Journal of Colloid and Interface Science 445 (2015) 252–261

Contents lists available at ScienceDirect

Journal of Colloid and Interface Science

www.elsevier.com/locate/jcis

Use of drinking water treatment solids for arsenate removal from

desalination concentrate

Xuesong Xu a, Lu Lin a, Charalambos Papelis a, Maung Myint a, Tzahi Y. Cath b, Pei Xu a,⇑

a

b

Department of Civil Engineering, New Mexico State University, NM 88003, United States

Department of Civil and Environmental Engineering, Colorado School of Mines, CO 80401, United States

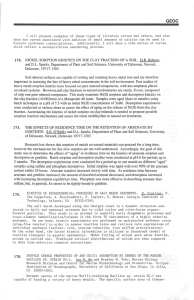

g r a p h i c a l a b s t r a c t

Arsenate removal

100%

80%

60%

Screen

40%

Effluent

20%

Chemisorption

Arsenate

0%

0

200

400

600

800

Iron

hydroxide

Drinking water

treatment solids

Gravels

Screen

Arsenate

NOM

Peristaltic pump

Influent: RO concentrate

a r t i c l e

i n f o

Article history:

Received 10 October 2014

Accepted 27 December 2014

Available online 9 January 2015

Keywords:

Arsenate removal

Arsenic

Sorption

Drinking water treatment solids

Desalination concentrate

a b s t r a c t

Desalination of impaired water can be hindered by the limited options for concentrate disposal. Selective

removal of specific contaminants using inexpensive adsorbents is an attractive option to address the

challenges of concentrate management. In this study, two types of ferric-based drinking water treatment

solids (DWTS) were examined for arsenate removal from reverse osmosis concentrate during continuousflow once-through column experiments. Arsenate sorption was investigated under different operating

conditions including pH, arsenate concentration, hydraulic retention time, loading rate, temperature,

and moisture content of the DWTS. Arsenate removal by the DWTS was affected primarily by surface

complexation, electrostatic interactions, and arsenate speciation. Results indicated that arsenate sorption

was highly dependent on initial pH and initial arsenate concentration. Acidic conditions enhanced arsenate sorption as a result of weaker electrostatic repulsion between predominantly monovalent H2AsO

4

and negatively charged particles in the DWTS. High initial arsenate concentration increased the driving

force for arsenate sorption to the DWTS surface. Tests revealed that the potential risks associated with

the use of DWTS include the leaching of organic contaminants and ammonia, which can be alleviated

by using wet DWTS or discarding the initially treated effluent that contains high organic concentration.

Ó 2015 Elsevier Inc. All rights reserved.

1. Introduction

1.1. Reverse osmosis (RO) concentrate treatment

Desalination of seawater, brackish water, and reclaimed water

has been a viable solution to providing alternative water supplies.

Reverse osmosis (RO), nanofiltration, electrodialysis, and thermal

⇑ Corresponding author at: Department of Civil Engineering, New Mexico State

University, 3035 S Espina Street, NM 88003, United States.

E-mail address: pxu@nmsu.edu (P. Xu).

http://dx.doi.org/10.1016/j.jcis.2014.12.090

0021-9797/Ó 2015 Elsevier Inc. All rights reserved.

distillation are well-established desalination technologies, producing fresh water for industrial, domestic, and agricultural uses [1–4].

However, with increasing water recovery (ratio of product to feed

water) during desalination, the concentrations of dissolved constituents in the concentrate stream increase. Consequently, proper

disposal of brines, and particularly those containing elevated concentrations of toxic contaminants, including heavy metals, is one of

the primary impediments for implementation of desalination

technologies [5].

Ocean discharge is widely used by desalination facilities in

coastal areas, but concentrate disposal remains a major challenge

253

X. Xu et al. / Journal of Colloid and Interface Science 445 (2015) 252–261

for inland plants where disposal options are limited by the quantity

and quality of concentrate, regulations, and geographical and geological constrains. A recent review of technologies for concentrate

treatment was published, focusing on concentrate volume minimization and beneficial uses [6]. However, most of these technologies

are often costly and energy intensive. Selective removal of specific

contaminants (e.g., arsenic and heavy metals) using inexpensive

materials could be an alternative to meeting disposal requirements

or water quality criteria for beneficial use applications [5].

1.2. Arsenic removal technologies

If present in water and consumed in large quantities, arsenic, a

metalloid abundant in nature in the form of organic and inorganic

compounds, can cause a variety of pathological conditions, including cutaneous and visceral malignancies [7]. The acute minimal

lethal dose of arsenic in adults is 70–200 mg per day, or 1 mg per

kg weight per day [8]. The United States Environmental Protection

Agency (USEPA) has set an enforceable regulatory limit for arsenic

in drinking water at 0.01 mg L1 (10 ppb).

A variety of physicochemical techniques are being utilized for

arsenic removal, including coagulation [9], ion exchange [10], RO

[11], liquid–liquid extraction [12], and sorption [13]. Specifically,

sorption using ferric-based sorbents is an effective treatment technology because of the high sorption capacity of iron for arsenic and

simple operation. Table 1 summarizes the arsenic sorption capacity

of different sorbents. Studies have shown that these materials have

a strong affinity for arsenic under natural pH conditions compared

to commonly used activated alumina. For sorption processes, alternative sorbents that meet the requirement of cost-effectiveness

and eco-friendly disposal are needed. A low-cost and potentially

effective substitute for arsenic sorbents could be the solid residuals

from coagulation/flocculation water treatment processes, which

often utilize ferric-based coagulants [14].

1.3. Drinking water treatment solids (DWTS)

Drinking water treatment solids (DWTS) are the residuals

produced during water treatment using iron or aluminum salts

as primary coagulants. Laboratory studies have demonstrated

that DWTS have strong affinity to sorb contaminants such as

phosphorus [15,16], hydrogen sulfide [17], metals [18,19], fluoride [20], and arsenic [5,21]. Laboratory batch equilibration studies have shown that both ferric-based and aluminum-based

DWTS have a high affinity for arsenite [As(III)] and arsenate

[As(V)] species [22]. Gibbons and Gagnon examined the sorption

of arsenic from groundwater in batch and column experiments

using the solids from different water treatment plants [23].

The results showed that ferric and lime solids were effective sorbents for arsenic removal [23]. The arsenic removal mechanism

by DWTS involves mainly inner-sphere complexation with ferric

hydroxides [24], which is affected by the ferric mass in the

DWTS [25,26].

