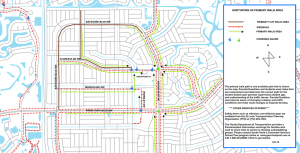

CITY of CHARLOTTE Pilot SCM Monitoring Program Lowe’s – South Blvd Store

advertisement