068-2-3, test Ca approx. 5 g Approvals Authority Voltage rating Current ratings VDE AC 240 V 0.63...10 A DC 50 V 0.63...2.5 A UL, CSA USA (847) 827-7600 - www.e-t-a.com - ☎ DC 28 V 2.5 ...10 A AC 250 V; DC 50 V 0.63...10 A CANADA (905) 764-9510 59 Thermal Overcurrent Circuit Breaker 1410-L/-G... Dimensions Internal connection diagrams 12.8 .504 1410-L110-L1F1-S01 12.5 .492 15 .591 1 1410-L11... 1410-L21... 1410-G11... 2 3 2 1 1 5 .197 8.6 .339 17 .669 20.1 .791 1.8 .071 4.6 ±0.2 .181 ±.008 1.8 .071 25 .984 0.8 .031 mounting holes 1410-L210-L2F1-S02 2 16.3 ±0.2 .642 ±.008 Typical time/current characteristics at +23°C/+73.4°F 9 .354 10000 1 1000 0.8 .031 1 .039 6.4 .252 7.6 .299 10.15 .400 mounting holes 3 6.4 ±0.2 .252 ±.008 7.6 ±0.1 .299 ±.004 7.5 .295 1410-G111-L2F1-S01 2 100 1 +0.1 10.15- 0.2 .400 +.004 - .008 1 10.15 3 .118 2 0.8 .031 1 2 4 6 8 10 20 40 … times rated current mounting hole 11 .433 15.7 .618 0.01 9 .354 8.9 - 0.1 .350 - .004 7.6 .400 .299 28 1.10 8.8 .346 3.3 .130 1 .039 6.4 .252 1 0.1 1.2 .047 11.3 .445 11 .433 0.7 .028 ø7 .276 3 10 7 .276 3/8-27UNS-2A Trip time in seconds 3.3 .130 3 6 ±0.2 .236 ±.008 3.5 .138 1.2 .047 9.6 .378 0.8 .031 1.4 .055 33 1.30 30 1.18 28 1.10 Installation drawings 1410-L11... ø9.6 - 0.1 SW14 .551 1410-G111-P2F1-S01 operating area wall made of insulating material .378 - .004 13 .512 7 .276 1410-G... 3 .118 1 0.8 .031 operating area wall made of insulating material 9 .354 blade terminal DIN 46244-A2.8-0.8 (QC .110) 15.7 .618 8.9 - 0.1 .350 - .004 10.15 7.6 .400 .299 28 1.10 1.2 .047 8 .315 8.8 .346 2.8 .110 6.4 .252 2 mounting hole mounting area 11 .433 ~20° mounting area 11 .433 0.7 .028 11.3 .445 3 SW14 .551 60 1 .039 3/8-27UNS-2A ø7 .276 ø9.6 - 0.1 .378 - .004 13 .512 mm This is a metric design and millimeter dimensions take precedence ( inch ) ☎ USA (847) 827-7600 - www.e-t-a.com - ☎ CANADA (905) 764-9510 Issue D