Research Journal of Applied Sciences, Engineering and Technology 2(7): 669-672,... ISSN: 2040-7467 © M axwell Scientific Organization, 2010

advertisement

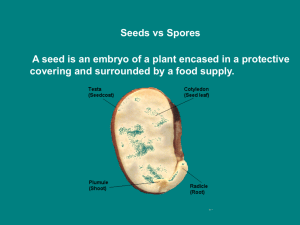

Research Journal of Applied Sciences, Engineering and Technology 2(7): 669-672, 2010 ISSN: 2040-7467 © M axwell Scientific Organization, 2010 Submitted Date: September 18, 2010 Accepted Date: October 06, 2010 Published Date: October 25, 2010 Determination of Some Physical Properties of Nutmeg (Myristica fragrans) Seeds 1 M.H.R .O. A bdu llah, 2 P.E. Ch’ng and 3 T.H . Lim 1 Department of Applied Sciences, 2 Department of Com puter and M athematical Sciences, 3 Academy of Language Studies, Universiti T eknolog i MAR A (U iTM ), 135 00 P ermatang Pauh, P enang, M alaysia Abstract: Some physical properties of nutmeg (Myristica fragrans) seeds were determined at moisture content of 81.85% wet basis. The mean length, width and thickness of the seeds were 23.09, 21.20 and 18.64 mm, respectively. The average value for geometric mean diameter, sphericity, mass, surface area, volume, true density, bulk density and porosity were 20.88 mm, 90.45%, 5.270 g, 1388.85 mm2 , 5860.00 mm 3 , 1199.18 kg/m 3 , 686.60 kg /m 3 and 41.83%, respectively. The coefficient of static friction on four types of structural surface w as found to be ranging from 0.206 (galvanized steel sheet) to 0.376 (rub ber). Key w ords: Myristica fragrans, nutmeg seed, physical properties INTRODUCTION Nutmeg (Myristica fragrans) is a nutlike fruit popularly cultivated and harvested for its spice. A nutmeg tree on average can grow up to 12 m and begins to bear fruits after about six years of planting. Upon ripening, the nutmeg fruit will turn yellow and split open to expose a shining dark b rown seed that is surrounded by a reddish mac e. Nutmeg seed ha s many ap plication s particu larly in culinary, pharmaceutical and cosmetic industries. The nutmeg seed usually is processed to extract its oil. About 30-55% of the seed consists of oils an d 45-60% consists of solid matter including cellulose materials. There are two types of oils extracted from the nutm eg seed, namely the "essential oil" which accounts for 5-15% of the seed and the "fixed oil" or sometimes called the "nutmeg butter" which accoun ts for 24-40% of the seed (Forrest and Heacoc k, 197 2). Due to its arom a, the essential oil extracted from the nutmeg seed has been used as a natural flavouring and as a perfume in the cosmetic industries (W inter, 1989). The oil has been used as a flavouring agent to replace gro und nutm eg to avoid leaving particles in foods and beverages. The oil has also been employed as a flavour in dental creams in combination with pepperm int, methyl salicylate and cloves (Poucher and Jouhar, 1991). In the pharmaceutical industry, nutmeg has been used as a form of medicine to treat man y illnesses ranging from those affecting the nervous system to the digestive system (W eil, 1965). W orld production of nutm egs is estimated to average between 10,000 and 12,000 tons per year with annual world demand estimated at 9,700 tons (ITC, 2003) while the production of mace is estimated at 1,500 to 2,000 tons. The major producers of nutmeg are Indonesia and Grenada which dom inate production and ex ports of both products with a world market of 75 and 20%, respectively. Other cou tries that supply nutmeg to the world market include India, Malaysia, Papua New G uinea and Sri Lanka, and other Carib bean coun tries. The main importers are the European Community, the United States, Japan and India. Physical properties such as