The factors influencing arsenic sorption include pH, loading

rate, initial arsenic concentration, competing ligands or complexing metals, temperature, and specific physicochemical properties

of the adsorbing solids (e.g., specific surface area, total carbon content, porosity) [22,27,28]. X-ray absorption spectroscopy demonstrated that strong, inner-sphere complexes are formed between

sorbed arsenic and the Al/Fe-hydroxide components of the solids

[29,30]. Arsenic leaching tests indicated that 50–60% of the total

arsenic in DWTS was bound strongly on amorphous iron hydroxides [31]. Maintaining non-alkaline and high redox potential conditions is critical for minimal arsenic mobilization in DWTS [31].

Thermodynamic studies indicate that arsenic sorption increases

with increasing water temperature [32].

Although previous studies have demonstrated the feasibility of

arsenic removal using DWTS (Table 1), there is lack of knowledge

on the removal efficiency of arsenic from saline water, such as

desalination concentrate, in which competition with co-existing

ions and high ionic strength may affect the selective sorption of

arsenic. Therefore, this study focused on investigating sorption of

arsenate from RO concentrate using different types of DWTS during continuous-flow operation. The impacts of operating conditions on arsenate removal were investigated by performing

experiments at different pH, initial arsenate concentration in RO

concentrate, hydraulic retention time, temperature, and loading

rate using different types of DWTS.

Table 1

Summary of results from arsenic sorption studies using various sorbents under different testing conditions.

Adsorbent

Char carbon

Activated carbon

Iron oxide coated sand

Ferric-based water

treatment residual

Lime-based water

treatment residual

Activated aluminum

MnO2

Hydrous ferric oxide

(HFO)

Zirconium-loaded

activated carbon

(Zr-AC)

Granular ferric

hydroxide (GFH)

Activated alumina

grains

FeCl3 treated tea

fungal biomass

Type of water

Synthetic 0.1 M

NaCl solution

Synthetic 0.1 M

NaCl solution

Drinking water

Ground water

Ground water

pH

As concentration

1

7.6

8.0–8.2

157-737 lg L for

193-992 lg L1 for

157-737 lg L1 for

193-992 lg L1 for

100 lg L1

38.8-47.2 lg L1

8.0–8.2

38.8-47.2 lg L1

2–3

6.4–7.5

Temp.

(°C)

As(V);

As(III)

As(V);

As(III)

1

Operating condition and models for

calculating adsorption capacity

Adsorption

capacity (mg/g

solids)

As(III)

As(V)

Refs.

25

Batch

89.0

34.46

[33]

25

Batch

29.9

30.48

[33]

22 ± 2

22

Batch & Langmuir

Batch & Langmuir

–

0.043

2.23

[34]

[35]

22

Batch & Langmuir

–

0.16

[35]

0.172

7.0

[36]

[37]

[38]

0.041

Drinking water

Drinking water

Drinking water

7.6

7.9

9.0

1 mg L

<1 mg L1

0-60 mg L1

25

25

22

Batch & Langmuir

Column & Langmuir

Batch

0.180

–

28.0

Drinking water

8–9

5-100 mg L1

25

Column

–

2.8

[39]

Drinking water

8–9

5-100 mg L1

25

Column

–

2.3

[39]

25

Batch & Langmuir

3.48

15.9

[40]

30

Batch & Freundlich

5.4

10.26

[41]

Drinking water

Ground water

5.2 for As(V);

7.0 for As(III)

7.20

1

2.85-11.5 mg L for As(V);

0.79-4.90 mg L1 for As(III)

0.9 mg L1 for As(V);

1.3 mg L1 for As(III)

–

254

X. Xu et al. / Journal of Colloid and Interface Science 445 (2015) 252–261

2. Materials and Methods

2.1. RO concentrate and water quality analysis

RO concentrate was collected from the Kay Bailey Hutchison

Desalination Plant in El Paso, Texas, the largest inland desalination

plant in North America that treats brackish groundwater. The total

dissolved solids (TDS) concentration of the RO concentrate was

10 ± 2.3 g L1. The major ions in the RO concentrate included

sodium (2660 ± 368 mg L1), calcium (673 ± 113 mg L1), chloride

(4993 ± 656 mg L1), and sulfate (1272 ± 226 mg L1), while minor

ions

included

potassium

(69 ± 5.4 mg L1),

magnesium

1

(168 ± 22 mg L ), manganese (332 ± 8.6 lg L1), and arsenic

(63 ± 11 lg L1). The brackish groundwater is chlorinated before

RO desalination for biofouling control; therefore, the arsenic in

the RO concentrate is oxidized to arsenate. The pH of the concentrate was 7.8 ± 0.4, the alkalinity 388 ± 6 mg L1 as CaCO3, and

the dissolved organic carbon (DOC) concentration in the RO concentrate was 4.1 ± 2.6 mg L1.

Throughout the study, all RO concentrate and treated samples

were diluted to levels suitable for analysis with the analytical

instruments. Sample collection and handling followed the guidelines in Section 1060 of Standard Methods [42]. Water samples

were filtered through 0.45 lm cellulose acetate filters (Toyo Roshi

Kaisha, Ltd., Japan) when applicable.

Common ions, including sodium, calcium, potassium, magnesium, chloride, phosphate, and sulfate were measured using ion

chromatography (ICS-2100, Dionex, Sunnyvale, CA, USA).

Concentrations of aluminum, arsenic, boron, chromium, copper,

iron, manganese, lead, and selenium were quantified using inductively coupled plasma mass spectrometry (ICP-MS PerkinElmer,

Elan DRC-e, Waltham, MA, USA). Alkalinity was measured using a

digital titrator (Hach, Colorado, USA) and titrated with 1.6 N sulfuric acid standard solutions to pH endpoint of 4.6. The pH was measured using a portable pH meter (Oakton 300 Series, Eutech

Instruments, Singapore), and electrical conductivity was measured

using a benchtop conductivity meter (Model 431-61, Cole-Parmer,

Vernon Hills, IL). DOC was analyzed using a TOC Analyzer (Shimadzu TOC-L, Kyoto, Japan), and TDS concentration was quantified by

evaporation at 180 °C after filtering the RO concentrate samples

through 0.45 lm filters.

2.2. DWTS and characterization

Two types of dewatered DWTS were studied to compare their

arsenate sorption capacities. Surface water DWTS (referred to as

SDWTS) was collected from a conventional surface water treatment plant in Colorado, USA, which uses coagulation, flocculation,

sedimentation, and green sand filtration to treat water diverted

from a creek to produce potable water. Ferric sulfate (20–

50 mg L1) is used as a coagulant to remove turbidity and natural

organic matter (NOM) from the river water. The SDWTS was collected from the dewatering filter press of the treatment plant.

