Research Journal of Applied Sciences, Engineering and Technology 4(14): 2176-2182,... ISSN: 2040-7467

advertisement

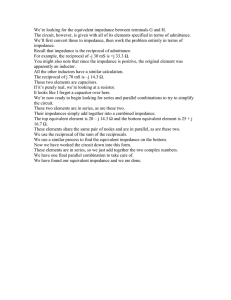

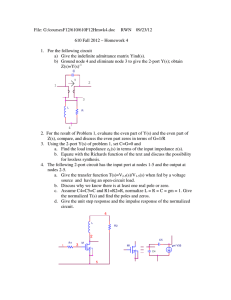

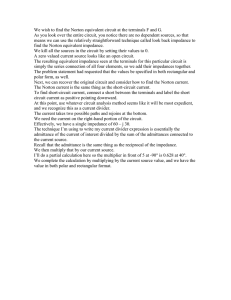

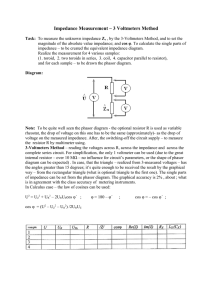

Research Journal of Applied Sciences, Engineering and Technology 4(14): 2176-2182, 2012 ISSN: 2040-7467 © Maxwell Scientific Organization, 2012 Submitted: March 07, 2012 Accepted: April 04, 2012 Published: July 15, 2012 On Characterization and Equivalent Circuit of Triple-Layer Piezoelectric Element in Thickness Vibration Mode Li-Jiao Gong, Min Lu, Zhi-Chao Zhang and Xihuizi Liang Mechanical and Electrical Engineering College, Shihezi University, Shihezi 832003, China Abstract: This study presents the fabrication of triple-layer piezoelectric vibrator and analyzes its electrical impedance. The characterization of the electrical impedance and equivalent circuit of the triple-layer piezoelectric element in thickness vibration mode is discussed. The dielectric, elastic, piezoelectric and electro mechanical coupling constants (kt) of the samples were evaluated from the experimental impedance data. A simple but practical equivalent circuit expressed using only the electrical parameters of triple-layer piezoelectric vibrator, was explored. Analysis based on this equivalent circuit can provide a good understanding of the behavior of triple-layer piezoelectric vibrators as a function of frequency in the thickness mode. This will in turn aid the design and analysis of piezoelectric transducers. Key words: Ctrical impedance characterization, ele, equivalent circuit models, piezoelectric vibrator, PZT INTRODUCTION Piezoelectric materials are the most widely used functional materials in smart structures. They have many outstanding advantages that make them suitable for use in transducers. These include small dimensions, simple structures, low noise factors, excellent mechanicalelectrical coupling characteristics and frequency response characteristics. These permit them broad applications in the generation, damping and conversion of vibrations into electrical energy and vice versa. Some novel devices based on piezoelectric materials have been developed in recent years for a wide range of electromechanical applications (Steven et al., 2007; Shenck and Paradiso, 2001). The potential of triple-layer piezoelectric element in energy harvesting applications has been investigated through experiments (Li-jiao and Xing, 2010). Because the electrical signals are involved in most piezoelectricbased systems, a good understanding of the electrical characteristics of piezoelectric materials is essential to the design and analysis of these systems. It is therefore desirable to build an equivalent circuit for piezoelectric materials. On the one hand, the impedance properties of the piezoelectric resonator can be represented by a lumpedparameter equivalent circuit. The Van Dyke circuit model is widely used to represent the equivalent circuit of lossless piezoelectric vibrators (Martin, 1954) and is recommended by the IEEE Standard on Piezoelectricity (1987). Sherrit et al. (1997) have used complex circuit parameters to describe an improved equivalent circuit model for an unloaded piezoelectric resonator in thickness mode: by treating the elements of the circuit as complex quantities, the losses of the piezoelectric resonator were taken into account (Sherrit et al., 1997). Mingjie and Liao (2004) proposed a kind of real lumped-parameter circuit using resistance values to represent energy loss. On the other hand, the impedance properties of the piezoelectric resonator can be calculated from the materials point of view. Some researchers have deduced the equation for electrical impedance at thickness extensional piezoelectric lossless resonance (Stewart and Binu, 2007). In