Charlotte Historic District Commission

Staff Review

HDC 2015-176

LOCAL HISTORIC DISTRICT:

Plaza Midwood

PROPERTY ADDRESS:

1465 Haywood Court

SUMMARY OF REQUEST:

New Construction

APPLICANT:

Tim McCollum

Application for a Certificate of Appropriateness

Date: August 12, 2015

Details of Proposed Request

Existing Conditions

The existing site is a vacant parcel and the end of Haywood Court. The four adjacent structures on the street are one and,

one and one half single family homes. Across the street is a large vacant tract and the rear yards of two single family

homes.

Proposal

The proposal is a new two story single family house and detached garage. Features of the house include a full width front

porch, wood and cedar shake siding, wood trim details, brick foundation and clad STDL windows. Column material

proposed is synthetic wood, painted. Total height is +/- 24’. The garage will have design details to match the house.

Garage height is approximately 23’-9”.

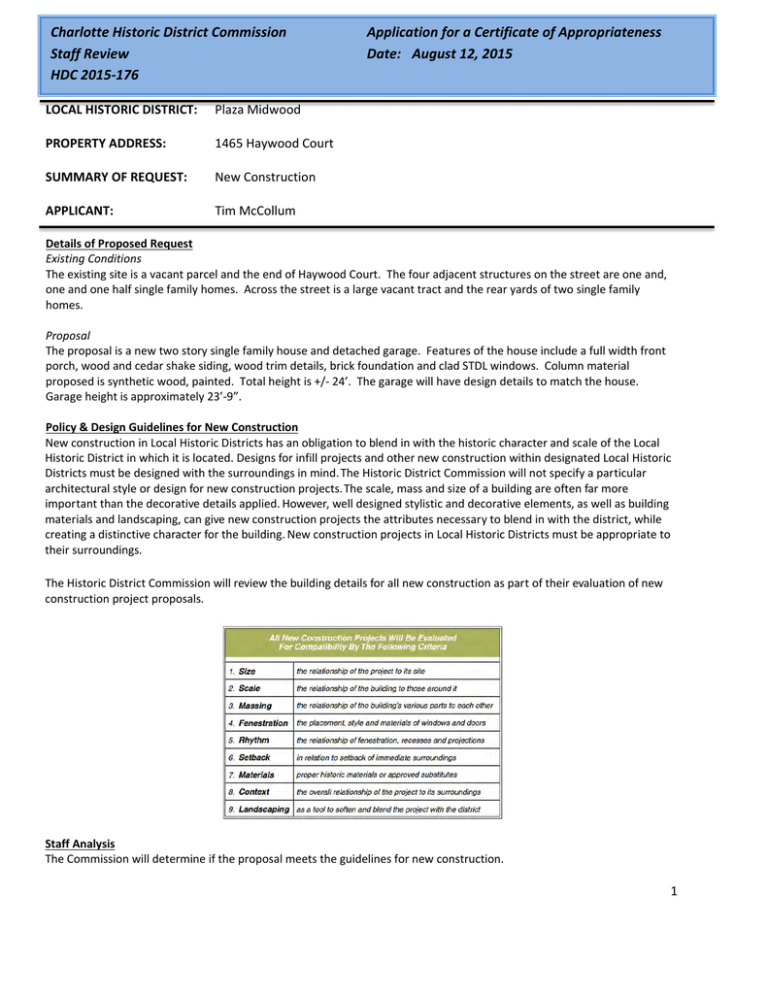

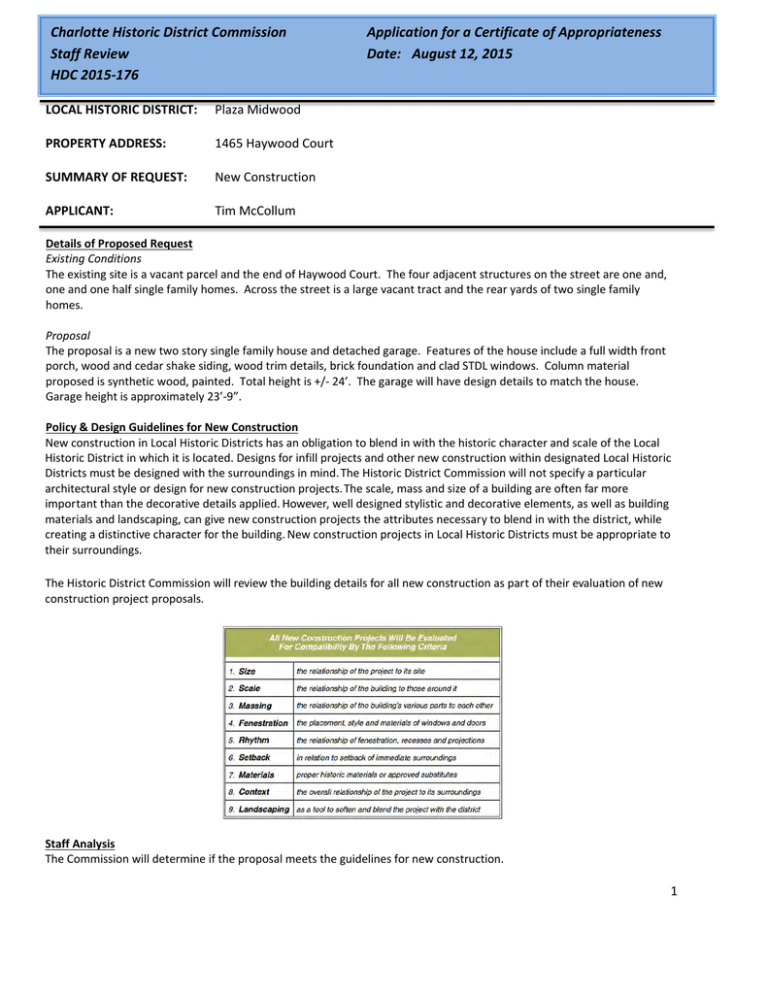

Policy & Design Guidelines for New Construction

New construction in Local Historic Districts has an obligation to blend in with the historic character and scale of the Local

Historic District in which it is located. Designs for infill projects and other new construction within designated Local Historic

Districts must be designed with the surroundings in mind. The Historic District Commission will not specify a particular

architectural style or design for new construction projects. The scale, mass and size of a building are often far more

important than the decorative details applied. However, well designed stylistic and decorative elements, as well as building

materials and landscaping, can give new construction projects the attributes necessary to blend in with the district, while