Groundwater DWTS (referred to as GDWTS) was collected from a

groundwater treatment plant in Texas, USA, which removes NOM

and naturally occurring arsenic (concentrations in the range of

11–16 lg L1) with chlorination, coagulation using ferric chloride

(9–15 mg L1), followed by sand filtration. The filter backwash

GDWTS was collected from sand drying beds in the treatment

plant.

To compare the impact of moisture content (i.e., hydration of iron

oxide) on sorption capacity, both wet SDWTS (dewatered SDWTS)

and dry SDWTS (dried at 105 °C for 48 h) were investigated. The

water content of the DWTS was measured by standard thermal

evaporation method in an oven (OF-01E, Jeio Tech, Korea) at

105 °C for 24 h. The organic content was measured using ignition

test by heating the DWTS at 550 °C for 8 h in a muffle furnace (Furnace Vulcan 3–550, Dentsply International Inc., PA, USA). The elemental composition of the DWTS was analyzed using the acid

digestion method, namely mixing of 0.2 g DWTS with 5 mL 67–

70% nitric acid concentrate (Fisher Scientific, Canada), 10 mL deionized water, and 2 mL 12.1 N hydrochloric acid (Fisher Scientific,

Canada), followed by digestion in a microwave oven (Multiwave

3000, Anton Paar, Austria) [43]. The filtered digested samples were

then analyzed using ICP-MS. X-ray diffraction (XRD, MiniFlex II, Rigaku, Japan) was used for mineralogical analysis of the DWTS.

To quantify the contribution of alkalinity from the DWTS to the

water, the alkalinity of the suspension equilibrated with the DWTS

was determined by titration. Deionized water or a 10 g L1 NaCl

solution was used to simulate the leaching of alkalinity from the

DWTS to fresh water and the RO concentrate, respectively. Two

grams of the DWTS were mixed with 20 mL of deionized water

or 10 g L1 NaCl solution and stirred for 24 h before measuring

alkalinity.

The pH at the point of zero charge (pHPZC) was measured to

investigate the impact of DWTS charge on arsenate sorption. The

salt titration (ST) method was modified in the study based on the

methods developed by Sakurai et al. [44] and Jain et al. [45]. Two

grams of the DWTS were mixed with 20 mL of 0.02 M or 0.2 M NaCl

solution. Then 1 mL of 0.3 N HCl solution was added to each DWTS

suspension. The DWTS aqueous suspensions were stirred for 1 h

each day and equilibrated for 4 days. The equilibrium pH values

of the DWTS suspensions were measured every 24 h (pH1 for

0.02 M NaCl solution, pH2 for 0.2 M NaCl solution). The value of

DpH = pH2 pH1 was calculated, and the graph of DpH versus

pH1 was plotted to determine pHPZC at which DpH = 0. All the

DWTS samples were characterized using triplicate measurements.

2.3. Continuous-flow once-through column adsorption tests and

calculations

Continuous-flow sorption and leaching experiments were conducted in column reactors (5 cm in diameter and 30 cm long),

which were packed with 200 g wet DWTS or 42 g dry DWTS (with

the same amount of dry solids mass). Washed gravel was packed at

the bottom of the columns for water to percolate through (approximately 3 cm thickness). Wet DWTS were packed directly in the

columns. Dry solids were crushed and sieved to particle sizes

between 0.8 and 2.0 mm before packing. The schematic of the testing system is shown in Fig. 1.

Leaching tests were conducted to determine the leachability of

constituents from the SDWTS to deionized water. Dissolved metal

and metalloid ions (aluminum, arsenic, calcium, iron, magnesium,

Screen

Effluent

DWTS

Gravel

Screen

Peristaltic pump

Influent: RO concentrate

Fig. 1. Schematic of the continuous-flow column testing system.

255

X. Xu et al. / Journal of Colloid and Interface Science 445 (2015) 252–261

manganese, potassium, selenium, and sodium), organics (DOC),

inorganic ions (ammonium, bromide, fluoride, chloride, nitrate,

nitrite, phosphate, and sulfate), electrical conductivity, and pH

were measured at 0, 0.5, 2, 4, 8, 12, 18, and 24 h, during the continuous-flow leaching test.

Sorption experiments were conducted by pumping RO concentrate from a 20 L tank to the bottom of the column by a peristaltic

pump with Masterflex L/S Variable-Speed Drive (Cole-Parmer, Illinois, USA) at flow rates of 11–33 mL min1. The effects of operating

conditions on sorption processes, including influent pH, moisture

content, different DWTS, columns-in-series, and temperature, were

investigated. Effluent samples were collected at 0, 0.5, 2, 4, 8, 12,

18, and 24 h, and once a day for the following 15 days, aiming at

monitoring long-term removal efficiency. It should be noted that

the sorption experimental results throughout the study were

highly reproducible with percent removal standard deviation in

the range of 1–3% for duplicate samples.

The number of bed volumes (dimensionless), mass loading rate

(MLR, L kg1 h1), hydraulic retention time (HRT, min), arsenate

percent removal (%), and uptake rate (lg g1 h1) were calculated

as follows:

Bed volumes ¼ Volume of water processed=solids volume

Mass loading rate; MLR ¼ Water flow rate=mass of dry solids

Hydraulic retention time; HRT ¼ Solids volume=water flow rate

Percent removal ¼ ½ðFeed concentration

effluent concentrationÞ=feed concentration

100

Arsenate uptake rate ¼ ðFeed concentration

effluent concentrationÞ

Water flow rate =mass of dry solids

3. Results and discussion

3.1. Characteristics of the DWTS

The water and organic contents of the wet SDWTS were 78.9%

and 4.64%, respectively, and the organic content was 22% for the

dry SDWTS. The water and organic contents of the GDWTS were

4% and 14%, respectively. The major metals in the solids included

manganese, aluminum, iron, calcium, and magnesium (Table 2). It

should be noted that iron is not the dominant element in the DWTS

although both treatment plants use ferric salts as primary coagulants. The higher amount of aluminum in the DWTS is attributed

to aluminosilicate minerals (in silt, sand and clay) retained during

the coagulation/flocculation/sedimentation and filtration processes.

High manganese content in the SDWTS is attributed to manganese

precipitation from the surface water in which manganese concentration is 0.2–0.5 mg L1. The detected trace inorganic constituents

concentrations for the SDWTS included copper (360 ± 71 lg g1),

chromium (45 ± 5.2 lg g1), lead (27 ± 1.6 lg g1), arsenic

(22 ± 0.6 lg g1), and selenium (4.4 ± 0 lg g1); and the detected

trace inorganic constituents concentrations for the GDWTS included

copper (288 ± 0 lg g1), chromium (119 ± 2.1 lg g1), lead

(2.8 ± 0.2 lg g1), arsenic (43 ± 1.3 lg g1), and selenium

(1.6 ± 0 lg g1).

