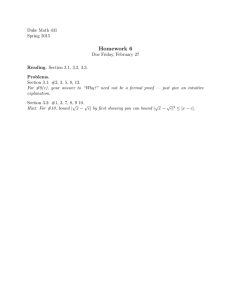

The stability of shallow tunnels ... openings in cohesive material DAVIS,

advertisement

DAVIS,E. H., GUNN, M. J., MIUR, R. J. & SENEVIRATNE,H. N. (1980). G&technique 30, No. 4, 397416 The stability of shallow tunnels and underground openings in cohesive material E, H. DAVIS,* M. J. GUNN,_F R. J. MAIR$ and H. N. SENEVIRATNEg- A basic engineering decision to be made in designing a tunnel in soft clay is whether or not the tunnel can be excavated without internal support. The safety of constructing a shallow heading in soft clay can be assessed in terms of the fluid support pressure which may be required to maintain stability. This can be estimated by means of the lower and upper bound theorems of plasticity. The Paper considers three different shapes of shallow underground opening relevant to tunnelling and upper and lower bound stability solutions are derived for collapse under undrained conditions. Solutions are also derived for assessment of the risk of blow-out failure caused by excessively high fluid pressures. Conditions are considered under which local collapse can occur, independent of the cover above the tunnel. Une decision fondamentale doit Ctre prise lorsque l’on veut realiser un tunnel dans de l’argile molle; il s’agit, en effet, de decider si un support interne sera ou non ntcessaire pour l’excavation du tunnel. La securitb de la construction dune galerie peu profonde dans de l’argile molle peut itre evalute en fonction de la pression du fluide support qui pourrait btre ntcessaire au maintien de la stabilite. Cette estimation peut se faire a l’aide des thtoremes a limites infirieure et superieure. L’article envisage trois formes differentes d’ouverture souterraine peu profonde interessant le creusement de tunnels, et des solutions de stabilite a limites inferieure et superieure sont trouvees pour l’affaissement dans des conditions non drain&es. Des solutions sont egalement trouvees en ce qui conceme l’evaluation du risque de rupture par eruption due aux pressions excessives du fluide. Les conditions dans lesquelles un affaissement local peut se produire sont envisagees, independamment de la couverture sit&e audessus du tunnel. INTRODUCTION Figure 1 shows schematically the normal method of constructing a shallow tunnel in soft ground using a tunnel shield. Soil is removed from the tunnel face either by hand or by cutters on a machine that forms a complete unit with the shield. The shield is jacked forward using hydraulic rams which react against the tunnel lining. As the tunnel progresses, new rings of the lining are installed at the rear of the shield. When the tunnel face is excavated by hand, the shield protects the tunnellers from a roof collapse and the most obvious threat to the tunnellers arises from possible instability of the face. When compressed air is used in the tunnel the stability of the face is increased since the air pressure replaces to some extent the pre-existing in situ ground stresses. Compressed air is also often used in conjunction with tunnelling machines but here an increasingly popular alternative is the use of bentonite or clay slurry under pressure. There is usually a bead on the tunnelling machine which leads to overcutting, so that the initially excavated diameter of the tunnel is greater than the diameter of the shield. If the fluid or air pressure is great enough then the soil will not close up around the machine and an annular gap will remain. Under these circumstances it is possible to idealize the process of tunnelling as shown in Fig. 2, where a circular tunnel of diameter D is shown being constructed with a depth of cover C. The tunnel lining is regarded as rigid and in front of it the tunnel heading is represented by a Discussion on this Paper closes 1 March, 1981. For further details see inside hack cover. *University of Sydney. t Cambridge University. $ Scott Wilson Kirkpatrick & Partners. 0 Ove Arup & Partners. 