creating a distinctive character for the building. New construction projects in Local Historic Districts must be appropriate to

their surroundings.

The Historic District Commission will review the building details for all new construction as part of their evaluation of new

construction project proposals.

Staff Analysis

The Commission will determine if the proposal meets the guidelines for new construction.

1

Charlotte Historic District Commission - Case 2015-176

Historic District; Plaza Midwood Belv

edere A

v

The Pl

aza

St

Belle T

e

rre Av

Belle T

err

e Av

Belle T

e

Thoma

s

Av

Haw

thor

ne L

n

Kenno

n

Thoma

s

Av

Belva

dere

Av

t Av

100

aza

The P

l

Kensi

n

Property Lines Kensi

Av

200

400

Feet

Plaza Midwood

gtoHistoric

n Dr District

Map Printdate;

August .;2015

ngton

Building Footprints

laz a

0

t Av

1465 Haywood Court

Peca

n

!

I

Chestn

u

Thoma

s

Pecan

Av

Av

Chestn

u

The Pl

aza

Haywood Ct

Dr

1

2

3

4

5

6

E

D

D

McCollum Residence

PROJECT

1465 Haywood Court

Charlotte, NC 28205

1501 HAYWOOD COURT

1507 HAYWOOD COURT

OWNER

Revolve Residential

130 West Worthington Avenue

Charlotte, NC 28203

tim@revolveresidential.com

C

C

505DESIGN TEAM

CONSULTANTS

Charlotte Historic

District Commission

Submittal

08/14/15

1511 HAYWOOD COURT

1508 HAYWOOD COURT

REVISIONS

NO.

B

1815 THOMAS AVENUE

B

SITE SURVEY AND

STREETSCAPE

IMAGES

A

A1.01

1823 THOMAS AVENUE

A

1

DATE

1465 Haywood Ct Survey

1" = 30'-0"

8/3/2015 8:05:53 PM

1A

DESCRIPTION

2

3

4

5

6

@ 2015 505DESIGN, INC

1465

1501

1508

1507

1511

1

2

3

4

5

6

E

D

D

McCollum Residence

PROJECT

1465 Haywood Court

Charlotte, NC 28205

McCOLLUM RESIDENCE

OWNER

GARAGE LEVEL 2

7' - 7"

Revolve Residential

130 West Worthington Avenue

Charlotte, NC 28203

tim@revolveresidential.com

C

C

505DESIGN TEAM

CONSULTANTS

Charlotte Historic

District Commission

Submittal

08/14/15

REVISIONS

NO.