size, shape, mass, surface area, volum e, density, ect. are essential information in the design of equipment for handling, processing and storing of the nutmeg seeds. In recent years, physical and mechanical properties of seeds have been reported by many researchers. The physical properties have been studied for various types of se eds, such as locust bean seed (Ogu njimi et al., 2002), quinoa seeds (Vilche et al., 2003), amaranth seeds (Abalone et al., 2004), caper seed (Dursun and D ursun, 2005), sweet corn seed (Bulent et al., 2006), cucurbit seeds (Milani et al., 2007), jatropha seed (Garnayak et al., 2008), roselle seeds (Sánchez-Mendoza et al., 2008), chia seeds (Ixtaina et al., 2008), fennel seed (Ahmadi and Mollazade, 2009) and arigo se eds (Da vies, 2010). Currently the harvesting and processing of nutmeg seeds in Malaysia are done m anually. The operations are slow and labou r intensive. The aim of this wo rk was to determine some physical properties of nutmeg seeds which could be useful in facilitating the design of machines to handle and process the seeds. MATERIALS AND METHODS Fresh nutm eg fruits were procured from a wet market in Bukit Mertajam town located in Penang state, M alaysia Corresponding Author: M.H.R.O. Abdullah, Department of Applied Sciences, Universiti Teknologi MARA (UiTM), 13500 Permatang Pauh, Penang, Malaysia 669 Res. J. Appl. Sci. Eng. Technol., 2(7): 669-672, 2010 where m = mass of individual seed (kg) and V = volume of individual seed (m 3 ). The bulk density (D B ) was determined using the method described by F raser et al. (1978) by filling an emp ty 250 mL cylindrical container with nutmeg seeds. The seeds were poured from a constant height, striking off the top level and weighing. Bulk density was calculated as: on 21st July, 2010. Upo n arrival, the fruits were processed man ually to detach the seeds from their shells and mace. Foreign materials, broken and immature seeds w ere removed from the sample. The physical properties of the seeds were determined at the temperature and relative hum idity of 24ºC and 6 3% , respectively. Moisture content of the seeds was determined using ASAE standard m ethod (A SAE , 1993). The seeds w ere dried in an air ventilated oven at 90ºC for 48 h. Mo isture content (wet basis) was calculated as: (6) (1) where,m B = mass of seeds (kg) and V B = volume of container (m 3 ). Porosity (P) of the seed was determined as (Thom pson an d Isaac, 196 7): whe re MC(%) is the m oisture content, m i is the initial mass and m d is the final mass of the se ed. The length (L), width (W) and thickness (T) of 100 seeds were m easured using a digital vernier calliper (Model CD-6BS-M itutoyo Corporation, Jap an) w ith resolution of 0.01 mm. The measurements for each dimension were replicated 100 times. Geometric mean diameter (D) was found using the following equation (M ohsenin, 1970): (7) The coefficient of static friction (: s ) was tested on plywood, galvanized steel sheet, rubber and glass surfaces. Seed was placed on the surface and raised gradually by screw until the seed b egin to slide. T he an gle that the inclined surface makes with the horizontal when sliding begins w as measured. The coefficient of static friction was calculated using: (2) Sphericity (S) of the seed was calculated as (Mohsenin, 1970): (8) (3) where, 2 = angle that the incline makes with the horizontal when sliding begins The mass of 100 individual seeds was measured using an electronic balance (Model PS200/2000/C/2RADWAG, Poland) with accuracy of 0.001 g. The measurements w ere replicated 100 times. Surface area, (A) was calculated