A CMOS contact imager for locating individual cells

advertisement

A CMOS contact imager for locating individual

cells

Honghao Ji, David Sander, Alfred Haas, Pamela A. Abshire

Department of Electrical and Computer Engineering, Institute for Systems Research

University of Maryland, College Park, Maryland 20742, USA

Email: {jhonghao, dsander, ahaas, pabshire@umd.edu}

Abstract— We describe the design of a contact imager for

applications in lab-on-a-chip systems, such as sample preparation

and manipulation and monitoring of cells. This is a challenging

task because most cells are nearly transparent, so the contrast

between the presence and absence of a cell is small. Thus

additional image processing is necessary to locate cells. To

enhance the image contrast and facilitate object recognition, the

contact imager implements on-chip one bit quantization with a

dynamic threshold that adapts to the background illumination.

The imager is capable of locating dark objects in a bright

background or bright objects in a dark background. The locations of recognized cells are generated as outputs to alleviate

computational requirements for generating control signals in

closed-loop systems.

I. I NTRODUCTION

0-7803-9390-2/06/$20.00 ©2006 IEEE

(a)

90

80

70

60

Number of pixels

Interest in single cell analysis has grown rapidly [1] due to

potential applications including scientific studies of intracellular processes, drug development, medical diagnostics, and

the development of cell-based sensors. Lab-on-a-chip systems

(LOC) are attracting increasing research attention as promising

instruments for individual cell characterization without relying

on significant laboratory infrastructure [2]–[6] . LOCs also offer the promise of multiple sensing modalities, low cost due to

minimum sample usage, high throughput, and portability. For

challenging tasks such as single cell manipulation and steering,

LOC must perform both actuation and sensing without relying

on external instruments. Whereas suitable methods exist for

microfluidic actuation of cells, including both electro-osmotic

flow (EOF) and dielectrophoresis (DEP), suitable devices are

necessary to locate cells and generate the control signals

required for steering cells onto different probing sites.

Several approaches to on-chip sensing have been reported

[5]–[7]. Optical sensing based on contact imaging using

CMOS active pixel sensor (APS) was reported in [6], [8],

which demonstrated that cells directly coupled to the chip

surface can be visualized without requiring bulky intervening

optics. The remaining challenges for closing the feedback loop

are: 1. scaling down the pixel size to match that of cells; 2.

improving the sensitivity and noise immunity to achieve real

time sensing; and 3. implementing simple signal processing so

that the location of cells can be extracted without sacrificing

resolution and speed. To address these issues, this paper

describes a CMOS image sensor designed for cell sensing in

a commercially available 0.18 µm technology. The sensor has

a pixel size of 5µm. We incorporate techniques for locating

50

40

30

20

10

0

0.45

0.5

0.55

0.6

signal level (V)

0.65

0.7

0.75

(b)

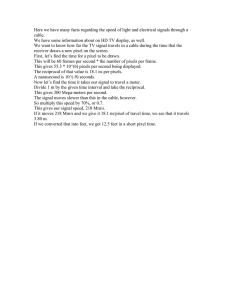

Fig. 1. (a) Image of cells acquired from a previously designed contact imager,

where locations of cells are highlighted with circles, and (b) histogram of the

signal distribution of (a).

cells into the sensor architecture so that post-capture image

processing is unnecessary and only information about cell

locations is collected, while retaining the resolution and speed

of the image sensor.

The rest of this paper is organized as follows: section

II introduces the algorithm used to improve sensitivity and

locate multiple objects; section III describes the design in

detail including architecture design, pixel design, and adaptive

3357

ISCAS 2006

(a)

(b)

(c)

Fig. 2. The image in 1(a) is quantized using (a) mean, (b) median signal

levels, and (c) Vavg .

threshold; section IV presents simulation results; and section

V summarizes this work and outlines future directions.

II. C ELL LOCATION TECHNIQUE

We briefly review existing image processing techniques potentially useful for locating cells. The winners-take-all (WTA)

method identifies the strongest signal or signals out of an

ensemble [9]. It is not suitable for our application because

the number of cells is not known a priori. Multiple cells

could be present in one row or column, and their images

may correspond to different signal levels. In [10], Burns et al.

described a binary object location system (OLS) and proposed

a cumulative cross section (CCS) readout system for object

location. Both systems rely on comparing the photovoltages

of each pixel to a global threshold to generate two 1 − D

data arrays. Although CCS can identify the number of pixels

in each row with their photovoltages less than a threshold,

it doesn’t provide the address for every identified pixel. In

addition, comparison between photovoltages and the global

threshold are performed in pixel, so it can detect either

dark objects in light backgrounds or bright objects in dark

backgrounds, but not both. It also results in large pixel size.

