STANDARD OPERATING PROCEDURE EPPENDORF MINISPIN SOP Ref. No.

advertisement

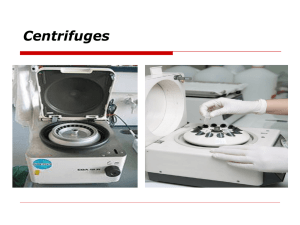

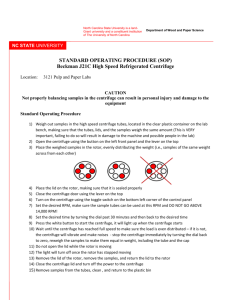

UNIVERSITY OF MALTA FACULTY OF MEDICINE & SURGERY PHARMACY DEPARTMENT SOP Ref. No. SOP/PD/301_02 STANDARD OPERATING PROCEDURE EPPENDORF MINISPIN® Valid for: 2 years from approval Page 1 of 8 UNIVERSITY OF MALTA FACULTY OF MEDICINE & SURGERY PHARMACY DEPARTMENT SOP Ref. No. SOP/PD/301_02 STANDARD OPERATING PROCEDURE EPPENDORF MINISPIN® Valid for: 2 years from approval 1. Scope This Standard Operating Procedure (SOP) applies to the staff and students using and/or maintaining the Eppendorf MiniSpin® Centrifuge in the laboratories of the Pharmacy Department, University of Malta. 2. Objective To give an account of the procedure for the installation, operation and maintenance of the Eppendorf MiniSpin® Centrifuge. 3. Definitions 3.1 Centrifuge: A device in which materials of different densities are separated by rotation at various speeds about a fixed, central point, by way of centrifugal force. The denser particles tend to move along the length of the tube to a greater radius of rotation, displacing the lighter particles to the other end. 3.2 Rotor: The rotating part of the centrifuge which holds the samples. 4. Responsibility 4.1 The members of the Department of Pharmacy (staff and students) are responsible for following this SOP. 4.2 The designated Laboratory Officer or Laboratory Assistant is responsible for ensuring that this SOP is followed. 5. Procedure 5.1 Diagram of Eppendorf Minispin® and its Display Panel Page 2 of 8 UNIVERSITY OF MALTA FACULTY OF MEDICINE & SURGERY PHARMACY DEPARTMENT SOP Ref. No. SOP/PD/301_02 STANDARD OPERATING PROCEDURE EPPENDORF MINISPIN® Valid for: 2 years from approval 5.2 Installation 5.2.1 5.2.2 5.2.3 5.2.4 Place the centrifuge onto a level surface. Ensure that the ventilation slits are not blocked. Place the rotor onto rotor axle, followed by the rotor nut. Turn rotor nut clockwise to fasten tightly in place. 5.3 Operation 5.3.1 Turn on the mains switch. 5.3.2 Press Open to open lid. 5.3.3 Load the rotor symetrically. 5.3.4 Fasten the rotor lid and close the centrifuge lid. 5.3.5 Press the left Up and Down arrow keys to select duration of centrifuge spin between 15 seconds and 30 minutes. 5.3.6 Press the right Up and Down arrow keys to select the speed of centrifuge rotation between 800rpm and 13400rpm. 5.3.6 Press Start/Stop key to start the run. 5.3.7 Press Start/Stop key to end the run prematurely. 5.3.8 Press the left and right Up and Down arrow keys respectively to change the duration of centrifuge spin and rotational speed during a centrifuge run. 5.3.9 Hold the Short Spin key down for as long as needed to perform short spin centrifugation for a maximum speed of 13,400 rpm. 5.3.10 Wait until the lid opens automatically after the run to remove samples. 5.4 Maintenance 5.4.1 Clean the outside of the centrifuge regularly with a moist cloth. 5.4.2 Disconnect the centrifuge from the mains supply to remove the rotor to clean separately. 5.4.3 Use neutral agents for cleaning purposes and use alcohol-based disinfectants for disinfection purposes. 5.4.4 Remove any residues present in the bores of the rotor using a bottle brush and a hand-hot cleaning solution. Rinse well. Leave bores facing downwards on a cloth to allow them to dry. 5.4.5 Check rotor and rotor bores regularly for deposits or damage. 5.4.6 Allow the rotor to accelerate once to the maximum speed after cleaning. Page 3 of 8 UNIVERSITY OF MALTA FACULTY OF MEDICINE & SURGERY PHARMACY DEPARTMENT SOP Ref. No. SOP/PD/301_02 STANDARD OPERATING PROCEDURE EPPENDORF MINISPIN® Valid for: 2 years from approval 5.5 Flow Charts 5.5.1 Installation Start Place centrifuge onto a level surface No Ventilation slits blocked Place rotor onto rotor axle, followed by rotor nut Yes Unblock ventilation slits before use Turn rotor nut clockwise to fasten tightly in place End Page 4 of 8 UNIVERSITY OF MALTA FACULTY OF MEDICINE & SURGERY PHARMACY DEPARTMENT SOP Ref. No. SOP/PD/301_02 STANDARD OPERATING PROCEDURE Valid for: 2 years