_________ ________________ 2.830J / 6.780J / ESD.63J Control of Manufacturing Processes (SMA... MIT OpenCourseWare

advertisement

MIT OpenCourseWare

http://ocw.mit.edu

_________

___

2.830J / 6.780J / ESD.63J Control of Manufacturing Processes (SMA 6303)

Spring 2008

For information about citing these materials or our Terms of Use, visit: ________________

http://ocw.mit.edu/terms.

Control of

Manufacturing Processes

Subject 2.830/6.780/ESD.63

Spring 2008

Lecture #4

Probability Models of

Manufacturing Processes

February 14, 2008

Manufacturing

1

Note: Reading Assignment

• May & Spanos

– Read Chapter 4

• Montgomery

– Skim/consult Chapters 2 & 3 if need additional

explanations or examples beyond May & Spanos

Manufacturing

2

Turning Process

Manufacturing

3

Observations from Experiments

• Randomness + Deterministic Changes

CNC Turning

0.7020

random or

unknown

0.7010

Δα

0.7000

0.6990

0.6980

Shift changes

0.6970

Run Number

Manufacturing

4

CNC Data

0.6253

Outer

Middle

Inner

0.6251

0.6249

Operating Points:

High Feed=1

Low Feed = 2

0.6247

0.6245

0.6243

0.6241

0.6239

0.6237

0.6235

1

2

3

Manufacturing

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

5

Brake Bending of Sheet

Output:

Angle

M

M

ε

σ

Manufacturing

6

Bending Process

Springback

Manufacturing

7

Observations from Bending Process

• Clear Input-Output Effects (Deterministic)

• Also Randomness as well

90

80

Steel 0.6 In

70

Aluminum 0.6 In

60

Steel 0.3 In

50

40

Aluminum 0.3 In

Angle

changes

with depth

ΔY ⇒ Δu

30

20

Manufacturing

8

Observations from Injection Molding

QuickTime™ and a

Graphics decompressor

are needed to see this picture.

Run Chart for Injection Molded Part

Holding Time = 5 sec

Injection Press = 60%

41.00

Holding Time = 5 sec

Injection Press = 40%

40.95

Holding Time = 10 sec

Injection Press = 40%

Holding Time = 10 sec

Injection Press = 60%

2/3/05

50

40.90

40.85

Width (mm)

Average

40.80

40.75

40.70

40.65

40.60

0

10

20

30

40

50

60

Number of Run

Manufacturing

9

Observations from Data

• Clearly some measurement “noise”?

90

80

70

60

shift 3

50

40

shift 1

shift 2

30

20

Manufacturing

10

Observations from Data

• Systematic/traceable “operator error”

Sheet Shearing

1.01

0.99

0.97

0.95

steel

0.93

0.91

0.89

0.87

shift

change

steel

shift

change

aluminum

0.85

Manufacturing

11

How Model to Distinguish these Effects?

Irreducible

Disturbances

Inputs

Process

Outputs

+

"Noise"

Disturbances

(Reducible)

A Random Process + A Deterministic Process

Manufacturing

12

Random Processes

• Consider the Output-only, “Black Box” view of the

Run Chart

Process

Y(t)

• How do we characterize the process?

– Using Y(t) only

• WHY do we characterize the process

– Using Y(t) only?

Manufacturing

13

The Why

•

•

•

•

Did output really change?

Did the input cause the change?

If not, why did the output vary?

How confident are we of these answers?

Process

• Can we model the randomness?

Manufacturing

14

Background Needed

• Theory of Random Processes and Random

Variables

• Use of Sample Statistics Based on

Measurements

– SPC basis

– DOE: use of experimental I/O data

– Feedback control with random disturbances

Manufacturing

15

How to Describe Randomness?

