Experimental Validation of High-Voltage-Ratio Low-Input-Current-Ripple Converters for Hybrid Fuel Cell Supercapacitor Systems

advertisement

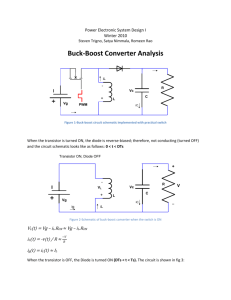

3430 IEEE TRANSACTIONS ON VEHICULAR TECHNOLOGY, VOL. 61, NO. 8, OCTOBER 2012 Experimental Validation of High-Voltage-Ratio Low-Input-Current-Ripple Converters for Hybrid Fuel Cell Supercapacitor Systems Mohammad Kabalo, Student Member, IEEE, Damien Paire, Benjamin Blunier, David Bouquain, Marcelo Godoy Simões, and Abdellatif Miraoui, Senior Member, IEEE Abstract—Electric vehicle technology has been adopting fuel cells (FCs) for hybrid applications over the past few years. Therefore, the development of advanced power electronic systems for the integration of fuel cells with on-board energy management is fundamental for achieving high-performance systems. An FC for vehicular applications is usually a low-voltage current-source like device that produces electricity and heat directly from input hydrogen and oxygen. Most often, it is required that the FCs be stacked for high-voltage dc-link in order to supply the input power for the drivetrain and electric motor drive system. The FC has a nonlinear nature, and it must be controlled to operate in the highefficiency operating range. Hybrid electric vehicles have physical constraints such as volume and weight under limited cost and expected lifetime. There is a need for high-voltage input/output ratio of dc-dc boost converters to be connected between the FC to the motor drive dc-link. In addition, it is necessary to have low input ripple at the dc-dc boost converter in order to maximize the FC lifetime, and the traditional dc-dc boost converter topologies have poor performance on these specifications. This paper proposes a new dc-dc converter family of topologies aimed at improving the application to electric vehicle power control. This family is defined as floating-interleaving boost converters (FIBCs). The paper will thoroughly show analysis and experimental verification of FIBC’s, and they will be compared with conventional boost converter characteristics. The paper supports how performance figures related to the passive components, i.e., the inductor and capacitor, will have better volume and weight, extremely low input current ripple, and improved efficiency and transfer ratio. The analysis presented in this paper shows how to choose the most suitable topology in order to achieve the desired specifications. The selected topology is fully validated experimentally using advanced nonlinear sliding mode control, which has the additional feature of operating even in faulty conditions. Index Terms—Boost converter, dc-dc converter, fuel cell (FC) hybrid vehicle, sliding mode control. Manuscript received December 8, 2011; revised March 28, 2012; accepted June 20, 2012. Date of publication July 11, 2012; date of current version October 12, 2012. The review of this paper was coordinated by Dr. Z. Nie. M. Kabalo, D. Paire, and D. Bouquain are with the Université de Technologie de Belfort-Montbéliard, 90010 Belfort, France (e-mail: mohammad. kabalo@utbm.fr; damien.paire@utbm.fr; david.bouquain@utbm.fr). B. Blunier, deceased, was with the Université de Technologie de BelfortMontbéliard, 90010 Belfort, France. M. G. Simões is with Colorado School of Mines, Golden, CO 804010-1887 USA (e-mail: msimoes@mines.edu). A. Miraoui is with Cadi Ayyad University, Marrakech 511-40000, Morocco (e-mail: abdellatif.miraoui@utbm.fr). Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TVT.2012.2208132 I. I NTRODUCTION A FUEL cell (FC) may be one of the promising solutions to decrease carbon dioxide emissions under the assumption that the hydrogen can be produced from renewable-energy sources such as photovoltaic and wind energy or as a subproduct of currently wasted energy of large power plants under a low-load situation (e.g., when base power plants are producing higher power than the demand). In automotive applications, proton exchange membrane FCs appear to be the most suitable, because their working conditions at low temperature allow the system to start up faster than those technologies using hightemperature FCs; moreover, the solid state of their electrolyte (no leakage and low corrosion) and their high power density make them fit for transport applications. Finally, they also provide very good tank-to-wheel efficiency, compared with internal combustion engines [1], [2]. FCs are low-voltage current intensive sources. A single cell produces a voltage of approximately 1 V; therefore, several cells must be stacked to achieve high voltage output. FC stacking reduces its reliability and lifetime as a chain of series-connected cells is as strong as the weakest cell. Due to reliability and lifetime reasons, practical FC stack output voltage is reduced to approximately 100 V. On the other hand, the vehicle powertrain dc bus has a high voltage of a few hundred volts. Therefore, a dc-dc converter is required to interface the FC stack with the powertrain dc-bus voltage and to achieve good power management of the input power source [3]–[8]. The FC dc-dc converter is also required for voltage conditioning as the FC output voltage strongly varies with the load. Ideally, the