using the formula given by McCabe et al. (1986): RESULTS AND DISCUSSION The results of some of the physical properties of the nutmeg seeds measured in this study were shown in Tab le 1. The leng th, width and thickness of the se eds w ere found to be in the range of 17.86-29.52, 16.45-27.51 and 13.86-23.81 mm, respectively. The calculated geom etric mean diameter ranges from 16 .58 to 26.59 mm with mean value of 20.88 m m. The mean sphericity of the nutmeg seeds was 90.45% while the mean mass of the seeds was 5.270 g. The average surface area was found to be 1388.85 mm 2 . The mean volume determined for 10 seeds was 5860.00 mm 3 . True density and bulk density of the seeds were 119 9.18 and 6 86.60 kg/m 3 , respectively. The avera ge po rosity of the nutmeg seeds wa s 41.83% . The coefficient of static friction of nutmeg seeds against four types of structural surface was determined. The results were indicated in Table 2 . It was found that the rubber surface had the highest coefficient of static friction followed by plywood, glass and galvanized steel (4) Volume (V) for 10 individual seeds was determined using water displacement method (Dutta et al., 1988). The seeds were weighed and coated with table glue and allowed to dry in order to prevent water absorption. The seed was low ered into a measuring cylinder containing water such that the seed did not float during immersion in water. The weight of water displaced by the seed was recorded. The ratio of mass to volume of the seed was treated as true density (D T ): (5) 670 Res. J. Appl. Sci. Eng. Technol., 2(7): 669-672, 2010 Table 1: Some physical properties of nutmeg seeds Physical properties Unit of measurement M ois ture co nte nt (w .b.) Length Width Thickness G e om e tr ic m ea n d ia m et er (G M D ) Sp heric ity Ma ss Surface area Volume Tru e de nsity Bu lk de nsity Po rosity % mm mm mm mm % g mm 2 mm 3 kg/m 3 kg/m 3 % No. of observation Mean value Minimum value Maximum value S .D . 5 100 100 100 100 100 100 81.85 23.09 21.20 18.64 20.88 90.45 5.270 1388.85 5860.00 1199.18 686.60 41.83 77.11 17.86 16.45 13.86 16.58 77.09 2.623 863.38 3400.00 1058.33 622.99 35.10 85.10 29.52 27.51 23.81 26.59 98.80 10.421 2220.94 8000.00 1685.88 729.59 60.67 3.08 2.68 2.49 2.65 2.51 3.60 1.852 331.76 1735.38 178.77 37.65 7.50 Minimum value 0.194 0.158 0.213 0.176 Maximum value 0.404 0.287 0.488 0.344 S .D . 100 10 10 10 10 Table 2: Coefficient of static friction of nutmeg seeds on four types of structural surface Unit of No. of Mean Coefficient of static friction on measurement observation value Plywood 25 0.328 Galvanized steel sheet 25 0.206 Rubber 25 0.376 Glass 25 0.264 W 2 sheet. This property is of paramount importance in determining the steepness of the storage container, hopper or any other loading and unloading device (Davies, 2010). DB DT :S CONCLUSION The average m oisture content (wet basis) of the nutmeg seeds determ ined in this study was 81.85% . The mean length, width and thickness of the seeds were 23.09, 21.20 and 18.64 mm, respectively. The average value for geometric mean diameter, sphericity, mass, surface area, volume, true density, bulk density an d porosity w ere 20.88 mm, 90.45%, 5.270 g, 1388.85 mm 2 , 5860.00 mm3 , 1199.18 kg/m 3 , 686.6 0 kg/m 3 and 41.83%, respectively. The coefficient of static friction on four types of structural surface was found to be vary from 0.206 (galvanized steel sheet) to 0.376 (rubber). The technica l data obtained in this study may be useful in the design of machine for handling and processing of the nutmeg seeds. 