398 E. H. DAVIS, M. J. GUNN, R. J. MAIR AND H. N. SENEVIRATNE Ground surface ~~~~_-~~~_~___ I ----------- Bead Tunnel shield Fig. 1. Shield tunnelling Section Fig. 2. X-X An idealization of shield tunnelling cylindrical cavity of length P in which there acts a uniform fluid pressure cr.. The ground has a unit weight y and a uniform pressure a, acts on the soil surface: this may be due to a large flexible footing or an overburden of water (or very weak material). This Paper investigates what tunnel pressures err are necessary to maintain the stability of the heading for different values of the parameters that have been defined (D, C, P,y,a,) and the strength of the ground. The collapse of the tunnel heading will usually be a sudden event (caused, for example, by a sudden loss of tunnel pressure) and hence it is appropriate to characterize the strength of the ground by its undrained shear strength cU.In the following analysis it is assumed that c, is constant with depth, although in practice c, will vary with depth depending on the history of the site. There are, however, many situations where this assumption will be adequate and the methods of analysis that are used here can be extended to cases where there is an arbitrary distribution of c, with depth. Broms & Bennermark (1967) conducted experiments in which they extruded clay under pressure through vertical circular openings and they considered field observations both where failure had occurred and where stability had been maintained. They defined a stability ratio N, equal to the difference between the total overburden stress in the ground at the axis of the tunnel STABILITY OF SHALLOW TUNNELS IN COHESIVE (before the tunnel is constructed) strength c,. MATERIALS 399 and the tunnel pressure divided by the undrained shear N = [a,-a,+y(C +D/~)]/c, (1) They concluded that if N is less than 6 then the opening will be stable. Their results are relevant to the problem defined in this Paper for the particular case when P = 0. In practice, the air pressure in a tunnel is often given a value to ensure that there is no flow of water into the tunnel. This is achieved by applying a tunnel pressure greater than the pore-water pressure at the tunnel invert. One possible approach to maintaining stability would be to set the tunnel pressure equal to the overburden stress (i.e. N = 0). The problem with this approach is its expense and also the health risks for tunnellers working at high air pressures. It is therefore important to establish the minimum pressure necessary for stability. It is appropriate to remark here that the Paper does not investigate whether the stability of a tunnel heading improves or deteriorates in time. For a tunnel in heavily overconsolidated clay, a reduction in tunnel pressure will be accompanied by the generation of negative excess pore pressures which will dissipate as time passes. The clay around the tunnel will soften and after a certain ‘stand-up’ time collapse is possible. Whether or not the heading collapses (and if it does, the stand-up time) will depend on the geometry of the heading, the magnitude of the negative pore pressures generated and the consolidation characteristics of the clay. In a tunnel in lightly overconsolidated clay positive excess pore pressures will be generated and stability of the heading will not deteriorate with time. Although an assessment of stand-up is of major concern to tunnelling engineers (and is presently the subject of continued research at Cambridge University) the Authors believe that the immediate undrained stability problem considered here is a useful starting point when considering this phenomenon. THE LIMIT THEOREMS AND THEIR APPLICATION Stability solutions will be obtained using the limit theorems of plasticity. The soil is idealized as an elastic, perfectly plastic material with a cohesion equal to c,. There is considerable experimental evidence that this is a reasonable assumption for many clays. According to the theory of plasticity, the collapse load for a particular configuration of loading on a perfectly plastic body is unique, i.e. the load carrying capacity of the body cannot be changed by applying the various loads in a different order. The lower bound theorem states that if any stress field can be found which supports the loads, and is everywhere in equilibrium without yield being exceeded, then the loads are lower than (or equal to) those for collapse. The upper bound theorem states that if a work calculation is performed for a kinematically admissible collapse mechanism then the loads thus deduced will be higher than (or equal to) those for collapse. Since the tunnel pressure resists the collapse of soil into the tunnel it is a negative load in the sense discussed above. The lower bound theorem will furnish a safe estimate of the tunnel pressure required to maintain stability (i.e. higher or equal to that actually required) whereas the upper bound theorem will provide an unsafe estimate. It is convenient to approach the solution of the problem via a number of dimensionless parameters or groups which can be formally derived by dimensional analysis, such as CID,P/D,cssjcu, gT/c,, and yDfc,. For reasons which will become clear later GJC, and or/c, can be replaced by the single parameter (a, - crr)/c,. Thus the problem can be regarded as finding the value of (a, - r~r)/c, for limiting stability once the values of the independent parameters CID,PJD and yDJc, have been fixed. Since the solution of the complete problem defined in Fig. 2 is not straightforward (in particular, it is difficult to find a good lower bound) three simpler cases are considered in turn; 400 E. H. DAVIS, M. J. GUNN, R. J. MAIR AND H. N. SENEVIRATNE ff. 1 ! 