power conditioner must have minimal losses, leading to higher efficiency [9]. Power-conditioning efficiency values can typically be higher than 90% [10]. The most important requirements expected from dc-dc converter for FC applications are high voltage ratio and low current ripple [11]. The lower the current ripple, the longer the FC lifetime [12], [13]. However, in an FC electric vehicle (FCEV), the high voltage ratio and low current ripple, which are associated with volume, weight, reliability, and efficiency constraints, are very important requirements. A cascade dc-dc converter composing of two phase-interleaved boost converters and three level series boost converters is proposed in [14]. This solution suffers from low efficiency and reliability problem. In [15] and [16], a parallel resonnant converter resonant topology with a capacitor as output filter is proposed. However, in this topology, determination of the leakage inductance and capacitance, as 0018-9545/$31.00 © 2012 IEEE KABALO et al.: VALIDATION OF RIPPLE CONVERTER FOR HYBRID FC SUPERCAPACITOR SYSTEM 3431 well as the topology modeling, is very complex. A multiphase interleaved boost converter for FC applications is proposed in [17]. The proposed topology has a voltage ratio identical to that of the classic boost converter, which leads to low efficiency for applications where high voltage ratio is required. A review of isolated and nonisolated boost dc-dc converters suitable for FC and photovoltaic grid-connected applications is proposed in [18] and [19]. The limitations of the conventional boost converters in these applications are analyzed. Furthermore, the advantages and disadvantages of these converters are discussed. In this paper, new dc-dc converter topologies defined as the floating-interleaving boost converter (FIBC) family will be presented. These topologies are compared to conventional boost converters, and the analysis will support the choice for the best topology corresponding to specified constraints. The selected topology is then experimentally validated using an advanced nonlinear sliding-mode controller, which, for technical reasons, will be explained later. II. S YSTEM S PECIFICATIONS AND P ROPOSED T OPOLOGIES In high-power FCEV applications, the major drawbacks of using conventional boost converters are the difficulty in the design of magnetic components and high input current ripple, which may lead to reduce the FC stack lifetime. Reducing the rating current and voltage applied to passive and power electronic components (keeping the same system rated power) is a proposed solution. This makes the magnetic component construction easier, giving further flexibility for the selection of power electronic components used in the converters. Fig. 1 shows the proposed topologies in addition to the conventional boost converter. These topologies have a floating output and interleaving input, which permits reduction in not only current stress but also voltage stress, unlike conventional interleaved topologies. The benefits of the N -phase FIBC are the following: 1) increasing the overall converter efficiency; 2) increasing the input and output ripple frequency without increasing the switching frequency; 3) decreasing the input ripple current; 4) enhancing the system reliability by paralleling phases and not by paralleling multiple devices; 5) decreasing current and voltage ratings of power electronic devices; 6) reducing the size and weight of the passive components. The system specifications are presented in Table I. Table II shows that the current and voltage ratings of the power electronic devices of FIBCs are smaller than those of the boost and interleaving boost converters. The duty cycle of the proposed topologies is expressed as follows: D= VBus − VFC . VBus + VFC (1) Fig. 1. Proposed topologies. (a) Conventional boost. (b) Two-phase FIBC. (c) Four-phase FIBC. (d) Six-phase FIBC. On the other hand, the conventional boost converter duty cycle is given by D= VBus − VFC . VBus (2) 3432 IEEE TRANSACTIONS ON VEHICULAR TECHNOLOGY, VOL. 61, NO. 8, OCTOBER 2012 TABLE I S YSTEM S PECIFICATIONS For conventional boost converter ΔiFC = ΔiL = DVFC . Lfs (4) The input current slope of the N -phase FIBC is expressed as follows: TABLE II C URRENT AND VOLTAGE R ATINGS OF P OWER E LECTRONIC D EVICES n=N diL diFC diLoad n = − . dt dt dt n=1 (5) The ratio of the input current ripple to the inductor current ripple of a two-phase FIBC as a function of duty cycle M2 (D) is given by 1−2D 1−D , 0 < D < 0.5 (6) M2 (D) = 2D−1 D , 0.5 < D < 1. The ratio of the input current ripple to the inductor current ripple of a four-phase FIBC as a function of duty cycle M4 (D) is ⎧ 1−4D 0 < D < 0.25 ⎪ 1−D , ⎪ ⎪ ⎨ 3D−4D2 −0.5 , 0.25 < D < 0.5 D(1−D) M4 (D) = 5D−4D (7) 2 −1.5 ⎪ ⎪ ⎪ D(1−D) , 0.5 < D < 0.75 ⎩ 4D−1 0.75 < D < 1. D , Fig. 2. Duty cycle comparison. Fig. 2 shows that, for the same FC rated power, the basic boost duty cycle is higher than the proposed topology duty cycle. The higher the duty cycle, the lower the converter efficiency [20]. III. I NPUT C URRENT R IPPLE E VALUATION The mathematical expressions for input current ripple are derived under six assumptions. 