Document 13272797

advertisement

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

Bulletin 356

February, 1953

· UBRARY

\.c'?:oC

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

GRICUIJTURAL EXPERIMENT ST ATION

JUANHATTAN.• KANSAS

STATE BOARD OF REGENTS

WALTERS. FEEs, Chairman, Iola

UGHEY............Concordia

DREW McLAUGHLIN

........... ..... ..Paola

.,~,,_,,, ..,," •'··· ..............Wichita

GROVER PooLE..

. ..Manhattan

·~.:, ............... ...... .....Hutchinson

L. B. SPAKE.

. ..... .. .Kansas City

......... Garden City

O sCAR S. STAUl"FER ..... ........... ..... ...Topeka

HUBERT BRIGHTON, Secretary

Eo BuRGE, Busi11ess j\fanager, Concordia

ADliiNISTRATION

.. . ... President of the College

.Director of the Station

.......... Associate Directo r

......... ..... ..... ...... ... ..... .. ...Assistant Director

.... Comptroller

M<>N'T"''Mnv..... ... .... . . ..... ... ... .. ...... .....Agricultural

Economics

..... Agricult ural Engineering

.............Agronomy

.. ... ...Animal H usbandry

.... ...Bacteriology

..... ....Botany

..C hemistry

..Chemical Engineering

..Dairy H usbandry

.,., ....Entomology

: ....... H ome Economics

......... ... .....

.. . . Hor ticulture

.. .. ......... ........

.Milling Industries

.... ..... . .. .... .............. Physics

. Poul try Husbandry

.. ....Veterinary Medicine

........ Zoology

Statistician

. Editor

OF BRANCH STATIONS

A. B. ERHART.....

T. B. STINSON .:

F. E. D AVIOSON .

......Garden City

...Tribune

..Mound Valley

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

DEHYDRATED ALFALFA'

'.rABLE OF CONTENTS

INTRODUCTION .......... .............................................

HISTORI CAL

ALFALFA F'O~·~;~;~~~;~~·~··························· ··············· · ··············· .·.·

Alfalfa Breeding .................. .... ·· ........................... .......................... , .

Cutting Alfalfa

.... ........ .... ........................... ............. ..

Soil Treatment .::::::::::::::::::::::::............................. ........................... . ·

······························

ME~HODS OF PRODUCTION

Field Equip

t

··························· ·························

Dehydrators~~~ ... ::::::::::::::::::::::········ ···························

············ .. ········: ··

Automatic Feeding Equipment ...........................

........................... . ..

Ma~n~enance of Feeding Value· ........................... ...................... .

Eff1c1ency of Dehydration ........:················: ........................... ........... .

Special Equipment .........

. ........................... .................... .

Cost of Production

.... ........................... ....................... ...... .

ENGINEERING RESE~~~~ ....... ..... ........................... ........... .

Retention of Carotene

· · · · · · ........ · · · · · · · · · · · · · ........... · · .. · ........... · ...... .

Fractionation of Dehyd;~t~·d·Air~if'~...... .. . ......... ....... ......................... :

Drum Rotation Rate .................

.. ........................... ................... .