1 4 4 4 Unit weighty C Undrained shear strength c, Undrained cu 4. , II 1, I--‘. . ” k CT D tf-. 1 Fig. 3. shear strength The plane strain unlined circular tunnel Fig. 4. ‘7 D . . . . J. The plane strain tunnel heading each of which is relevant to the stability of tunnels or underground openings and from which some conclusions can be made as to the more general situation. The first and second cases are shown in Figs 3 and 4: both are problems of plane strain. The stability of the long cylindrical cavity of Fig. 3 (Case 1) will determine the radial pressure a cylindrical tunnel shield must resist. This case is equivalent to the case illustrated in Fig. 2 when the ratio P/D is large. The case shown in Fig. 4 (Case 2) is a ‘plane strain heading’; the excavated volume is not cylindrical but instead is similar to a long wall mining excavation. The third case to be considered is the Broms & Bennermark problem which has the configuration of Fig. 2 when P/D = 0. Of course the results for this case are directly relevant to the stability of the hand excavated tunnel referred to at the start of the introduction. The three problems defined above will be referred to as Cases 1,2 and 3 in the remainder of this Paper. THE PLANE STRAIN UNLINED CIRCULAR Lower bound. yD/c, = 0: weightless The radially symmetric TUNNEL (Case 1) soil stress field within the annular region shown in Fig. 5 is given by c I =G T +2c ” In 2 0D rJ@= fJ,+2c, (2) ?I3 = 0 using the normal the lower bound notation. solution Outside is the annular region there is an isotropic (a, - or.)/cU = 2 In (2C/D + 1) stress field a,. Thus (3) The influence of surface and tunnel pressures on the lower bound solutions appearing in this Paper can be described by the single parameter o, -cr.. The reason for this is that the undrained shear strength is independent of the total mean normal stress; hence the addition of an arbitrary isotropic stress produces an equally valid solution. Lower bound, yDjc, > 0 For different values of yD/c, a computer program (Seneviratne, 1979) has been used to generate equilibrium stress fields around the tunnels which are everywhere in a state of plastic STABILITY OF SHALLOW TUNNELS IN COHESIVE MATERIALS 401 yield. When the two plane equilibrium equations are combined with the yield condition a pair of hyperbolic partial differential equations are obtained which can be numerically integrated along two characteristic directions (e.g. Booker & Davis, 1977). Figure 6 shows the stress characteristics generated for the case yD/c, = 2. The characteristic lines are the directions of maximum shear stress and are identical to the ‘slip-lines’ of metal plasticity. To obtain a complete solution for a particular C/D ratio a strong discontinuity is constructed starting from the point on the surface directly above the tunnel axis. This discontinuity completely surrounds the tunnel as shown in Fig. 6. Outside the discontinuity, the above stress field is replaced by Fig. 5. A lower bound stress field for the plane strain circular tunnel (yD/c, = 0) --- Fig. 6. - -- Strong discontinuities Stress characteristics around a plane strain circular tunnel (yD/c, = 2) 402 E. H. DAVIS, M. .I. GUNN, R. I. MAIR AND H. N. SENEVIRATNE another stress field which satisfies the stress boundary condition at the surface and extends to infinity without violating yield. This construction is illustrated in Fig. 7. Lower bound solutions for values of yD/c, from 1 to 4 are shown in Fig. 8. For low values of C/D when yD/c, = 3 or 4 it was not possible to complete the solution as described above without violating yield and these solutions are not illustrated in Fig. 8. For values of yD/c, greater than 4 the stress characteristics overlapped above the tunnel and no solution is Fig. I. Extension of the lower bound stress field for a plane strain circular tunnel (yD/c, > 0) Fig. 8. Lower bounds for the plane strain circular tunnel under gravity loading STABILITY OF SHALLOW