1) 2) 3) 4) 5) 6) The resistances of inductor and capacitor are negligible. Stray inductor and capacitor are negligible. Switches are ideal. Passive components are identical. Switches in parallel operate (360/N )◦ out of phase. The converters operate in continuous conduction mode (CCM). The ratio of the input current ripple to the inductor current ripple is given by M (D) = ΔiFC . ΔiL (3) The ratio of the input current ripple to the inductor current ripple of a six-phase FIBC as a function of duty cycle M6 (D) is given by ⎧ 1−6D 0 < D < 1/6 ⎪ 1−D , ⎪ ⎪ ⎪ 3D−6D2 −1/3 ⎪ , 1/6 < D < 1/3 ⎪ ⎪ D(1−D) ⎪ ⎪ ⎨ 9D−6D2 1 , 1/3 < D < 1/2 D(1−D) M6 (D) = 7D−6D (8) 2 2 ⎪ D(1−D) , 1/2 < D < 2/3 ⎪ ⎪ ⎪ ⎪ 9D−6D 2 −10/3 ⎪ ⎪ , 2/3 < D < 5/6 ⎪ D(1−D) ⎪ ⎩ 6D−5 5/6 < D < 1. D , The previous analysis permits having the generalized expression of the ratio of the input current ripple to the inductor current ripple of the N -phase FIBC as a function of duty cycle MN (D) (X − N D) D − X−1 ΔiFC N MN (D) = (9) = ΔiL D(1 − D) where X is the interval between two duty cycle values, resulting in zero current ripple. The variation of the ratio of input current ripple to inductor current ripple as a function of duty cycle is shown in Fig. 3. On the one hand, by studying Fig. 3, it can be observed that input current ripple cancelation occurs at specific duty cycles, which are multiple duties of 1/N , such as 0.5 in a two-phase FIBC; 0.25, 0.5, and 0.75 in a four-phase FIBC; and 0.16, 0.33, 0.5, 0.66, and 0.83 in a six-phase FIBC. On the other hand, it is clear that the input current ripple is always less than the inductor current ripple. The fact that the input current ripple is always less than the inductor current ripple permits to increase this latter and, consequently, decrease the inductor value according to (4). However, due to core losses KABALO et al.: VALIDATION OF RIPPLE CONVERTER FOR HYBRID FC SUPERCAPACITOR SYSTEM Fig. 3. Ratio between the input current ripple and the inductor current ripple versus duty cycle. 3433 Fig. 4. Input current ripple as a percentage of the FC rated current according to the number of phases. and the CCM condition, the critical inductor current ripple for the proposed N -phase FIBC is defined as follows: ΔiLcritical ≤ 4IFC . N (1 + D) (10) Decreasing both the inductor value and the current flowing through it permits to reduce its volume, weight, and cost, as will be shown in the next section. The best way to show how the input current ripple (as a percentage of input rated current) decreases with the number of phases is to determine this first according to the system specifications presented in Table I for a given inductor value. For this evaluation, the inductor value will be chosen as 100 μH. On the one hand, Fig. 4 shows that decreasing the input current ripple from a four-phase to a six-phase FIBC is not important. It is not the case from a one-phase or a two-phase to a fourphase FIBC. On the other hand, depending on the rated power of the system, a six-phase FIBC can have input current ripple bigger than a four-phase FIBC, which is not the case when one compares a four-phase with a two-phase FIBC for any rated power. Consequently, from the input current ripple reduction point of view, we can see that the benefits of six-phase converter are not so attractive compared with its increased complexity and costs. IV. E VALUATION OF THE I NDUCTOR VOLUME To evaluate the reduction in the inductor volume for the proposed topologies compared with that of the conventional boost, it is necessary to go through the details of the electromagnetic used for similar magnetic cores. In this analysis, the material of the selected core is ferrite. Fig. 5 shows the top and frontal views of the inductor magnetic circuit. Some guidelines of magnetic material comparison and selection for high-power Fig. 5. Geometry of the inductor core. high-frequency inductors in dc-dc converter can be found in [21] and [22]. The stored energy in the inductor is proportional to the inductor and peak current value, i.e., E= 1 2 LI . 2 peak (11) 3434 IEEE TRANSACTIONS ON VEHICULAR TECHNOLOGY, VOL. 61, NO. 8, OCTOBER 2012 On the other hand, the stored energy as a function of the inductor’s dimensions for the proposed geometry is given by 1 B 2 g b2 → − − → E= H · B dV = (12) 2 4μo → − → − where B and H are the magnetic field density and strength, respectively, and μo is the magnetic permeability of air. The volume of the geometry shown in Fig. 5 is given by g V = (2b + 2kb b)(b + 2kb b) b + h + . (13) 2 This volume can be expressed as follows [23]: 0.75 4kB L IL2 V =K JΔB 2 kB K= (1 + kb ) 1 + (1 + 2kb ). 