Pneumatic Type Alfalfa Drier .................... .. ........................... ........ .

~~~!~~::~i:~ ~~:~lt~············· ...::::::::::::::::::::::::::::::::::::::::::::::::::::::::·

··••·

Storage of Dehydrated.Aif~i·t~ ........................... ........................... ..... ·

Fire Hazards ........................... .' ....... ·· · · · · · · · · · .. · ........ · · · · · · · · · · · ........... · · · ·" ·

STABILIZATI ON OF CAROTEN~........................... ......................... ..

N ature of Carotene Destruction ........................... ................ ..

Storage Temperature

........................... ............ ........... .

Inert .A.tmospheres .... ~~~~~::~~:~~::············ .. ·························

Moisture Content of Meal

.................. ........................... ...... :.. ..

Pelleting ...... .. ................... ::::::::::::::::::::::::::::::::·............ ................

Antioxida nts .................... ..

Addition of Feed Ingredieu't~.. :: ........................... .......................... .

COMPOSITION OF ALFALFA

........................... ....................... ..

Major Constituents .............. ~:::::·········· ······················ · ···· ············· · · .·

~[~!?}:~:::':~~:::;,~~~;.

:::

:.

UTIL_IZATIO;;··~;·~~~;~-~~;~·~-·~~;~~;~........................... ...... · .·•

Ch1cken Ratio

................. · .............

Turkey Ration~s ........................... ........................... .................... .

Swine Productio~ ··:::::::: · ........................... ........................... ......... .

Lamb Production ...... ... :~ :~ ~~~~~~:::: ........................... ........................ ·.·.

Other Feed Uses .......................... ......... ..................... .................... .···

Industrial Utilization

........................... .......................... .

ANALYTICAL PROBLEJ~~ ........................... ........................... .......... .

Determination of Carotene........................... ........................... .......... :

Detection of Sun-cured Alf~lf~.. i~"i:)·~h;d.;~t~d: ...Air~if~ ................ •·

ACKNOWLEDG MENT

.................................................. .............. ,: ..

LITERA.T\mE CITED

·····································································

H. L. Mitchell, Ralph E. Silker, C. 0. Grandfield,

. H. Honstead, and R . G. Taecker2

INTRODUCTI ON

occupies a favorable position with respect to

of d ehydrated alfalfa the Kansas IndusCommission felt a resear ch program devoted

of this industry would be of value to the state.

such a program was initiated, and although this

•···· attempt to survey alfalfa and alfalfa dehydration

· • there are numerous references to the r esearch

sponsored by the Kansas Industrial Development

"'".''n'·'"'" are also engaged in similar r esearch. Among

uu:G<~.L!uns are the Agricultural Experiment Stations

the United States Department of Agriculture,

e Western Regional Research Laboratory, Aland t he various commercial firms which use

American Dehydrators Association also has

r esearch iii t his field and they, through their

are financing and sponsoring projects of direct

HISTORICAL

feed material has been known for cenrds of alfalfa production date back to

gr own at that time in what is now the

. The Greeks and Romans also were faand its value as a feed. Cato (B.C. 234-149)

·•"De Agricultura" as a means of improving

· · .. 0 A.D. Columella wrote of its usefulness for

soil, its perennial nature, and m ethods of

( 48) has written a history of alfalfa, and

) has given a r eview of its history, bring•·

tion to the United States. The name

·..· originated in the Arabian language and

"best fodder" or " h orse fodder." The

. is used commonly in Europe for alfalfa ,

· from the fact that in its early history in

'•<J,Lua.,un.,

o f Chem i s t ry ; No. 46 8, Depar tme nt of

o f Ch emi cal E n ginee r i ng.

· ass o ciat e p r ofessor, Depa r t m e n t of