EPPENDORF MINISPIN® from approval 5.5.2 Operation Start Turn on mains switch Press Open to open lid Load rotor symmetrically Fasten rotor lid and close centrifuge lid Desired duration of centrifuge spin being displayed No Press left Up and Down arrow keys to adjust Yes Desired speed of centrifuge rotation being displayed No Press right Up and Down arrow keys to adjust Yes Press Start/Stop key to start run No Require changing time setting and/or rotational speed during a run Need to stop run prematurely Yes Press Start/Stop key during run Yes No Require short spin centrifugation ? Yes Press right and/or left Up and Down arrow keys respectively Hold Short Spin key down for as long as needed Wait until lid opens automatically before taking out samples End Page 5 of 8 No UNIVERSITY OF MALTA FACULTY OF MEDICINE & SURGERY PHARMACY DEPARTMENT SOP Ref. No. SOP/PD/301_02 STANDARD OPERATING PROCEDURE EPPENDORF MINISPIN® Valid for: 2 years from approval 5.5.3 Maintenance Start Clean outside of the centrifuge regularly with moist cloth Rotor needs cleaning No Yes Disconnect from mains supply and remove to clean separately Use neutral agents for cleaning purposes and alcohol-based disinfectants for disinfection purposes Residues or deposits present in the bores of the rotor Yes Remove using bottle brush and hand-hot cleaning solution. Rinse well and leave bores facing downwards to allow drying Check rotor and rotor bores regularly for deposits or damage Allow rotor to accelerate once to maximum speed after cleaning End Page 6 of 8 No UNIVERSITY OF MALTA FACULTY OF MEDICINE & SURGERY PHARMACY DEPARTMENT SOP Ref. No. SOP/PD/301_02 STANDARD OPERATING PROCEDURE EPPENDORF MINISPIN® Valid for: 2 years from approval 6. Precautions 6.1 Do not position objects that could cause damage to centrifuge operation in the space around it. 6.2 Ensure that the rotor and rotor lid are always securely fastened. If the centrifuge makes unusual noices when started, switch device off by pressing Stop and fasten rotor lid tightly. 6.3 Load rotor symmetrically to reduce wear on the drive and to cut running noise. If an odd number of samples is present, use water samples to balance rotor out. 6.4 Do not use centrifuge if it has not been correctly installed or repaired. 6.5 Do not operate centrifuge in a hazardous or flammable environment. 6.6 Do not use centrifuge for explosive or highly reactive substances. 6.7 Clean centrifuge properly if you spill toxic or radioactive substances in the rotor or rotor chamber. 6.8 Inspect microcentrifuge tubes for material damage prior to centrifugation. Do not centrifuge damaged tubes. 6.9 Always use microcentrifuge tubes of the same type during a run. 6.10 Close the microcentrifuge tube lids tightly before centrifugation. 6.11 Do not exceed a liquid density of 1.2g/ml at the maximum rotational speed. 6.12 To prevent damage caused by condensation, allow centrifuge to warm up in lab for at least three hours before plugging it in. 6.13 Avoid damage to rotor or rotor lids caused by aggressive chemicals. Clean rotor immediately using a neutral cleaning liquid if contaminated by an aggressive chemical. 6.14 Do not use damaged rotors. 6.15 Do not move the centrifuge during the run. 6.16 After a run, do not open the lid of the centrifuge since it opens automatically. 6.17 Disconnect the centrifuge from the mains supply in case of power failure. Wait until the rotor has come to a standstill. Lift up the centrifuge and insert a pen into the opening in the ground plate to move the disc in the direction of the arrow. Lift the centrifuge from the edges only since the underside may be very hot. 7. References Eppendorf. MiniSpin® and MiniSpin® Plus Operating Manual. Hamburg: Eppendorf AG; 2005. 8. Appendices N/A Page 7 of 8 UNIVERSITY OF MALTA FACULTY OF MEDICINE & SURGERY PHARMACY DEPARTMENT SOP Ref. No. SOP/PD/301_02 STANDARD OPERATING PROCEDURE EPPENDORF MINISPIN® Valid for: 2 years from approval 9. Revision History Version Number 01 02 Amendments/ Reasons for change Initial Release Inclusion of subheading titles of Procedure section in Table of Contents Page 8 of 8