8/3/2015 8:06:09 PM

B

1A

1

2

3

4

5

6

DATE

B

STREETSCAPE

ELEVATION SURVEY

A

A1.02

STREETSCAPE ELEVATION SURVEY

1" = 20'-0"

A

DESCRIPTION

@ 2015 505DESIGN, INC

1

2

3

4

5

6

E

REAR YARD

SETBACK

N

20' - 0"

A2.03

4B

A2.03 2D

2B A2.03

D

REAR YARD TOTAL SF:

7,280

IMPERVIOUS TOTAL SF:

1,856

PERVIOUS TOTAL SF:

5,424

D

McCollum Residence

PROJECT

1465 Haywood Court

Charlotte, NC 28205

4D

A2.03

A2.02

FROM PROPERTY LINE TO

FACE OF EXTERIOR WALL

3D

OWNER

5' - 0"

SIDEYARD SETBACK

5' - 0"

Revolve Residential

130 West Worthington Avenue

Charlotte, NC 28203

tim@revolveresidential.com

SIDEYARD SETBACK

PROPERTY LINE

C

C

505DESIGN TEAM

3A A2.02

A2.01 3A

CONSULTANTS

Charlotte Historic

District Commission

Submittal

08/14/15

REVISIONS

NO.

DESCRIPTION

DATE

1A

20

'-

0"

A1.02

B

B

SITE PLANS

FRONTYARD

SETBACK

8/3/2015 8:10:42 PM

Ha

yw

oo

dC

ou

rt

1A

ARCHITECTURAL SITE PLAN

3/32" = 1'-0"

5A

LANDSCAPE PLAN

3/32" = 1'-0"

A

A

1

2

3

4

5

6

A1.03

@ 2015 505DESIGN, INC

1

2

3

4

5

6

E

52' - 5 1/2"

1A

A3.01

ASPHALT SHINGLE ROOFING

12

12

4

PAINTED METAL HALF ROUND GUTTER

12

4

4

Roof Top Plate

20' - 8 1/2"

6" WOOD CORNER BOARD, PAINT FINISH

5/4 WOOD LAP SIDING, PAINT FINISH

CEDAR SHAKE SIDING WITH

STAIN FINISH

24' - 1"

D

2 1/2"

2 1/2"

5A

A3.01

DOUBLE HUNG WOOD WINDOW, TYP

12

12

ASPHALT SHINGLE ROOFING

12

2 1/2"

Level 2

11' - 7"

D

McCollum Residence

PROJECT

1465 Haywood Court

Charlotte, NC 28205

PAINTED METAL HALF ROUND GUTTER

GARAGE

2

5/4

WOOD LAPLEVEL

SIDING, PAINT

FINISH

7' - 7"

SYNTHETIC WOOD COLUMN CASING

W/ SMOOTH PAINT FINISH

MASONRY COPING ROWLOCK COURSE

PAINTED WOOD RAILING

BRICK MASONRY RUNNING BOND

OWNER

Level 1

0"

Grade

-3' - 0"

Revolve Residential

130 West Worthington Avenue

Charlotte, NC 28203

tim@revolveresidential.com

4' - 4 1/4"

62' - 10"

3D

South Elevation

1/4" = 1'-0"

C

C

505DESIGN TEAM

CONSULTANTS

33' - 10 1/4"

Charlotte Historic

District Commission

Submittal

ASPHALT SHINGLE ROOFING

12

4

PAINTED METAL HALF ROUND GUTTER

Roof Top Plate

20' - 8 1/2"

08/14/15

6" WOOD CORNER BOARD TYP, PAINT FINISH

REVISIONS

5/4 WOOD LAP SIDING, PAINT FINISH

NO.

CEDAR SHAKE SIDING WITH

STAIN FINISH

DESCRIPTION

DATE

DOUBLE HUNG WOOD WINDOW, TYP

MASONRY CHIMNEY FOR GAS FIREPLACE

ALTERNATE: CEDAR SHAKE SIDING WITH

MASONRY BASE

ASPHALT SHINGLE ROOFING

24' - 1"

12

12

2 1/2"

2 1/2"

B

Level 2

11' - 7"

PAINTED METAL HALF ROUND GUTTER

B

HOUSE ELEVATIONS

A

A2.01

CEDAR SHAKE SIDING WITH STAIN FINISH

5/4 WOOD LAP SIDING, PAINT FINISH

SYNTHETIC WOOD COLUMN CASING

W/ SMOOTH PAINT FINISH

MASONRY COPING - ROWLOCK COURSE

Level 1

0"

Grade

-3' - 0"

PAINTED WOOD RAILING

53' - 1"

8/3/2015 8:08:02 PM

BRICK MASONRY - RUNNING BOND

3A

West Elevation

1/4" = 1'-0"

A

1

2

3

4

5

6

@ 2015 505DESIGN, INC

1

2

3

4

5

6

E

18' - 0 1/2"

34' - 5"

ASPHALT SHINGLE ROOFING

12

PAINTED METAL HALF ROUND GUTTER

4

12

4

Roof Top Plate

20' - 8 1/2"

6" WOOD CORNER BOARD, PAINT FINISH

5/4 WOOD LAP SIDING, PAINT FINISH

FIXED WOOD WINDOW

DOUBLE HUNG WOOD WINDOW, TYP

24' - 1"

