Organizations and Projects November 13, 2012 Prof. Dan Braha

advertisement

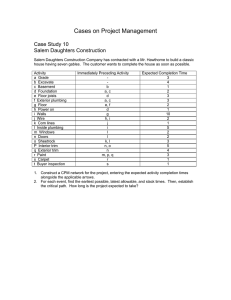

+ - Organizations and Projects Lecture 15 November 13, 2012 Prof. Dan Braha http://necsi.edu/affiliates/braha/dan_braha-description.htm ESD.36 SPM 1 + People Relationships Organization Architecture Guiding principles of design and evolution Image removed due to copyright restrictions. 2 + - Organization Architecture AMF Bowling ̶ a leading designer and manufacturer of bowling equipment: pin spotters, ball returns, scoring equipment Image by Biso. License: Creative Commons Attribution 3.0. Pratt & Whitney ̶ a world leader in the design, manufacture and service of aircraft engines, industrial gas turbines and space propulsion systems. Source: Public domain. 3 + - Project Organizations Project organization is the scheme by which individuals designers and developers are linked together into groups Organizations are formed by establishing links among individuals Reporting Relationships Supervisor/Subordinate Office/Floor/Building/Site Physical Layout Links Financial Arrangements Budget Category/ Profit & Loss Statement Coordination mechanisms Meetings/Collaborative Tools/ Liaisons/Shared Rewards/Shared Knowledge + - Classical Project Organizations Influence (Functional) Project Organization Weakest form of project organization “Functional” organization, workers are “on loan” to project Project coordinator, but has no budget or tasking authority CEO FM FM FM PM 5 + - Classical Project Organizations Dedicated Project Organization Team members work 100% for the project Empowered project manager Organizationally recognized unit for a certain time PM Staff TL1 TL2 Project Customer Steering Committee TL3 6 + - Classical Project Organizations Matrix Organization Project manager has tasking and budget authority Line manager has functional authority, promotions Team members remain in their functional organizations (have 2 bosses) Potential for conflicts GM PMs FM FM FM PM PM PM 7 + Concept Question 1 - Which type of project organization are you most familiar with or have you spent most of your career in? Dedicated Project Organization Matrix Organization Influence (Functional) Organization None of the above 8 + - Comparison of Project Organizations Influence (Functional) Project Organization Strengths: no org change, one person participates in multiple projects, in-depth expertise, low bureaucracy, easy post-project transition Weaknesses: slow response time, poor integration, lack of focus, lack of ownership Examples: customization development (custom motors, bearings, packaging) Major issues: how to integrate different functions 9 + - Comparison of Project Organizations Matrix Organization Strengths: efficient use of resources, resource flexibility, easier postproject transition, strong project focus Weaknesses: conflicts between functional (line) managers and PM, resource contention, stressful (at least two bosses) Examples: automobile, electronics, aerospace companies how to balance functions and projects; Major issues: how to evaluate simultaneously project & functional performance 10 + - Comparison of Project Organizations Dedicated Project Organization Strengths: uniform dedication towards project goals, fast, motivation & cohesiveness, cross-functional integration Weaknesses: “projectitis”, limited technological expertise, expensive, recruitment difficult, difficult post-project transition, Examples: start-up companies, “tiger teams”, “skunk works”, firms working in extremely dynamic environment Major issues: how to maintain functional specialization over product generation how to share technical learning from one project to another 11 + - Project Organization Selection Matrix PO Influence PO Dedicated PO Scope small medium large Duration short (<<1y) medium large (>2y) Uniqueness small neutral one-of-a-kind Complexity low medium-high