Energy

advertisement

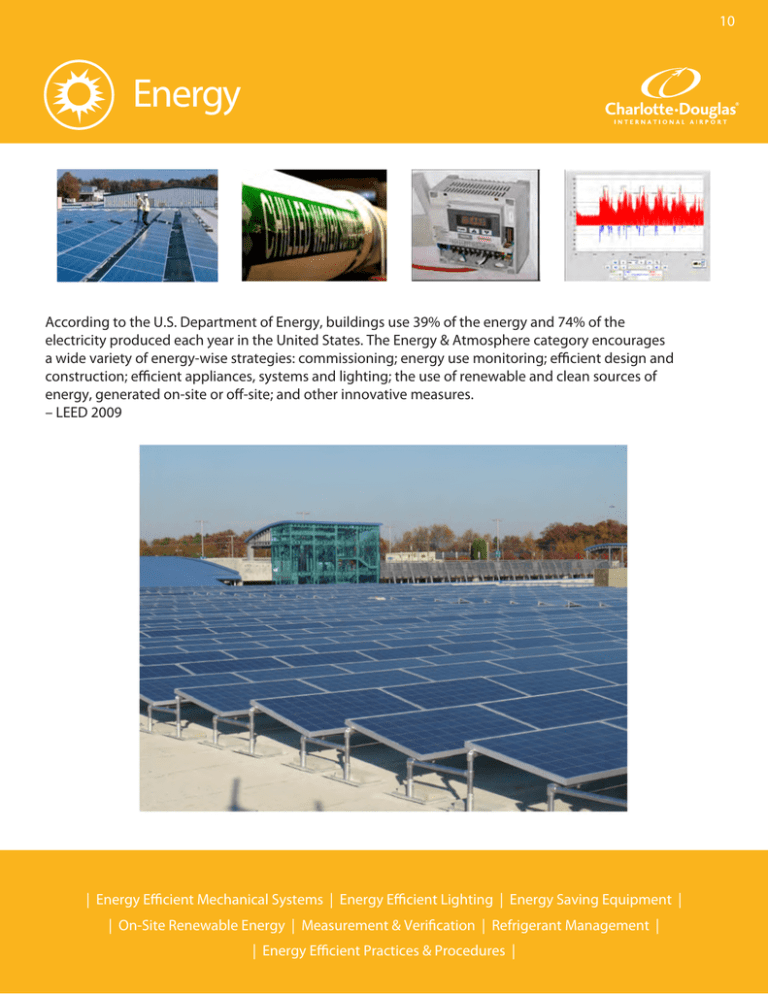

10 Energy According to the U.S. Department of Energy, buildings use 39% of the energy and 74% of the electricity produced each year in the United States. The Energy & Atmosphere category encourages a wide variety of energy-wise strategies: commissioning; energy use monitoring; efficient design and construction; efficient appliances, systems and lighting; the use of renewable and clean sources of energy, generated on-site or off-site; and other innovative measures. – LEED 2009 | Energy Efficient Mechanical Systems | Energy Efficient Lighting | Energy Saving Equipment | | On-Site Renewable Energy | Measurement & Verification | Refrigerant Management | | Energy Efficient Practices & Procedures | 11 SUSTAINABILITY PROJECTS Profile Sheet Variable Frequency Drives Project Overview Per the U.S Department of Energy, about 50% of U.S. electricity for businesses flows through motors. To help reduce its energy footprint, CLT is constantly working on phasing out all single speed drives and replacing them with variable frequency drives (VFD’s). A VFD is a system for controlling the rotational speed of an alternating current electric motor by controlling the frequency of the electrical power supplied to the motor. VFD’s are widely used in ventilation systems for large buildings to save energy by allowing the volume of air moved to match the system demand. They allow the Airport to program the air handling unit motors to slow down when the space setpoint is met. The traditional energy inefficient designs allowed the motors to run at 1800 RPM’s with the inlet vanes on the fans to regulate the air flow. Fast Facts Start Date.............................................................................................. 2005 Completion Date....................................................................... Ongoing Updated...................................................................................... 7/10/2012 Location......................................................................................... Terminal Environmental Benefit.................................... Energy use reduction Industry Standards LEED.................................................................. 2009 O&M - EA Credit 1 IgCC....................................................................................... Section 606.6 SAM................................................................................................. O&M 3.4 IECC.............................................................................. Section C403.2.10 Project Notes Manufacturer................................................................................ Yaskawa Use........................................................................................................... 24/7 Benefits of VFD’s • Energy savings • Extended equipment life • Reduced maintenance • Tighter process control Global Initiative #: 20 Focus Area: 12 CLT’s Commitment to Sustainability: Identify and pursue fiscally responsible practices and strategies that minimize environmental impacts to achieve a sustainable enterprise for the benefit of the region. 5501 Josh Birmingham Parkway Charlotte, NC 28208 moving towards a sustainable future P.O. Box 19066 Charlotte, NC 28219 P 704.359.4000 F 704.359.4030 T 1.800.FLY.CDIA cltairport.com 12 SUSTAINABILITY PROJECTS Profile Sheet Metasys Software Project Overview There was a need to trend building energy usage and the Airport suggested that Johnson Controls, a diversified technology firm, offer CLT monitoring software to help achieve this goal. The result was the installation of the ADX server and Metasys v 6.0. This ADX server can receive wireless signals from devices, controller and temp sensors which will allow for less expensive office upfits. The data storage on the server allows for endless point monitoring for a long term history of space conditions. The Airport can also issue unique passwords in for each operator with varying levels of system access. Benefits of BAS & Monitoring • Good control of internal comfort conditions • Increased staff productivity • Effective monitoring and targeting of energy consumption • Effective response to HVAC-related complaints • Central or remote control and monitoring of building • Increased level of comfort and time saving • Ease of information availability problem • Early detection of problems • More satisfied occupants Fast Facts Start Date................................................................................... May 2011 Completion Date................................................ July 2011 & Ongoing Updated..................................................................................... 7/10/2012 Location................................................................................ Concourse A Environmental Benefit........................................ Reduce energy use Industry Standards LEED............................................................... 2009 O&M - EA Credit 3.1 IgCC.................................................................................... Section 603.2.1 SAM.............................................................................................. O&M 3.6.1 IECC.................................................................................... Not Applicable Project Notes Provider.......................................................................................... Metasys Use........................................................................................................... 24/7 . Global Initiative #: 24 Focus Area: 6 CLT’s Commitment to Sustainability: Identify and pursue fiscally responsible practices and strategies that minimize environmental impacts to achieve a sustainable enterprise for the benefit of the region. 5501 Josh Birmingham Parkway Charlotte, NC 28208 moving towards a sustainable future P.O. Box 19066 Charlotte, NC 28219 P 704.359.4000 F 704.359.4030 T 1.800.FLY.CDIA cltairport.com 13 SUSTAINABILITY PROJECTS Profile Sheet High Efficiency Chillers Project Overview With the expansion of E-Concourse, the Airport decided to incorporate energy efficient centrifugal chillers. The facilities maintenance staff collaborated with the design firm to specify centrifugal chillers instead of traditional heat recovery chillers. A centrifugal chiller utilizes the vapor compression cycle to chill water and reject the heat collected from the chilled water and the heat from the compressor to a second water loop cooled by a cooling tower. A standard heat recovery chiller will consume 0.7 KW/ton, yet only provide 110 degree water for reheat purposes and manage the load by opening and closing the inlet vane to load and unload the machine. The new centrifugal chillers will use variable frequency drives (VFD’s) to load and unload the machine as opposed to an inlet vane. This allows for further energy savings. CLT realized that chiller efficiency improvement offers a substantial and cost-effective means to reduce greenhouse gas emissions for the largest use of electricity in commercial buildings. The refrigerant selection also influences both the attainable efficiency and the direct action of releases as greenhouse gases. The new chillers will operate on R-134a, an environmentally friendly refrigerant. Fast Facts Start Date................................................................................... June 2011 Completion Date.............................................................. October 2011 Updated..................................................................................... 7/10/2012 Location............................................................................... East Terminal Environmental Benefit......................................... R-134A Refrigerant Industry Standards LEED...................................................................... 2009 NC - EA Credit 4 IgCC....................................................................................... Section 606.1 SAM.................................................................................................. D&C 4.4 IECC....................................................................................... Section C 403 Project Notes Provider............................................................. York/Johnson Controls Total System Size............................................................ 0.3KW per ton .... . CLT Centrifugal Chillers • Operate at 0.3 KW/ton cooling capacity • Contain VFD’s • Use R-134a refrigerant • Low maintenance • Reliability • Quiet operation Global Initiative #: 20 Focus Area: 4 CLT’s Commitment to Sustainability: Identify and pursue fiscally responsible practices and strategies that minimize environmental impacts to achieve a sustainable enterprise for the benefit of the region. 