TUNNELS IN COHESIVE MATERIALS 403 presented. It can be shown (see the section entitled Local collapse) that as yD/c, is increased a point is reached when it becomes impossible to maintain stability regardless of the magnitude of the applied uniform tunnel pressure. The overlapping stress characteristics or the failure to complete the extended stress field for low values of C/D when yD/c, = 3 or4 does not necessarily mean that these cases are inherently unstable. No attempt has been made to find alternative lower bounds since the generated solutions cover most of the range of parameters which is of practical significance. Upper bound Four upper bound mechanisms are shown in Figs 9 to 12. Mechanisms A and B are simple ‘roof and ‘roof and sides’ mechanisms each containing one variable dimension (or angle) and were deduced from model tunnel tests at Cambridge University (Cairncross, 1973; Mair, 1979). The procedure for determining the critical collapse load is to derive an expression for (6, - (or) (involving the variable dimension or angle) and then to minimize the value of (a, - oT) with respect to the variation of the dimension or angle. This can be done either analytically or numerically (e.g. by a digital computer program). Fig. 9. Fig. 10. Upper bound mechanism A Upper bound mechanism B 404 E. H. DAVIS, M. J. GUNN, Fig. 11. Upper bound mechanism C Fig. 12. Upper bound mechanism D R. J. MAIR AND H. N. SENEVIRATNE The reason that a, and rrr appear only in the form (oS- rrT)in the upper bound calculations is that since a kinematically permissible mechanism for cohesive material involves no volume change then the decrease in area of the tunnel must equal the area of ground loss at the surface. Hence the work done by the pressures in the work calculation will be (0, -Q=) multiplied by that area. Mechanism C has four variable angles in its specification and includes mechanisms A and B as special cases. Mechanism D is a ‘roof, sides and bottom’ mechanism with three variable angles. Figures 13 and 14 show the results of a numerical optimization to discover the critical mechanisms for yD/c, = 0 and 3. In both cases mechanism C is more critical for low values of C/D and is superseded by mechanism D for high values of C/D. It can be seen that the value of C/D at which this changeover takes place is lower for the greater value of yD/c,. Figures 13 and 14 also show the lower bounds which lie close to the best upper bounds indicating that the exact collapse loads have been closely bracketed. In the neighbourhood of the optimum upper bound, changes in the variable angles lead to small changes in the collapse load. There is not much STABILITY OF SHALLOW TUNNELS Mechanism D IN COHESIVE 405 MATERIALS Mechanism C Mechanism B Mechanism A Lower bound 1 1 1 2 3 8 4 5 CID Fig. 13. Stability solutions for the plane strain circular tunnel (yD/c, = 0) 2 t CID Lower bound -12 t Fig. 14. Stability solutions for tbe plane strain circular tunnel (yD/c, = 3) 406 E. H. DAVIS, M. J. GUNN, - - -- - R. J. MAIR AND H. N. SENEVIRATNE Lower bound Upper bound Fig. 15. Upper and lower bound stability ratios for plane strain circular tunnels Note: Stresses shown are normalized bye Fig. 16. ” A lower bound stress field for the plane heading (C/D = 4) STABILITY OF SHALLOW TUNNELS IN COHESIVE MATERIALS 407 Note: Stresses shown are normalized by cu. Unlabelled stress components are mmor and are two less than major principal stress components. Fig. 17. A lower bound stress field for the plane strain heading (C/D = 2.875) difference between mechanisms B, C and D for practical purposes (i.e. in estimated collapse load) although the mechanics of deformation are very different. In general it seems that a mechanism with one variable will yield an adequate upper bound (i.e. close to a good lower bound) providing an appropriate pattern of collapse is chosen. Figure 15 shows the bounds for different values of yD/c, all plotted as stability ratio N against CID. For values of CID greater than 3 the upper and lower bounds of N do not change significantly with yD/c,. Below C/D = 3 there is a larger spread but adopting the lower bound for yD/c, = 0 as a criterion for deciding the tunnel pressure should be a safe procedure. This is because it always corresponds to a lower value of N, or a higher value of oT, than those prescribed by the lower bounds for higher values of yD/c,. It is important, however, to consider also the possibility either of local failure at high values of yD/c, (see the section entitled Local collapse) or of failure caused by ‘blow-out’ for very shallow tunnels (see the section entitled Blow-out). THE PLANE STRAIN HEADING (Case 2) yD/c, = 0 Lower bound. Lower bound solutions for the plane strain heading can be constructed from three- sided and four-sided areas of constant stress at or below yield. Two such typical fields of stress are shown in Figs 16 and 17. These are systematically extended from two radial zones emanating from the top and bottom of the heading (Gunn, 1980). These fields transmit a shear load from the soil to the tunnel lining. Figure 16 shows 87% of the undrained shear strength being mobilized on the soil-lining interface. This degree of mobilization would be reasonable for rough linings in soft clay but solutions based on smooth linings would be more appropriate in other cases. Solutions for a smooth lining can be obtained by adapting the analyses of Booker & Davis (1973) or Ewing & Hill (1967) for the problems of bearing capacity near a vertical face and a Vnotched tension bar respectively. In particular the addition of an isotropic stress field to Ewing & Hill’s slip line solution gives as a lower bound (a, - a,)/~, = 2 + 2 In (C/D + 1) (4) 408 E. H. DAVIS, Fig. 18. M. J. GUNN, R. J. MAIR AND H. N. SENEVIRATNE An upper bound mechanism for the plane strain heading tar a_&_--- 6> ,, q . *.-.__, Stress field lower bound Lower Douna (smoorn Immgj (After Ewing & Hill) N=2+21n(C/D+l) 01 0 Fig. 19. 1 2 CID 3 4 I 5 Stability solutions for tbe plane strain beading Upper bound. When the upper bound mechanism illustrated in Fig. 18 is optimized with respect to the three variable angles, the critical collapse load is found to be (%--J/c, = 4&P++) (5) with tan u = tan /I = 2 J(C/D+ 4)and 6 = 7~12. The upper and lower bounds are plotted in Fig. 19 and again the exact collapse loads have been reasonably closely bracketed. The upper bound is not affected by the degree of roughness of the tunnel lining in contrast to the lower bounds where the collapse load for a rough lining is 0 to 20% higher (depending on C/D ratio) than that for a smooth lining. STABILITY OF SHALLOW TUNNELS IN COHESIVE MATERIALS 409 If the work done by the self weight of the soil is accounted for in the work calculation for the mechanism shown in Fig. 18 then the same optimum is obtained and (0s - ~r)/cu + YDMCID + )) = 4 &C/D +t) (6) Since the expression on the left is equal to the stability ratio N, it follows that this mechanism predicts the same stability ratio regardless of the value of yD/c,. Similarly it is possible to add a hydrostatic stress field to obtain new lower bounds for various values of yD/c,. In these lower bounds, however, the tunnel pressures vary linearly with depth, the pressures being yD higher at the bottom of the heading than at the top. If the average tunnel pressure is adopted in the calculation of the stability ratio then the results for yD/c, = 0 apply for any value of yD/c,. Figure 19 can therefore be regarded as a plot of stability ratio against C/D for all values of yD/c,. The stability ratio for a safe tunnel pressure (determined as above) is not a lower bound for the originally specified problem (constant or. with depth) but the results for the circular tunnel suggest that this assumption is a safe one. As in the case of the circular tunnel the possibilities of local collapse and blow-out must also be considered when determining a safe tunnel pressure. THE CIRCULAR TUNNEL HEADING (Case 3) yD/c, = 0 Lower bound. The first lower bound stress field is shown in Fig. 20(a). Within the cylindrical volume of soil which is the continuation of the already excavated tunnel the axial stress is equal to cr. In planes perpendicular to the tunnel axis, the two principal stresses are equal to a,+ 2c,. Outside this cylinder there is a radially symmetric stress field similar to that adopted for the plane strain circular tunnel with the axial stress being some intermediate value between the radial and circumferential stresses. Outside the larger cylinder of diameter (C +(D/2)) there is an isotropic stress field a,. The lower bound is (Go- rrr)/c, = 2 + 2 In (2C/D + 1) (7) Figure 20(b) illustrates an alternative lower bound stress field. Within a hemispherical cap on the end of the tunnel there is an isotropic stress field cr. Outside this hemisphere there is a spherically symmetric stress field given by 0, = uT + 4c, In (2r/D) (8) 1 Outside the sphere (to which the surface is a tangent plane) there is an isotropic stress field a,. The lower bound is 00 = a, +2c, (a, - G&C, = 4 In (2C/D + 1) (9) It can be seen