0.75 kB kb (14) ΔB = 0.2 T is the change in flux density J, which is the current density varying between 2 and 5 A/mm2 . In our analysis, it is chosen as 3.5 A/mm2 . kB is a coefficient greater than 1, which takes into account the difference between the effective section of the conductors and the required section windings. It is related to the shape of the conductors and the presence of different levels of isolation. In this analysis, it is chosen as (kB = 1.5). kb is a geometric coefficient, and in our case, it is taken to be equal to 1. Equation (15), shown below, gives the reduction in total inductor stored energy and associated magnetic volume, as compared with that in the conventional boost converter. EInductor(1) and VInductor(1) are the stored energy and the associated volume in the traditional boost, respectively. EInductor(N ) and VInductor(N ) are the stored energy in the single-phase inductor and the corresponding volume of the N -phase FIBC, respectively. E(N ) and V (N ) are the percentage of inductor stored energy and volume reduction, respectively, given by EInductor(1) − N × EInductor(N ) E(N ) = 100 EInductor(1) VInductor(1) − N × VInductor(N ) V (N ) = . (15) 100 VInductor(1) From (15), the total stored energy and volume going from conventional boost to a two-phase FIBC have been reduced by 62.6% and 49.3%, respectively. For a four-phase FIBC, they are reduced by 86% and 83.7% and by 87.2% and 87.35% for a six-phase FIBC. In conclusion, from this point of view, it can be seen that there is no great benefit to use a six-phase FIBC, compared with a four-phase FIBC. V. ROOT M EAN S QUARE C APACITOR C URRENT E VALUATION The output filter capacitor ensures dc-bus stabilization and also filters discontinuous diode current behavior. In the one hand, reducing the root mean square (RMS) value of the capacitor current leads to avoiding utilization of a bulky capacitor; on the other hand, it permits the reduction of capacitor heating by decreasing resistive losses because of the equivalent series internal resistance (ESR). The lower the capacitor temperature and RMS current, the longer the capacitor lifetime [24]. The boost RMS capacitor current as a function of the duty cycle and the FC rated current is given by 0 ≤ D ≤ 1. (16) IRMSC = IFC D(1 − D), For a two-phase FIBC, the RMS capacitor currents as a function of the duty cycle and the FC rated current are given by D(1 − D) IRMSC1,C2 = IFC , 0 ≤ D ≤ 1. (17) (1 + D)2 For a four-phase FIBC, the RMS capacitor currents as a function of duty cycle and the FC rated current are expressed as ⎧ D−2D 2 ⎪ I 0 ≤ D ≤ 0.25 FC ⎪ 2(1+D)2 , ⎪ ⎪ ⎪ ⎨ 2 −0.5 IRMSC1,C2 = IFC 4D−4D (18) 4(1+D)2 , 0.25 ≤ D ≤ 0.75 ⎪ ⎪ ⎪ ⎪ ⎪ ⎩I 3D−2D 2 −1 0.75 ≤ D ≤ 1. FC 2(1+D)2 , Finally, a six-phase FIBC, the RMS capacitor currents as a function of duty cycle, and the FC rated current are expressed as ⎧ D(1−3D) ⎪ ⎪ I 0 ≤ D ≤ 1/6 FC ⎪ 3(1+D)2 , ⎪ ⎪ ⎪ ⎪ ⎪ 7D−9D 2 −2/3 ⎪ ⎪ I 1/6 ≤ D ≤ 1/3 ⎪ FC 9(1+D)2 , ⎪ ⎪ ⎪ ⎨ 2 −4/3 IRMSC1,C2 = IFC 9D−9D 1/3 ≤ D ≤ 2/3 (19) 9(1+D)2 , ⎪ ⎪ ⎪ ⎪ ⎪ 11D−9D 2 −8/3 ⎪ ⎪ , 2/3 ≤ D ≤ 5/6 ⎪ IFC 9(1+D)2 ⎪ ⎪ ⎪ ⎪ ⎪ ⎪ ⎩ IFC 5D−3D2 −2 5/6 ≤ D ≤ 1. 3(1+D)2 , The following gives the percentage of the RMS capacitor current reduction: IRMSC (1) − IRMSC (N ) I(N ) = . (20) 100 IRMSC (1) From (20), it can be seen that the RMS capacitor current from a traditional boost to a two-phase FIBC is reduced by 30%, by 56% from a two-phase to a four-phase FIBC, and by 60% from a four-phase to a six-phase FIBC. This reduction in RMS current will reduce electrical stress in the output capacitor and improve the converter’s reliability and lifetime. The RMS capacitor current analysis shows that the four-phase FIBC is the best choice among the proposed topologies. VI. E FFICIENCY A NALYSIS An N -phase FIBC is analyzed to evaluate losses in every component and compare them with those of a conventional KABALO et al.: VALIDATION OF RIPPLE CONVERTER FOR HYBRID FC SUPERCAPACITOR SYSTEM boost topology. This allows determining the most suitable converter among these topologies from the efficiency point of view. This analysis is reported according to the system specifications presented in Table I. given by IS = • Traditional boost converter losses: VS = 1) Inductor losses: These losses include copper losses (Pcop ), which are caused by the skin effect and proximity effect, and core losses (Pcore ), which are caused by the hysteresis phenomenon and eddy currents. These losses depend on the core type and the wire type used, i.e., Δi2FC 2 + Pcop = RL IFC 12 1.74 ΔB m (21) Pcore = 6.5(fs )1.51 2 where RL is the equivalent series resistance of the inductor, and m is the weight of the magnetic circuit in kilograms. 2) Capacitor losses: They are due to ESR; in this analysis, they are neglected. 3) Switch losses: These losses include the conduction (Psconl ) and the switching losses (Pswl ) Δi2FC 2 + Psconl = D Rs IFC + Vs IFC 12 Pswl = 2 2 Vbus tfs IFC 2Itest Vtest t = td(on) + tr + td(off) + tf (22) Pdconl = (1 − D) (Rd λ + Vd IFC ) Δi2FC 2 λ = IFC + 12 2 IFC IRM trr fs Vbus 2Itest Vtest (23) where Vd and Rd are the voltage drop and the resistance in the ON-state of the diode, respectively. IRM and trr are the reverse recovery current and reverse recovery time, respectively. They can also be obtained from the manufacturer’s data sheet. • N -phase FIBC: The switch current and voltage during the commutation of the proposed N -phase FIBC are N 2 IFC (1 + D) Vbus . (1 + D) (24) (25) By increasing the number of phases, the ratio (IS V S/Itest Vtest ) becomes lower, and consequently, the switching losses become lower. 1) Inductor losses: These losses are the sum of the losses of each inductor of an N -phase FIBC, and they are expressed as a function of phases number, i.e., 2 4IFC N Δi2L + PNcop = RL N (1 + D)2 12 1.74 ΔB PNcore = N 6.5 (fs )1.51 m. (26) 2 2) Switch losses: These losses represent the sum of the losses of each switch of an N -phase FIBC. They are given by 2IFC Vs PNsconl = D Rs κ + 1+D 2 4IFC N Δi2L κ= + N (1 + D)2 12 PNswl = where Vs are Rs are the voltage drop and the resistance in the ON-state of the switch, respectively; and td(on) , tr , td(of f ) , and tf are the turn-on delay time, turn-on rise time, turn-off delay time, and turnoff fall time, respectively. They can be obtained from the manufacturer’s data sheet. Itest and Vtest are the current and the voltage, respectively, under which the switch was tested to determine its data sheet. 4) Diode losses: These losses include the conduction (Pdconl ) and reverse recovery (Pdrrl ) losses Pdrrl = 3435 2 2 Vbus tfs 2IFC . 4 N (1 + D) Itest Vtest (27) 3) Diode losses: These losses represent the sum of the losses of each diode of an N -phase FIBC. They are given by 2IFC Vd PNdconl = (1 − D) Rd κ + 1+D PNdrrl = 2 IFC IRM trr fs 2Vbus . N (1 + D)4 Itest Vtest (28) Fig. 6 shows the proposed converter efficiency as a function of the FC current. By analyzing Fig. 6, one can see, on the one hand, that a four-phase FIBC and a six-phase FIBC keep high efficiency for a wide range of load power. However, a traditional boost and a two-phase FIBC efficiency drastically decrease when increasing the system power. For the rated power of the system in Table I, a four-phase and a sixphase FIBC have nearly the same efficiency. Therefore, from the efficiency analysis point of view, we can see that a four-phase FIBC is the best choice among the proposed converters. It has to be noted that the previous calculations are based on an insulated-gate bipolar transistor (IGBT) switch (ref. 38NAB066V1) from Mitsubishi Electric company. For the diode, the antiparallel emitter-to-collector free-wheel diode (FWDi) of the previous IGBT has been used. The inductor series resistance numerical value has been chosen to correspond to the one of the real inductor. 3436 IEEE TRANSACTIONS ON VEHICULAR TECHNOLOGY, VOL. 61, NO. 8, OCTOBER 2012 Fig. 9. Convergence relation for control of four-phase FIBC. A. Sliding-Mode Controller Fig. 6. Efficiency versus input current. Fig. 7. Implemented four-phase FIBC. Since a sliding-mode controller is based on the large signal model of dc-dc converters, its stability is not restricted by the variations around the operating point, which contributes to an overall improved controller performance. Therefore, the large signal model of the four-phase FIBC is defined as follows: dIL1 dt dIL2 dt dIL3 dt dIL4 dt dVC1 dt dVC2 dt 1 ((D1 + 1)VFC − 2rL1 IL1 + (D1 − 1)VBus ) 2L1 1 = ((D2 + 1)VFC − 2rL2 IL2 + (D2 − 1)VBus ) 2L2 1 = ((D3 + 1)VFC − 2rL3 IL3 + (D3 − 1)VBus ) 2L3 1 = ((D4 + 1)VFC − 2rL4 IL4 + (D4 − 1)VBus ) 2L4 1 = ((1 − D1 )IL1 + (1 − D2 )IL2 − ILoad ) C1 1 = ((1 − D3 )IL3 + (1 − D4 )IL4 − ILoad ) . (29) C2 = The sliding surfaces or the control laws are defined by the following expression: t SILi = ILi − Ki + KILi (ILi − Ki ) dτ (30) 0 Fig. 8. FCEV architecture. VII. E XPERIMENTAL VALIDATION OF F OUR -P HASE F LOATING I NTERLEAVING B OOST C ONVERTER The previous evaluations show that the four-phase FIBC is top choice among all the proposed topologies. The implemented four-phase FIBC and the FCEV architecture are shown in Figs. 7 and 8, respectively. The high-voltage battery in Fig. 8 can be replaced by a supercapacitor connected to the dc bus via bidirectional four-phase FIBC. To achieve instantaneous power sharing between the phases and good power management of the input power source, each converter phase has its own current controller. A nonlinear sliding-mode controller is used to generate the required control input for each switch of the four-phase FIBC [25]–[27]. where i = [1, . . . , 4], ILi is the average value of the inductor current, Ki is the desired inductors current, and KILi is a coefficient that defines the dynamic of convergence to zero of the static error. The convergence dynamic of the sliding surfaces to zero is defined as follows: SI˙Li = −λILi SILi (31) where λILi are positive real numbers and are called the convergence factors. The convergence relation for control of fourphase FIBC is shown in Fig. 9. According to (31), the larger the convergence factors, the faster the system reaches its steady state. However, due to limits on the system parameters such as duty cycle, it is not possible to increase the convergence factors beyond a certain value. KABALO et al.: VALIDATION OF RIPPLE CONVERTER FOR HYBRID FC SUPERCAPACITOR SYSTEM 3437 To design the controller, it is necessary to combine (31) with (29) and (30). This will result in equations for control inputs in terms of the state variables and the system parameters. The duty cycle of each phase of the four-phase FIBC as a function of time is shown by Di (t) = 1 + 2 (rLi ILi − VFC + Li χ) VFC + VBus (32) where χ = (K̇i − λILi SILi − KILi (ILi − Ki )). Equation (32) shows that the control inputs are irrelevant with the value of load resistance R. Therefore, this controller will not be perturbed by the variations of the load. Because each duty cycle is relevant with its own phase parameters, this controller is able to work in degraded mode. This is a very important feature as the reliability is a major criterion in FCEV. At the steady state, where the state variables ILi are following the commanded references Ki , the duty cycle is given by VBus − VFC . (33) Di = VFC + VBus By replacing the control inputs in the large signal model of four-phase FIBC, we get t y dτ = 0 (34) ẏ + (KILi + λILi )y + KILi λILi 0 where y = ILi − Ki by deriving (34) ÿ + (KILi + λILi )ẏ + KILi λILi y = 0. (35) This equation is irrelevant with the topology parameters, which underlines the robustness of the controller. The coefficients in (35) are positive. This means that all roots of the system have negative real parts, which ensure its stability. The method for a second-order system can be used to determine the coefficients KILi and the convergence factors λILi to get the desired performance. B. Experimental Setup The four-phase FIBC test bench and the four-phase FIBC converter are shown in Fig. 10. Each inductor current has zeroflux Hall effect current sensor for feedback control where the inductor current references Ki are generated by a real-time board dSPACE DS 1104. The control system developed in this study has been downloaded using the Matlab-Simulink and ControlDesk software. Experimental results have been obtained by an emulated FC power source. The benefits of interleaving the input current ripple make the control signals of the main switches be shifted 90◦ from each other. In the experimental evaluation implemented for this project, the control signals are shifted by means of a Field-Programmable Gate Array control card. The specification of the implemented four-phase FIBC are detailed in Table III. C. Experimental Results 1) Sliding-Mode Controller Validation: The dynamic response of the sliding-mode controller for a step variation of inductor current from 13 to 20 A shown in Fig. 11. It shows that Fig. 10. Test bench and four-phase FIBC converter. (a) Test bench. (b) Fourphase FIBC converter. TABLE III F OUR -P HASE FIBC S PECIFICATION the currents perfectly follow the reference signal with a settling time of 0.8 ms and with no noticeable ringing or overshoot. This indicates that the proposed controller has excellent dynamic performance. Fig. 12 shows the steady-state FC current, the converter input current, and the inductor current for an inductor current reference of 17.5 A. Similar to its dynamic performance, the proposed sliding controller has very good steady-state response with negligible steady-state error around 17.5 A. 3438 IEEE TRANSACTIONS ON VEHICULAR TECHNOLOGY, VOL. 61, NO. 8, OCTOBER 2012 Fig. 11. Sliding-mode controller dynamic response for a step variation of inductor current from 13 to 20 A. The value of the coefficients KILi and the convergence factors λILi for this excellent performance of the proposed sliding-mode controller are given by λILi = KILi = 6000. (36) The steady-state waveforms underline the great benefit of the four-phase FIBC from the current ripple point of view. One can go from a 22-A current ripple in the inductors to 3 A at the converter input. By using a second-order low-pass filter, the FC current ripple is nearly zero, as shown in Fig. 12. The steady-state switch driving signals with 70% steady-state duty cycle and 90◦ out of phase from each other are shown in Fig. 13. Fig. 14 shows experimental and analytical four-phase FIBC efficiency curves, which indicate that the implemented converter has a maximum efficiency of 95% at a power demand of 2.5 kW and an efficiency of 94.7% at a power demand of 5 kW (operating point). Such efficiency is very good for intensive-current low-voltage power source and much higher than an equivalent traditional dc-dc boost converter for the same application. VIII. C ONCLUSION This paper has proposed a new family of converter topologies for optimized hybrid integration of FCs and supercapacitors. Three different solutions have been investigated, i.e., two- Fig. 12. Sliding-mode controller steady-state response for inductor current reference of 17.5 A. phase, four-phase, and six-phase FIBCs have been compared with the conventional dc-dc boost converter. Analysis has shown that these proposed FIBC converters have all better characteristics for input current ripple, inductor volume, and capacitor stress better than classic boost converters. Studies have been made to evaluate their operation for an increased number of phases. As a result, it has been concluded that a six-phase FIBC shows that is an efficiency figure comparable with a four-phase FIBC for the same rated power and similar circuit complexity. In addition, there are benefits in decreasing inductor volume and capacitor stress, corroborating that all the relevant design parameters are optimized for a four-phase FIBC when compared with other FIBC structures. As a conclusion, a four-phase FIBC has been selected, and nonlinear slidingmode control has been implemented for the feedback look, KABALO et al.: VALIDATION OF RIPPLE CONVERTER FOR HYBRID FC SUPERCAPACITOR SYSTEM 3439 R EFERENCES Fig. 13. Steady-state switch driving signals with 70% steady-state duty cycle and 90◦ out of phase from each other. Fig. 14. Implemented converter efficiency. The four-phase FIBC has an efficiency of 94.7% at a power demand of 5 kW (operating point). where experimental results showed excellent performance with augmented characteristics such as improved input current ripple reduction, a decrease in inductor volume, and higher efficiency under a full-range transfer function voltage. The proposed solution demonstrates much potential and promise for utilization in modern FCEV applications. ACKNOWLEDGMENT The authors dedicate this paper to the memory of their friend and coauthor Dr. B. Blunier, Associate Professor with the Université de Technologie de Belfort-Montbéliard, who passed away on February 23, 2012. [1] B. Blunier, M. Pucci, G. Cirrincione, M. Cirrincione, and A. Miraoui, “A scroll compressor with a high-performance sensorless induction motor drive for the air management of a PEMFC system for automotive applications,” IEEE Trans. Veh. Technol., vol. 57, no. 6, pp. 3413–3427, Nov. 2008. [2] B. Blunier and A. Miraoui, “Proton exchange membrane fuel cell air management in automotive applications,” J. Fuel Cell Sci. Technol., vol. 7, p. 041007, 2010. [3] A. Ravey, N. Watrin, B. Blunier, D. Bouquain, and A. Miraoui, “Energy sources sizing methodology for hybrid fuel cell vehicles based on statistical description of driving cycles,” IEEE Trans. Veh. Technol., vol. 60, no. 9, pp. 4164–4174, Nov. 2011. [4] A. Ravey, B. Blunier, and A. Miraoui, “Control strategies for fuel cell based hybrid electric vehicles: From offline to online,” in Proc. IEEE VPPC, 2011, pp. 1–4. [5] J. Bernard, S. Delprat, F. Buchi, and T. Guerra, “Fuel-cell hybrid powertrain: Toward minimization of hydrogen consumption,” IEEE Trans. Veh. Technol., vol. 58, no. 7, pp. 3168–3176, Sep. 2009. [6] O. Sundstrom, P. Soltic, and L. Guzzella, “A transmission-actuated energy-management strategy,” IEEE Trans. Veh. Technol., vol. 59, no. 1, pp. 84–92, Jan. 2010. [7] J. Solano-Martinez, D. Hissel, M. Pera, and M. Amiet, “Practical control structure and energy management of a test bed hybrid electric vehicle,” IEEE Trans. Veh. Technol., vol. 60, no. 9, pp. 4139–4152, Nov. 2011. [8] M. Zandi, A. Payman, J. Martin, S. Pierfederici, B. Davat, and F. Meibody-Tabar, “Energy management of a fuel cell/supercapacitor/ battery power source for electric vehicular applications,” IEEE Trans. Veh. Technol., vol. 60, no. 2, pp. 433–443, Feb. 2011. [9] A. Emadi, K. Rajashekara, S. Williamson, and S. Lukic, “Topological overview of hybrid electric and fuel cell vehicular power system architectures and configurations,” IEEE Trans. Veh. Technol., vol. 54, no. 3, pp. 763–770, May 2005. [10] A. Emadi, S. Williamson, and A. Khaligh, “Power electronics intensive solutions for advanced electric, hybrid electric, and fuel cell vehicular power systems,” IEEE Trans. Power Electron., vol. 21, no. 3, pp. 567– 577, May 2006. [11] M. Kabalo, B. Blunier, D. Bouquain, and A. Miraoui, “State-of-the-art of DC-DC converters for fuel cell vehicles,” in Proc. IEEE VPPC, Lille, France, Sep. 1–3, 2010, pp. 1–6. [12] G. Fontes, C. Turpin, S. Astier, and T. Meynard, “Interactions between fuel cells and power converters: Influence of current harmonics on a fuel cell stack,” IEEE Trans. Power Electron., vol. 22, no. 2, pp. 670–678, Mar. 2007. [13] F. Profumo, A. Tenconi, M. Cerchio, R. Bojoi, and G. Gianolio, “Fuel cells for electric power generation: Peculiarities and dedicated solutions for power electronic conditioning systems,” EPE J., vol. 16, no. 1, p. 44, 2006. [14] A. Shahin, M. Hinaje, J. Martin, S. Pierfederici, S. Rael, and B. Davat, “High voltage ratio DC-DC converter for fuel-cell applications,” IEEE Trans. Ind. Electron., vol. 57, no. 12, pp. 3944–3955, Dec. 2010. [15] J. Martin-Ramos, J. Diaz, A. Pernia, J. Lopera, and F. Nuno, “Dynamic and steady-state models for the PRC-LCC resonant topology with a capacitor as output filter,” IEEE Trans. Ind. Electron., vol. 54, no. 4, pp. 2262– 2275, Aug. 2007. [16] J. Martin-Ramos, A. Pernia, J. Díaz, F. Nuño, and J. Martinez, “Power supply for a high-voltage application,” IEEE Trans. Power Electron., vol. 23, no. 4, pp. 1608–1619, Jul. 2008. [17] P. Thounthong and B. Davat, “Study of a multiphase interleaved stepup converter for fuel cell high power applications,” Energy Convers. Manage., vol. 51, no. 4, pp. 826–832, 2010. [18] M. Mohr, W. Franke, B. Wittig, and F. Fuchs, “Converter systems for fuel cells in the medium power range—A comparative study,” IEEE Trans. Ind. Electron., vol. 57, no. 6, pp. 2024–2032, Jun. 2010. [19] W. Li and X. He, “Review of non-isolated high step-up DC/DC converters in photovoltaic grid-connected applications,” IEEE Trans. Ind. Electron., vol. 58, no. 4, pp. 1239–1250, Apr. 2011. [20] R. Erickson, “DC-DC power converters,” in Wiley Encyclopedia of Electrical and Electronics Engineering. New York: Wiley, p. 80 309-0425. [21] M. Rylko, K. Hartnett, J. Hayes, and M. Egan, “Magnetic material selection for high power high frequency inductors in DC-DC converters,” in Proc. 24th Annu. IEEE APEC, 2009, pp. 2043–2049. [22] M. Rylko, B. Lyons, K. Hartnett, J. Hayes, and M. Egan, “Magnetic material comparisons for high-current gapped and gapless foil wound inductors in high frequency DC-DC converters,” in Proc. 13th IEEE EPEPEMC, 2008, pp. 1249–1256. 3440 IEEE TRANSACTIONS ON VEHICULAR TECHNOLOGY, VOL. 61, NO. 8, OCTOBER 2012 [23] J. Ferrieux and F. Forest, Alimentations à Découpage Convertisseurs à Résonance: Principes Composants Modélisation. Paris, France: Dunod, 1999. [24] V. Sankaran, F. Rees, and C. Avant, “Electrolytic capacitor life testing and prediction,” in Conf. Rec. 32nd IEEE IAS Annu. Meeting, 2002, vol. 2, pp. 1058–1065. [25] A. Lachichi, S. Pierfedirici, J. Martin, and B. Davat, “An hybrid fixed frequency controller suitable for fuel cells applications,” in Proc. 36th IEEE PESC, 2005, pp. 943–949. [26] J. Mahdavi, A. Emadi, and H. Toliyat, “Application of state space averaging method to sliding mode control of PWM DC/DC converters,” in Conf. Rec. 32nd IEEE IAS Annu. Meeting, 1997, vol. 2, pp. 820–827. [27] A. Shahin, B. Huang, J. Martin, S. Pierfederici, and B. Davat, “New non-linear control strategy for non-isolated DC/DC converter with high voltage ratio,” Energy Convers. Manage., vol. 51, no. 1, pp. 56–63, 2010. Mohammad Kabalo (S’09) received the B.S. degree from the University of Tishreen, Lattakia, Syria, and the M.S. degree in electrical engineering from the Ecole Centrale de Lyon, Ecully, France, in 2005 and 2009, respectively. He is currently working toward the Ph.D. degree in electrical engineering with the Research Institute on Transportation, Energy and Society, Université de Technologie de BelfortMontbéliard, Belfort, France. His current research interests include power electronics and dc-dc power converters for fuel cell applications. Damien Paire was born in France in 1979. He received the M.S. degree in electrical engineering from INSA of Lyon, Villeurbanne, France, in 2002, the Agregation degree from the Ecole Normale Superieure de Cachan, Cachan, France, in 2003, and the Ph.D. degree from System and Transport Laboratory, Université de Technologie de Belfort-Montbéliard (UTBM), Belfort, France, in 2010. He was a Lecturer with UTBM from 2004 to 2011 and has been an Associate Professor since 2011. His research interests include energy management, power electronics, and hybrid systems. Benjamin Blunier (deceased) received the M.Sc. and Ph.D. degrees in electrical engineering from the Université de Technologie de Belfort-Montbéliard (UTBM), Belfort, France, in 2004 and 2007, respectively. He studied fuel cell system modeling and particularly their air management and control for hybrid and electric vehicles. He was an Associate Professor with UTBM until his death on February 23, 2012. His research interests included fuel cells systems; electric, hybrid, and plug-in hybrid vehicles; and intelligent energy management in smart grids and microgrids. David Bouquain received the M.S. degree in electrical engineering from the Franche-Comté University, Besancon, France, in 1999 and the Ph.D. degree in electrical engineering from the Université de Technologie de Belfort-Montbéliard (UTBM), Belfort, France, in 2008. From 2000 to 2002, he has been an Engineer with the Laboratory of Electrical Engineering and Systems. He worked on a prototype of hybrid truck for the French army. Since September 2002, he has been Teacher and Researcher with the UTBM. He is currently an Associate Professor with System and Transport Laboratory, UTBM, working in the research field of energy management of electric and hybrid vehicles and fuel cell systems. Marcelo Godoy Simões received the B.S. and M.S. degrees from the University of São Paulo, São Carlos, Brazil, the Ph.D. degree from The University of Tennessee, Knoxville, in 1985, 1990, and 1995, respectively, and the D. Sc. degree (Liv re-Docência) from the University of São Paulo, São Carlos, Brazil, in 1998. He is currently an Associate Professor with Colorado School of Mines (CSM), Golden, where he has been establishing research and education activities for the development of intelligent control for high-power-electronic applications in renewable and distributed energy systems, where he currently serves as Director of the Center for the Advanced Control of Energy and Power Systems. He has been involved in activities related to control and management of smart grid applications since joining CSM. Abdellatif Miraoui (SM’09) was born in Morocco in 1962. He received the M.Sc. degree from Haute Alsace University, Mulhouse, France, in 1988 and the Ph.D. and Habilitation degrees from the University of Franche-Comté, Besancon, France, in 1992 and 1999, respectively. He is currently the President of Cadi Ayyad University, Marrakech, Morocco. Since 2000, he has been a Full Professor of electrical engineering (electrical machines and energy) with the Université de Technologie de Belfort-Montbéliard, Belfort, France, where he was the Vice President of Research Affairs from 2008 to 2011, the Director of the Electrical Engineering Department from 2001 to 2009, and the Head of the “Energy Conversion and Command” Research Team (38 researchers in 2007). He is a Doctor Honoris Causa of the Technical University of Cluj-Napoca, Cluj-Napoca, Romania. He was an Editor of the International Journal on Electrical Engineering Transportation. He is the author of more than 80 journal and 150 international conference proceeding papers. He is also the author of four textbooks about fuel cells. His special research interests include fuel cell energy, energy management in transportation, and the design and optimization of electrical propulsions/tractions.