the derivation of the equation, the material constants were assumed to be real. Several researchers have used complex material constants in the function of impedance to fit impedance spectrum and found these to have better agreement with experimentally measured curves (IEEE Standard on Piezoelectricity, 1987). In our previous study, we investigated (Li-jiao and Xing, 2010) such a complex model near an isolated resonance in piezoelectric thickness mode; Triple-layer piezoelectric elements often study as flexural piezoelectric vibrators. For this reason, we also (Li-Jiao and Jiang-Quan, 2011) investigated the equation for the equivalent admittance for the symmetrical triple-layer flexural piezoelectric vibrators. The purpose of this investigation is to determine under what circumstances piezoelectric resonators in thickness mode can be made to vibrate and under what circumstances piezoelectric resonators undergo bending vibration. In this study, the equivalent circuit of the triple-layer piezoelectric vibrator in frequencies of several modes of vibration at thickness extensional resonance is discussed. We evaluate the best methods to determining the parameters that characterize the electrical model of the Corresponding Author: Li-Jiao Gong, Mechanical and Electrical Engineering College, Shihezi University, Shihezi 832003, China 2176 Res. J. Appl. Sci. Eng. Technol., 4(14): 2176-2182, 2012 triple-layer piezoelectric vibrator in the thickness mode. A triple-layer piezoelectric element made of PZT was fabricated and its impedance properties were characterized and studied. The dielectric, elastic, piezoelectric, constants and the electromechanical coupling constants (kt) of the samples will then be extracted from the impedance data obtained from these fabricated devices. MATERIALS AND METHODS Sample preparations: The structure of the triple-layer piezoelectric element is illustrated as a piezoelectricmetal-piezoelectric sandwich structure in Fig. 1. It was made of a metal layer covered symmetrically by two transversely piezoelectric layers poled along the thickness direction. The piezoelectric material was lead Zirconate Titanate (PZT) (P-51, Haiying Enterprise Group Co. Ltd) and the metal elastic layer was beryllium bronze for its larger elastic modulus. The two piezoelectric layers were bonded to the non-piezoelectric layer with polymeric epoxy bonding materials and then cured at a temperature of 80ºC for 2 h. The overall design of insulation was carefully considered to prevent current leakage. The geometric dimensions of the specimens measured are given in Table 1 (length l, width w and thickness t). Key material parameters are listed in Table 2. Impedance measurements: An impedance analyzer (Agilent 4294A) was used to measure and record the impedance data and spectrum. The electrical impedance measurements are performed with sweep voltage level in the impedance analyzer set to 500 mV and sweeping frequency signal in the 40Hz-10 kHz range. The upper bound of the frequency range was set to 10 kHz so that the bandwidth is wide enough to cover all possible resonance frequencies of the specimens. The end of the sample with leads was clamped in the vertical direction, while the other end was left free. The leads were connected to the Agilent 4294A by the 42941A probe kit. The schematic view of the impedance measurement setup is shown in Fig. 2. A personal computer was used to calculate the circuit constants and the material parameters. Retrospection on the theory of representing electrical impedance curves of piezoelectric materials: The equation for the electrical impedance described by IEEE Std. 176-1987: IEEE Standard on Piezoelectricity (1987) for the impedance equation for analyzing ideal lossless piezoelectric materials in the thickness resonance mode is given as follows: Z (ω ) = t s iAωε33 (1 − kt2 tan[ω / (4 f p )] ω / (4 f p ) ) (1) Table 1: Physical dimensions of the sample Dimension lp wp tp lm Size (mm) 33 14 0.4 63 wm 14 tm 0.3 Table 2: Properties of the piezoelectric and beryllium bronze Property Symbol Value Displacement coefficient [×10G12C / N] d33 400 gT33 2100 Relative dielectric constant 9.0 Elastic compliances constant [×10G12m2 / N] SD33 3 3 Dp 7.45 Density of piezo material [×10 kg / m ] 1.30 Young’s modulus of bronze [×1011N / m2] E Dm 8.23 Density of bronze [×103kg / m3] Fig. 1: Schematic drawing of the triple-layer piezoelectric bender: 1: Piezoelectric material layer; 2: Metal material; 3: Thin film electrodes; 4: Condutive adhesive layer; p: The direction of polarization Fig. 2: Schematic view of the impedance measurement Here, t is the sample thickness, A is the electrode area, kt is the thickness electromechanical coupling constant, gS33 is the clamped dielectric permittivity and fp is the parallel resonance frequencies at which the real parts of the impedance have a maximum. The parameters kt, gS33 and fp were originally assumed to be real numbers in the derivation of the resonator in Eq. (1). Sherrit et al. (1997) and Kin et al. (1997) considered the constants kt, gS33 and fp to be complex numbers in order to account for the dielectric, elastic and piezoelectric losses (Sherrit et al., 1997). The coupling factor can be determined from frequencies fs and fp in (1) as follows: kt2 = π fs 2 fp tan( π f p − fs 2 fp ) (2) The equivalent circuit with lumped circuit parameters: The Van Dyke circuit model, as shown in Fig. 3a, is widely used to represent the impedance properties of piezoelectric excited vibrators near isolated resonance by a lumped-parameter equivalent circuit (Sherrit et al., 1997; IEEE Standard on Piezoelectricity, 2177 Res. J. Appl. Sci. Eng. Technol., 4(14): 2176-2182, 2012 L1 = 1 4π 2 f S2C1 (6) The complex parallel and series resonance frequencies of the circuit shown in Fig. 3b can be calculated using Eq. (7) and (8): fs = Fig. 3: The impedance properties of a piezoelectrically excited vibrator can be represented near an isolated resonance by a lumped-parameter equivalent circuit, (a) The Van Dyke circuit model: The values of the circuit elements are real, (b) A complex circuit with three complex parameters 1987). The Van Dyke model uses four real circuit parameters, C0, C1, L1 and R1, to represent the impedance of a free-standing piezoelectric resonator around resonance. This is recommended by the IEEE standard on piezoelectricity. The close proximity in frequency of several modes of vibration may be represented by adding additional R-L-C branches in parallel to the R1-L1-C1 branch shown. The motional resistance R1 in the equivalent circuit represents the mechanical dissipation of the piezoelectric resonator. The motional inductance L1 in the equivalent circuit represents the inertia of the piezoelectric resonator. The motional resistance C1 is relevant to the spring constant of the piezoelectric vibrator. Complex circuit model as proposed by Sherrit et al. (1997): Sherrit et al. (1997) proposed the complex circuit model shown in Fig. 3b Kin et al. (1997). The model contains three circuit elements, C0, C1 and L1, which are defined as complex. It takes into account the dielectric, elastic and piezoelectric losses of piezoelectric material. The model applies to unloaded piezoelectric resonators in the thickness, thickness shear and length extensional modes. According to Sherrit’s theory, the circuit parameters can be expressed as functions of the material constants as shown in formulas (3)-(6). Thus the material constants can be extracted by solving these equations, if the circuit parameters are known: C0 + C1 = C1 = C0 = s ε33 A/t 1 − kt2 2 2 s ε33 A / t f p − fs 1 − kt2 s ε33 A/t 1 − kt2 f p2 − C1 1 fp = 2π L1 C1C0 C1 + C0 (7) (8) Once the complex frequencies fs and fp are calculated, the electromechanical coupling constant kt can be determined from Eq. (2). The dielectric permittivity will take the following complex-valued form: S ε33 = (t / A) (1 − kt2 ) (C1 + C0 ) (9) Resonance equations in thickness mode: The electric field can be coupled to the mechanical stress in a material at a given frequency T by driving the material electrically at T (Stewart and Binu, 2007). The resonance equations can be derived from the constitutive equation, wave equation and boundary conditions. The resonance equations, then, can reflect the relationship between the physical dimension and material constants for the piezoelectric resonator and the frequency T. Consider a poled piezoelectric material plate of electrode area A and thickness t. If it is poled in parallel to the thickness direction and perpendicular to the electrode planes and its lateral dimensions are much larger than its thickness, then the thickness mode impedance equation is given as a function of the frequency T as follows (Stewart and Binu, 2007): ⎛ ⎛ ρ ⎞⎟ ⎞⎟ ⎜ tan⎜⎜ tπ f D ⎟⎟ ⎜ c33 ⎝ ⎠ t ⎜ 1 − kt2 ⎟ Z (ω ) = s ⎜ ⎟ iAωε33 ρ tπ f ⎜ ⎟ D ⎜ ⎟ c33 ⎝ ⎠ (10) where, kt2 is defined as: (3) (4) 1 2π L1C1 s D 2 kt2 = e33 / (ε33 c33 ) (11) where, e33 is the piezoelectric stress constant. The elastic stiffness cD33 may be determined by measurement of fpi IEEE Standard no. 177 (1966): (5) D c33 = 4 ρ ( f pi t / i ) 2 2178 (12) Res. J. Appl. Sci. Eng. Technol., 4(14): 2176-2182, 2012 model shown in Fig. 3a. Based on the model, we can fit the experimental impedance spectrum by choosing the values of the electronic components. The close proximity in frequency of several modes of vibration may be represented by adding additional R-L-C branches in parallel to the R1-L1-C1 branch as shown. We used a lumped Van Dyke’s model with three resonance circuits to fit the measured specimen. The impedance of the resonant circuits is as follows: 6 Impedance value (Ohm) 10 5 10 4 10 3 10 2 0 0 10 0 00 9 00 8 00 70 00 60 00 50 00 40 00 30 00 0 1 00 0 20 0 0 10 Z= Impedance phrase (degree) -20 -30 -40 (13) 1 iωCo + 1 R1 + i (ωL1 − 1 ωC1 + ) 1 R2 + i (ωL2 − 1 ωC2 + ) 1 R3 + i (ωL3 − 1 ωC3 ) -50 -60 -70 -80 0 900 10 000 0 800 70 00 60 00 50 00 40 00 0 100 0 200 0 30 00 -90 Fig. 4: Impedance and phase angle of the specimen vs. frequency. The magnitude of the impedance is plotted on a logarithmic scale against the frequency (top) and the impedance phase versus the frequency (bottom). The solid line is the measured curve of the impedance magnitude and phase of the specimen. The dash-dot line was generated using Eq. (13) fitted to the experimental data RESULTS AND DISCUSSION In order to evaluate the electrical impedance characteristics and the equivalent circuit of triple-layer piezoelectric transducers, we applied various previously described theories to generate impedance spectra. The dielectric, elastic, piezoelectric and the electromechanical coupling constants of the sample were evaluated from the impedance data. We compared the spectrum generated against measured spectra. The measured impedance results are shown as a solid line in Fig. 4. From this figure, we can divide the impedance curve into two parts, the resonant frequency portion and the non-resonant portion. We see that the experimental curves of the triplelayer piezoelectric transducer have three distinct resonance modes. Representation of the measured spectrum by the Van Dyke circuit model: For transducer applications, it is more practical to fit the impedance plots to lumped circuit models to fit the impedance curve in the vicinity of the resonant frequency and predict the electrical behavior of the resonator. We first consider the Van Dyke circuit The results for the impedance of the circuit model are shown as the dash-dot line in Fig. 4. When determining the values of the electronic components, the dominant component C0 should be first considered according to the impedance magnitude. After the value of C0 is chosen, the values of C1, C2 and C3 can be determined according to the appearance of the impedance spectrum around the appropriate resonance. The component Ci (i = 1, 2, 3) has significant effect on the total impedance in the vicinity of appropriate resonance frequency bandwidth. The value of the components Li (i = 1, 2, 3) is relevant to Ci (i = 1, 2, 3) and is considered according to the appropriate resonant frequency. The value of component Ri (i = 1, 2, 3) is adjusted according to impedance phase in the vicinity of the appropriate resonance frequency bandwidth. The values of parameters of the components are listed in Table 3. We can see that a lumped Van Dyke’s model with several resonances fit the experimental impedance magnitude well but does not agree with the impedance phase curve below the first resonant frequency within the non-resonant range. From the impedance phase response, we can see that the impedance phase curve within the non-resonant range is close to -90º but not equal to -90º. This means that the feature below the first resonant frequency cannot be considered pure capacitance but rather must be considered resistance capacitance. It is clear that there is little energy dissipation. The fit by complex circuit model: Sherrit et al. (1997) pointed out that the circuit model of a piezoelectric vibrator near an isolated resonance can be characterized by its complex material constants as shown in Fig. 3b. To model this piezoelectric structure, we used the complex circuit model shown in Fig. 5, in which the circuit elements Li and Ci are complex. The impedance of an isolated resonant circuit is defined as follows: 2179 Zn= sLn+1/(sCn), n=1, 2, 3, s = iT (14) Res. J. Appl. Sci. Eng. Technol., 4(14): 2176-2182, 2012 Fig. 5: The complex circuit model for the piezoelectric structure. The values of all the circuit element are complex numbers The total impedance can then be calculated using the following equation: Z(s) =1/(sC0+1/(Z1)+ 1/(Z2)+ 1/(Z3)) (15) To fit the experimental impedance spectrum, the method of parameter selection is similar to that used previously. However, the real value must be chosen before the imaginary value. The circuit constants for this simulation are listed in Table 3. The impedance of the 6 Impedance value (Ohm) 10 5 10 4 10 3 10 2 0 0 10 000 9 00 8 00 70 00 60 00 50 00 40 00 30 00 0 200 0 1 00 0 10 Frequency (Hz) 0 -10 -20 -30 -40 -50 -60 -70 0 900 10 000 0 800 70 00 60 00 40 00 50 00 0 -80 -90 100 0 200 0 30 00 Impedance phrase (degree) Table 3: Values of the components in the equivalent circuit and the material parameters of the sample. The various curves generated with these constants are shown in Fig. 4, 5, 6 and 7 Constant Value (real and imaginary) Van Dyke model C0 (F) 15.63×10G9 C1 (F) 0.368×10G9 L1 (H) 69.142 R1 (S) 39.219×103 C2 (F) 0.886×10-9 L2 (H) 3.571 R2 (S) 2.791×103 C3 (F) 0.563×10G9 L3 (H) 3.026 R3 (S) 5.913×103 Sherrit’s complex circuit model C0 (F) 16.065×10G9 (1-0.0168i) C1 (F) 0.368×10G9 (1-0.091i) L1 (H) 69.142 (1+0.035i) C2 (F) 0.886×10G9 (1-0.0466i) L2 (H) 3.571 (1+0.0191i) C3 (F) 0.563×10G9 (1-0.0419i) L3 (H) 3.026 (1+0.00131i) Resonance frequency fs1 (Hz) 995.06 + 2.7752i fp1 (Hz) 1006.4 + 2.7232i fs2 (Hz) 2827.2 + 3.8833i fp2 (Hz) 2904.2 + 3.7629i fs3 (Hz) 3852.6 + 7.8152i fp3 (Hz) 3919.6 + 7.7846i Material parameters gS33(FmG1) 3.805×10G8 (1-0.01643i) kt 0.1660 (1-0.0361i) D (kg/m3) 76710 CD33(N/m2) 3.7579×104 (1+0.0542i) Frequency (Hz) Fig. 6: Impedance and phase angle of the specimen vs. frequency. The magnitude of impedance is plotted on a logarithmic scale against the frequency (top) and the impedance phase versus the frequency (bottom). The solid line is the measured curves of the impedance magnitude and phase of the specimen. The dashed line was generated using Eq. (15) and