The total alkalinity contributed from the dry and wet SDWTS

was similar (1.2–1.7 mg as CaCO3 per g dry solids), while the alkalinity contribution of the GDWTS (4.9–6.9 mg as CaCO3 per g dry

Table 2

Organic carbon and major metals in the DWTS (in mg per gram of dry solids mass).

Organic carbon

Al

Ca

Fe

Mg

Mn

Dry SDWTS

Dry GDWTS

220

17 ± 0.4

2.5 ± 0.8

3.3 ± 0.2

2.4 ± 0.2

30 ± 0.2

140

53 ± 1.4

17 ± 0.9

1.1 ± 0.0

13 ± 0.5

1.0 ± 0.0

solids) was approximately 4–5 times higher than that of the

SDWTS. The SDWTS was more acidic than the GDWTS with the

pHPZC in the order of dry SDWTS (4.8), wet SDWTS (5.4), and

GDWTS (6.9). The pHPZC values were similar to those reported by

Zhou et al. [46] (5.6–5.7) for aluminum-derived DWTS. As the

major constituents of DWTS were organic matter and aluminosilicate particles, the pHPZC values of the DWTS differed from that of

iron oxide precipitates, which is in the range of 7.5–9 [47]. Indeed,

the absence of characteristic peaks corresponding to crystalline

ferric hydroxide phases from X-ray diffraction spectra is consistent

with the disordered nature of the SDWTS and GDWTS phases.

3.2. Leaching of chemical constituents from the SDWTS

Sodium, phosphate, potassium, aluminum, manganese, ammonium, chloride, sulfate, and nitrate were detected in all or some

leachates of the SDWTS, while no arsenic, bromide, calcium, fluoride, iron, magnesium, nitrite, or selenium were detected in any

of the SDWTS leachates. Higher amounts of organics and inorganic

constituents leached from the dry SDWTS than from the wet

SDWTS, as shown in Fig. 2 and Table 3, and their concentrations

decreased significantly with processed bed volumes of deionized

water. Substantial amount of organics leached from the dry

SDWTS; the DOC concentration reached 140 mg L1 at the beginning of the testing and declined to below 10 mg L1 after 120

bed volumes. In contrast, less than 6 mg L1 DOC leached from

the wet SDWTS throughout the testing, that is 0.79 mg carbon leached per gram of dry solid mass, whereas the organics leached

from the dry DWTS was 8 times higher (6.74 mg carbon leached

per gram of dry SDWTS). Similarly, 62 mg L1 ammonium leached

from the dry SDWTS at the beginning of the testing as compared to

22 mg L1 from the wet SDWTS, resulting in average of 1.5 and

1.08 mg ammonium per gram of dry solids mass leached from

the dry and wet SDWTS, respectively. Nitrate concentration was

below 5 mg L1 in the leachates of the dry SDWTS whereas it

was below 0.1 mg L1 for the wet SDWTS throughout the testing.

Because ammonium was not detected during surface water treatment, the high amount of ammonium in the SDWTS is the result

of the decomposition of organic matter in the solids. The pH of

the effluent was slightly acidic, increasing from 5.76 to 7 during

the leaching test.

The leaching tests indicate that the potential risks from the use

of the SDWTS are primarily associated with the leaching of organic

constituents and ammonia. The risks can be alleviated when wet

SDWTS is used as adsorbent, or the initial treated effluent with

high organic content is discarded. The leaching results are consistent with previous studies [29,30] showing that arsenic is firmly

bonded to solids and does not leach from the wet and dry SDWTS

to deionized water. In this study DOC was used as an indicator to

characterize the leaching of organic constituents that are composed of mainly NOM removed from surface water sources. However, it is worth identifying the composition of organic carbon

further, using advanced analytical methods to understand the

potential risks of organic leachate from the SDWTS.

256

X. Xu et al. / Journal of Colloid and Interface Science 445 (2015) 252–261

160

70

dry SDWTS

wet SDWTS

140

120

50

NH4+ (mg·L-1)

DOC (mg·L-1)

dry SDWTS

wet SDWTS

60

100

80

60

40

30

40

20

20

10

0

0

0

100

200

300

400

500

600

700

0

100

200

18

dry SDWTS

wet SDWTS

80

500

600

700

dry SDWTS

wet SDWTS

16

70

14

60

K (mg·L-1)

Mn (mg·L-1)

400

Bed volumes

Bed volumes

90

300

50

40

12

10

8

30

6

20

4

10

2

0

0

0

100

200

300

400

500

600

0

700

100

200

Bed volumes

300

400

500

600

700

Bed volumes

35

dry SDWTS

wet SDWTS

200

160

120

25

20

15

80

10

40

5

0

dry SDWTS

wet SDWTS

30

Cl- (mg·L-1)

SO42- (mg·L-1)

240

0

0

100

200

300

400

500

600

700

0

100

200

300

400

500

600

700

Bed volumes

Bed volumes

Fig. 2. Leaching of organics (DOC) and ions (manganese, sulfate, ammonium, potassium, and chloride) from dry and wet SDWTS as a function of bed volumes at 23 °C.

3.3. Effect of pH on arsenate sorption

H3 AsO4 H2 AsO4 þ Hþ ðpKa1 ¼ 2:19Þ

The impact of pH on arsenate sorption to the DWTS was

investigated at pH values of 5.5 (adjusted with hydrochloric acid

solution) and 7.8 (ambient pH of the RO concentrate). Many RO

systems operate at acidic pH to prevent membrane scaling. The

testing pH values of 5.5 and 7.8 are within the operating pH

range of typical RO concentrates in desalination facilities. The

pH of the solution also affects the charge of DWTS, resulting

in different electrostatic interactions between arsenate and the

solids.

Arsenate sorption efficiency increased substantially when the

pH of the RO concentrate decreased from 7.8 to 5.5 (Fig. 3). The

solution pH affects the speciation of arsenate in aqueous solutions

(controlled by the acid dissociation constant, pKa) and the surface

charge of DWTS (determined by the pHpzc). As described by the

three equilibrium reactions, arsenate species exist primarily as H22

AsO

4 (3 < pH < 7) or HAsO4 (7 < pH < 11) [48]:

þ

H2 AsO4 HAsO2

4 þ H ðpKa2 ¼ 6:94Þ

3

þ

HAsO2

4 AsO4 þ H ðpKa3 ¼ 11:5Þ

Table 3

Total amount of detected chemical constituents leached from the SDWTS (in mg per

gram of dry solids mass).