In order to locate multiple cells which have sizes comparable to the size of a pixel, we modified OLS by performing

a global one-bit quantization to generate a binary image

where either ones or zeros are identified as objects based

on the contrast between cells and the background. Figure 1

shows a previously acquired image of cells coupled to the

sensor surface along with the amplitude statistics of its analog

intensity signals. Since cells are sparingly distributed on the

chip surface, most pixels have signals corresponding to the

background illumination level. As shown in Figure 1(b), most

signals cluster around 0.67 V in a nearly Gaussian distribution,

which arises from the differences in gains of different pixels

and random noise. A few signals scatter between 0.45 V

and 0.6 V , which correspond to the presence of cells in the

image. These signals would be another Gaussian distribution

centered somewhere between 0.45 V and 0.6 V , if there were

enough cells present in the image. The poor contrast between

photovoltages due to the absence and presence of nearly

transparent cells can be significantly enhanced if we transform

the original image into a binary one by one-bit quantization.

Additionally, variations in background light level will cause

this distribution to shift, so it is desirable to dynamically

generate the threshold level on chip. Intuitively, the threshold

level for one-bit quantization should be the value where the

two Gaussian distributions start overlapping. When there are

only a few cells present as in Figure 1, the threshold should

be a value close to the left edge of the Gaussian distribution

in Figure 1(b) in order to locate the objects and suppress

background noise. To ease computational burden on chip,

the global threshold is taken to be the average value Vavg

of the maximum and minimum photovoltages assuming that

the two Gaussian distributions have the same variance. Figure

2 shows the quantized version of Figure 1(a) using Vavg as

the threshold. For comparison, binary images of Figure 1(a)

quantized using mean and median signal levels are also shown.

The figure illustrates that choosing the correct threshold is

critical for removing the noise and correctly locating cells.

III. S YSTEM D ESIGN

A. Chip architecture

The block diagram of the image sensor is shown in Figure

3. Signal processing circuitry is separate from the sensor

array and readout circuitry. Therefore, the design of processing

circuitry can be optimized without sacrificing the pixel size,

scalability of the pixel array, or speed. The sensor array

consists of 256 × 256 pixels, row decoder, column decoder,

and column-wise readout circuits. The inputs for each decoder

can be generated from on-chip counters for scanning operation,

as shown in Figure 3, or supplied from off-chip for random

access (not shown). The processing unit includes a threshold

generator, comparator, and object address generator. Analog

photovoltage generated from each pixel is read out from the

pixel array and compared to the threshold computed using

the intensity data of the previous frame. The output of the

comparator is one if the photovoltage is larger than the threshold, and zero otherwise. A control signal determines whether

objects are bright or dark compared to the background. For

bright objects (such as cells labeled with fluorescent probes),

the quantized outputs directly gate a “Clk addressout” clock

signal to generate the clock for two sets of shift registers,

which have the row address and column address of the selected

pixel as their inputs respectively. The address of an identified

3358

cell is captured by the shift registers and serially read out of

chip. For dark objects (such as stained cells), the quantized

outputs are inverted before gating the “Clk addressout” clock.

To eliminate false alarms when there are no cell s on the chip

surface, the threshold generator produces a “No object” signal.

When “No object” is on, both address-capturing shift registers

are disabled.

Row sel

Rst

V tune

Background_cont

Clk_addressout

Vth generator

256 256

No_objects

Column wise

readout circuit

Col. ADC

Counter

Col. Decoder

8 shift 8

reg.

Col bus

V sig

V rst

8

Clk2

Clk1

Start

APS array

Vth

Row Decoder

Counter

Vg

Fig. 4.

The schematic of a modified pixel circuit.

D out

Col add.

Vtune

8 shift 8

reg.

Row add.

No_object

V shifter

Vsig

SWmax

Fig. 3. The image sensor architecture, where the processing unit is enlosed

in the dashed box.

Vmax

Clk_eval

Ø2

Vavg

Ø2

B. Pixel array

Ø1

C1

C3

Vrst

We used a modified pixel structure as shown in Figure 4

to enhance performance. One additional transistor is added to

a conventional three-transistor one-photodiode APS pixel. The

pixel has an area of 5µm×5µm, with a fill factor of 31%. The

pixel can operate in different modes selected by control signals

for either reset noise suppression or dark current reduction. A

description of the pixel design considerations and its modes

of operation can be found in [11].

Ø1

Vdd

C2

Ø1

C4

Ø2

SWmin

C. Threshold generator

A diagram of the threshold generator is shown in Figure 5.

The reset voltage Vrst and signal voltage Vsig after integration

for each pixel are fed into both Vmax and Vmin detectors. If

Vsig is higher than the previous stored Vmax , corresponding

to a smaller photovoltage (Vrst − Vsig ), it is stored as the

new Vmax . Similarly, if it’s less than the previously stored

Vmin , it will be stored as new Vmin . To prevent difficulty in

closing SWmax (SWmin ) due to the coupling through Cgs of

SWmax (Cgd of SWmin ) and disturbance of the stored Vmax

(Vmin ) due to uncertainty in the comparator’s output when the

stored voltage approaches its new value, one additional switch

is added between SWmax (SWmin ) and the storage capacitor

C1 (C2). This switch is controlled by a separate clock signal

“Clk eval”. After reading out each frame, the new Vmax

and Vmin are passed to the next buffer stage by closing the

switches controlled by Φ2. After switches controlled by clock

Fig. 5.

Threshold voltage Vavg generator.