from Fig. 21 that lower bound (a) allows higher loads to be supported for values of CIDcO.86, whereas for values of C/D> 0.86 lower bound (b) is better. Upper bound. The mechanism of Fig. 18 is adopted but the plane strain sliding blocks are replaced by blocks with elliptical cross-sections. The length of the semi-axes perpendicular to the plane of the diagram is equal to D/2. Optimization of the upper bound with respect to the three variable angles leads to the line shown in Fig. 21. E. H. DAVIS, M. J. GUNN, R. J. MAIR AND H. N. SENEWRATNE Section X-X (a) Thick cylinder Section X-X (b) Thick sphere Fig. 20. Lower bound stress fields for the circular tunnel heading The effect of the self weight of the soil can be added in exactly the same way as for case 2 leading to the interpretation of Fig. 21 in terms of stability ratio as well as (a, - c~)/c,, for the weightless case. The relatively large gap between the upper and lower bounds for this case is a reflection of the increased complexity of the three-dimensional problem. STABILITY OF SHALLOW TUNNELS IN COHESIVE 411 MATERIALS 24- 20 - 16Lower bound (thick sphere) 2 12- Lower bound (thick cylinder) N=2+2/0(2C/D+1) 0 1 2 3 4 5 CID Fig. 21. Stability solutions for the circular tunnel beading (a) Plane strain circular tunnel Fig. 22. Upper bound mechanisms (b) Plane strain tunnel heading (c) 30 circular tunnel heading for local collapse LOCAL COLLAPSE It can easily be demonstrated that if the ratio yD/c, is sufficiently large then collapse will take place for any value of uniform tunnel pressure. For Cases 1, 2 and 3 which were defined earlier optimization of the mechanisms shown in Figs 22(a), (b) and (c) results in upper bounds on yD/c, for collapse of 8.71,8-28 and 1096 respectively. Even though these mechanisms involve no immediate subsidence of the ground surface, it is likely that this would be the first step of a progressive failure which would eventually propagate to the surface. Since for a given site the value of y/c, would be predetermined, the limiting value of yD/c, can be viewed as specifying the maximum height of tunnel heading which can be constructed under uniform tunnel pressure. To calculate safe values of yD/c, for the various cases lower bound solutions are required. For the plane strain circular tunnel the evidence of the stress characteristics lower bounds is that, for any value of C/D, stability is maintained provided that yD/c, < 2. Stability can still be maintained for values of yD/c, between 2 and 4 when C/D exceeds certain minimal values (see Fig. 8). E. H. DAVIS, M. J. GUNN, R. J. MAIR AND H. N. SENEVIRATNE 412 Fig. 23. A lower bound stress field for local collapse (Cases 2 and 3,62c,/y(Pastot’s Fig. 24. 3) solution) A lower bound stress field for local collapse (Case 2) using Pastor’s solution For both the plane strain tunnel heading and the circular tunnel heading, stress fields based on Fig. 23 show that there will be no possibility of local collapse for tunnelling when yD/c, < 4 and uniform tunnel pressure equals y(C[D/2) (i.e. stability ratio N = 0). It is possible to improve the solution for the plane strain heading by using Pastor’s (1978) lower bound for the critical height of a vertical cut in cohesive material. Using a linear programming approach, an allowable stress field with 208 zones of linearly varying stresses and a safe height of 3.63 c,/y was obtained. Adopting this field as shown in Fig. 24 then the heading is stable for yD/c, = 5.63 when eT = y(C+O.3550). In contrast to the plane strain circular tunnel these solutions are valid for any value of C/D. BLOW-OUT The problem of causing a failure by having a tunnel pressure which is too large has already been mentioned. For Cases 2 and 3 the solutions already obtained can be directly adapted as follows. STABILITY OF SHALLOW TUNNELS IN COHESIVE 413 MATERIALS Upper bound For both the plane strain and circular heading the result can be written in the form (08- a,)/~, + yUc,(CP + 3) = N = f(V) (10) for collapse into the tunnel. It is possible to identify the first term in this equation with the net work done by the pressures; the second term with work done by gravity; and the third term with the plastic work dissipated on the sliding surfaces. When the direction of motion is reversed or> as and @Jr- %)/C, = YD/C”(CP + t) +f(cP) or (a, - D~)/c, + yD/c,(C/D + +) = -f(C/D) = - N (11) Hence an unsafe (or high) estimate of tunnel pressure to cause blow-out can be obtained by reversing the sign of the stability ratio for inward collapse. Lower bound If the