ASPHALT SHINGLE ROOFING

D

12

2 1/2"

Level 2

11' - 7"

D

McCollum Residence

PROJECT

PAINTED METAL HALF ROUND GUTTER

1465 Haywood Court

Charlotte, NC 28205

5/4 WOOD LAP SIDING, PAINT FINISH

SYNTHETIC WOOD COLUMN CASING

W/ SMOOTH PAINT FINISH

MASONRY CHIMNEY FOR GAS FIREPLACE

ALTERNATE: CEDAR SHAKE SIDING WITH

MASONRY BASE

BRICK MASONRY - ROWLOCK COURSE

BRICK MASONRY - RUNNING BOND

OWNER

Level 1

0"

Grade

-3' - 0"

Revolve Residential

130 West Worthington Avenue

Charlotte, NC 28203

tim@revolveresidential.com

58' - 5 3/4"

3D

C

North Elevation

1/4" = 1'-0"

C

505DESIGN TEAM

33' - 10 1/4"

CONSULTANTS

ASPHALT SHINGLE ROOFING

12

4

Charlotte Historic

District Commission

Submittal

PAINTED METAL HALF ROUND GUTTER

Roof Top Plate

20' - 8 1/2"

08/14/15

REVISIONS

NO.

FIXED WOOD WINDOW

DESCRIPTION

DATE

CEDAR SHAKE SIDING WITH

STAIN FINISH

5/4 WOOD LAP SIDING, PAINT FINISH

ASPHALT SHINGLE ROOFING

24' - 1"

6" WOOD CORNER BOARD, PAINT FINISH

PAINTED METAL HALF

ROUND GUTTER

12

2 1/2"

Level 2

11' - 7"

12" WOOD TRIM BOARD, PAINT FINISH

B

5/4 WOOD LAP SIDING,

PAINT FINISH

DOUBLE HUNG WOOD WINDOW, TYP

SYNTHETIC WOOD COLUMN

CASING W/ SMOOTH PAINT

FINISH

6" WOOD BASE BOARD, PAINT FINISH

B

HOUSE ELEVATIONS

A

A2.02

BRICK MASONRY ROWLOCK COURSE

BRICK MASONRY RUNNING BOND

Level 1

0"

Grade

-3' - 0"

8/3/2015 8:08:11 PM

21' - 11 1/2"

3A

East Elevation

1/4" = 1'-0"

A

1

2

3

4

5

6

@ 2015 505DESIGN, INC

1

2

3

4

5

6

E

12

4

ASPHALT SHINGLE ROOFING

12

12

4

PAINTED METAL HALF ROUND GUTTER

12

4

ASPHALT SHINGLE ROOFING

4

PAINTED METAL HALF ROUND GUTTER

6" WOOD CORNER BOARD, PAINT FINISH

6" WOOD CORNER BOARD, PAINT FINISH

5/4 WOOD LAP SIDING, PAINT FINISH

5/4 WOOD LAP SIDING, PAINT FINISH

DOUBLE-HUNG WOOD

WINDOW

D

23' - 9 3/4"

23' - 9 3/4"

ASPHALT SHINGLE ROOFING

PAINTED METAL HALF ROUND GUTTER

D

DOUBLE-HUNG WOOD

WINDOW

PROJECT

ASPHALT SHINGLE ROOFING

12

McCollum Residence

1465 Haywood Court

Charlotte, NC 28205

PAINTED METAL HALF ROUND GUTTER

2 1/2"

SYNTHETIC WOOD COLUMN CASING W/

SMOOTH PAINT FINISH

METAL PANEL AUTOMATIC GARAGE

DOORS

10' - 8"

BRICK MASONRY - ROWLOCK COURSE

OWNER

BRICK MASONRY - ROWLOCK COURSE

BRICK MASONRY - RUNNING BOND

BRICK MASONRY - RUNNING BOND

Revolve Residential

130 West Worthington Avenue

Charlotte, NC 28203

tim@revolveresidential.com

31' - 6 1/4"

2D

GARAGE - WEST ELEVATION

1/4" = 1'-0"

4D

GARAGE SOUTH ELEVATION

1/4" = 1'-0"

C

C

505DESIGN TEAM

CONSULTANTS

Charlotte Historic

District Commission

Submittal

08/14/15

12

4

ASPHALT SHINGLE ROOFING

12

4

PAINTED METAL HALF

ROUND GUTTER

REVISIONS

ASPHALT SHINGLE ROOFING

NO.