Φ2 are open, clock Φ1 closes the switch connecting C3 and

C4 to generate a new threshold. Meanwhile Vmax and Vmin

are reset to 0V and 3.3V respectively. A voltage shifter, as

shown in Figure 6, is also included in the threshold generator

to generate a voltage of Vbg = Vmax − ∆V where ∆V

can be adjusted by a control signal Vtune to suppress errors

due to noise-induced non-uniformity. If the threshold is larger

than Vbg , i.e. the average photovoltage Vavg is less than the

smallest photovoltage plus ∆V , “N o object” becomes zero

and disables the address capturing shift registers. Thus false

alarms due to the absence of objects can be eliminated.

The finished chip layout is shown in Figure 7.

3359

3

Vtune

2.5

output of Vmax detector

input signal

output of Vmin detector

Vdd

Vin

Signals (V)

2

Vout

1.5

1

0.5

0

0

0.2

0.4

0.6

Time (sec)

Fig. 6.

Schematic of voltage shifter.

0.8

1

−3

x 10

Fig. 8. The simulation results of Vmax and Vmin detectors with a sinusoidal

signal as input. The input signal has a maximum value of 2.9 V and minimum

value of 1.1V.

V. C ONCLUSION

An image processing technique for locating multiple cells

along with its physical implementation has been presented.

A 256 × 256 APS array with pixel size of 5µm × 5µm was

designed to achieve adequate resolution for contact imaging

of individual cells. Addresses of identified cells are generated

as outputs to facilitate the generation of control signals for

microfluidic actuation. We plan to integrate this image sensor

with microfluidic actuation in a closed-loop feedback system

to form an autonomous lab-on-a-chip (LOC) system.

R EFERENCES

Fig. 7.

Chip layout. The size is 3 mm × 3 mm including the padframe.

IV. S IMULATION RESULTS AND DISCUSSION

The implementation of the technique for identifying multiple cells described above was fully simulated using Spectre.

The simulation results of every block meet their expected

functionalities. To avoid saturation, the integration time and

the frame rate can be controlled externally through the decoders according to the sensitivity of the fabricated sensor

and illumination level. The threshold generator is the key

component for successfully tracking the cells. Figure 8 shows

simulation results for both Vmax and Vmin detectors. Within

the expected output range (1.1 V to 2.9 V), both Vmax and

Vmin detectors store the maximum and minimum values with

an offset less than 7mV . The chip will be fabricated in a

commercially available 0.18 µm one-poly, six-metal CMOS

process.

[1] Helene Andersson and Albert van den Berg, “Microtechnologies and

nanotechnologies for single-cell analysis,” Curr. Opin. Biotechnol., vol.

15, no. 1, pp. 44-49, 2004

[2] Helene Andersson and Albert van den Berg, “Microfluidic devices for

cellomics: a review,” Sens. Actuators, B, vol. 92, no. 3, pp. 315-325,

2003

[3] Darwin R. Reyes, Dimitri Iossifidis, Pierre-Alain Auroux, and Andreas

Manz, “Micro total analysis systems. 1. introduction, theory, and technology,” Anal. Chem., vol. 74, no. 12, pp.2623-2636, 2002

[4] Pierre-Alain Auroux, Dimitri Iossifidis, Darwin R. Reyes, and Andreas

Manz, “Micro total analysis systems. 2. analytical standard operations

and applications,” Anal. Chem., vol. 74, no. 12, pp. 2637-2652, 2002

[5] G. Medoro, N. Manaresi, A. Leonardi, L. Altomare, Tartagni, and R.

Guerrieri, “A lab-on-a-chip for cell detection and manipulation,” IEEE

Sens. J., vol.3, no. 3, pp.317-325, 2003

[6] N. Manaresi, A. Romani, G. Medoro, L. Altomare, A. Leonardi, M.

Tartagni, and R. Guerrieri, “A CMOS chip for individual cell manipulation

and detection,” IEEE J. Solid-st. Circ., vol. 38, no. 12, pp. 297-2305, Dec.

2003

[7] Yehya Ghallab and Wael Badawy, ”A novel CMOS lab-on-a-chip for

biomedical applications,” Proc. of ISCAS, pp.1346-1349, 2005

[8] Honghao Ji, Mario Urdaneta, Elisabeth Smela, and Pamela Abshire,

“CMOS contact imager for monitoring cultured cells,” Proc. of ISCAS,

pp. 3491-3494, 2005

[9] A. Fisher, D. Turchin, and O. Yadid-Pecht, “An APS with 2-D winnertake-all selection employing adaptive spatial filtering and false alarm

reduction,” IEEE Trans. Electron Dev., vol. 50, no. 1, pp. 159-165, 2003

[10] R.D. Burns, J. Shah, C. Hong, S. Pepić, J. S. Lee, r. I. Hornsey, and P.

Thomas, “Object location and centroiding techniques with CMOS active

pixel sensor,” IEEE Trans. Electron Dev., vol. 50, no. 12, pp. 2369-2377,

2003

[11] Honghao Ji and Pamela Abshire, ”A CMOS image sensor for low light

applications,” Proc. of ISCAS 2006 (Vision sensors session)

3360