DOC

Al

Na

K

Mn

NH+4

Cl

NO

3

SO2

4

Dry SDWTS

Wet SDWTS

6.74

0.013

2.38

0.50

5.12

1.50

2.84

0.825

7.83

0.79

0.011

0.93

0.28

0.89

1.08

0.80

0.011

3.33

257

X. Xu et al. / Journal of Colloid and Interface Science 445 (2015) 252–261

100%

100%

(a)

90%

80%

80%

Percent removal

Percent removal

(b)

90%

70%

60%

50%

40%

30%

20%

70%

60%

50%

40%

30%

20%

pH 7.8

pH 5.5

10%

pH 7.8

pH 5.5

10%

0%

0%

0

100 200 300 400 500 600 700 800

0

10

20

Bed volumes

30

40

50

60

70

80

90

Bed volumes

100%

(c)

90%

Percent removal

80%

70%

60%

50%

40%

30%

20%

pH 7.8

pH 5.5

10%

0%

0

100 200 300 400 500 600 700 800

Bed volumes

Fig. 3. Percent arsenate removal as a function of bed volumes and pH at 23 °C by (a) dry SDWTS at an MLR of 23.5 L kg1 h1; (b) wet SDWTS at an MLR of 13.9 L kg1 h1; and

(c) dry GDWTS at an MLR of 23.5 L kg1 h1. Error bars represent the standard deviation of duplicate samples.

3.4. Effect of initial concentration on arsenate sorption

To evaluate the effect of different arsenate concentrations on

DWTS sorption capacity, arsenate (Na2HAsO47H2O, reagent grade,

Fisher Scientific, Fairlawn, NJ) was spiked into the RO concentrate

to simulate high arsenate concentrations in natural groundwater. It

should be noted that the arsenate concentration varied significantly from 39 to 75 lg L1 among the batches of RO concentrate

100%

90%

80%

Percent removal

At pH 5.5, approximately 93% of arsenate exists as H2AsO

4,

while at pH 7.8, approximately 92% as HAsO2

4 . When the pH

increases from 5.5 to 7.8, arsenate is converted from monovalent

to divalent anions, resulting in stronger electrostatic repulsion

between HAsO2

4 ions and the negatively charged DWTS. The surface charge of the DWTS is determined by the transfer reactions

of proton between solution and solids. At pH 5.5, the dry SDWTS

is slightly negatively charged (pHPZC 4.8), the wet SDWTS is near

neutral (pHPZC 5.4), and the GDWTS is positively charged (pHPZC

6.9). Because of the strong inner-sphere complexes formed

between monovalent H2AsO

4 ions and the ferric hydroxide components in the solids, all DWTS maintained high removal efficiency

(greater than 70%) at pH 5.5 after 24 h of continuous operation.

As pH increases to 7.8, the surface charge of the DWTS becomes

increasingly negative. For the dry SDWTS, arsenate percent

removal decreased from 77% to 29%, whereas for the dry GDWTS

it reduced to 12%, after 700 bed volumes of RO concentrate being

processed. Greater electrostatic repulsion between the solids and

divalent H2AsO2

4 ions resulted in lower sorption capacity of the

DWTS, compared to that at pH 5.5.

70%

60%

50%

40%

30%

dry GDWTS, As 408 µg·L-1

dry SDWTS, As 335 µg·L-1

dry GDWTS, As 42 µg·L-1

dry SDWTS, As 75 µg·L-1

20%

10%

0%

0

200

400

600

800

Bed volumes

Fig. 4. Percent arsenate removal by dry SDWTS and GDWTS as a function of bed

volumes and initial arsenate concentration at a pH of 5.5, MLR of 23.5 L kg1 h1,

and 23 °C. Error bars represent the standard deviation of duplicate samples.

collected at different times from the RO desalination plant due to

variation of groundwater quality.

The experiments were conducted with the dry SDWTS and

GDWTS at pH 5.5, MLR 23.5 L kg1 h1, and 23 °C (Fig. 4). At high

arsenate concentrations of 335 lg L1 (dry SDWTS) and 408 lg L1

(GDWTS), the percent removal of arsenate decreased from 95.5% to

78.6% after 700 bed volumes for both DWTS. For low arsenate concentrations of 75 lg L1 (dry SDWTS) and 42 lg L1 (dry GDWTS),

258

X. Xu et al. / Journal of Colloid and Interface Science 445 (2015) 252–261

8.65 lg h1 for dry GDWTS at high arsenate concentrations

(Fig. 5). Despite the differences between the two types of DWTS

with regard to water source, plant operation, and chemical composition, no significant differences were observed using these solids

for sorption of arsenate with various concentrations as shown in

Figs. 4 and 5.

Arsenic uptake rate (µg·g-1·h-1)

10

9

8

7

6

5

3.5. Arsenate sorption during long-term operation

y = 0.0217x - 0.3359

R² = 0.9989

4

3

2

1

0

0

200

400

Initial arsenic concentration

600

(µg·L-1)

Fig. 5. Correlation between initial arsenate concentration and uptake rate by dry

SDWTS and GDWTS at pH 5.5, MLR 23.5 L kg1 h1, and 23 °C.

both DWTS exhibited similar percent removals, declining from

over 80% to 65–69% after 700 bed volumes. With the increase of

arsenate concentration in the RO concentrate, the number of arsenate ions at the solid-solution interface also increases, resulting in

the increase in removal efficiency. Total arsenate sorption capacities (as arsenic) achieved in 24 h continuous operation were normalized to the mass of dry solids (per gram), which were

calculated as 0.029 mg for dry SDWTS and 0.017 mg for dry

GDWTS at low arsenate concentrations; and 0.16 mg for dry

SDWTS and 0.21 mg for dry GDWTS at high arsenate

concentrations.