PAINTED METAL HALF ROUND GUTTER

6" WOOD CORNER BOARD,

PAINT FINISH

5/4 WOOD LAP SIDING, PAINT FINISH

11' - 7"

2 1/2"

SYNTHETIC WOOD COLUMN

CASING W/ SMOOTH PAINT

FINISH

22' - 8 1/4"

23' - 9 3/4"

23' - 9 3/4"

5/4 WOOD LAP SIDING, PAINT FINISH

12

B

8/3/2015 8:08:19 PM

GARAGE

ELEVATIONS

6" WOOD BASE BOARD, PAINT

FINISH

CEDAR SHAKE SIDING,

STAIN FINISH

BRICK MASONRY - ROWLOCK

COURSE

BRICK MASONRY - ROWLOCK COURSE

BRICK MASONRY - RUNNING

BOND

2B

GARAGE EAST ELEVATION

1/4" = 1'-0"

BRICK MASONRY - RUNNING BOND

4B

Elevation 4 - a

1/4" = 1'-0"

A

A

1

DATE

6" WOOD CORNER BOARD, PAINT FINISH

FIXED WOOD WINDOW

B

DESCRIPTION

2

3

4

5

6

A2.03

@ 2015 505DESIGN, INC

1

2

3

4

5

6

E

3' - 0"

6" DIA. HALF ROUND

PAINTED GUTTER

Roof Top Plate

20' - 8 1/2"

1X WOOD FASCIA - PAINT FINISH

1X2 TRIM BOARD - PAINT FINISH

WOOD T&G SOFFIT - STAIN FINISH

1X2 FRIEZE BOARD

5/4 LAP WOOD SIDING, PAINT FINISH

D

D

ROOF SLOPE BEYOND

McCollum Residence

PROJECT

1465 Haywood Court

Charlotte, NC 28205

OWNER

ASPHALT ROOF SHINGLES

1' - 6"

Level 2

11' - 7"

2' - 3"

GUTTER SUPPORTS

6" DIA. HALF ROUND

PAINTED GUTTER

Revolve Residential

130 West Worthington Avenue

Charlotte, NC 28203

tim@revolveresidential.com

6" DIA. HALF ROUND

PAINTED GUTTER

1X WOOD FASCIA - PAINT FINISH

C

0' - 9"

WOOD FASCIA

1 3/4"

PORCH BEAM - STRUCTURAL WOOD

BEAM WITH SYNTHETIC WOOD CASING

- SMOOTH FINISH FOR PAINT

1X2 TRIM BOARD - PAINT FINISH

3 1/2"

WOOD T&G SOFFIT - STAIN FINISH

1X2 TRIM BOARD - PAINT FINISH

C

505DESIGN TEAM

COLUMN TRIM TO MATCH COLUMN

FINISH

PORCH BEAM - STRUCTURAL WOOD

BEAM WITH SYNTHETIC WOOD CASING

- SMOOTH FINISH FOR PAINT

CONSULTANTS

PORCH COLUMN - STRUCTURAL WOOD

COLUMN WITH 8"X8" SYNTHETIC WOOD

CASING - SMOOTH FINISH FOR PAINT

0' - 8"

PORCH COLUMN - STRUCTURAL WOOD

COLUMN WITH 8"X8" SYNTHETIC WOOD

CASING - SMOOTH FINISH FOR PAINT

Charlotte Historic

District Commission

Submittal

4' - 9"

1X2 FRIEZE BOARD

5' - 6"

WOOD T&G SOFFIT - STAIN FINISH

08/14/15

DOUBLE-HUNG WOOD WINDOW

RAILING

COLUMN BASE TRIM TO MATCH

COLUMN FINISH

5 1/2"

INTERIOR SPACE

1 1/2"

2X6 WOOD TOP RAIL, PAINT FINISH

ALIGN BELOW ROWLOCK COPING

REVISIONS

3/4"

NO.

DESCRIPTION

DATE

ROWLOCK BRICK MASONRY

COPING

(2) 2X4 WOOD RAILS, PAINT FINISH

0' - 4"

3 1/2"

2X4 WOOD PICKET, PAINT FINISH

B

0' - 6"

3' - 4"

2' - 5"

PAINTED WOOD RAILING

STAINED LIGHTWEIGHT CONCRETE

SLAB ON WOOD FRAMING, SLOPE 1/4"

PER FT MIN

ROWLOCK BRICK MASONRY

COPING

B

BUILDING SECTIONS /

DETAILS

A

A3.01

2" MIN CLR

7' - 0"

3 1/2"

Level 1

0"

VARIES PER GRADE

(2) 2X4 WOOD RAILS, PAINT FINISH

8/3/2015 8:08:24 PM

1A

Level 1

0"

BRICK MASONRY - RUNNING

BOND

Wall Section - Typical at Porch

3/4" = 1'-0"

5A

PORCH COLUMN ELEVATION

3/4" = 1'-0"

A

1

2

3

4

5

6

@ 2015 505DESIGN, INC

Garage Door Example

Railing and Fence Example

McCollum Residence

Charlotte Historic District Commission Exhibits - 08/12/15

P1

IN HEAD-TO-HEAD

COMPETITION,

IT’S NO CONTEST.

MIRATEC VS HARDBOARD/FIBER AND OSB TRIM

• MiraTEC is not laminated.

• MiraTEC has greater moisture resistance which means

better long term performance.

• MiraTEC performs up to 9 times better in Weatherability

Testing, which evaluates a product’s ability to withstand

exposure to the elements over time. See chart at right.

• MiraTEC has a more authentic wood grain texture.

• MiraTEC accepts all shades of paint beautifully.

• MiraTEC is not prone to thermal expansion.

• MiraTEC is made from sustainable materials and

renewable resources.

• MiraTEC costs up to 50% less.

No other trim

performs like MiraTEC.

Anyone can talk performance.

MiraTEC proves it.

>> Resists moisture, rot and termites.

resistant: As measured by

4 Moisture

q

ASTM D1037 for Water Absorption and

Thickness Swelling.

4 Rot resistant: Tested per AWPA E16 Field

q

>> Reversible with clear cedar wood grain

texture on one side and smooth on

the other.

>> Easy to handle, machine, cut and nail.

>> Won’t check, split or crack.

>> Cuts consistently due to uniform

product density.

>> Primed with an ultra-low VOC primer

containing a mildewcide.

IN HEAD-TO-HEAD

COMPETITION,

IT’S NO CONTEST.

PERCENTAGE RESIDUAL CALIPER SWELL

40

30

20

10

WEATHERABILITY TESTING PROVES

MIRATEC PERFORMS BETTER THAN

HARDBOARD/FIBER AND OSB TRIM

30

4

MIRATEC VS PVC TRIM

• MiraTEC has a more authentic wood grain texture.

• MiraTEC accepts all shades of paint beautifully.

• MiraTEC is not prone to thermal expansion.

• MiraTEC is made from sustainable materials and

renewable resources.

• MiraTEC costs up to 50% less.

>> Resists moisture, rot and termites.

resistant: As measured by

4 Moisture

q

ASTM D1037 for Water Absorption and

Thickness Swelling.

4 Rot resistant: Tested per AWPA E16 Field

q

>> Won’t check, split or crack.

>> Cuts consistently due to uniform

product density.

>> Primed with an ultra-low VOC primer

containing a mildewcide.

26.3%

25

20

15

11.6%

10

5

0

2.7%

4/4 MIRATEC

10.3%

4/4 LP

SMARTSIDE

TRIM

4/4 COLLINS

REVERSIBLE PINE

FIBER

TRUWOOD

(HARDBOARD) TRIM

4/4 LP

SMARTSIDE

TRIM

SINGLE-FACED

CEDAR

(OSB)

SOURCE: Test performed by FPINNOVATIONS

For test details email miratec-testdetails@jeld-wen.com.

Building code compliant

(ESR-3043): MiraTEC is the

first and only wood composite

trim to earn an evaluation report

(ESR-3043) from ICC-ES.

Anyone can talk performance.

MiraTEC proves it.

>> Easy to handle, machine, cut and nail.

FIBER

CEMENT

48 HOURS

Preservatives by Field Tests with Stakes.

No other trim

performs like MiraTEC.

>> Reversible with clear cedar wood grain

texture on one side and smooth on

the other.

MIRATEC

4 Termite resistant: Tested per AWPA E7

q

Standard Method of Evaluating Wood

MIRATEC ABSORBS LESS WATER

THAN FIBER CEMENT TRIM

PERCENTAGE RESIDUAL CALIPER SWELL

50

40

30

20

10

MIRATEC

FIBER

CEMENT

24 HOURS

MIRATEC

FIBER

CEMENT

48 HOURS

SOURCE: Test performed by Stork Twin City Testing Corporation. For test details email miratec-testdetails@jeld-wen.com.

PERCENTAGE RESIDUAL CALIPER SWELL

• MiraTEC is not laminated.

• MiraTEC has greater moisture resistance which means

better long term performance.

• MiraTEC performs up to 9 times better in Weatherability

Testing, which evaluates a product’s ability to withstand

exposure to the elements over time. See chart at right.

FIBER

CEMENT

24 HOURS

MIRATEC VS FIBER CEMENT TRIM

MIRATEC VS HARDBOARD/FIBER AND OSB TRIM

MIRATEC

Test for Evaluation of Wood Preservatives to

be Used Out of Ground Contact: Horizontal

Lap-Joint Method.

• MiraTEC has a more authentic wood grain texture.

• MiraTEC is reversible.

• MiraTEC is highly resistant to moisture. Independent tests show

fiber cement absorbs five times more water (ASTM 24 - Hour

Soak Test). See chart at right.

• MiraTEC is 100% silica free. Cutting fiber cement releases silica,

a known carcinogen.

• MiraTEC is not brittle or difficult to stack.

• MiraTEC is as easy to handle, cut and nail as wood, requires no

special tools.

• MiraTEC is available in widths up to 16” and lengths of 16’,

takes less time and labor to install.

• MiraTEC is backed by a 50-year limited warranty.

Most fiber cement has a 15-year limited warranty.

• MiraTEC costs up to 30% less.

MIRATEC VS PRIMED WOOD TRIM

• MiraTEC has none of wood’s frustrating

drawbacks.

• MiraTEC doesn’t require significant

maintenance and replacement, because it

resists moisture, rot and termites. Primed

wood may be treated, but many do not offer

rot and termite protection.

• MiraTEC is a more advanced, engineered

material.

• MiraTEC offers consistent density.

• MiraTEC won’t warp, split or check over time.

• MiraTEC is one solid piece. Primed wood is

normally finger jointed to make longer lengths

and edge glued to make the width - with a

limited warranty on the glue joints.

MIRATEC VS PVC TRIM

50

SOURCE: Test performed by Stork Twin City Testing Corporation. For test details email miratec-testdetails@jeld-wen.com.

PERCENTAGE RESIDUAL CALIPER SWELL

MIRATEC VS PRIMED WOOD TRIM

• MiraTEC has none of wood’s frustrating

drawbacks.

• MiraTEC doesn’t require significant

maintenance and replacement, because it

resists moisture, rot and termites. Primed

wood may be treated, but many do not offer

rot and termite protection.

• MiraTEC is a more advanced, engineered

material.

• MiraTEC offers consistent density.

• MiraTEC won’t warp, split or check over time.

• MiraTEC is one solid piece. Primed wood is

normally finger jointed to make longer lengths

and edge glued to make the width - with a

limited warranty on the glue joints.

MIRATEC ABSORBS LESS WATER

THAN FIBER CEMENT TRIM

MIRATEC VS FIBER CEMENT TRIM

• MiraTEC has a more authentic wood grain texture.

• MiraTEC is reversible.

• MiraTEC is highly resistant to moisture. Independent tests show

fiber cement absorbs five times more water (ASTM 24 - Hour

Soak Test). See chart at right.

• MiraTEC is 100% silica free. Cutting fiber cement releases silica,

a known carcinogen.

• MiraTEC is not brittle or difficult to stack.

• MiraTEC is as easy to handle, cut and nail as wood, requires no

special tools.

• MiraTEC is available in widths up to 16” and lengths of 16’,

takes less time and labor to install.

• MiraTEC is backed by a 50-year limited warranty.

Most fiber cement has a 15-year limited warranty.

• MiraTEC costs up to 30% less.

WEATHERABILITY TESTING PROVES

MIRATEC PERFORMS BETTER THAN

HARDBOARD/FIBER AND OSB TRIM

30

26.3%

25

20

15

11.6%

10

5

0

2.7%

4/4 MIRATEC

4/4 LP

SMARTSIDE

TRIM

4/4 COLLINS

REVERSIBLE PINE

FIBER

TRUWOOD

(HARDBOARD) TRIM

10.3%

4/4 LP

SMARTSIDE

TRIM

SINGLE-FACED

CEDAR

(OSB)

SOURCE: Test performed by FPINNOVATIONS

For test details email miratec-testdetails@jeld-wen.com.

Test for Evaluation of Wood Preservatives to

be Used Out of Ground Contact: Horizontal

Lap-Joint Method.

4 Termite resistant: Tested per AWPA E7

q

Standard Method of Evaluating Wood

Preservatives by Field Tests with Stakes.

4

Building code compliant

(ESR-3043): MiraTEC is the

first and only wood composite

trim to earn an evaluation report

(ESR-3043) from ICC-ES.

Miratec Product Information

McCollum Residence

Charlotte Historic District Commission Exhibits - 08/12/15

P2

MiraTEC Trim Outperforms Hardboard Trim

MiraTEC trim earned ESR-3043 and performs to a standard that hardboard products can’t – MiraTEC is not hardboard trim.

Treated Wood Composite Trim

Hardboard Trim

Brands

MiraTEC

LP SmartSide Trim Reversible Fiber (Hardboard),

Collins Pine TruWood Trim

Manufacturing

Process

TEC™ patented and proprietary manufacturing process

was created specifically to make trim.

TEC manufacturing process creates an engineered wood

product with uniform density.

MiraTEC is one solid piece – will not delaminate.

Made in a sealed press with steam injected for added

durability.

Hardboard manufacturing process was created

to manufacture exterior siding.

Hardboard manufacturing process may create a

product with variable density.

Hardboard trim may be manufactured by

laminating thinner panels together to create trim

thicknesses – may delaminate over time.

Made in an open press between heated platens.

Durability

Easy to handle, machine, cut and nail.

Won’t check, split or crack.

Treated with zinc borate for superior termite resistance.

Made with phenolic resins for excellent moisture resistance.

More authentic wood grain texture.

Easy to handle, machine, cut and nail.

May delaminate.

MiraTEC trim earned an evaluation report (ESR-3043)

from ICC-ES. MiraTEC meets the strict requirements of

ICC-ES Acceptance Criteria (AC424). Hardboard trim

cannot meet those requirements. This new evidence

supports the claim that MiraTEC is a worry-free product

with incredible durability and a strong 50-year warranty.

Hardboard trim does not have a building code

listing.

MiraTEC trim has no

added urea formaldehyde.

This is certified by

Scientific Certification

Systems under certificate number SCS-MC-01802.

Varies by brand.

Building Code

Approved/Listed

Green

®

LP SmartSide Trim Reversible Fiber (Hardboard)

and Collins Pine TruWood Trim are laminated in

all thicknesses.

Less authentic wood grain texture.

Hardboard trim cannot perform to the standards

in ESR-3043.

Made from sustainable materials. No old growth wood is

used in the manufacture of MiraTEC trim.

Complies with CARB.

MiraTEC trim is factory-primed on four sides with a low

VOC primer containing a mildewcide.

Contributes to industry green building programs such as LEED.

Warranty

Backed by an industry-best 50-year warranty.

Protects against hail damage, rot, termite

damage and edge swell.

R 20827

Surface Burning Characteristics

Flame Spread 120

Smoke Developed 90

miratectrim.com

Warranty coverage varies from 10 to 50 years

by brand.

LP SmartSide Trim Reversible Fiber (Hardboard)

warranty excludes hail damage, termite damage

and swelling and/or edge checking.

© 2013 CraftMaster Manufacturing, Inc. All rights reserved. All

trademarks and service marks (registered and unregistered)

shown are owned by or licensed to CraftMaster Manufacturing,

Inc. or its affiliates.

Covered by one or more of the following patents: 5,677,369;

4,726,881; 5,980,798; 6,030,562; 5,993,709.

159 8/13

Miratec Product Information

McCollum Residence

Charlotte Historic District Commission Exhibits - 08/12/15

P3

MiraTEC Trim Performs 9x Better

than Hardboard Trim in Long Term

Weatherability Testing

• MiraTEC performed 4.29 times better than LP SmartSide Trim (Reversible Fiber, which is a hardboard product).

• MiraTEC performed 9.4 times better than Collins Pine TruWood Trim.

Residual Swell (%)

30

26.3%

percentage residual caliper swell

25

20

15

11.6%

10

5

0

2.7%

4/4 MiraTEC

4/4 LP SmartSide

Trim Reversible

Fiber (Hardboard)

4/4 TruWood

Trim

Test Objective

The Weatherability Test, a known standard in wood and composite product testing, evaluates a product’s ability

to withstand climate change. It is performed in accordance with ANSI A 135.6 (2006). It is meant to show a

product’s response to real-world weather conditions that assess durability in hot summers, cold winters and

rainfall.

Test Protocol

All trim samples used in the test were subject to six (6) cycles of exposure to: soak, steam, freeze, dry, steam

again and dry again. All samples tested were nominal 4/4 thickness. The MiraTEC 4/4 product measures a

full ¾.” The LP SmartSide 400 Series Trim (reversible fiber, which is a hardboard product) is a scant product,

meaning it measures 5/8” instead of the standard.

Test

Measurement

Results are calculated by the residual, or remaining, thickness swell of the trim. A trimboard exhibits thickness

swelling when exposure to exterior conditions breaks down the resin bonds within the trim, leading to water

absorption. The thickness of the sample is calculated at the beginning and at the end of the test.

Test Agency

Test performed by FPInnovations (formerly Forintek). Email miratec-testdetails@jeld-wen.com.

Miratec Product Information

McCollum Residence

Charlotte Historic District Commission Exhibits - 08/12/15

P4

Miratec Product Information

McCollum Residence

Charlotte Historic District Commission Exhibits - 08/12/15

P5

Andersen 400 Series Window Product Information:

Alternate product = Pella 450 Series

McCollum Residence

Charlotte Historic District Commission Exhibits - 08/12/15

P6

Andersen 400 Series Window Product Information:

Alternate product = Pella 450 Series

McCollum Residence

Charlotte Historic District Commission Exhibits - 08/12/15

P7

Andersen 400 Series Window Product Information:

Alternate product = Pella 450 Series

McCollum Residence

Charlotte Historic District Commission Exhibits - 08/12/15

P8

Andersen 400 Series Window Product Information:

Alternate product = Pella 450 Series

McCollum Residence

Charlotte Historic District Commission Exhibits - 08/12/15

P9