very complex Ambitiousness (prob. of success) easy success achievable challenging Significance (for company) low priority important live-or-die Risk small depends large <M$1 M$1-100 >>M$100 many a few very few (# tasks) (# years) (# similar proj.) (#dependencies) (impact of failure) Cost (total budget) Simultaneity (# concurrent proj) 12 + - Project Organization Selection An image of CHAPARRAL STEEL CO. Logo has been removed due to copyright restrictions. The second largest producer of structural steel beams in North America (acquired by Gerdau Ameristeel in 2007). Classifies projects into three categories: advanced development, platform, and incremental Typically, Chaparral has 40-50 projects underway: 1 or 2 are advanced projects 3 to 5 are platform projects remainder are small, incremental projects 13 + - Project Organization Selection An image of AMF Logo has been removed due to copyright restrictions. A leading designer and manufacturer of bowling equipment: pin spotters, ball returns, scoring equipment AMF chose to organize its PD staff in a matrix structure The functions involved in PD are: engineering, manufacturing, marketing, sales, purchasing, quality assurance The AMF matrix organization is closest to the weak project organization Project managers are not typically the most senior managers in the division; thus, do not have direct control of resources and staffing 14 + - Project Organization Selection An image of AMF Logo has been removed due to copyright restrictions. With weak project organization the assignment of staff to smaller projects and the balancing of workload within a function are more easily accomplished AMF is a very lean company. The Capital Equipment Division has fewer than 100 salaried employees generating and supporting sales of over $100 million per year Everyone works in the same building; Employees earn substantial financial rewards when the Division is highly profitable; Members of project teams are motivated to look beyond their own functions, and work together to develop successful products 15 + - Project Organization Selection An image of AMF Logo has been removed due to copyright restrictions. The engineering manager works daily to ensure that the appropriate coordination occurs, for example, between marketing and engineering The senior management places emphasis on PD and encourages effective teamwork; The general manager devotes several days each month to monitoring the progress of projects 16 + - Project Organization Selection General Motors Powertrain Division Design small-block V8 engine 22 PDTs E n g in e B lo c k PDT composition C ylin d e r H e a d s 1 p ro d u c t re le a se e n g in e e r C a m sh a ft/V a lve T ra in 1 C A D d e s ig n e r P is to n s 3 m a n u fa c tu rin g e n g in e e rs C o n n e c tin g R o d s 2 p u rch a sin g re p re s e n ta tive s C ra n k sh a ft 2 ca s tin g e n g in e e rs F ly w h e e l m a c h in e to o l su p p lie r A c ce s so ry D rive 1 p ro d u c tio n c o n tro l a n a ly st L u b ric a tio n 1 fin a n c ia l p la n n e r W a te r P u m p /C o o lin g p ro d u c tio n p e rso n n e l In ta ke M a n ifo ld Exhaust E .G .R . A ir C le a n e r A .I.R . F u e l S y ste m T h ro ttle B o d y Image of V8 engine animation removed due to copyright restrictions. EVAP Image of Corvette engine removed due to copyright restrictions. Ig n itio n S ys te m E le c tro n ic C o n tro l M o d u le E le c tric a l S ys te m E n g in e A s se m b ly Source: McCord, KR. MIT Sloan School of Management. WP 3594. 1993. 17 + - Data Collection How often do you need to share technical information with the other PDTs in order to complete the technical tasks of your PDT? Source: McCord, KR. MIT Sloan School of Management. WP 3594. 1993. 