directions of major and minor principal stress are reversed in the stress fields considered for collapse-in and the gravity field added as before then equivalent results to the upper bounds are obtained (0, - cr)/c, + Y%(‘V + 3) = - N This expression allows the calculation of safe tunnel pressures but as before the lower bound stress field includes a tunnel pressure varying ‘linearly with depth and not the constant distribution which is of real interest. It is not possible to make use of the collapse-in results for case 1 in exactly the same way as above. Figure 15 demonstrated that upper bound solutions do not lead to values of N that are independent of yD/c,. This is because the work done by gravity would be equivalent to an expression of the form yD/c,(C/D + x) where x has a value between 0 and f depending on the optimum mechanism for a particular case. Hence to obtain results for blow-out the complete set of upper bound mechanisms should be re-examined with the direction of movement reversed and new lower bounds should be generated where the tunnel pressure is the major principal stress. However, it is likely that blow-out will only be a problem for very shallow tunnels when failure will occur similarly to mechanism A (Fig. 9) and that as for collapse-in safe tunnel pressures will be close to dT = a,. DISCUSSION AND CONCLUSIONS Tunnel pressures necessary for the support of shallow tunnels and underground openings in soft ground have been estimated using the limit theorems of plasticity. Two of the situations considered have been special cases of the idealization suggested in the Introduction for the process of constructing a shallow circular tunnel using a shield or tunnelling machine. The results indicate (as might be expected) that higher tunnel pressures are required for stability of the unlined circular tunnel (P/D + 00) than for the circular tunnel heading (P/D = 0). The stability ratio N, originally proposed by Broms & Bennermark, has provided a convenient framework for interpreting the results and can be used to estimate tunnel pressures required for stability. In contrast to Broms & Bennermark, however, the results presented here indicate that the critical values of N show a marked variation with the depth of burial (i.e. C/D) 414 E. H. DAVIS, M. J. GUNN, R. J. MAIR AND H. N. SENEVIRATNE B Ii + Force m73-y+7(C+qa Fig. 25. Moment 703/i 2 The equivalent stability problem in weightless medium of the tunnel. Indeed, adoption of the Broms & Bennermark criterion (N < 6 for stability) would indicate that some shallow headings would be stable with no support pressure whereas an upper bound calculation demonstrates that collapse would be inevitable without a supporting pressure. A possible objection to the lower bound or safe tunnel pressures suggested for the headings is that they are based on stress fields where the tunnel pressures vary linearly with depth. Although the adoption of the average pressure as safe seems reasonable, it is not satisfactory from the point of view of the theory of plasticity. At first sight the adoption of the pressure at the bottom of the heading as safe might seem to deal with this objection because now there is a greater overall pressure supporting the heading than in the actual stress field. This process is equivalent to a reduction in the safe value of N by &D/c,) but is again not satisfactory from the point of view of plasticity theory because the greater constant support pressure is not proportionally greater than the linearly varying support pressure. Indeed both these approaches could be used to predict safe tunnel pressures when the results of the section entitled Local collapse indicate that collapse would definitely occur. There is, however, a simple way in which the results already presented can be adapted to predict safe tunnel pressures which are theoretically justified. Figure 25 shows the loads acting when the effect of gravity and the surface pressure is subtracted (according to plasticity theory the collapse load is not affected by this subtraction). A linearly varying tunnel pressure is now the only load acting and it can be regarded as consisting ofa tensile load equal to D[o, - a,+ y(C + D/2)] and a moment equal to yD3/12. The tensile load is clearly responsible for failures involving the surface (as in Fig. 18) whereas the moment is responsible for local collapse. These two loads can be regarded as independent and according to plasticity theory the corresponding failure locus on the interaction diagram must be convex. Figure 26 shows (for the particular cases of a plane strain heading with C/D = 2 and C/D = 2.875) the three upper bound lines and lower bound points (A, B, C) on the appropriate (nondimensionalized) interaction diagram. From the convexity property AB must represent safe values of N, and this line can be regarded as a criterion for the reduction of N with increasing yD/c,. For the case of Fig. 26(a) with yD/c, = 3 the average pressure criterion gives a safe N of 4, i.e. o*/c,, > 1.5, whereas the above criterion gives a safe N of 2.3, i.e. GJC, > 3.2. The practical tunnelling engineer will want to know what experimental evidence there is for the solutions presented here. Tests on unlined circular model tunnels carried out at Cambridge University (Mair, 1979; Seneviratne, 1979) have shown that the experimental collapse loads lie between the lower and upper bound solutions that have been presented (see Fig. 27). A series of STABILITY OF SHALLOW TUNNELS IN COHESIVE t 6 4 Upper bound (collapse in) _------------_ A Lower bound 415 MATERIALS Upper bound (collapse in) -------------- I I I I Upper 1bound I Lower bound f I Upper 1bound 1(Local 1collapse) I I I I (Local 1collapse) i I B I 20 6 ‘1 9/c” I 2 I I I 4 Upper bound (blowout) _------_--e---s I , I 1 6 Upper bound (blowout) - - - -- (a) C/D = 413 -_--- --- i (b) C/D = 2,875 Fig. 26. Interaction diagrams for tbe plane strain beading 5- 4- 3- 4 2- b" Upper bound D Experimental CID -1 - Fig. 27. Comparison yD/c, = 2.6) of the stability solutions presented in this Paper with experimental observations (Case I: 416 E. H. DAVIS, M. J. GUNN, R. J. MAIR AND H. N. SENEVIRATNE tests on model tunnel headings (Mair, 1979) has resulted in collapse loads which lie fairly close to the lower bounds suggested for Case 3. For shallow tunnels (Case 1) the experimentally observed collapse mechanism is usually very close to the optimum upper bound mechanism. For deeper, i.e. (C/D)> 2, Case 1 tunnels and for most of the Case 3 tests, however, significant differences are observed between the sliding block mechanisms presented here and the pattern of deformation observed experimentally. The sliding block mechanisms suggest that a movement of soil inwards near the tunnel is accompanied by an (approximately) equal settlement of the surface. In practice, however, large movements near the tunnel are accompanied by much smaller settlements of the surface, perhaps indicating a zone of plastically yielded soil near the tunnel which is supported by a surrounding elastic region. Nevertheless the Authors believe that the experimental evidence currently available indicates that the results presented in this Paper can be used with confidence for the calculation of the undrained stability of tunnels when C/D < 3. ACKNOWLEDGEMENTS The work presented in this Paper forms part of a wider programme of research into the behaviour of shallow tunnels in soft ground at Cambridge University supported by the Transport and Road Research Laboratory. The research has been conducted under the overall direction of Professor A. N. Schofield and the Authors are grateful to him for several stimulating discussions. REFERENCES Booker, J. R. & Davis, E. H. (1973). Some adaptations of classical plasticity theory for soil stability problems. Proceedings of the symposium on the role of plasticity in soil mechanics, ed. Andrew C. Palmer, 2441. Cambridge, 1973. Booker, J. R. & Davis, E. H. (1977). ‘Stability analysis by plasticity theory’, in Numerical methods in geotechnical engineering, eds C. S. Desai and J. T. Christian, Chapter 21. London: McGraw-Hill. Broms, B. B. & Bennermark, H. (1967). Stability ofclay in vertical openings. J. Soil Mech. Fdns Div. Am. Sot. Cio. Engrs, 193, SMl, 71-94. Cairncross, A. M. (1973). Deformations around model tunnels in stiff clay. PhD thesis, Cambridge University. Ewing, D. J. F. & Hill, R. (1967). The plastic constraint of V-notched tension bars. J. Mech. Phys. Solids, 15, 1155124. Gunn, M. J. (1980). A note on the centred-fan stress field and its use in plasticity problems relevant to geotechnical engineering. Cambridge University Engineering Department Internal Report. Pastor, J. (1978). Analyse limite: determination numirique de solutions statistiques completes. Application au talus vertical. J. Mtc. appl. 2, No. 2, 167-196. Mair, R. J. (1979). Centrqial modelling of tunnel construction in soft clay. PhD thesis, Cambridge University. Seneviratne, H. N. (1979). Deformations and pore pressure uariations around shallow tunnels in sqfi clay. PhD thesis, Cambridge University.