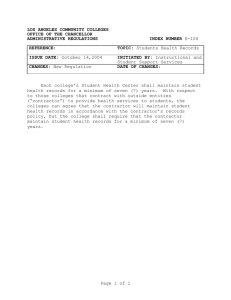

SAFE HOME PROGRAM CONTRACTOR’S GUIDELINES

advertisement