18 + - PDT Interactions A Team-based DSM Engine Block A Cylinder Heads B Camshaft/Valve Train C Pistons D Connecting Rods E Crankshaft F Flywheel G Accessory Drive Lubrication Water Pump/Cooling Intake Manifold Exhaust H I J K L E.G.R. M Air Cleaner C D E • • • • • • • • Throttle Body Q • U Engine Assembly V L • • • • • • • • • • M N O P Q R • • • • • • • • I • • • • • • Source: McCord, KR. MIT Sloan School of Management. WP 3594. 1993. • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • K • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Frequency of PDT Interactions • • • • • • J • • • • • • • • • • • L • • • • • • • • • • M • N • • • • O • • • • • • P • • • • • • • • • • Q • • • • • R • S • • • • • • • • • • • • • • • • T • • • • • • • • • • U • • • • • • • • • • • • • • • V • • • V • • • • • • • • H U • • • • T • • • • • • S • • • • • Electrical System • • • • • • K • • • J • • • I • • • • • • • • P E.C.M. T • H • Fuel System Ignition S G • EVAP R Source: Public domain <http://en.wikipedia.org/wiki/File:Cshaft.gif>. F • • • • • B • • • • C • • • D • • • • E • • • • • F • • G • • • • • • • • • • • • • • A N A.I.R. O B Daily • Weekly • Monthly 19 + - Existing System Teams A Engine Block A Crankshaft F Flywheel • G • Pistons D • Connecting Rods Lubrication Cylinder Heads E I B Camshaft/Valve Train C Water Pump/Cooling J Intake Manifold Fuel System Accessory Drive Air Cleaner K A • • • • • F • F • • G E G Throttle Body Q Exhaust L E.G.R. M • D • • • • • E • • E.C.M. T Electrical System U Engine Assembly V • I • B • • • • • • • • • • • K P H N O Q • • L M • • R • • • • • • • • • • • • • • • C • • • J • • • K • • • • • • • P • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • V • • • • • U • • • • T • • • • • • • H • • • • • • • N • • • • • • O • Q • • • • • • • • L • • • • • • • • • M R • • S • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • S • • • J • • • EVAP R Ignition S C • N A.I.R. O B • P H I • • • • • • • • • • • • D • • • • • • • • • • • • • • • • • • • • • T • • • U • • • V Frequency of PDT Interactions • Daily • Source: McCord, KR. MIT Sloan School of Management. WP 3594. 1993. Weekly • Monthly 20 + Proposed System Teams Crankshaft F Flywheel G Connecting Rods Pistons E F G F • • • • • • • E D G E • • • • • • • • • • I • • • D • • I • • I A C • • • Cylinder Heads B1 • • • Intake Manifold K1 Engine Block Camshaft/Valve Train Water Pump/Cooling • • J Fuel System P Air Cleaner N Throttle Body Q • • • C • • D Lubrication A B K • J B2 Intake Manifold K2 • Accessory Drive H Ignition S • • • • • • • • C • • B1 • • • • • • K1 • • • • • J A • E.C.M. T • • • • P • • • N • • • • • • • • • Electrical System U • Engine Assembly V • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Team 3 • • • • S T • • • • • U • V • • • • • • • • • • • • • H • • • • M • • • • L Team 2 • • O • • Integration Team • • K • • • • B • • • E.G.R. M R • • • L Q • • A.I.R. O Exhaust N Team 1 EVAP R Cylinder Heads P • • Q • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • K2 • • • • • O • • • • L • • • M • • • • H • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Team 4 • B2 • • • • • • R • • • • • • • • • • • • • T • • • • U • • • • V S Frequency of PDT Interactions • Daily • Weekly • Monthly Source: McCord, KR. MIT Sloan School of Management. WP 3594. 1993. 21 Development Organization: P&W 4098 Jet Engine + - Low intensity interaction (0 to 5 scale) Courtesy of United Technologies. Used with permission. High intensity interaction (0 to 5 scale) 60 design teams clustered into 10 groups. Reported interactions took place during the detailed design period of the product development process. Design executed concurrently. Six system integration teams Source: Sosa ME, Eppinger SD, Rowles CM, Management Science. Vol. 50. 