Document 13444014

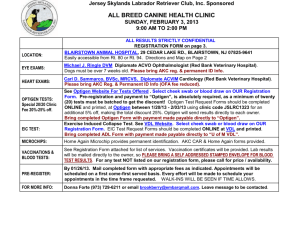

advertisement

Lecture: Systems Analysis Methodologies

Dr. John C. Wright

MIT - PSFC

28 SEP 2010

Introduction

Outline

O UTLINE

Scoping study

Systems analysis - increasing

detail

Life cycle analysis

Simulation models

Risk analysis and uncertainty

How are all these connected?

2

SE T-4 Systems Analysis

Introduction

Outline

I NTRODUCTION

Many issues for sustainability

requiring balance

We need to quantify to

proceed

Deal with complexity and

uncertainty

Economics Environment

This is the goal “Systems

Analysis”

Society

End result often involves very,

very large computer codes

How do we make such

computer models?

3

SE T-4 Systems Analysis

Scoping study

S COPING STUDY CHARACTERISTICS

We’ll see more of this in a fuel costs example next week.

Basic guidelines for a scoping study:

Highly simplified

Mostly linear analysis - add separate costs

Very few feedback effects

Advantages

Relatively simple to understand

Good overall picture

Identification of weaknesses

4

SE T-4 Systems Analysis

Systems Analysis

S YSTEMS A NALYSIS IS THE NEXT STEP IN EVALUATION

Assume a favorable scoping study

Next step is a detailed systems analysis

All elements are analyzed in much greater detail

For example in our nuclear plant scoping study we gave the fuel

price in $/kg

In a system analysis model these costs are further broken down

Fuel costs:

Mining costs

Conversion costs

Enrichment costs

Finance costs

5

SE T-4 Systems Analysis

Systems Analysis

M ODULARIZATION OF SYSTEMS ANALYSIS

Each of these may be further analyzed one or two levels deeper.

Input data will be based on experience and future projections.

The analysis will account for uncertainties.

All lower level contributions are combined to form one module of

the systems code

⇒ the fuel cost module.

6

SE T-4 Systems Analysis

Systems Analysis

SA INCLUDES NON - LINEAR EFFECTS

A critical feature in SA is the inclusion of interdependencies.

Systems analysis are not linear.

They include feedback effects.

For example consider mining costs:

Plenty of Reserves – no problem, linear relation works.

Reserves dwindle – other issues arise

Fuel costs will rise

Will new fuel be found, if so how much?

How will this affect the projected cost of fuel?

7

SE T-4 Systems Analysis

Systems Analysis

B EWARE OF COMPLEX CODES .

Systems analysis code contains a large number of complex

modules

Often hard to understand the whole picture, often expert in part of

the picture.

Should be more reliable than a scoping study thought.

Warning:

Be very careful using complex systems

analysis codes!!

8

SE T-4 Systems Analysis

Systems Analysis

SA IS NOT ONLY ABOUT MONEY

Investors are not the only people to carry out systems analysis

Investors focus on financial returns

Architectural engineers focus on technical credibility, schedule,

and cost

Environmentalists focus on pollution, waste disposal, greenhouse

gasses, etc.

Government focuses on the public good

9

SE T-4 Systems Analysis

Systems Analysis

G OVERNMENT IMPACT ON SA IS THROUGH REGULATION

Desirability of a regulation is in the eye of the stakeholder.

Everyone is a lobbyist.

Financial institutions.

Engineering firms.

Environmental groups.

Industrial groups.

Consideration of impact of regulation is part of any SA.

There often is an uncertain political aspect to a regulation.

10

SE T-4 Systems Analysis

Systems Analysis

S TRUCTURE OF A S YSTEMS A NALYSIS

Number of approaches to systems analysis

Method below is fairly typical

Goal of the analysis – answer the question

Does it make sense to build a new power

plant (of type X)?

The end product – a large, complex, hopefully all inclusive,

simulation code.

11

SE T-4 Systems Analysis

Systems Analysis

T HE S IMULATION C ODE

Technical aspects from a life cycle analysis

Regulation aspects from a risk analysis

Include feedback effects

Combine to create a financial analysis

12

SE T-4 Systems Analysis

Life Cycle Analysis

Systems Analysis

Life Cycle Analysis

L IFE C YCLE A NALYSIS (LCA) ELEMENTS

Emissions

Energy

Production of

Raw Materials

Wastes

Manufacturing

Process

Use of

Product

Wastes

Wastes

Disposal

Recycle

Wastes

Comprehensive cradle-to-grave, wells-to-wheels, dust-to-dust

Attributes:

analysisCosts, Resource use, Emissions, Wastes, Costs, Performance, etc.

Includes

Sum cumulative

attributes over total life cycle of product to compare net impacts

Raw materials

Materials processing

Manufacturing

Distribution

Repair and maintenance

Waste disposal

Decommissioning

13

SE T-4 Systems Analysis

MacDonald’s

Styrofoam or paper?

Oil (bad?)

Trees (natural?)

Chemicals (worse)

Paper (good ?)

Styrofoam (??)

Oil

Chlorine or

Peroxide

Pulp

Paper

PCBs +

Dioxins

Benzene + C2H4 + etc.

Acid or Alkali

Water

Wastewater

Hard to recycle

Plastic coating

Landfill

Trash

CFCs

CO2

Pentane

Styrene

Polystyrene foam

McD

Recycle

Courtesy of Elisabeth M. Drake. Used with permission.

Hydrogen Production Example

• Make from steam methane

reforming?

• Make from water electrolysis

using wind power?

Courtesy of Elisabeth M. Drake. Used with permission.

Steam Methane Reforming

System Boundary Definition

Upstream

processes

Plant Construction

& Decommissioning

Resources

in

Hydrogen

Natural gas

production & distribution

Fossil fuel

energy in

SMR plant

operation

Electricity

generation

System Boundary

Courtesy of Elisabeth M. Drake. Used with permission.

Emissions

air, water,

wastes

SMR Results

H2 is a clean fuel, but its production from natural gas

has environmental consequences

H2 plant itself produces few emissions, except CO2

CO2 is the largest air emission (98 wt%) and accounts

for 77% of the GWP

0.64 MJ of H2 produced for every 1 MJ of fossil

energy consumed

Courtesy of Elisabeth M. Drake. Used with permission.

Wind/Electrolysis Study

turbines

electrolyzer

H2 storage

Wind turbines:

Atlantic Orient Corporation (50kW x 3)

Class 5 wind data from upper Midwest site

(North Dakota)

Electrolyzer:

Stuart Energy (30 Nm3/hr nominal capacity)

Cars fueled: fleet of 46 at 3 kg/car/week

Courtesy of Elisabeth M. Drake. Used with permission.

GWP and Energy Balance

Wind/Electrolysis

Preliminary results:

• GWP = 650 g CO2-eq/kg H2

– Only 5% of the greenhouse gas emissions from SMR

• Energy balance = 20 MJ of H2 produced for every

1 MJ of fossil energy consumed

– 31 times more than the net energy balance from SMR

• Emissions are from equipment manufacture

– Majority from concrete bases for wind turbines

– Water consumption in electrolysis accounts for nearly

all resources

Courtesy of Elisabeth M. Drake. Used with permission.

Hydrogen Production Choice?

• Wind power offers significant reduction in GHG

emissions

• For transportation, there is a mismatch between

wind turbine energy availability and the large

concentrated populations of cars

• Costs for hydrogen from wind power are MUCH

higher than those from SMR

• For SMR, more fossil energy is consumed than H2

energy produced

Courtesy of Elisabeth M. Drake. Used with permission.

Systems Analysis

Life Cycle Analysis

ACCURACY REFLECTS UNCERTAINTIES

Technical accuracy is good

Based on established engineering principles

Amount of fuel per year

Amount of stainless steel pipe

Average lifetime of valves

Converting technical into $ more difficult

Interest rates

Inflation rates

Cost of fuel

14

SE T-4 Systems Analysis

Systems Analysis

An Example

A N LCA OF NUCLEAR FUEL COST INCLUDING SCARCITY

Cost of nuclear fuel including scarcity

Reference case: U=$2000/kg

Breakdown from the MIT study for cost per kg

Ore

Enrichment

Fabrication

Storage and Disposal

Total

$437

$117

$825

$351

$2040

15

SE T-4 Systems Analysis

#$%&'(&)&*&+,&'-.%/&*0

12 3'2.&4',$05'''''''''''''''''''''678889:;<=

>5? 3'!'@>& A?&*%B'C+B''''''7B!D!8!8':>?*9E*

F'3'F.*+'*G5&''''''''''''''''''''''!B!D!8H':>?*9:;

I2'3'>5?9F'3'2.&49E*''''''''''''7B8D!8J :;<=9E*

K2 3'I2D12 3'!05 E*').&4''''''''6J7'I9E*

KLC2.&4 3'2.&4',$059:>?*

8BMH',&+509:>?*

!"

#$%&'($)(*+,(%$'*($-($.,

/"(01($.,(23,45'(/(01(.,652(*$(&',(7

8$'*($-($.,(3'(*+&'(9::;01<$.,

=.,(.,',.>,'(6*(*+3'(?.3%,(@(A3

A3 )$*(B,44(0)$B)

C''&D,(E"(2,6.'($-(.,',.>,'(-$.(!E"()&0,'

F+,)

#! ! #$ " %$ " &%$ " $ " ! #&'% "#$ ! $ " ! &'% "#$" ()*+,-.

G6%+()&0,(.,5&%,'(.,',.>,'(H2( #$$ " % ()*+,-.

!"

#$%&'(%&)*+,-,./, 01,23*.,-,./,-*2-*2*45&67%8&*84*7%9,

$! !% " ! $" #$&' #%

08-7*84*8.,*$%((*%&6.,2-,*.23%'(:*2-*.,-,./,-*

'$%&'(,

;%93(,*98',(

$

#$&' % ¬¯

¬­¯

"

#

­­­°

+()* !% " ! + " %&' ¡¡,# #­­°° ! +" %&' ¡¡,#

$!

$" #$&' #% ®­°

­

®

¢

±

¢

±

<" =*!>?

!"

"#$%&''()($*+,%-../0)1

2345/6%$.%*30,/+6%7,+*)1%4+8%09+*:/%

#()9%)(4/

&1%0$1)%$.%$6/%:$/1%37%*/#%6/1/6;/1%

4+8%5/%.$3*'

<$)9%/../0)1%9+;/%+*%(47+0)%$*%)9/%

+4$3*)%$.%6/1/6;/1

!!

#$%&'()*%+&,-&'(.%/

#$+%%&%--%01/&2%1%+)34345&'

6%7890%)%41&,-&,82&4(.%/

6%7890%&,82&0,98&78941/&:31$&;<!&-+%%&4(.%/

=>&%8%01+3031?&2%)942&:388&340+%9/%&%90$&

?%9+&@ )%%1&4%:&2%)942&:31$&4(.%/

<82&4(.%/&+%7890%2&*?&4%:&4(.%/

<82&0,98&+%7890%)%41/&A&'0,98B#&A&CD!EB?+

'%:&2%)942&A&F&340+%9/%&G&1,198&78941/&A&E

!"

#$%&'()*%+&,-&'(.%/&01,234

5,)*62%&3%+)/

* !+" ! #$%&'%()*+,-.& " /012*3.4215.6.(' " +.7*51415%'8

*!"#$

! *********%&'( ***** " *******

+ ********9***:;:<*%&'(+

,)

! =:: " ==;>+

7%+%8&'2(.% 9&:;;8&'1,<= 9&!>;8&#? 9&";&@+/8&3&6/&

)%</(+%A&62&@%<+/

!"

#$%&'$($)*$(

'$($)*$(&+,&-,%.&o /,(0&,1&,)$&+,$(&23

4,(0&,1&,)$&+,$(&23&o ($5)/6&1,)&.$%&,)$

#$%&)$($)*$(&/,(0&7,)$&065.&8.80859&)$($)*$(

:20&;,2&9,($&7,)$&<$/52($&,1&8./)$5(8.+&

-$75.-&065.&;,2&+58.&%806&.$%&)$($)*$(

!"

#$%&'$($)*$(&+,-./0

1&(2345$&3-6$5

% !"# $& % % $

% !"# && ¬­

!

­­

'$ " ! '() # *" * " '

'$ $& % ! '$ " " ( #

% !"# ®­

% !"# $& %

7$)$&'28 9&!:;<=8> ?@A-)$B&C2 9&DEE&F&?@A-)$B&

G.6&?H&9&!

#-/$&/I$&J$$6KG,?&5--4

C-)$+/0&6$4$.6(&-.&'2+/0

'2+/0&6$4$.6(&-.&C-)$+/0&

!"

Systems Analysis

An Example

E QUATIONS FOR THE COST OF ORE ARE NON - LINEAR

Known reserves and cost of ore are inter-related

� �

Core (t) = Ci exp k1

10N(t)MF t

Ri (t) − 10N(t)MF t

�

�

Ncoal

N(t) = Ni0 +

+ k2 Ni0 t

Tp

�

�

Core (t) − Ci

Ri (t) = Ri0 1 + k3

Core (t)

��

k1 = 2.3, k2 = 0.05, k3 = 2

16

SE T-4 Systems Analysis

Systems Analysis

An Example

C OST OF ORE FROM SYSTEMS ANALYSIS

C[$/kg]

N[#]

R[107 kg]

1,000

800

Note the

singular

response

around 40

years. What

causes this?

600

400

200

What does a

plot of R vs C

look like?

0

0

10

20

Year

30

17

40

SE T-4 Systems Analysis

Systems Analysis

An Example

C ONCLUSION

Cost of ore increases by 30

Ore is 1/5 the cost of uranium

COE of uranium = 0.56 cent/kWhr

This yields 3.8 cents/kWhr

Not as bad when you calculate the present value

Still – it could be a problem

Uncertainty: what is the sensitivity to k1 , k2 , k3

18

SE T-4 Systems Analysis

Systems Analysis

Risk Analysis

R ISK A NALYSIS

Risk analysis involves accidents to people or mechanical failures

Too many injuries or failures lower the capacity factor and reduce

revenue

We want to minimize risk but it is not possible to achieve zero risk

Qualitatively risk can be written as

Risk = Frequency × Consequence

19

SE T-4 Systems Analysis

Systems Analysis

Risk Analysis

T YPES OF R ISK

Risk can be continuous or discrete

Continuous: exposure to toxic fumes

Discrete: steam pipe explosion

Consequences could cause minor injuries

Consequences could cause death

Consequences could involve land or water contamination

Even if no human or ecological damage, mechanical failures

lower capacity factor

20

SE T-4 Systems Analysis

Systems Analysis

Risk Analysis

AVOIDING R ISK

Three basic approaches:

Ultra robust design to minimize failure

Redundancy – one system fails, another takes over

Increased shut-downs for maintenance and repairs

21

SE T-4 Systems Analysis

Systems Analysis

Risk Analysis

D ETERMINING R ISK

How do we determine risk?

This is the realm of risk analysis

Single component failures relatively easy

Qualification data available

History of real world experience

Can predict the mean time between failure

Single small failures often harmless

Single gigantic failures very rare

22

SE T-4 Systems Analysis

Systems Analysis

Risk Analysis

C OMPLEX FAILURES

Largest danger: often a sequence of

minor failures leads to major

catastrophe

For example: TMI, Challenger

Analysis requires sophisticated tools

Fault tree analysis

Event tree analysis

Uncertainty analysis

Probability of a severe accident

Greater for a sequence of minor

failures

Fault Tree example

Smaller for a single major failure

23

SE T-4 Systems Analysis

Systems Analysis

Risk Analysis

W HAT TO DO ?

Recommendations vary by group

Builders tend to underestimate risks to keep the cost down

Example: Don’t worry – the Big Dig is safe

Others tend to overestimate the risks to avoid or delay

construction

Example: Nuclear is unsafe – don’t build it.

Example: Wind kill birds – don’t build it.

Often the arbiter of risks are government agencies – the EPA,

NRC, FDA, etc.

Desire risk informed regulations

Regulations consistent with severity of the risk

24

SE T-4 Systems Analysis

#$%&''()*+,*-./%/0,12'/

345%64/)%+-)7%,88/9*%94$)*+(9*-4$%94)*%48%,%

245/+%2',$*:

#))(1/%-$-*-,'%9,2-*,'%94)*%-$9'(6/)%,''%

+/;(',*-4$)%,))49-,*/6%5-*<%+-)7

#)%94$)*+(9*-4$%2+49//6)=%$/5%+-)7)%1,>%?/%

-6/$*-8-/6

@</)/%9,$%'/,6%*4%$/5%+/;(',*-4$)

A/5%+/;(',*-4$)%'/,6%*4%94$)*+(9*-4$%9<,$;/)

B<,$;/%4+6/+)%-$9+/,)/%*-1/%,$6%94)*%48%

94$)*+(9*-4$

!"