Higher solute concentration can increase the arsenate concentration gradient between sorbent and solution, thus enhancing

the driving force for arsenate diffusion and sorption from the RO

concentrate to the DWTS pores. Previous study by Papelis demonstrated that the rate of ion sorption on large, porous sorbents, such

as DWTS, could be limited by mass transfer, and specifically by

intraparticle diffusion [49]. The increase in arsenate concentration

in aqueous solution enhanced the driving force for intraparticle

diffusion, thus improving the arsenate uptake rate by the DWTS,

as shown in Fig. 5. Under steady state conditions the average arsenate uptake rate per gram of dry solids mass increased linearly as a

function of initial arsenate concentration, that is, 1.20 lg g1 h1

for dry SDWTS and 0.69 lg g1 h1 for dry GDWTS at low arsenate

concentrations; and 6.82 lg g1 h1 for dry SDWTS and

100%

90%

Percent removal

80%

70%

60%

50%

40%

30%

20%

10%

0%

0

250

500

750

1000 1250 1500

Bed volumes

Fig. 6. Percent arsenate removal by wet SDWTS as a function of bed volumes at a

pH of 5.5, MLR of 13.9 L kg1 h1, and 23 °C. Error bars represent the standard

deviation of duplicate samples.

In order to investigate arsenate removal efficiency for a longer

period of time, a 16-day continuous-flow, once-through experiment was conducted using the wet SDWTS (Fig. 6). During the

experiment, arsenate concentrations in the RO concentrates collected at different times from the desalination plant fluctuated

between 39 and 75 lg L1.

After treating more than 1300 bed volumes of RO concentrate at

pH 5.5, arsenate removal leveled off at 48% and the sorption capacity achieved 0.27 mg (as arsenic) per gram of dry solids. The arsenate sorption capacity for RO concentrate appears lower in this

study than the data reported in the literature. Gibbons and Gagnon

examined arsenic sorption in batch and column experiments using

a low salinity groundwater that had an average arsenic concentration of 43 lg L1 and a pH of 8.1 [35]. In batch sorption experiments, Langmuir isotherm modeling was used to determine that

a ferric-based SDWTS and a commercial granular ferric hydroxide

(GFH) sorbent had maximum sorptive capacities of 2230 and

640 mg As/g dry solids, respectively. In a column sorption experiment, the ferric-DWTS achieved arsenic removal of >26,000 bed

volumes before breakthrough above 10 lg L1, whereas the effluent arsenic concentration from the GFH column was below the

method detection limit at 28,000 bed volumes [35]. Although there

are some differences in hydraulic retention times (12.5 min vs.

3.4 min in this study), initial arsenic concentration (38 lg L1 vs.

66 lg L1 in this study), and column geometry, the major factors

contributing to the lower arsenic sorption capacities in our study

are the significant differences in ferric mass in the DWTS and feed

water quality.

In our study, the amount of iron in the DWTS for arsenate sorption is very low (1.1 mg g1 and 3.3 mg g1 of dry solids for GDWTS

and SDWTS, respectively), approximately 100–500 times lower

than the ferric mass in the study by Gibbons and Gagnon

(277.3 mg g1 and 528.8 mg g1 of dry solids for the DWTS and

GFH) [35]. Such low ferric mass in the DWTS could result in low

arsenic sorption capacity in our study. If the arsenic sorption

capacity is normalized with respect to ferric mass in the solids,

the arsenate sorption capacity of the wet SDWTS in our study

would be at least 82 mg As per g Fe, which falls within the maximum sorption capacity range of 8–158 mg As per g Fe reported

by Gibbons and Gagnon for different types of ferric-based DWTS

and GFH [35].

Another important reason for the low arsenate sorption capacity is the presence of competing anions in the RO concentrate and

the solids, including sulfate and NOM. In the study by Gibbons and

Gagnon, the salt concentration in the feed water was not reported,

but can be assumed to be low because the groundwater was from a

drinking water well. In the RO concentrate, the TDS concentration

was approximately 10 g L1, with sulfate concentration of

1300 mg L1. Given that the molar ratio of S:As is 23,660 in the

RO concentrate, sulfate ions can compete with arsenate ions for

the sorption sites in the DWTS, although sulfate ions are assumed

to form only weak outer-sphere complexes whereas arsenate ions

can form strong inner-sphere complexes.

The NOM present in both RO concentrate and DWTS may play

an important role in arsenate speciation in water and sorption to

the DWTS [50]. NOM, mainly negatively charged at neutral pH,

contains functional groups such as carboxylic, esteric, phenolic,

259

X. Xu et al. / Journal of Colloid and Interface Science 445 (2015) 252–261

100%

90%

Percent removal

80%

70%

60%

50%

40%

30%

T 35℃, pH 5.5

T 35℃, pH 7.8

T 23℃, pH 5.5

T 23℃, pH 7.8

20%

10%

0%

0

50

100

Bed volumes

Fig. 7. Percent arsenate removal by wet SDWTS as a function of bed volumes,

temperatures, and pH at MLR of 13.9 L kg1 h1. Error bars represent the standard

deviation of duplicate samples.

quinone, amino, nitroso, sulfhydryl, hydroxyl, and other moieties

[51]. Besides the competition for sorption sites with arsenate,

NOM could form aqueous and surface inner-sphere complexes

with soluble cationic metals and the NOM-metal complexes could

associate strongly with arsenate in RO concentrate by a metalbridging mechanism, inhibiting arsenate from forming surface

complexes with the DWTS [52]. The average DOC concentration

in the RO concentrate was 4.1 mg L1, and DOC was also leaching

from the DWTS, thus reducing arsenate sorption to the DWTS.

The impact of water chemistry on arsenate adsorption by the

DWTS needs further investigation.

3.6. Effect of temperature on arsenate sorption

The effect of temperature on DWTS sorption was investigated

using the wet SDWTS at MLR of 13.9 L kg1 h1 and pH of 7.8

and 5.5 (Fig. 7). At the initial pH of the RO concentrate, arsenate

removal efficiency increased slightly with increasing temperature,

which is not expected if the chemical interactions between different arsenic species and the DWTS are the rate limiting process for

arsenate sorption. Previous thermodynamic studies by Banerjee

et al. demonstrated that under steady-state the sorption of arsenate and arsenite onto granular ferric hydroxide (GFH) is a spontaneous and endothermic process [32]. The activation energy values

100%

3.7. Effect of hydraulic retention time (HRT)

The effect of HRT on arsenate removal was investigated using

the dry SDWTS at two conditions: (1) at a pH of 7.8 with an HRT

of 1.1 (MLR 46.9 L kg1 h1), 2.1 (MLR 23.5 L kg1 h1), and

3.2 min (MLR 13.9 L kg1 h1) using 42.2 g solids; and (2) pH of

5.5 with an HRT of 2.1 min (MLR 23.5 L kg1 h1) using 42.2 g solids, and 8.1 min (MLR 6.2 L kg1 h1) using 126.6 g solids (Fig. 8).

Longer HRT and lower MLR improved arsenate sorption because

of longer contact time and increased opportunity for interactions

between arsenate and the SDWTS. At pH 7.8 and 350 bed volumes

the average removal efficiencies achieved 32.5%, 46.1%, and 59.8%

for HRTs of 1.1, 2.1, and 3.2 min, respectively. After that, the effect

of HRT on arsenate sorption decreased and leveled off at 20–28%

after additional 1000 bed volumes (Fig. 8a). Similarly, at pH 5.5,

arsenate removal at an HRT of 8.1 min increased the average

removal efficiency by 10% compared to an HRT of 2.1 min

(Fig. 8b). Although longer retention time allowed more opportunities for arsenate to sorb onto the solids, the impact of HRT declined

as the solids saturated with arsenate and other species sorbed from

100%

HRT 1.1 minutes

HRT 2.1 minutes

HRT 3.2 minutes

90%

70%

60%

50%

40%

30%

HRT 2.1 minutes

HRT 8.1 minutes

90%

80%

Percent removal

80%

Percent removal

obtained for arsenate at pH 6.5 was about 35% less than that

obtained at pH 7.5, resulting in a faster adsorption rate and better

removal at pH 6.5 than at pH 7.5. The equilibrium adsorption coefficients of arsenate increased by 335% and 262% at pH 6.5 and 7.5,

respectively, when temperature increased from 20 °C to 40 °C.

Maximum arsenate adsorption capacity of GFH also increased from

3.13 mg/g to 4.57 mg/g with increasing temperature [32]. However, our column experiments did not observe this significant temperature impact on arsenate sorption. At pH 5.5, the removal

efficiency increased by less than 5% for the same bed volumes

when water temperature increased from 23 °C to 35 °C. At pH

7.8, the removal efficiency increased by less than 10%, except at

the beginning of the experiment, where it increased by 13%. The

results are in agreement with the study by Zhou et al. where metal

sorption by DWTS increased by less than 5% between 20 °C and

60 °C [46].

Banerjee’s et al. study was conducted at batch operation under a

steady-state and an equilibrium condition (24 h), whereas our column experiments were conducted under a non-steady state with

an HRT of 3.2 min. It suggests that the continuous-flow arsenate

sorption process is diffusion-controlled, in which the activation

energies would be substantially lower than the chemosorption

process, therefore major temperature effects would not be

expected.

70%

60%

50%

40%

30%

20%

20%

10%

10%

(a)

(b)

0%

0%

0

300

600

900

Bed volumes

1200

1500

0

200

400

600

800

Bed volumes

Fig. 8. Percent arsenate removal by wet SDWTS as a function of bed volumes and HRT at 23 °C and (a) pH of 7.8 and (b) pH of 5.5. Error bars represent the standard deviation

of duplicate samples.

260

X. Xu et al. / Journal of Colloid and Interface Science 445 (2015) 252–261

While the disposal of used DWTS with high arsenic content was

not evaluated in this study, this is an important issue that needs

further investigation.

100%

90%

Percent removal

80%

70%

Acknowledgments

60%

50%

40%

30%

20%

10%

0%

dry SDWTS, pH 7.8

dry SDWTS, pH 5.5

wet SDWTS, pH 7.8

wet SDWTS, pH 5.5

0 2 4 6 8 10 12 14 16 18 20 22 24 26

Volume processed (L)

Fig. 9. Percent arsenate removal by dry and wet SDWTS as a function of bed

volumes and pH of 5.5 and 7.8, at 23 °C. Error bars represent the standard deviation

of duplicate samples.

the RO concentrate. Thus, the differences in percent removal

decreased as the number of bed volumes increased.

3.8. Effect of moisture content of the SDWTS

The moisture content of DWTS changes over time and depends

on the dewatering/drying processes in a water treatment plant.

Dry DWTS may be preferred because of the reduced solid volume

that needs to be transported. The impact of the DWTS moisture

content on arsenate removal was evaluated with the wet SDWTS

(MLR 13.9 L kg1 h1) and the dry SDWTS (MLR 23.5 L kg1 h1)

at pH 5.5 and 7.8, and 23 °C (Fig. 9). The wet SDWTS exhibited

slightly higher arsenate removal efficiency than the dry SDWTS

by an average of 6% and 12% at pH 5.5 and 7.8, respectively, during

a 24-h continuous operation.

Water contained in the wet SDWTS facilitated the hydrolysis of

iron, aluminum, and cations on the surface, contributing to higher

sorption efficiency. The lower removal efficiency of the dry SDWTS

could be attributed to the loss of surface-active hydroxyl sites after

drying at 105 °C, or the air trapped in the dry solids, which prevents the contact between the concentrate and the solids. As sorption time passes, the dry SDWTS is wetted by the RO concentrate

and should behave similarly to the wet SDWTS after saturation.

This assumption is consistent with the experimental results; at

pH 5.5 and 7.8, the removal efficiency of the dry SDWTS and the

wet SDWTS overlapped after treating approximately 14 L and

10 L of the RO concentrate, respectively.

4. Conclusions

This study demonstrates that DWTS is effective for removing

arsenate from RO concentrate. Arsenate sorption by the DWTS is

mainly affected by pH and initial arsenate concentration, while

hydraulic retention time, temperature, and moisture of the DWTS

have marginal impacts on arsenate removal. The two types of

DWTS show negligible differences in arsenate sorption, although

higher ferric mass in DWTS is anticipated to enhance sorption

capacity. The competition by other ions in the RO concentrate

may hinder the sorption of arsenate on DWTS. The leaching tests

indicate that the potential risks associated with the use of DWTS

include the leaching of organic contaminants and ammonia. The

risks can be alleviated when wet DWTS is used as sorbent, or the

initially treated effluent with high organic content is discarded.

Support for this study was provided by the National Science

Foundation Engineering Research Center Program under

Cooperative Agreement EEC-1028968 (ReNUWIt). The authors

thank John Balliew, Hector Gonzalez and Mike Fahy with El Paso

Water Utilities, and Ashley Dalton with Golden Drinking Water

Treatment Plant for technical support. The authors also acknowledge Mark Chidester with New Mexico State University for

assistance in chemical analysis.

References

[1] C. Charcosset, Desalination 245 (2009) 214–231.

[2] N. Ghaffour, T.M. Missimer, G.L. Amy, Desalination 309 (2013) 197–207.

[3] P. Xu, J.E. Drewes, C. Bellona, G. Amy, T.-U. Kim, M. Adam, T. Heberer, Water

Environ. Res. 17 (2005) 40–48.

[4] P. Xu, J.E. Drewes, D. Heil, Desalination 225 (2008) 139–155.