2004. pp.1674-1689. Team Interactions + - Product Development Principles ‘Iteration’ Changes and rework propagate through the design network. ‘Parallelism’ Large development efforts require multiple activities to be performed in parallel. ‘Decomposition & Integration’ ‘Stability’ Splitting a complex system into sub-systems and combining them The total number of design problems eventually falls below an acceptable threshold within a specified time frame 23 + - The Design Churn Phenomenon The oscillatory nature of PD: development tasks (thought to be finished) reappear or repeat Design Churn: “a scenario where the total number of problems being solved does not reduce monotonically as the project evolves over time” # Open Problems Time + Examples of Churn Bug Data and Daily Builds from Excel 5.0. Milestone 2 Engineering Changes per Month Source: Cusumano & Selby. Microsoft Secrets. Free Press, 1995 Engineering Changes in a Stereo Integrated Amplifier Project Appearance Vehicle Design 70 60 50 40 30 20 10 0 Month Source: Weelwright & Clark. Revolutionizing Product Development. Free Press, 1992. Source: Yassine, Joglekar, Braha, Eppinger & Whitney. Research in Engineering Design. Vol. 14. 2003. pp. 145-161. + - Potential Sources of Churn Exogenous Changes in design objectives (management directives, requirement changes) Performance variability/uncertainty Oscillatory resource allocation (firefighting) Endogenous Product architecture – interdependencies System/local decomposition Feedback delays – information hiding + - Why is Churn Bad? Myopic resource allocation decisions Elongated PD time Organizational memory lapses Frustration and deteriorated morale + - System/Local Decomposition & Information Hiding Decomposition of development into local and system tasks leads to information hiding which results in churn Testing & Integration System Team PD Team 1 PD Team 2 Local Teams PD Team n System Team: Consistency Check; System-Wide Directives Frequent Information Update Intermittent System Feedback Development Team i Local Team + - Numerical DSMs Task A Task B Task C Task A 0.6 Task B 0.2 Task C 0.4 0.7 0.7 0.2 Numbers along the diagonal are the rate of problem solving per unit time: 0 100% Off-diagonal numbers are dependency strengths between tasks: 0 100% + System/Local DSMs - System Team System Team DSMsys DSM-system DSM 1 DSM 2 Local Teams DSM n Intermittent System Feedback Frequent Information Update DSMi Local Team Several DSMs (Local & System) with at least one unit of time of delay for information exchange + DSM Representation - P&W 4098 Jet Engine m local DSMs & a single System DSM L1: DSM1 T1 L2: DSM2 t1,m t1,S T2 tm,1 Lm: DSMm t2,S tm,S Tm S: DSMsys Courtesy of United Technologies. Used with permission. + - How Does Decomposition/Integration Affect Performance Dynamics? Given a local DSM, system DSM, and a choice of information update frequency, what are the conditions under which: Design churn occurs? Convergence of development is guaranteed? + - Case Study: Automotive Appearance Design Process The process of designing all interior and exterior automobile surfaces for which appearance, surface quality and operational interface is important to the customer Image removed due to copyright restrictions. Examples Exterior sheet metal design Visible interior panels 33 + - Case Study: Automotive Appearance Design Process Market Study Case Study Scope: Appearance Design 52 weeks Industrial Design Engineering Design Tooling Development Prototyping Production Time Internal information exchanges Weekly feasibility meetings Industrial Design Engineering Design Periodic (6 weeks) scan transmittals + - Case Study: Automotive Appearance Design Process Input DSMs Local DSM 1 2 3 4 5 6 7 8 9 10 L1 L2 L3 L4 L5 L6 L7 L8 L9 L10 Carpet Center Console Door Trim Panel Garnish Trim Overhead System Instrument Panel Luggage Trim Package Tray Seats Steering Wheel 1 2 3 4 5 0.85 0.12 0.02 0.06 0.06 0.1 0.53 0.04 0.3 0.02 0.24 0.02 0.02 0.04 0.47 0.08 0.24 0.02 0.18 0.02 0.18 0.68 0.14 0.1 0.06 0.04 6 8 9 10 1 2 3 4 5 6 7 8 9 10 0.06 0.02 0.08 0.83 0.3 0.26 0.16 0.28 0.06 0.02 0.02 0.1 0.06 0.76 0.06 0.04 0.06 0.83 0.16 0.04 0.16 0.63 0.2 0.2 0.7 0.1 