#$%&'()*+,-.+/()&0(1%2

3**-4%&+$%&/)/+/52&.56/+52&.(*+&/*&'.56

3**-4%&+$%&/)/+/52&.()*+,-.+/()&+/4%&/*&#.

7%8&,%9-25+/()*&(:+%)&(..-,&,5)1(42;

<(,&*/462/./+;&5**-4%&+$5+&)%8&,%9-25+/()*&

(..-,&5+&+$%&,5+%&r 6%,&;%5,

=5.$&)%8&,%9-25+/()&/).,%5*%*&.(*+&>;&Ʃ'

=5.$&)%8&,%9-25+/()&/).,%5*%*&+/4%&>;&Ʃ+

?(52@&.52.-25+%&+$%&)%8&.(*+&(:&+$%&625)+&

/).2-1/)9&)%8&,%9-25+/()*

!"

#$%&'%(&)*+,-./0-1*+&2%.1*3

'%(&0*+,-./0-1*+&-14%&#05&6&*.171+89&-14%&#0

:9/,&%;-.8&.%7/98-1*+&-14%&'Ʃ '&6&.#05&6&-*-89&+/4<%.&*=&0$8+7%,

>8-$%48-10899?

"!a ! "! " # %$ ! "! " %"!a%$

@*9A%&=*.&#05

"!a !

"!

! % %$

'*-%&-$8-&.Ʃ-&B&C&=*.&0*4:9%-1*+

!"

#$%&'%(&)*+,

-&+./.012&1234/%5,&$*06+&7*2&,$%&5%(&8*+,

a ! & !"# " ' %& ! & !"# "

& !"#

$%!

%&

! $ %(

'*,%&,$1,&Ʃ,&156&Ʃ)&12%&2%01,%6

91:%&Ʃ,&0123%2&; 7%(%2&(*2:%2+&5%%6%6<&0%16+&

,*&0*(%2&8*+,+

=4,&,$%>&12%&?1.6&*@%2&1&0*53%2&,./%

A.B%6&8*+,+&C%D3D&.5+42158%<&E%5%7.,+<&%,8DF&0%16&

,*&1&5%,&.582%1+%&.5&)81? 64%&,*&6%01>+

!"

"#$%&'(#)'Ʃ*

+,-)%.%,/'0,-&1$%2'34)$54)%'4,$'&46#)

%( ! %( !"#$ " %( %"&'#

746#)'-#2/2'0,-)%42%'42'Ʃ/'0,-)%42%2

+,-)%.%,/4&'&46#)'-#2/2'4)%'4221.%$'/#'2-4&%'

&0,%4)&8'50/3'0,0/04&'&46#)'-#2/2'*&46#)

%( %"&'# ! +!( %"&'#

%*

,)

9: 02'4'-#,2/4,/'46#1/'%;14&'/#':

!!

#$%&'())(*&+,-%

#$%&-%.&/(-0)12/),(-&/(0)&,0&3,4%-&56

%*!

%+ ¬­

a ! , !"# "

­­

, !"#

%, $"%& " -!, '"()%

*! ®­

! % %+

#$%&5%0)&0)17)%36

8,-,0$&/(-0)12/),(-&70&0((-&70&9(00,5:%&

%4%-&,;&,)&*%7-0&5(11(.,-3&*(1%&*(-%6&

29&;1(-)

!"

#$%&'$()#*+'),+-)''

Total Capital Cost

8

8

6.5

Ccapny

( )

5

3.5

2

2

0

0

0.1

0.2

0.3

y

delta t (years)

0.4

0.5

0.5

!"

MIT OpenCourseWare

http://ocw.mit.edu

22.081J / 2.650J / 10.291J / 1.818J / 2.65J / 10.391J / 11.371J / 22.811J / ESD.166J

Introduction to Sustainable Energy

Fall 2010

For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms.