Human Factors & System Safety Mark-Alexander Sujan Human Reliability Ltd.

Human Factors &

System Safety

Mark-Alexander Sujan

Human Reliability Ltd.

1

• Is not a property of individual components

• but of their interaction in specific contexts

• and includes the people working with technological components

• as well as their social interaction

2

The individual view:

Incidents are mainly due to individual failings

3

Cause:

“ Human error —maintenance staff failed to use procedures (violation), therefore critical action omitted.”

Corrective Actions:

– “Maintenance personnel to be disciplined.”

– “Directive to be issued regarding the importance of using procedures.”

4

Individual View of Human Error 1: incidents are caused by failure to follow rules

• Causes • Solutions :

–Negligence

–Lack of commitment

–Improve motivation

–Improve commitment

–Failures to follow rules or procedures

–Write a new rule or procedure to prevent the error

5

6

Individual View of Human Error 2: incidents are caused by lack of competence

• Cause

–Lack of capability

–Accident proneness

–Inadequate skill

–Loss of skill

• Solution

–Selection

–Selection / ‘Weeding out’

–More training (more of the same?)

–Refresher training

All of these solutions focus on Individual Causes

7

8

The systems view:

Human error is mainly due to deficiencies in the system which create the pre conditions for error

Why did the maintenance staff fail to use the procedures?

9

• There were frequent distractions

• The maintenance staff were working under pressure on several pieces of equipment at once

• Responsibilities were not defined

• Maintenance operators had too many roles

10

Why Were the Procedures

Not Used ?

• There was a large amount of irrelevant paperwork

• Operators did not participate in procedures development (therefore did not ‘own’ them)

• Procedures generally regarded as inaccurate and impractical (If followed to the letter job could not be done within time constraints)

• Using procedures regarded as only necessary for novices

• Under time pressure maintenance staff did not usually bother to look at procedures

11

Assessing the context:

Maintenance Activity (simplified)

Factors affecting errors in maintenance activity

12

Suitability of tools and equipment

Technical competence

Time Stress

Features of the activity

Quality of procedures

Degree of complexity

Isolated steps

Similarity to other activities

Stability of activity method

Accessibility of components

Design of system for maintainability

Component design

Access to parts

Amount of removal

Error potential analysis

Evaluating the Error Potential

Score for Violations

13

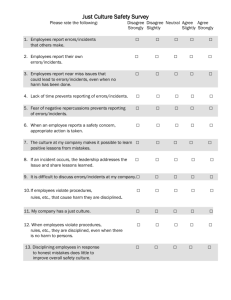

Violations

Strongly disagree

Disagree Neutral Agree

Strongly agree

Following the procedure makes the task more time consuming

Following the procedure makes the task more difficult

The task is carried out under time pressure

0

0

0

2

2

2

4

4

4

6

6

6

8

8

8

Violations EPS = 2 + 2 + 0 = 4

• Dependability of the HW/SW System is meaningful only with respect to the context – including humans !!

• Systems factors may make incidents inevitable

• The operator is often held responsible for deficiencies in systems

• Interventions should address the systems factors that provoke error

14