Stage I Vapor Control Requirements Instructions for Form S2

advertisement

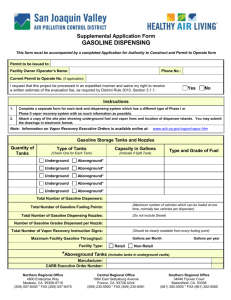

Stage I Vapor Control Requirements Instructions for Form S2 Form S2 contains specific equipment / process-related information on the facility being permitted. One Form S2 is to be completed for each permit application when new equipment is to be installed or existing, permitted equipment is to be modified. LOCATION, OPERATION and PROJECTED GASOLINE THROUGHPUT FACILITY NAME: List the gasoline dispensing facility name. LOCATION: List the address of the facility. GASOLINE DISPENSING START DATE: List the potential start date for a new, modified or reconstructed facility. OTHER PERMITTED FACILITIES IN MECKLENBURG COUNTY: If the Owner and\or Operator has any other Air Quality Permits issued by Mecklenburg County, list the Permit Numbers. Monthly Throughput: Total volume of gasoline loaded into or dispensed from all storage tanks at the GDF during a month. Calculation of Monthly Throughput: Summing the volume of gasoline loaded into, or dispensed from (i.e., not both) all storage tanks during the current day, plus the total volume of gasoline loaded or dispensed from storage tanks during the previous 364 days, then divide that sum by 12. NOTE: This applies to any sequential 365 day time period, not just a calendar year. PROJECTED ACTUAL ANNUAL LOADING OF GASOLINE INTO STORAGE TANKS (in gallons): List the projected actual annual loading of gasoline into storage tanks for the facility. Previously unpermitted facilities must provide a projected annual gasoline loading figure. Previously permitted Stage I gasoline dispensing facilities that will be modified or reconstructed must provide a projected annual gasoline loading figure. Per MCAPCO Regulation 2.0928 – “Gasoline Service Stations Stage I”, gasoline dispensing facilities exceeding 50,000 gallons combined annual throughput of gasoline at a facility is not exempt and must have an air quality permit. This is applicable to facilities making gasoline product transfers from truck tanks to storage tanks or gasoline product transfers from tank to tank. EMISSION SOURCES TANK TYPE: List if the tank is an above ground storage tank (AST) or an underground storage tank (UST). TANK CAPACITY: List the tank capacity (in gallons) for the non-exempt gasoline storage tank(s). PRODUCT STORED: List the type of product to be stored in the tank [i.e., regular, mid-grade, premium, racing, or ethanol (E-85)]. ORIGINAL INSTALLATION DATE OF TANK: List the initial installation date of the storage tank. STAGE I VAPOR CONTROL/VAPOR BALANCE SYSTEM INSTALLATION DATE: List the initial installation date of the Stage I vapor control/vapor balance equipment. GASOLINE STORAGE TANK AND/OR PRESSURE/VACUUM VALVE REPLACEMENT DATE: If gasoline storage tank(s), submerged fill pipes or pressure/vacuum valve(s) were replaced, list the dates. INSIGNIFICANT ACTIVITY SOURCE(S) INSIGNIFICANT ACTIVITY DESCRIPTION - List exempted insignificant activity sources, per MCAPCO Regulation 1.5211 (g)((1), MCAPCO Regulation 2.0928 and 40 CFR 63, Subpart CCCCCC. Contact MCAQ regarding emergency generators. (MCAPCO Regulation 1.5211) (g) The following activities do not need a permit or permit modification under this Article; however the Director may require the owner or operator of these activities to register them under MCAPCO Regulation 2.0202 - "Registration of Air Pollution Sources": (D) storage tanks: (i) storage tanks used solely to store fuel oils, kerosene, diesel, crude oil, used motor oil, lubricants, cooling oils, natural gas or liquefied petroleum gas; (ii) storage tanks used to store gasoline for which there are no applicable requirements except Stage I Mecklenburg County Air Quality – Permit Application S2 Form Instruction, Rev. 06/11 controls under MCAPCO Regulation 2.0928 - "Gasoline Service Stations Stage I"; storage tanks used solely to store inorganic liquids; or storage tanks or vessels used for the temporary containment of materials resulting from an emergency response to an unanticipated release of hazardous materials; (2) activities exempted because of size and production rate (These activities shall not be included in the permit. If the facility is subject to the permitting procedures under MCAPCO Section 1.5500 - "Title V Procedures", these activities shall be listed on the permit applications; otherwise, these activities shall not be listed on the permit applications.): (A) storage tanks: (i) above-ground storage tanks with a storage capacity of no more than 1100 gallons storing organic o liquids