[5] P. Xu, M. Capito, T.Y. Cath, J. Hazard. Mater. 260 (2013) 885–891.

[6] P. Xu, T. Cath, A.P. Robertson, M. Reinhard, J.O. Leckie, J.E. Drewes, Environ. Eng.

Sci. 30 (2013) 502–514.

[7] M. Matsui, C. Nishigori, S. Toyokuni, J. Takada, M. Akaboshi, H. Ochi, M.

Ishikawa, S. Imamura, J. Dermatol. Sci. 16 (Supplement 1) (1998) S54.

[8] R.C. Dart, Medical Toxicology, Williams & Wilkins, Lippincott, 2004.

[9] T. Viraraghavan, K.S. Subramanian, J.A. Aruldoss, Water Sci. Technol. 40 (1999)

69–76.

[10] E.O. Kartinen Jr, C.J. Martin, Desalination 103 (1995) 79–88.

[11] R.Y. Ning, Desalination 143 (2002) 237–241.

[12] R. Güell, C. Fontàs, V. Salvadó, E. Anticó, Sep. Purif. Technol. 72 (2010) 319–

325.

[13] S.K. Maji, A. Pal, T. Pal, J. Hazard. Mater. 151 (2008) 811–820.

[14] K.C. Makris, D. Sarkar, J.G. Parsons, R. Datta, J.L. Gardea-Torresdey, J. Hazard.

Mater. 171 (2009) 980–986.

[15] C. Wang, Y. Qi, Y. Pei, Chem. Eng. J. 209 (2012) 379–385.

[16] C. Wang, Z. Wang, L. Lin, B. Tian, Y. Pei, J. Hazard. Mater. 203–204 (2012) 145–

150.

[17] C. Wang, Y. Pei, Chemosphere 88 (2012) 1178–1183.

[18] E. Lombi, D.P. Stevens, M.J. McLaughlin, Environ. Pollut. 158 (2010) 2110–

2116.

[19] L. Lin, X. Xu, C. Papelis, T.Y. Cath, P. Xu, Sep. Purif. Technol. 134 (2014) 37–45.

[20] A.O. Babatunde, Y.Q. Zhao, Crit. Rev. Environ. Sci. Technol. 37 (2007) 129–164.

[21] M.L. Pierce, C.B. Moore, Water Res. 16 (1982) 1247–1253.

[22] K.C. Makris, D. Sarkar, R. Datta, Chemosphere 64 (2006) 730–741.

[23] M.K. Gibbons, G.A. Gagnon, Water Res. 44 (2010) 5740–5749.

[24] S.K. Gupta, K.Y. Chen, J. Water Poll. Contr. Fed. 50 (1978) 493–506.

[25] R.D. Wauchope, J. Environ. Qual. 4 (1975) 355–358.

[26] N.T. Livesey, P.M. Huang, Soil Sci. 131 (1981) 88–94.

[27] D.D. Sarkar, K.C. Makris, M.T. Parra-Noonan, R. Datta, Environ. Int. 33 (2007)

164–169.

[28] K.C. Makris, W.G. Harris, G.A. O’Connor, T.A. Obreza, H.A. Elliott, Environ. Sci.

Technol. 39 (2005) 4280–4289.

[29] K.C. Makris, D. Sarkar, J.G. Parsons, R. Datta, J.L. Gardea-Torresdey, J. Hazard.

Mater. 171 (2009) 980–986.

[30] K.C. Makris, D. Sarkar, J.G. Parsons, R. Datta, J.L. Gardea-Torresdey, J. Colloid

Interface Sci. 311 (2007) 544–550.

[31] M. Shafiquzzaman, M.S. Azam, J. Nakajima, Q.H. Bari, Desalination 261 (2010)

41–45.

[32] K. Banerjee, G.L. Amy, M. Prevost, S. Nour, M. Jekel, P.M. Gallagher, C.D.

Blumenschein, Water Res. 42 (2008) 3371–3378.

[33] J. Pattanayak, K. Mondal, S. Mathew, S.B. Lalvani, Carbon 38 (2000) 589–596.

[34] O.S. Thirunavukkarasu, T. Viraraghavan, K.S. Subramanian, Water Air Soil Poll.

142 (2003) 95–111.

[35] M.K. Gibbons, G.A. Gagnon, Water Res. 44 (2010) 5740–5749.

[36] T.S. Singh, K.K. Pant, Sep. Purif. Technol. 36 (2004) 139–147.

[37] S. Ouvrard, M.-O. Simonnot, M. Sardin, Ind. Eng. Chem. Res. 41 (2002) 2785–

2791.

[38] V. Lenoble, O. Bouras, V. Deluchat, B. Serpaud, J.-C. Bollinger, J. Colloid Interf.

Sci. 255 (2002) 52–58.

[39] B. Daus, R. Wennrich, H. Weiss, Water Res. 38 (2004) 2948–2954.

[40] T.-F. Lin, J.-K. Wu, Water Res. 35 (2001) 2049–2057.

[41] G.S. Murugesan, M. Sathishkumar, K. Swaminathan, Bioresour. Technol. 97

(2006) 483–487.

[42] Standard Methods for the Examination of Water & Wastewater, American

Public Health Association, American Water Works Association, and Water

Environment Federation, 2005.

[43] J.M. Cook, M.J. Gardner, A.H. Griffiths, M.A. Jessep, J.E. Ravenscroft, R. Yates,

Mar. Pollut. Bull. 34 (1997) 637–644.

X. Xu et al. / Journal of Colloid and Interface Science 445 (2015) 252–261

[44]

[45]

[46]

[47]

[48]

K. Sakurai, Y. Ohdate, K. Kyuma, Soil Sci. Plant Nutr. 34 (1988) 171–182.

A. Jain, K.P. Raven, R.H. Loeppert, Environ. Sci. Technol. 33 (1999) 1179–1184.

Y.-F. Zhou, R.J. Haynes, Water Air Soil Pollut. 215 (2010) 631–643.

G. Sposito, The Surface Chemistry of Soils, Oxford University Press, 1984.

M. Habuda-Stanić, B. Kalajdžić, M. Kuleš, N. Velić, Desalination 229 (2008) 1–9.

261

[49] C. Papelis, Environ. Sci. Technol. 29 (1995) 1526–1533.

[50] B.T. Hart, Environ. Technol. Lett. 2 (1981) 95–110.

[51] A.D. Redman, D.L. Macalady, D. Ahmann, Environ. Sci. Technol. 36 (2002)

2889–2896.

[52] P. Thanabalasingam, W.F. Pickering, Environ. Pollut. 12 (1986) 223–246.