0.046 0.032 0.060 0.041 Width of seed, mm Angle that the incline makes with the horizontal when sliding begins Bulk den sity, kg/m 3 True density, kg/m 3 Coefficient of static friction REFERENCES Abalone, R., A. Cassinera, A. Gast'on and M.A. Lara, 2004. Some physical properties of amaranth seeds. Biosys. Eng., 89: 109-117. Ahmad i, H. and K. Mollazade, 2009. Some physical and mechanical properties of fennel seed (Foeniculum vulgare). J. Agric. Sci., 1(1): 66-75. ASAE, 1993. ASA E-S3 52.2. Moisture Measureme nt. Ungrounded Seed and Seeds. In: ASAE Standards 1993, 449. St. Joseph, M.I. American Society of Agricultural Engineers. Bulent, C.M ., I. Yalcin and C. Oza rslan, 2006. Physical properties of sw eet corn seed (Zea mays sac chara ta Sturt.). J. Food Eng., 74(4): 523-528. Davies, R.M ., 2010 . Som e phy sical pro perties of Arigo seeds. Int. Agrophys., 24: 89-92. Dursun, E. and I. Dursun, 20 05. Some physical properties of caper seed. Biosys. Eng., 92: 237-245. Dutta, S.K., V.K. Nema and R.K. Bhardway, 1988. Physical properties of gram. J. Agric. Eng. Res., 39: 259-268. Forrest, J.E. and R.A. Heacock, 1972. Nutmeg and Mace, the psychotropic spices from myristica fragrans. Lloydia, 35(4): 440-449. Fraser, B.M., S.S. Verma and W.E. Muir, 1978. Some physical properties of fanabeans. J. Agric. Eng . Res., 22: 53-57. NOTATION Surface area of seed, mm 2 Geometric mean diameter, mm Length of seed, mm Mass of individual seed, kg Mass of seeds in the determ ination of bulk density, kg mi Initial mass of seed before drying, kg md Final mass of seed after drying, kg MC(%) Moisture content (wet basis), % P Porosity, % S Sphericity, % T Thickness of seed, mm V Volume of individual seed, mm3 VB Volume of con tainer, m 3 A D L m mB 671 Res. J. Appl. Sci. Eng. Technol., 2(7): 669-672, 2010 Garnayak, D.K., R.C. Pradhan, S.N. Nalk and N. Bhatnag ar, 2008. Moisture-dependent physical properties of jatropha seed. Indus. Crops Prod., 27: 127-129. International Trade Centre (ITC), 2003. The Market for Nutmeg in the European Union. International Trade Centre UNCTA D/W TO, Geneva. Ixtaina, V.Y., S .M . N olasco and M .C. Tomas, 2008. Physical properties of chia (Salvia hispanica L.) seeds. Indus. Crop. Prod., 28: 286-293. McC abe, W .L., J.C. Smith and P. Harrio tt, 1986. Unit Operations of Chemical Engineering. M cGraw-H ill Press, New York, USA. Milani, E., S.M.A. Razavi, A. Koocheki, V. Nikzadeh, N . V a h ed i, M . M o e i n F o r d a n d A . Gholamh osseinPour, 2007. Moisture dependent physical properties of cucu rbit seed s. Int. Agrophys., 21: 157-168. Mohsenin, N.N., 1970. Physical Properties of Plant and Animal Materials. Gordon and Breach Science Publishers, New York, USA, Vol. 1. Ogunjimi, L.A.O., N.A. Aviara and O.A. Aregbesola, 2002. Some physical engineering properties of locust bean seed. J. Food Eng., 55: 95-99. Pouch er, W.A. and A.J. Jouhar, 1991. Poucher's Perfumes Cosmetics and Soaps: The Raw M aterial of Perfumery ., Vol. 1, 9th Edn., Chapm an an d Hall. London. Sánchez-Mendoza, J., A. Domínguez, S. Navarro-Galindo and J.A. Lüpez-Sandova, 2008. Some physical properties of roselle (Hibiscus sabdariffa L.) seeds as a function of moisture content. J. Food Eng., 87: 391-397. Thompson R. and W. Isaac, 1967. Porosity determination of grains and se eds w ith air comparison pycnometer. Trans. ASAE, 10(5): 693-696. Vilche, C., M. Gely and E. Santalla, 2003. Physical properties of quinoa seeds. Biosys. Eng., 86: 59-65. W eil, A.T., 1965. Nutmeg as a narcotic. Econ. Bot., 19(3): 194-217. W inter, R., 1989. A C onsu mers Dictionary of Co smetic Ingredients. Crown Publishers, Inc. New Y ork, pp: 215. 672