with a true vapor pressure of no more than 10.8 psi absolute at 70 F; or (ii) underground storage tanks with a storage capacity of no more than 2500 gallons storing organic o liquids with a true vapor pressure of no more than 10.8 psi absolute at 70 F; (iii) (iv) STAGE I VAPOR CONTROL/VAPOR BALANCE SYSTEM COMPONENTS Stage I Vapor Control/Vapor Balance System Components: Coaxial Poppeted Vapor Control/Balance Adaptor - Delivery of product and the recovery of vapors occurs through a single coaxial fitting on the storage tank. To accommodate this tube within a tube arrangement, the two hoses from the tanker hook onto a coaxial coupling (adapter) or delivery elbow. The fill tube is usually spring loaded (moveable) which allows for it to be pushed down approximately 1"when securing the coupling. In its resting position it maintains a vapor seal, against the fitting, similar to the dry break seal with dual system. Product is delivered through the inner drop tube while vapor is recovered in the space between the walls of the inner and outer tubes at the top of the tank. NOTE: Coaxial vapor controls cannot be installed at new, modified or reconstructed facilities. Diameter - All vent pipe shall be a minimum of two (2) inches in diameter or meet the local fire Codes. Dual Poppeted Vapor Control/Balance Adaptor - Delivery of product to the facility’s stationary storage tank and recovery of displaced vapor occurs through two separate openings in the tank. Product is dropped through the submerged fill pipe while the vapor is forced up a riser pipe. Vapor control/balance riser pipe openings are fitted with a spring loaded poppet valve that maintains a tight seal when a vapor control / balance hose is not connected. Height - Individual or manifolded vent lines equipped with pressure relief valves must be installed at a height of 12 feet above the driveway surface used for Stage I tank truck filling operations and in accordance with the applicable fire and safety codes. The outlets shall vent upward and be located to eliminate the possibility of vapor accumulating or traveling to a source of ignition or entering adjacent buildings. Manifold - The gasoline storage tanks are connected by a common header from which a single pipe leads to a pressure/vacuum vent. Poppeted Vapor Control/Balance Adaptor - A vapor control/balance adaptor that automatically and immediately closes itself maintaining a tight seal when the vapor control/vapor balance system line is not connected. Pressure/Vacuum Release Valve Performance Specifications- The release valve shall be installed on all vent pipe for Stage I Vapor recovery to prevent the tanks from venting vapors between loading and to protect the tanks from physical damage or permanent deformation caused by routine increases in internal pressure or vacuum The 40 CFR 63, Subpart CCCCCC federal rule was adopted on January 10, 2008 and amended on March 7, 2008, June 25, 2008 and January 24, 2011. With the exception of a Stage I gasoline dispensing facility that is new, reconstructed, or has replaced a gasoline storage tank and averages ≥ 100,000 gallons per month, all other facilities may continue to use their existing pressure/vacuum valve(s) that is/are capable of 3” ± 0.5” of H 2O pressure and 8" + 2.0" vacuum). Since January 10, 2008, if a Stage I gasoline dispensing facility that is new, reconstructed, or has replaced a gasoline storage tank and averages ≥ 100,000 gallons per month, the facility must install the pressure/vacuum valve described in 40 CFR 63, Subpart CCCCCC, Table 1, which requires: - a positive pressure setting of 2.5 to 6.0 inches of water; - a negative pressure setting of 6.0 to 10.0 inches of water; - a total leak rate of all PV vent valves at an affected facility, including connections, that shall not exceed 0.17 cubic foot per hour at a pressure of 2.0 inches of water and 0.63 inches cubic foot per hour at a Mecklenburg County Air Quality – Permit Application S2 Form Instruction, Rev. 06/11 vacuum of 4 inches of water. Slope - All vapor return lines and vent pipes shall slope a minimum of 1/8 inch per foot. A slope of 1/4 inch or more per foot is recommended wherever feasible. Submerged Fill Pipes: While gasoline is transferred from one storage tank to another, agitation or splashing will cause aeration of the liquid and thereby increase the formation of vapor. This is minimized by using a submerged fill pipe to deliver product under the surface of liquid in the tank. The fill pipe is usually an aluminum sleeve fitted inside the drop tube. MCAQ requires all storage tank submerged fill