5501 Josh Birmingham Parkway Charlotte, NC 28208 moving towards a sustainable future P.O. Box 19066 Charlotte, NC 28219 P 704.359.4000 F 704.359.4030 T 1.800.FLY.CDIA cltairport.com 14 SUSTAINABILITY PROJECTS Profile Sheet Rooftop Solar Project Project Overview As part of CLT’s efforts to become more energy independent and sustainable, a rooftop Solar Photovoltaic (PV) system was installed on the roof of the CLT Center, which houses the bulk of the Aviation Department’s operations and employees. Photovoltaics are a solar power technology that convert sunlight into electricity that can be used to power a building. This particular system generates enough electricity to power 30-40% of the CLT Center. • Installed 10/1/2010 • Started generating power on 12/29/2010 • Designed, funded, built and commissioned by NARENCO • The panels generate power (during daylight hours) that feeds into a grid operated by Duke Energy. • NARENCO owns the solar panels for 20 years, allowing CLT to save on installation and maintenance costs. • The panels are leased to CLT for 20 years. • NARENCO is receiving a federal tax credit. • In exchange, CLT is receiving renewable energy credits (REC). • CLT is selling these REC’s to Duke Energy. • CLT has the option to purchase the PV system at its depreciated value at years 6, 10, 15, or 20 . • The panels’ estimated life expectancy is a little more than 25 years. • If the project is successful, CLT may expand to other solar projects. • Future solar projects may include the top of concourses, parking decks and the remainder of CLT Center’s rooftop. • For educational purposes, digital display monitors will be placed in the terminal with current energy production of the panels for passengers to view. • Denver, San Francisco, Long Beach, Oakland and Austin-Bergstrom airports utilize solar technology. Fast Facts Start Date................................................................................... 10/1/2010 Completion Date................................................................... 12/29/2010 Updated...................................................................................... 7/10/2012 Location.................................................................................... CLT Center Environmental Benefit............................. 312 tons of CO2 avoided Industry Standards LEED.................................................................. 2009 O&M - EA Credit 4 IgCC....................................................................................... Section 610.2 SAM................................................................................................ O&M 3.7 IECC.................................................................................... Section C406.4 Project Notes Provider...................................................................................... NARENCO Total System Size.......................................................................... 235 KW Total Number of Panels................................. 1330, 230-Watt Panels Mounting Type........................................................................... Roof Top Total System Square Footage........................................ 38,000 Sq.Ft. Annual Power Production.......................................... 395 MWh/Year Homes that can be powered each year......................................... 60 Cars off the road equivalent....................................................... 13,825 Global Initiative #: 23 Focus Area: 2 CLT’s Commitment to Sustainability: Identify and pursue fiscally responsible practices and strategies that minimize environmental impacts to achieve a sustainable enterprise for the benefit of the region. 5501 Josh Birmingham Parkway Charlotte, NC 28208 moving towards a sustainable future P.O. Box 19066 Charlotte, NC 28219 P 704.359.4000 F 704.359.4030 T 1.800.FLY.CDIA cltairport.com