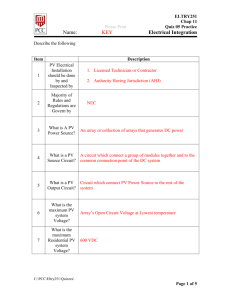

Memo MECKLENBURG COUNTY Land Use and Environmental Services Agency

advertisement