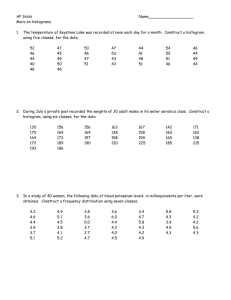

• Look at a Frequency Histogram of the Data

• Estimates likelihood of certain ranges

occurring:

– Pr(y1 < Y <y2)

– “Probability that a random variable Y falls

between the limits y1 and y2”

Manufacturing

16

Example: Thermoforming Histogram (2000 data)

12

1.505

Thermoforming Run Chart

1.5

1.495

10

1.49

Part Diameter

Shift Changes

1.485

1.48

8

1.475

Run Number

6

4

2

0

1.48

1.482

Manufacturing

1.484

1.486

1.488

1.49

1.492

1.494

1.496

1.498

1.5

1.502

17

How to Describe Continuous Randomness

• Process outputs Y are continuous variables

• The Probability of Y(t) taking on any specific value for a

continuum

Prob(Y(t) = y*) = 0

• Must use instead a Cumulative Probability Function

Pr(Y(t)<y*)

– Look at Cumulative Frequency

Manufacturing

18

Cumulative Frequency

60

12

10

8

6

50

4

2

0

1.48

1.482

1.484

1.486

1.488

1.49

1.492

1.494

1.496

1.498

1.5

1.502

A Continuous equivalent?

40

Pr(Y<1.49)=14/50

= 0.28

30

20

10

0

1.48

1.482

Manufacturing

1.484

1.486

1.488

1.49

1.492

1.494

1.496

1.498

191.5

Continuous Equivalents

• Probability Function: (P(x))

60

P

50

40

30

20

10

x

• Probability Density Function pdf(x) = dP/dx

0

1.48

1.482

1.484

1.486

1.484

1.486

1.488

1.49

1.492

1.49

1.492

1.494

1.496

1.498

1.5

12

p(x)

10

8

6

4

2

0

x

Manufacturing

1.48

1.482

1.488

1.494

1.496

1.498

1.5

1.502

20

Process Outputs as a Random Variable

• The Histogram suggests a pdf

– Parent or underlying behavior “sampled” by the

process

• Standard Forms (There are Many)

– e.g. The Uniform and Normal pdf’s

Normal Probability Density Function for σ2 = 1, μ=0

0.4

p(x)

0.3

0.2

0.1

-4

-3

-2

-1

0

1

2

3

4

x

Manufacturing

21

Analysis of Histograms

• Is there a consistent pattern?

• Is an underlying “parent” distribution suggested?

Manufacturing

22

Histogram for CNC Turning

CNC Turning

0.7020

25

0.7010

0.7000

0.6990

20

15

10

5

0.6980

0

0.697

0.698

Shift changes

0.7

0.699

0.6970

0.701

0.702

47

45

43

41

39

37

35

33

31

29

27

25

23

21

19

17

15

13

11

9

7

5

3

1

Bin Dimension (in)

Run Number

Manufacturing

23

Histogram for Bending

(MIT 2002 data)

Bending Data Sorted by Depth

150

140

14

0.3 in depth only

Dashed Lines are at group changes

120

12

110

Steel

0.6 in

depth

Aluminum

0.6 in depth

100

Aluminum

0.3in depth

10

Steel

0.3 in

depth

90

133

129

125

121

117

113

109

105

97

101

93

89

85

81

77

73

69

65

61

57

53

49

45

41

37

33

29

25

21

8

17

9

13

5

80

1

Angle (Deg.)

130

6

4

2

0

134

Manufacturing

134.5

135

135.5

136

136.5

137

137.5

138

138.5

139

139.5

140

140.5

141

141.5

142

24

Histogram for Bending

(MIT 2002 data)

Bending Data Sorted by Depth

150

0.6 in depth only

140

Dashed Lines are at group changes

18

Angle (Deg.)

130

120

110

16

Steel

0.6 in

depth

Aluminum

0.6 in depth

100

Aluminum

0.3in depth

Steel

0.3 in

depth

90

14

133

129

125

121

117

113

109

97

105

93

101

89

85

81

77

73

69

65

61

57

53

49

45

41

37

33

29

25

21

17

9

13

5

1

80

12

10

8

6

4

2

0

98

98.5

99

99.5

100

100.5

101

101.5

102

102.5

103

103.5

104

104.5

Mean Shift?