0.08 7 System DSM 0.24 0.18 0.02 0.02 0.08 0.04 0.02 0.26 0.2 S1 S2 S3 S4 S5 S6 S7 S8 S9 S10 1 Carpet Center Console Door Trim Panel Garnish Trim Overhead System Instrument Panel Luggage Trim Package Tray Seats Steering Wheel 2 3 4 5 6 7 8 9 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 Local to system transformation matrix 1 2 3 4 5 6 7 8 9 10 Carpet Center Console Door Trim Panel Garnish Trim Overhead System Instrument Panel Luggage Trim Package Tray Seats Steering Wheel 1 2 3 4 5 6 7 8 9 10 0.09 0.17 0.21 0.09 0.14 0.42 0.29 0.38 0.6 0.24 0.1 0.16 0.49 0.34 0.44 0.16 0.49 0.08 0.22 0.94 1.41 0.49 3.81 0.12 0.06 0.15 0.05 0.12 0.08 1 0.87 0.58 0.07 0.06 0.25 0.14 0.12 0.12 0.08 0.07 0.58 0.05 System to local transformation matrix 1 2 3 4 5 6 7 8 9 10 Carpet Center Console Door Trim Panel Garnish Trim Overhead System Instrument Panel Luggage Trim Package Tray Seats Steering Wheel 1 2 3 4 5 6 7 8 10 0.2 9 10 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 Low = 0.1 Med =0.2 Hi = 0.3 + Base Case Analysis - System is stable, but converges very slowly ‘Instrument Panel’ has the most destabilizing effect on total system performance 2.5 2 Instrument Panel 1.5 1 Other Nine Tasks 0.5 0 0 10 20 30 Weeks 40 50 60 + Effect of Mitigation Strategies - Scenario 1: Adding Resources Base Scenario Open Issues 2.5 2.5 2 2 Instrument Panel 1.5 Open Issues 1 1 0.5 0.5 0 1.5 0 0 10 20 30 40 50 60 0 10 20 30 40 50 60 Weeks Weeks Total Open Issues: Scenarios 1 & 2 Combined Scenario 2: Reduced Coupling 2.5 7 6 2 Open Issues Open Issues 1.5 1 5 Base 4 3 2 Combined 0.5 1 0 0 10 20 30 Weeks 40 50 60 0 0 10 20 30 Weeks 40 50 60 + Effect of Delay on Churning Behavior 1.6 1.8 1.8 1.4 1.6 1.6 T=1 1.2 1 T=2 1.4 1.2 1 T=3 1.4 1.2 1 0.8 0.8 0.8 0.6 0.6 0.4 0.4 0.2 0.2 0.2 0 0 0.6 0.4 0 10 20 30 40 50 60 1.8 2 1.6 1.8 T=4 1.4 1.2 1 0 10 20 30 40 50 0 60 0 10 20 30 40 50 60 2.5 T=5 1.6 1.4 1.2 T=6 2 1.5 1 0.8 0.8 0.6 0.4 0.4 0.2 0.2 0 1 0.6 0 0 10 20 30 40 50 60 0.5 0 10 20 30 40 50 60 0 0 10 20 30 40 50 60 + - Effect of Differential Delay Policy Slow convergence Uniform Policy Differential Policy Fast convergence Uniform T=5 T=4 T=3 T=2 Differential T1=5 T2=6 T1=4 T2=6 T1=3 T2=6 T1=2 T2=6 T=1 T1=1 T2=6 + Identifying “Bottleneck” Tasks - An image of automobile center console has been removed due to copyright restrictions. Slow Center Console Sensitive Fast 0 Slow Overhead System Autonomous local completion rate 0 .2 0 .4 0 .6 0 .8 0 .4 0 .6 0 .8 1 Autonomous local completion rate An image of automobile overhead system has been removed due to copyright restrictions Insensitive Fast 0 0 .2 1 + - Summary Decomposition/Integration Large development efforts require multiple activities to be performed in parallel The many subsystems must be integrated to achieve an overall system solution Organizations can be “designed” based upon this structure Decomposition/Integration and Dynamics Design Churn is a fundamental property of a decomposed development process + - Summary Intrinsic Sources of Churn Interdependency Concurrency Feedback delays and information hiding Strategies to mitigate churn Resource-based strategies Rework-based strategies Time-based strategies + - Further Reading Complex concurrent engineering Dan Braha and Ali Yassine. “Complex Concurrent Engineering and the Design Structure Matrix Approach.” Concurrent Engineering: Research and Applications. Vol. 11 (3). pp. 165-177. 2003. Read paper at http://necsi.edu/affiliates/braha/CERA.pdf The design churn effect Ali Yassine, Nitin Joglekar, Dan Braha, Steven Eppinger, and Dan Whitney. “Information Hiding in Product Development: The Design Churn Effect.” Research in Engineering Design. Vol. 14 (3). pp. 131-144. 2003. Read paper at http://necsi.edu/affiliates/braha/RED03_Info.pdf 43 MIT OpenCourseWare http://ocw.mit.edu ESD. 6\VWHP3URMHFW0DQDJHPHQW Fall 2012 For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms.