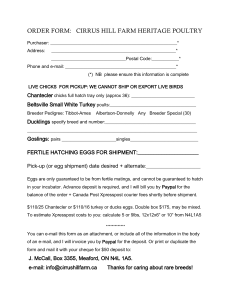

POULTRY MANAGEMENT'

advertisement