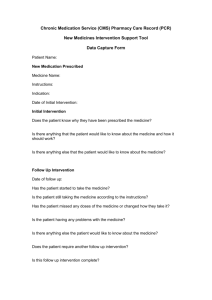

THE STUDY OF ERRORS, EXPECTATIONS AND SKILLS FOR MEDICATION by

advertisement