pipes installed after November 9, 2006 to be ≤ 6 inches from the bottom of the storage tank. If the opening of the submerged fill pipe is cut at a slant, the distance is measured from the top of the slanted cut to the bottom of the tank. Vapor Lines and Gasoline Product Loading Rates: No more than one (1) tank shall be loaded at a time if the manifold vapor lines are size 2 ½ inches (i.e., internal diameter) and smaller. If the manifold vapor lines are 3 inches (i.e., internal diameter) and larger, then a maximum of two (2) tanks at a time may be loaded. STAGE I VAPOR CONTROL/VAPOR BALANCE SYSTEM REQUIREMENTS MANAGEMENT PRACTICES FOR ALL STAGE I GASOLINE DISPENSING FACILITIES Mark the block if the following management practice will be implemented or exists: - Minimization of gasoline spills; - Cleaning up of gasoline spills as expeditiously as possible; - Covering all open gasoline containers and all gasoline storage tank fill-pipes with a gasketed seal when not in use; - Minimization of gasoline being sent to open waste collection systems, such as oil/water separators MALFUNCTIONS Record the number, duration, description of malfunctions and the actions taken to minimize emissions due to the vapor balance system during the calendar year. File a report with MCAQ by March 15 of the following year if malfunctions occurred. TANK CAPACITIES WITH NO VAPOR CONTROL/VAPOR BALANCE REQUIREMENTS Mark the block if the following gasoline storage tanks are on the premises. - gasoline storage tanks with a capacity of < 250 gallons that are constructed after January 10, 2008; - gasoline storage tanks with a capacity of < 2,000 gallons that are constructed before January 10, 2008; - gasoline storage tanks equipped with floating roofs, or the equivalent MANIFOLDED VAPOR CONTROL/VAPOR BALANCE LINE SIZE AND GASOLINE LOADING List the manifolded gasoline storage tanks required to have poppeted vapor control adaptor valves. Mark the block indicating the internal diameter of the vapor control lines. Lines which are ≤ 2.5 inches in diameter may only load one (1) gasoline storage tank at a time. Lines which are ≥ 3.0 inches in diameter may load two (2) gasoline storage tanks at a time. SUBMERGED FILL PIPE DISTANCE REQUIREMENTS Mark the block for the submerged fill pipe distances above the bottom of the gasoline storage tank. - ≤ 12 inches from the bottom of the gasoline storage tank, if installed on or before November 9, 2006; - ≤ 6 inches from the bottom of the gasoline storage tank, if installed after November 9, 2006 If cut on a slant, measure the submerged fill pipe distance from the bottom of the gasoline storage tank to the top of the slant cut. NOTE: All new installations of submerged fill pipes on gasoline storage tanks at existing, permitted facilities must be ≤ 6 inches from the bottom of the the tank by January 10, 2011. Submerged fill pipe compliance option. Submerged fill pipes not meeting the above distance requirements are allowed if the owner or operator can demonstrate that the liquid level in the tank is always above the entire opening of the fill pipe. MCAQ will review the facility documentation to determine compliance via this alternative method. Mecklenburg County Air Quality – Permit Application S2 Form Instruction, Rev. 06/11 STAGE I VAPOR CONTROL/VAPOR BALANCE SYSTEM ADAPTOR VALVES Mark the block indicating the type of vapor control/vapor balance system adaptor valve(s) that will be/are installed. - Dual point/poppeted vapor control/vapor balance adaptor; Where manifolded vapor lines are used, poppeted vapor control adaptors shall be used. NOTE: Existing installed coaxial vapor adaptor(s) may continue to be used until they are required to be replaced by the rule; however, coaxial vapor adaptor(s) may not be installed as new equipment. VENT PIPES Mark the block indicating the how the vent pipe(s) will be configured on the premises. List the correlating tanks associated with the vent pipes. - Vent pipe shall be a minimum of two (2) inches in diameter or meet the local fire codes; - Individual vent pipe for each gasoline storage tank, ≥ 12 feet above the lot surface; - Manifolded vent pipe ≥ 12 feet above the lot surface; - Vent pipes on gasoline storage tanks with vapor controls have pressure release valves or restrictors; - Projected/known average monthly gasoline dispensing total for the facility < 100,000 gallons; - Projected/known average monthly gasoline dispensing total for the facility ≥ 100,000 gallons. The pressure release valve will meet 40 CFR 63, Subpart CCCCCC, 63.11118, Table 1 performance specifications. PERFORMANCE