the model shown as Fig. 5 complex circuit model is shown as the dashed line in Fig. 6. The response curves of the impedance value and phase of the specimen are shown as the solid line in Fig. 6. As shown in Fig. 6, the proposed complex circuit model, on the basis of Sherrit’s complex circuit model, is appropriate for the transducer within frequencies of several modes of vibration. However, we need further study on how to select suitable parameters. The fit obtained using the equation for electrical impedance described by IEEE Std. 176-1987: The frequencies of the complex numbers and complex material constants were calculated using (2), (8) and (9). The calculated material constants are listed in Table 3. We propose the Eq. (16) for the thickness mode in frequency of several modes of vibration. The predicted impedance spectra generated by the impedance function (16) are shown as the dotted line in Fig. 7. The fit is good away from resonance and poor near resonance. This indicates that the Eq. (16) can be used to describe the impedance characteristics. The material constants determine the 2180 Res. J. Appl. Sci. Eng. Technol., 4(14): 2176-2182, 2012 6 6 10 Impedance value (Ohm) Impedance value (Ohm) 10 5 10 4 10 3 10 5 10 4 10 3 10 2 0 10 000 0 0 0 00 100 9 00 8 00 0 7 00 0 0 0 40 0 6 00 0 30 0 Frequency (Hz) -45 -45 0 0 0 0 7 00 8 00 9 00 00 0 6 00 100 0 5 00 0 40 0 -85 -90 0 Frequency (Hz) -75 -80 0 0 9 00 10 0 00 0 8 00 70 00 60 00 40 00 50 00 20 0 0 30 00 1 00 0 -85 -90 -70 30 0 -75 -80 -55 -60 -65 0 -70 -50 20 0 -55 -60 -65 1 00 Impedance phrase (degree) -50 0 Impedance phrase (degree) 5 00 0 20 0 0 Frequency (Hz) 1 00 0 2 10 9 00 8 00 70 00 60 00 50 00 40 00 30 00 0 200 0 1 00 0 10 Frequency (Hz) Fig. 7: Impedance and phase angle of the specimen vs. frequency. The magnitude of the impedance is plotted on a logarithmic scale versus the frequency (top) and the phase of the impedance is plotted versus the frequency (bottom). The solid line is the measured curves of the impedance magnitude and phase of the specimen. The dotted line is generated using Eq. (16) frequency characteristics and the resonance frequency can be used to calculate the material constants and provide the impedance curve of the device. The material constants, then, can be calculated using the measured value of the resonance frequency of the piezoelectric device: [ Z (ω ) = t s iAωε22 ] ⎤ ⎡ tan ω / (4 f p1 ) ⎥ ⎢1 − k 2 ( + t ⎥ ⎢ ω / (4 f p1 ) ⎥ ⎢ ⎢ tan[ω / (4 f p2 )] tan[ω / (4 f p 3 )] ⎥ + ) ⎥ ⎢ ω / (4 f p3 ) ⎥⎦ ⎢⎣ ω / (4 f p2 ) Fig. 8: Impedance and phase angle of the specimen vs. frequency. The magnitude of the impedance is plotted on a logarithmic scale against the frequency (top) and the impedance phase is plotted versus the frequency (bottom). The solid line is the measured curves of the magnitude of the impedance and the phase of the specimen. The dashed line was generated using Eq. (17) shown in Fig. 8. Figure 8 shows the fit to the experimental impedance data. The fit is good both away from resonance and near resonance. The impedance function demonstrated the relationship between material parameters such as the dielectric, elastic and electromechanical coupling constants and geometric dimension and the frequency T for these fabricated piezoelectric devices: (16) Representing the measured spectrum by resonance equations in the thickness mode: The complex material constants were calculated using (2), (8), (9) and (12). The calculated material constants are listed in Table 3. The elastic stiffness CD33 was obtained from the fundamental mode fp of the samples in (12). We propose Eq. (17) as a resonance equation of several modes of vibration in the thickness mode. The measured impedance spectra and the simulations obtained by the impedance function (17) are ⎛ ⎛ ⎞⎞ ⎛ ⎞ ⎜ ⎜ tan⎜ tπ f ρ ⎟ ⎟⎟ D ⎟ ⎜ ⎜ ⎜ ⎟⎟ c ⎝ 33 ⎠ ⎜ ⎜ ⎟⎟ + ⎜ ⎜ ⎟⎟ ρ ⎜ tπ f D ⎜ ⎟⎟ t c ⎜ ⎟⎟ 33 Z (ω ) = 1 − kt2 ⎜ S ⎜ ⎜ ⎟⎟ iAωε33 ⎛ πf ⎞ ⎟ ⎟ ⎛ π f ⎞ ⎜ ⎜ ⎟ ⎜ ⎟ ⎜ tan tan ⎜ ⎜ 2f ⎟ ⎟⎟ ⎜ 2f ⎟ ⎜ ⎝ p3 ⎠ ⎟ ⎟ ⎝ p2 ⎠ ⎜ ⎜ + ⎜ πf πf ⎜ ⎟⎟ ⎜ ⎟ ⎜ 2 f p2 2 f p3 ⎟⎠ ⎠ ⎝ ⎝ (17) Through evaluation of the four different equivalent circuit models against experimental impedance data, we can draw the following conclusions. For the above two 2181 Res. J. Appl. Sci. Eng. Technol., 4(14): 2176-2182, 2012 kinds of circuit models, the model whose circuit elements are complex is more effective than the model whose circuit elements are real. Analysis based on this equivalent circuit can provide a good understanding of the behavior of triple-layer piezoelectric vibrator as a function of frequency in the thickness mode. This will in turn aid the design and analysis of piezoelectric transducers. Further study is needed to better understand these proposed circuit models. We will look into ways of determining the values of the complex parameter circuit elements Li and Ci and into how to create simulation models using electronic simulating programs. CONCLUSION The equivalent circuit models of the triple-layer piezoelectric vibrator were studied and we found that the impedance information can be evaluated and the relative material properties of the triple layer piezoelectric vibrator can be calculated. The impedance curve spectrums are fitted with various models. The results of this fitting show that the impedance curves produced by complex circuit models effectively match the impedance measured for piezoelectric samples. ACKNOWLEDGMENT This study described in this study was supported by a grant from the National Natural Science Foundation of China (Project No. 50907042). Li-Jiao et al. (2011) was elected chosen by the Shihezi University “263 talent program” based on his reliable and impressive study as an investigator. We express our gratitude to the Aeronautical Science Key Laboratory for Smart Materials and Structures and to Nanjing University of Aeronautics and Astronautics in Nanjing for providing us with laboratory equipment. REFERENCES IEEE Standard on Piezoelectricity, 1987. IEEE Standard 176-1987. Institute of Electrical and Electronic Engineers. Kin, W.K., H.L.W. Chan and L.C. Chung, 1997. Evaluation of the material parameters of piezoelectric materials by various methods. IEEE T. Ultrason. Ferr., 44(4). Li-Jiao, G. and S. Xing, 2010. Study of piezoelectric cantilever for power generation. Adv. Tech. Elec. Eng. Energ. China, 29(1): 54-57. Li-Jiao, G., and L. Jiang-Quan, 2011. Research on impedance characterization of triple-layer piezoelectric bender. Appl. Mech. Mater. 50-51: 3236. Li-Jiao, G., L. Jiang-Quan and W. Yu-Shan, 2011. Analysis of the admittance of symmetrical triplelayer flexural piezoelectric vibrator. 2011 International Symposium on Applications of Ferroelectrics and 2011 International Symposium on Piezoresponse Force Microscopy and Nanoscale Phenomena in Polar Materials, Canada. Martin, G., 1954. Determination of equivalent circuit constants of piezoelectric resonators of moderately low Q by absolute-admittance measurements. J. Acoust. Soc. Am., 26(3): 413-420. Mingjie, G. and W.H. Liao, 2004. Studies on the Circuit Models of Piezoelectric Ceramics. IEEE Proceedings of International Conference on Information Acquisition, pp: 26-31. Shenck, N. and J. Paradiso, 2001. Energy scavenging with shoe-mounted piezoelectrics. IEEE Micro, 21(3): 30-42. Sherrit, S., H.D. Wiederick, B.K. Mukherjee and M. Sayer, l997. An accurate equivalent circuit for the unloaded piezoelectric vibrator in the thickness mode. J. Phys. D: Appl. Phys., 30: 2354-2363. Stewart, S. and K.M. Binu, 2007. Characterization of Piezoelectric Materials for Transducers. Arxiv preprint arXiv: 0711.2657-arxiv.org. Steven, R., H. Anton and A. Sodano, 2007. A review of power harvesting using piezoelectric materials (2003-2006). Smart Mater. Struct., 16: 1-21. 2182