Manufacturing

25

Consider: No Intentional Changes (Δu = 0)

• Shearing during shift 1(‘02) , aluminum only

60

50

40

30

20

10

0

0.91

Manufacturing

0.915

0.92

0.925

0.93

0.935

0.94

0.945

0.95

26

Consider: No Effective Changes (∂Y/∂u= 0)

• Injection Molding Entire MIT Run (2002)

25

1.895

1.89

20

1.885

1.88

1.875

15

Shift

Change

1.87

1.865

10

5

0

1.875

Manufacturing

1.8775

1.88

1.8825

1.885

1.8875

1.89

27

Injection Molding (S’2003)

66.4

40

66.2

35

66

65.8

Frequency

30

65.6

65.4

25

65.2

1

8

15

22

29

36

43

50

57

64

71

78

85

92

99 106 113 120 127

20

15

10

5

0

65.4 65.5 65.5 65.6 65.6 65.7 65.7 65.8 65.8 65.9 65.9

Manufacturing

66

66

28

Conclusion?

• When there are no input effect (no Δu or ∂Y/∂u) a

consistent histogram pattern can emerge

• How do we use knowledge of this pattern?

– Predict behavior

– Set limits on “normal” behavior

• Define analytical probability density functions

Manufacturing

29

Underlying or “Parent” Probability

• A model of the “true”, continuous behavior of the

random process

• Can be thought of as a continuous random variable

obeying a set of rules (the probability function)

• We can only glimpse into these rules by sampling the

random variable (i.e. the process output)

• Underlying process can have

– Continuous values (e.g. geometry)

– Discrete values (e.g. defect occurrence)

Manufacturing

30

Continuous Probability Functions

• Recall Probability Function (Cumulative)

P(x) = Prob(Y(t)<x)

P

• Define pdf = p(x) = dP/dx

Thus :

P(x) =

∫

x

−∞

x

p(x)

pdf (x)dx

x

Manufacturing

31

Use of the pdf : Expectation

E{x(t)} = expected value of x(t)

E{x(t)} =

∫

∞

-∞

x(t) pdf (x,t )dx

μ(t) = E{x(t)} mean value of x

Note that pdf and μ (or any other expected value)

can be functions of time.

In general, they may be non-stationary.

Manufacturing

32

Stationary Processes

pdf(x,t) = pdf(x) = p(x) : stationary pdf

E{x} =

∞

∫x

p(x)dx = μx

−∞

μx : theoretical or " true" mean

• For a stationary process μx is a constant

Manufacturing

33

Stationary Processes

E{( x − μx ) } =

2

∞

∫ (x − μ )

2

x

p(x)dx = σ

2

x

−∞

= "true" variance

• For a stationary process σx is a constant

σ = E{x } − μ

2

x

2

2

x

= mean square - square of mean

Manufacturing

34

The Uniform Distribution

1

r

p(x) = 0

p(x) =

p(x)

⇒ x1 < x < x 2

⇒ x < x1

x > x2

1/r

x1

Manufacturing

r

x2

x

35

The Normal Distribution

1

p(x) =

e

σ 2π

1 ⎛ x− μ⎞

− ⎜

⎟

2⎝ σ ⎠

2

0.4

“Standard normal”

z=

0.3

x−μ

σ

0.2

μz=0

σz=1

0.1

0

-4

-3

-2

-1

0

1

2

3

4

z

Manufacturing

36

Cumulative Distribution

P(z)

1

0.8

0.6

0.4

0.2

0

-4

-4

-3

-3

-2

-2

-1

-1

0

0

1

1

2

2

3

3

4

4

z

Manufacturing

37

Properties of the Normal pdf

• Symmetric about mean

• Only two parameters:

μ and σ

1

p(x) =

e

σ 2π

1 ⎛ x−μ⎞

− ⎜

⎟

2⎝ σ ⎠

2

• Superposition Applies:

– sum of normal random variables has a normal

distribution

Manufacturing

38

Superposition of Random Variables

If we define a variable

y = c1x1 + c2x2 + c3x3 + c4x4 + ...

• ci are constants

• xi are independent random variables

μy = c1μ1 + c2μ2 + c3μ3 + c4μ4 + ...

σy2 = c12σι2 + c22σ22 + c32σ32 + c42σ42

From expectation operation, for any pdf.

Manufacturing

39

Use of the PDF: Confidence Intervals

• How likely are certain values of the random

variable?

• For a “Standard Normal” Distribution:

z=

(x − μ )

σ

N(0,1)

μ=0

σ =1

z = 1 ⇒ x = 1σ

z = 2 ⇒ x = 2σ

z = 3 ⇒ x = 3σ

0.4

0.3

0.2

0.1

-4

Manufacturing

-3

-2

-1

0

0

1

2

3

4

40

Confidence Intervals

P(-1≤ z ≤ 1) = P(z ≤1) - P(z ≤-1) = 0.841 - (1-0.841) = 0.682

(+ 1σ)

P(-2≤ z ≤ 2) = P(z ≤2) - P(z ≤-2) = 0.977 - (1-0.977) = 0.954

(+ 2σ)

P(-3≤ z ≤ 3) = P(z ≤3) - P(z ≤-3) = 0.998 - (1-0.998) = 0.997

(+ 3σ)

P(z) tabulated (e.g. p. 752 of Montgomery)

Manufacturing

41

Confidence Intervals

0.4

0.3σ = 3/1000

• Probability that |x| >μ+3

68%

0.2

95%

0.1

99.7%

-4

-3

-2

-1

0

1

2

3

4

z

±σ

±2 σ

±3 σ

Manufacturing

42

Is the Process “Normal” ?

• Is the underlying distribution really normal?

– Look at histogram

– Look at curve fit to histogram

– Look at % of data in 1, 2 and 3 σ bands

• Confidence Intervals

– Probability (or qq) plots (see Mont. 3-3.7)

– Look at “kurtosis”

• Measure of deviation from normal

Manufacturing

43

Kurtosis: Deviation from Normal

k=

E( x − μ x )

σ

4

4

k=1 - normal

k>1 more “peaked”

k<1 more “flat”

Or for sampled data:

4

⎡

n(n + 1)

3(n − 1)2

⎛ xi − x ⎞ ⎤

k=⎢

⎟ ⎥−

⎜

∑

⎢⎣ (n − 1)(n − 2)(n − 3) ⎝ s ⎠ ⎥⎦ (n − 2)(n − 3)

Manufacturing

44

The Central Limit Theorem

– If x1, x2 ,x3 ...xN … are N independent observations of

a random variable with “moments” μx and σ2x,

– The distribution of the sum of all the samples will

tend toward normal.

Manufacturing

45

Example: Uniformly Distributed Data

70

60

x1

50

40

30

100

y = ∑ xi

20

10

0

Sum of 100 sets of

1000 points each

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

+

i =1

150

70

60

50

x2

40

30

20

100

10

0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

+...

50

70

60

50

x100

40

30

20

0

35

40

45

50

55

60

65

10

0

0

0.1

0.2

0.3

0.4

0.5

0.6

Manufacturing

0.7

0.8

0.9

1

46

Sampling: Using Measurements (Data)

to Model the Random Process

•

•

In general p(x) is unknown

Data can suggest form of p(x)

– e.g.. uniform, normal, weibull, etc.

•

Data can be used to estimate parameters of distributions

– e.g. μ and σ for normal distribution - p(x) = p(x, μ ,σ)

•

How to Estimate

– Sample Statistics

•

Uncertainty in Estimates

1

p(x) =

e

σ 2π

1 ⎛ x− μ⎞

− ⎜

⎟

2⎝ σ ⎠

2

– Sample Statistic pdf’s

Manufacturing

47

Sample Statistics

x( j) = samples of x(t ) taken n times

1 n

x = ∑ x( j) : Average or Sample Mean

n j =1

n

1

2

2

S =

(x( j) − x ) : Sample Variance

∑

n − 1 j =1

S =

1 n

2

(x( j) − x ) : Sample Std.Dev.

∑

n − 1 j =1

Manufacturing

48

Sample Mean Uncertainty

• If all xi come from a distribution with μx and σ2x, and

we divide the sum by n:

1 n

x = ∑ xi

n i =1

Then:

x = c1 x1 + c2 x2 + c3 x 3 + K cn xn

1

ci =

n

μx = μx

Manufacturing

and

1 2

1

σ = σ x or σ x =

σx

n

n

2

x

49

Conclusions

• All Physical Processes Have a Degree of

Natural Randomness

• We can Model this Behavior using Probability

Distribution Functions

• We can Calibrate and Evaluate the Quality of

this Model from Measurement Data

Manufacturing

50