TEST REQUIREMENTS FOR VAPOR CONTROL/VAPOR BALANCE SYSTEM All new, reconstructed or facilities which replace existing, permitted gasoline storage tanks that also have a projected/known average monthly gasoline dispensing throughput ≥ 100,000 gallons must conduct an initial performance test on the vapor control/vapor balance system when the affected source becomes subject (i.e., prior to commencing gasoline dispensing operations) to the performance testing requirements contained within 40 CFR 63, Subpart CCCCCC, 63.11120. Equipment To Be Tested (Pressure Vacuum Vent Valve and Vapor Balance System) and Test Procedure Pressure Vacuum Vent Valve Owner must demonstrate compliance of the vapor control/vapor balance system pressure-vacuum vent valves installed on the gasoline storage tanks with the leak rate and cracking pressure requirements of California Air Resources Board (CARB) Vapor Recovery Test Procedure TP-201.1E, - “Leak Rate and Cracking Pressure of Pressure/Vacuum Vent Valves”, adopted October 8, 2003 (incorporated by reference see 63.14) Vapor Balance System (Choose one of the following tests) Owner must demonstrate compliance of the vapor control/vapor balance system with the static pressure performance requirements of California Air Resources Board (CARB) Vapor Recovery Test Procedure TP TP 201.3 – “Determination of 2-Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing Facilities, adopted April 12, 1996 and amended March 17, 1999 (incorporated by reference see 63.14) OR Owner must demonstrate compliance of the vapor control/vapor balance system with the static pressure performance requirements of California Air Resources Board (CARB)(Bay Area Air Quality Management District) Vapor Recovery Test Procedure ST-30 – “Static Pressure Integrity Test Underground Storage Tanks”, adopted November 30, 1983 and amended December 21, 1994. Contact MCAQ if an alternative vapor control/vapor balance system is proposed. Performance Test Timeline Overview - Initial test of the vapor control/vapor balance system must be conducted within 180 days of the facility becoming an affected source; A written Performance Test Notification form must be submitted to MCAQ 60 days prior to the test; Test must be conducted prior to the facility commencing gasoline dispensing operations; Test results must be submitted to MCAQ within 60 days of the completed test; The facility must conduct the same tests again every three (3) years thereafter Mecklenburg County Air Quality – Permit Application S2 Form Instruction, Rev. 06/11 SECTION S S2 STAGE I GASOLINE DISPENSING FACILITY Facility Name: Location: When did/will the gasoline dispensing operation start? (Enter date): Does the Owner and/or Operator have any other Air Quality Permits issued by Mecklenburg County? If Yes, list the Permit Numbers: Projected Monthly Gasoline Throughput (in gallons): Yes No Projected Annual Gasoline Throughput (in gallons): EMISSION SOURCE(s) Indicate Type of Storage Tank: Above ground (AST) Underground (UST) Tank Capacity (in gallons) Product Stored Original Installation Date of Tank Stage I Vapor Control/Vapor Balance System Installation Date Storage Tank, Submerged Fill Pipe and/or Pressure Vacuum Valve Replacement Date (if applicable) INSIGNIFICANT ACTIVITY SOURCE(s) Insignificant Activity Description Insignificant Activity Applicable Regulation [i.e., diesel fuel or kerosene storage tanks, (if present)] MCAPCO 1.5211(g)(1)(D)(i) – diesel fuel storage tank (i.e., automobiles) MCAPCO 1.5211(g)(1)(D)(i) – diesel fuel storage tank (i.e., trucks) MCAPCO 1.5211(g)(1)(D)(i) – kerosene fuel storage tank STAGE I REQUIREMENTS MANAGEMENT PRACTICES FOR ALL STAGE I GASOLINE DISPENSING FACILITIES. MARK IF COMPLIANCE PROCEDURES EXIST. Minimize gasoline spills Clean up spills as expeditiously as practicable Cover all open gasoline containers and all gasoline storage tank fill-pipes with a gasketed seal when not in use Minimize gasoline sent to open waste collection systems, such as oil/water separators TANK CAPACITIES WITH NO VAPOR CONTROL / VAPOR BALANCE CONTROL REQUIREMENTS. MARK AND LIST IF PRESENT. gasoline storage tanks with a capacity of < 250 gallons that are constructed after January 10, 2008 gasoline storage tanks with a capacity of < 2,000 gallons that are constructed before January 10, 2008 gasoline storage tanks equipped with floating roofs, or the equivalent MANIFOLDED VAPOR CONTROL / VAPOR BALANCE LINE SIZE AND GASOLINE LOADING Gasoline storage tanks with manifolded vapor control shall have poppeted vapor control adaptor valves. Mark the appropriate block indicating the internal diameter o f the vapor control lines: ≤ 2.5 inches [.e., no more than one(1) gasoline storage tank may be loaded at a time] ≥ 3.0 inches [.e., two(2) gasoline storage tanks may be loaded at a time] SUBMERGED FILL PIPE DISTANCE REQUIREMENTS FROM THE BOTTOM OF THE TANK (If cut on a slant, measure distance from the top of the slant.)(Excluding tanks with capacities of < 250 gallons) NOTE: All new installations of submerged fill pipes on gasoline storage tanks at existing, permitted facilities must be ≤ 6 inches from the bottom of the tank by 1/10/11. ≤ 12 inches from the bottom of the gasoline storage tank, if installed on or before November 9, 2006 ≤ 6 inches from the bottom of the gasoline storage tank, if installed after November 9, 2006 Submerged fill pipes are not the proper distance above the bottom of the UST. Facility will ensure and demonstrate that the liquid level in the tank will always be above the entire opening of the fill pipe. Mecklenburg County Air Quality – Permit Application Page 1 S2 Form, Rev. 06/11 Vapor Control/Vapor Balance System Adaptor Valve Dual Point / Poppeted Vapor Control / Vapor Balance Adaptor NOTE: Existing installed coaxial vapor adaptor(s) may continue to be used until they are required to be replaced by the rule; however, coaxial vapor adaptor(s) may not be installed as new equipment. Vent pipes on tanks with Stage I controls (gasoline tanks) shall have pressure release valves or restrictors. Mark the blocks indicating the vent pipe configuration and type of pressure release valve / restrictor or pressure / vacuum valve present: Individual Vent Pipe(s) List affected gasoline storage tank(s): Manifolded Vent Pipe(s) List affected gasoline storage tanks: Pressure Release Valve or Restrictor: Projected average monthly gasoline loading total for the facility < 100,000 gallons Pressure / Vacuum Valve (P/V Valve): Projected average monthly gasoline loading total for the facility ≥ 100,000 gallons. The pressure release valve will meet 40 CFR 63, Subpart CCCCCC, 63.11118, Table 1, (g) performance specifications. PERFORMANCE TEST REQUIREMENTS FOR PV VENT VALVE AND VAPOR BALANCE SYSTEM All new, reconstructed or facilities which replace existing, permitted gasoline storage tanks that also have a projected average monthly gasoline loading ≥ 100,000 gallons must conduct an initial performance test on the vapor control/vapor balance system when the affected source becomes subject (i.e., prior to commencing gasoline dispensing operations) to the performance testing requirements contained within 40 CFR 63, Subpart CCCCCC, 63.11120. Equipment To Be Tested Pressure Vacuum Vent Valve - Owner must demonstrate compliance of the vapor control / vapor balance system pressure-vacuum vent valves installed on the gasoline storage tanks with the leak rate and cracking pressure requirements of California Air Resources Board (CARB) Vapor Recovery Test Procedure TP-201.1E, - “Leak Rate and Cracking Pressure of Pressure/Vacuum Vent Valves”, adopted October 8, 2003 (incorporated by reference see 63.14). [Per the requirements of 40 CFR 63, Subpart CCCCCC, Table 1,(g)] Vapor Balance System (Choose one of the following tests) - Owner must demonstrate compliance of the vapor control/vapor balance system with the static pressure performance requirements of California Air Resources Board (CARB) Vapor Recovery Test Procedure TP-201.3, - “Determination of 2-Inch WC Static Pressure Performance of Vapor Recovery Systems of Dispensing Facilities”, adopted April 12, 1996, and amended March 17, 1999 (incorporated by reference see 63.14). . OR Owner must demonstrate compliance of the vapor control/vapor balance system with the static pressure performance requirements of California Air Resources Board (CARB) (Bay Area Air Quality Management District) ST-30 – “Static Pressure Integrity Test Underground Storage Tanks”, adopted November 30, 1983, amended December 21, 1994. Contact MCAQ if an alternative vapor control/vapor balance system exists Performance Test Timeline Overview - Initial test of the vapor control/vapor balance system must be conducted within 180 days of the facility becoming an affected source; A written Performance Test Notification form must be submitted to MCAQ 60 days prior to the test; Test must be conducted prior to the facility commencing gasoline dispensing operations; Test results must be submitted to MCAQ within 60 days of the completed test; The facility must conduct the same tests again every three (3) years thereafter Mecklenburg County Air Quality – Permit Application Page 2 S2 Form, Rev. 06/11