U"lnar <m,An r. of Ch e m is try; a g ro nomist, D iv i. R e s . Adm. U.S.D.A . ; associate p r oo.I•·::..vrlenuc:"'' ..,.mc·m'""·,ng ; and associa te profe s sor, D o-

' respectively.

7.5M-2 -5 3

(5)

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

6

KANSAS BULLETIN 356

DEHYDRAT ED ALF'ALF'A

Europe it was cultivated and grew well in the Lake ""'~''"'"'' ..,

area in Switzerland .

A!falfa probab~y w.as introduced in Greece during the

doman and Persian mvasions. From Greece alfalfa

Italy and Africa. The Arabians also carried the plant to

a:nd from there it. traveled to Mexico, Peru, and Chile.

likely that its arrival on the west coast of the United

was brought ·about by the gold seekers enroute to

by way of Cape Horn and South America.

. George W~shington and Thomas Jefferson both grew

m the colomal period ( 4), according to reports.

From the standpoint of alfalfa production in the

States two important importation s were the introductio n of

Chilean variety in California in 1850 during the Gold Rush

the introductio n into Minnesota in 1857 of alfalfa brought

Baden, Germany, by Wendell Grimm. Alfalfa grew so well

the California valleys that it became known as 'u"'""J'

Clover."

Alfalfa supplies one-third of the hay crop of the

States and is the leading forage crop in Kansas. Most of

alfalfa is grown in the Midwest and Far West. Six mid

states including Kansas each have over a million acres.

Kansas the acreage has increased steadily since 1938 to

present figure of 1,026,000 acres (Fig. 1) . The increase in

ALFALFA ACR&A5~

KANSAS

l'XlO

1200

IN

llOO

~

~

~

0

~

~

~

0

~

~

]0

~

Fig. 1.-Alfalfa acreage in Kansa s.

use of alfalfa for commercial purposes has contributed to

~rowt~, since dehydrated alfalfa and alfalfa meal are imp

1ngred1ents of many mixed feeds.

··

· Alfalfa first came int o Kansas from the west in the

1860's and early '70's. It was first mentioned in the Report

7

. Kansas State Board of Agriculture in 1877, and in 1882

Agricultura l Ex1Jerimen t Station recommend ed the

of alfalfa. Alfalfa was not readily accepted by farmers;

stock wouldn 't eat it, and not until about 1900

a lfalfa acreage make much increase. At that time there

· about 300,000 acres. Up to 1900 alfalfa was more or less

experiment al stage and no one could tell the farmers

obtain stands or how to make good hay. Seed was scarce

home-grow n seed was available. During this early

alfalfa itself was becoming acclimated to Kansas conAfter several generations of production t he survival

best plants · began to assert itself in Kansas alfalfa and

. strain became known as Kansas Common. Kansas Com-·

established itself as a variety, and in the past had as wide

of adaptation as any single variety grown in the

States. It established a reputation for Kansas-gro wn

seed throughout the eastern part of the United ~t.a~es.

o alfalfa, a new variety developed by the Divlswn

Crops and Diseases, Bureau of Plant In.dustry,

Ao-ricultura l Engineerin g, United States Department

o

a nd the Kansas Agricultura l Experimen t Stahas all the qualificatio ns of Kansas Common plus

e to bacterial wilt Corynebacw rium insidlosum, will

nrllr,..llrV replace Kansas Common in its adapted area.

a the period between 1900 and 1915, alfalfa acreage in

increased by one million acres. This rapid growth

ted the use of unadapted seed to supply the demand,

during the last two years of the period. Because of

was an immediate reaction and the acreage decreased

for the next two years. During the next 20 years the

fluctuated but on the whole decreased by almost a

a cres. This decline was due to diseases such as bac. • wilt and to economic factors brought about by demands

·

grain. During the next 10-year p eriod, up to 1950,

· was a gradual increase in the alfalfa acreage to the presof over one million acres. This increase in acreage

to improved varieties, improved methods of handling,

increase in the commercial demand for alfalfa meal.

with a production of over 38lj2 million tons annually

·is harvested primarily as sun-cured hay. Within rehowever the artificial drying of alfalfa has develinto an important commercia l method of processing. A

.•. niform product of higher nutritional quality results.

··...

Otto Weiss of Wichita, Kansas, first put ground al'

m ixed f eeds. This marked the beginning

....."'"'·"'milling industry. Shortly thereafter, M. E. P~ters

Nebraska, mixed ground . a lfalfa and molasses m a

: These feeds met popular favor and resulted in an in··'"''"'"'~"'"

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

8

KANSAS BULLETI N 3 56

DEHYDR ATED ALF ALFA

creased use of alfalfa in mixed feeds. The industry ,

received demands for a uniform product, with color being

portant. As a res ult, artificia l drying was attempte d in

to meet this new demand. In 1931 the first dehydra tor

of the Mississi ppi a nd probably the second of commer cial

in the United States was con structed . By 1937 the United

Depart ment of Agricult ure recogniz ed the growth of the

hydratio n industry and publishe d a circular describi ng

ment used in t he industry (32) . Since that time the

dehydra tion industry grew r apidly with an a ccelerate d

in the early and middle 1940's. Kansas now has 86 units

ducing some 180,000 tons of meal annually valued at over

000,000. Thus this industry , develope d in the Middle West

the last 20 years, has added greatly to the demand for the

uct and provided employm ent for 1200 to 1500 people in

state.

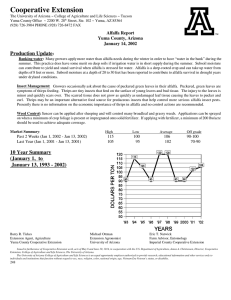

Product ion of dehydra ted alfalfa in the United States n

exceeds 717,000 tons per year (102). Figure 2, which is

to that presente d by Chrisma n (21) in his excellent r eview

1000

..

.-..

..,..

.

"'

c:

0

,',.o___ /

--~,

0

_o...... "'

- _. ... -

0

/

.:

0

',

',

',-o____

Sun-cured

--0-

~-

0

---o ....

..c

--

9

to stabilize as a new and valuable indust ry, prov idanoth er outlet for an importa nt farm crop.

problem s associat ed with the growth of such a n ew inare many. Such factors as equipment, efficient operahigh qua lity products , uniform products , packagi_ng,

.

promoti ons, etc., are much more numerou s and subJect

fluctuat ion and change than in an establish ed industry .

AJ.~F ALF A

FOR DEHYD RATION

Alfalfa Breedin g

:·AJIL<:t.u a breedino - in the past has been limited

largely to the

in prod;cti on of the plant itself as hay or to seed

T his has been accompl ished by obtainin g resistan ce,

breeding t echnique s, to some of the diseases o_f alfalfa

the selection of plants that have the mheren t

t o produce more hay or seed than others. T h rough alseveral n ew varietie s have been develope d. The

ost importan t of these are Buffalo and Ranger, both of

h ave a high degree of bacteria l wilt resistance. Buffalo

as previous ly mention ed, was develope d at the Kansas

al E xperime nt Station by selection and close breedplants selected from an old line of Kansas Common ,

to have been "TOWn in Kansas since 1907. Selected

s showing resista~ce to wilt were grown under isolat~on

to intercro ss, and wer e then reselecte d, resultm g

we n ow kno·,v as Buffa.lc. Tests have shown Buffalo

to yield as m uch hay as Kansas Common as long as the

are comD'.'.rable, but over a period of years it surpassed

Commo-n because o:: the loss of stands in the Common ,

to wilt (Table 1).

1.-Comr a rc~tive Sta n ds of Alfalfa, After Four Years on W iltSoil, Manhatta n, Kansas.

PP.rcent ?.ge Stancl

o rigina l

final

................ ................ ............

95

95

100

25

Year

···················-············ ················ ················

98

12

Fig. 2.-Produ ction of alfalfa meal in t he United States.

a Ccmmon ................ ................ .... ........

98

20

................ ................ ................

98

6

dehydra ted alfalfa producti on, illustrat es the growth of

dehydra tion industry since 1943. Most of t h e meal is used

chicken ration s, but m ore and more of it is finding its way

cattle feed, hog rations, sheep feed, a nd turkey mash.

formula feed industry is now using large quantiti es and it

r esults from other states have shown Buffa lo

as m uch hay as other varieties common ly grow n in

and to maintai n stands longer.

2 presen ts data from a test conducte d at Davis, Cali-

rr

~:::.::

i!'

--1!!!!!!!!!!!-- --- --- --- ---

·...,·

···""!0!

··. 111!!1!'!-!\1'!!

.•..•!1!!'

.•..!!!.

·····-

·- - ·- - -- - - _ j

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

10

KANSAS BULLETIN 3 56

fornia, which clearly indicates the ability of Buffalo

tain its stands longer and to make good yields at the

TABLE 2.-Comparative Stands of Buffal o Alfalfa After

California Agricultural Experiment Station, Davis,

V a r;iety

ntage Stand

final

0

Buffalo ......................... .

fl2

87

Kansas Common ......... .

90

32

California Common ..... .

95

42

Buffalo alfalfa is purple flowered, erect in its

growth, and rather quick to recover growth in the sp

after cutting.

.

Buffalo alfalfa is more resistant to the leaf and st · ··

eases common to this area than Kansas Common

·

and for this reason produces a higher quality

periods of weather favorable to the growth and

of the diseases. Some dehydrator operators have

the high carotene content of the Buffalo alfalfa

processed. Most of the nutrients in alfalfa are in the

therefore any variety containing a high percentao-e

will be higher in the nutritive elements than the o

may drop their leaves before being harvested.

The range of adaptation of Buffalo alfalfa is limited

north to the northern boundary of Kamoas by its

cold resistance, and in the south it is limited in the

wilt is not a factor by Hs abllity to comnete with

strain_s oi common alfalfas in hay-yielding ability.

speakmg, Buffalo a1falfa can be grown St'ccessfully

United States between the 31st and 43rd parallels.

where Buffalo is best adapted will be bounded on the n

the 40° parallel extending west to the Utah State line

diagonally up to the Puget Sound area. The southern

of its area of adaptation will extend south to the 31 o

then west to Texas and slightly north and west to

coast, eliminat ing the tropical areas of Arizona and

and the eastern coastal area. In all the area west of

sas line Buffalo will be in competition with high-yieldi

wilt-resistant, local strains in the south, and Ranger,

resistant variety, in the north. Buffalo w ill be used · ·

north as the 43 o parallel in the north centra l a:ad east,

ing west to the Wyoming line. In this area Buffalo

used for pasture mixtures and in short rotations

recovery is desired in the spring and after cutting,

a _heavier late fall growth may be obtained, than can

tamed from Ranger or other northern varieties.

DEHYDRATED ALFALFA

11

is a synthetic alfalfa as described by Tysdal

through the co-operative efforts of the NeExperiment Station and the Division of

Diseases, United States Department of Agwas synthesized fro m five selections. In

istics it exhibits considerable variabilof growth and flower color. It is distinctly

color. Ranger has more cold resistance

ore its range of adaptation is further north.

has proved to be one of the high-yielding

slightly below Buffalo. It is highly wiltsusceptible to the leaf and stem diseases

breeding in the past has been to increase

and resistance to alfalfa diseases. Inciwork has resulted in the increase of the

t. Enough research has been done to show

to increase t he quality of alfalfa by increassome of the feed elements in fresh alfalfa.

· been done at this s tation on carotene (pros indicated t hat carotene content in alfalfa

ble factors. It is reasonable to believe

differences in alfalfa plants in the

elements as well as other biologically active

and Tysdal ( 44) obtained strains and hi. . considered to differ inherently in carotene

· variations shown by the progeny were condetrimental to carotene content were held

t ( 41) found differences in t otal caro~+'~'AA" strain and clones of alfalfa and obcorrelation between carotene cont en t of

··.·and of their maternal parent s. He concluded

•... ·

in alfalfa is inherited. Brackney (15)

· · evidence and concluded that the inherita n ce

· · t in alfalfa rests on complex interaction be.. and heritable factors within the plant.

CUTTING ALFALFA

t ed, alfalfa is a multiple crop. The best

for one of the products for which a l . ·.. not be the best for another. Grandfield {34)

lfalfa stands have been ruined because of

t<t-LuJco::LJts, and described time of c.utting

stands, to increase hay yields, and to

all of which are di '~erent in some detail.

se quality, may be added.

with Alfalfa. The imnortant fact or in

is to k eep a plant healthy and v igorous.

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

12

KANSAS BULLETIN 356

13

DEHYDRATED A LFALFA

This can be done by allowing the plant time 1~etween

to accumulate plant food in the roots. This will make

more vigorous growth and higher cold resistance. The c

period is the fall season, and it is necessary to plan the

cuttings in order to allow the fall top growth to supply

roots with plant food for winter protection (Fig. 3). .

to the full bloom stage. This may n ot be the best manpractice to maintain stands or to produce high quality

If a seed crop is desired it is necessary that the grower

early in the season and cut the alfalfa accordingly.

,Increase Quality. Table 3 illustrates when to cut ~~ obta in

quality hay. This holds true with ot her nutntive .ele3.-Effeet of Stage of Maturity of Alfal fa on Yield of Hay, PerLeaves and Protein, and Total Protein Produced Per Acre (Aver.. 8 years).

40

Leaves

TOTAL CARBOHYDRATES

in hay

Tons

w

"

:!

z

Pounds

960

2.427

53.4

2.931

51.1

18.92

1,109

..........................

3.037

48.4

17. 63

1,071

...........................

2.647

41.6

16. 04

849

0

"'"' 15

Percent

19.78

···························

..,

Percen t

0.

~~-22-;9-~18~10~-~6--~J0~-~28~--~I~I-2=8~----~,_~a----------~----_j

'

OATE

OF

2•27

SAMPLING

Fig. 3.-Trend of plant food reserves in alfalfa roots plotted as

tions from the mean.

'

In this area the best management practice for hay

tion is to make the first and second cuttings in the early sta

of growth, then regulate the third and fourth to allow

cient top growth to dev.elop on the plants after the last

to build up food reserve in the roots for winter protection.

To Increase Hay Yields. If tonnage is all that is desired,

hay should be allowed to reach the mature stage before

The quality of the product will be lowered and the timinothe fall growth disregarded, thereby shortening the life

s tand.

Table 3 illustrates what happens to hay yields and hav

ity when alfalfa is cut at different stages of growth.

change in quality is primarily due to the loss of leaves as

plant matures, even though the tons per acre increase up

the full bloom stage.

To Increase Seed Yield. To produce a seed crop the rec

mended practice is to allow the crop previous to the seed

ot ·.

alfalfa as well as with proteins. Hauge ( 46) report ed

alfalfa was higher in vitamin A potency than was

the bloom stage. Meenen (61) has shown that t he

content of a lea f is continually being built up until

period of the plant. He found more carotene in

older plants than he did in young material and c ont the loss of total carotenoid content of the plant as

was probably due t o the loss of leaves. Any factor

·""''"'"<'" a chlorosis of the plant leaf will reduce its caroSome of the factors that cause alfalfa plants to

leaves prematurely in Kansas are leaf and stem

such as leaf spot, Pseudopeziza medicaginis, leaf

eudopeziza medicaginis Ionesii, alfalfa rust, Ul'omyces

black stem, Ascochyta imperfecti Pech ; leaf~·.· ..J.,,....vcephalns, low soil fertility, drought, etc.

of all commercial processors of a lfalfa is to

in the early stages of growth. This assures them

qu.tlity product, because of the high percentage of

recommended practice for cuttin g alfalfa for qualin the bud stage. However, if this practice is conthe season the plants will be weakened and

to diseases and winter killing, thereby reducing

· · The dehydrator must be assured of a st eady flow

the plant over the entire season for efficient operait necessary to start on some fields earlier in

.··. than recommended as t h e best cutting practice.

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

14

KANS AS BULL ETIN 3 56

DEHY DRATE D ALFA LFA

This ·may be comp ensat ed for parti ally by allow

to go to later stage s of grow th later in the seasoing t hese

n

The conc lusio n that may be draw n from the .

cutti ng pract ice is that the produ cer must

e the purpo .

for whic h he is growing alfal fa and use the decid

recom mend ed

ting pract ice that will giv e him the great est

retur ns in

gevit y of stand , tons of hay, bus hels of seed,

or quali ty

produ ct.

Soil Trea tmen t

To grow alfal fa succe ssful ly the soil must be

well supp li

with the nece ssary plan t food elem ents, lime,

phos

phor us,

potas sium . Lime and phos phor us are lacki ng

in

much

of

easte rn half of Kans as, and potas sium only

in th e

south easte rn part.

TABL E 4.-Ef fect of Fertil izer on Alfalf a

Hay Yields on South east

Exper iment Fields .

Avera ge y ield, ai r - dry h ay,

tons p e r acr e

Thaye r

4 - year

a verage

Moran

17 -year

averag e

rules whic h inclu de a definition of dehy drate d

alfalf a.

·. inclu de, essen tially, that the prod uct be dried

rapid ly

.. ~~··~~· ~4 mean s at a temp eratu re

a bove 212 ° F . and t hat no

alfal fa be mixe d in the produ ct.

t is quite expe nsive and must inclu de,

. dehy drato r prope r, field equip ment, t rucksin addit ion

, traile rs,

hamm er mills , sack-ing equip ment, and a repai

space is desir able and locat ions near railroad r shop .

erred . Most units in Kans as opera te on natu sidin gs

ral gas

· elect ricity for moto r-driv en equip ment ; there

fore these

of powe r must be avail able.

Field Equi pmen t

· equi pmen t may vary consi derab ly, from mow

ers

self-p ropel led cutte rs, chop pers, and tr ailer comb and

inat can make field oper ation a one-m an job.

such as that show n in Figu res 4 and 5 is owne

d

Colum b u s

16 -year

aver a ge 3

No treatm ent ........ ......... ......... ..

1.27

.90

.58

.Lime .................. ........ .......... ......

1.13

1.56

1.95

Manu re ......... ......... ......... ......... ..

1.57

1.65

Lima and superp hosphate ........

Lime, manu re, a nd super pho3p hate ......... ......... ......... ...

Lime, pota3 h, and super1)hOo phate ......... ......... ......... ...

2.29

2.44

2 .3 1

2. 9 8

2.7 8

2.87

2.00

The data in Tabl e 4 are f rom experime nts

Sout heast Kans as Expe rime nt Field s. The

respo nse

and phos phate was good. Any treat ment that

will i

the hay yield will also incre ase the yield of

the

nutri

ti

ment s if alfal fa is cu t at the prop er time.

·

METHODSOFPRODUCfiONOF

DEHYDRATED ALFALFA

Dehy drate d alfal fa varie s consi derab ly in quali

ty,

it is almo st alwa ys of much high er quali ty than

falfa .

Attem pts are being made to stand ardiz e dehy

The Ame rican Dehy drato rs' Asso ciatio n (5) hasdrate d

devis ed

15

from one field to anoth er. Thus

the fresh alfal fa to sellin g

~,..•. ~.~ ~· the contr ol of the plan t

owne r.

as close to the dehy drati ng unit

·v :''··• ·v.~• ~~-"' trans porta tion costs , They

sel.

for alfal fa, and prefe r t o stay

· .• unit requi r es abou t 1000 acres of aleffic iently durin g a norm al seaso n.

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

16

DEHYDRATED ALFALFA

KANSAS BU LLETIN 3 56

Fig. 5.-Self-propelle d field harvesting equipment.

Bert and Wetta, Maize, Kansas.

Drum. The H oward type of drier uses a single rodrum with baffles arranged along the inner surface. The

serve to keep the alfalfa falling through the stream of

air and combustion gases passing through the drum. The

chopped alfalfa enters one end of the drum and is dried .

conten,t of 4 to 8 percent in a single pass through

Figure 6 shows a unit of this type.

temperature in the drum varies from about 1500° F. at

inlet end of the drum to about 250° F . at the exit end. In

the high initial temperature very little alfalfa is burned

drying if a proper balance is maintained between the

ture and the feeding rate. The alfalfa passes through

and is dried in 5 to 8 minutes. The gas is burned in

third of the drum in this type of unit. More recently,

, a short firing tube has been used on the front of the

It is claimed that more efficient firing is thus obtained

that closer control of the temperature in the drum can be

Dehydrators

There are several different types of dehydrator~ in use.

few low t emperature units are in use, but most umts. a re

temperature units of rotating drum t ype :o~str~ct10n.

rotary drum driers are usually 10 to 12 feec m d1ameter

approximately 30 feet long. Two genera~ types of rotary.

driers are in use. Gas is the usual fuel m Kansas, but 011

be used and coal h as been used in one or two instances.

Drum. The Heil dehydrator is similar in outside

to the Howard. Its inner construction, however,

of three concentric drums with different drying con-

.

Fig. 6.- Howard-type dehydrating unit.

Manhatta n , Kans:<\s.

17

the three compartments . The fresh material enters

· . which is at the highest temperature. The alfalfa then

successive stages into the second and third drums,

maintained at lower temperatures. Figure ·7 repreconstruction of the multiple dr um dehydrator and

.· shows a regular installation of this type. An auxiliary

· ·or firing tube is used with this type of dehydrator.

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

.18

KANSAS BULLETIN 358

DEHYDRATED ALFALFA

19

proper feed rate. In any case, the use of 'aut omatic

has eliminated the need for manual labor in the feedt ion, and a more uniform meal is produced. Figures

10 illustrate typical aut omatic feeding equipment .

Fig. 8.-Double unit installation of Heil-type dehydrator.>.

tesy of the Arnold Dryer Co., Milwaukee, Wis.

Automatic Feeding Equipment

One of the critical points in producing a good quality,

form product is the maintenance of proper balance be

feed rate and temperature. Until recently this operation

performed manually, with the workers adjusting the feed

according to the temperature in the dehydration drum.

Within recent years several automatic feed devices

been manufactured and most operators now use some type

automatic feeder. Some of these units are regulated a-u~v_........,

cally according to drum temperature. Others run at a

constant rate, which may be varied slightly by a manual c

trol, in which case the operator has the responsibility for

0.-Automatic f eeder at Cozad, Nebrask a . Courtesy, The W.

o. , Neodesha, Kansa3, Division Archer-Daniel3-Midland· Co.

1\Iaintenance of l'eeding· Value

Fig. 9.- Automatic fee der a t the National Alfal fa Dehydrating a nd

ing Company, Lamar, Colorado.

produce a good quality dehydrated alfalfa it is

to have a good quality raw material. However, good

be damaged by I>Dor handling and dehydrat ion.

attempt to dry the alfalfa as soon after <;utting

e, since dest ruction of nutrients in the alfalfa, parcaroten e, begins as soon as the alfalfa is cut. Silker

(92) in a study on carotene l osses showed that the

otene from fresh chopped alfalfa was most rapid

after chopping, but amounted to less than 3 perhour over a period of severa l hours. The average

t ime between cutting the alfalfa and feeding it into

will be less than one hour under g ood managebreakdown in equipment may account for a l onger

on rare occasions.

carotene content of the dehydrated alfalfa is a lso af-

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

KANSAS BULLETIN 3 56

20

DEHYDRATED ALFALFA

21

by the operation of the dehydrating unit. Silker and

(92) have shown that the losses in the dehydrator vary

, but may be held to a relatively low value of 5 to

··.percent.

a further study losses of carotene during dehydration in

of units located in the Kansas river valley were ined. These data were taken a long with engineering data

measured the efficiency of operation of the units. Caroses ranged from 5.7 to 21.5 percent. The data are prein Table 5 and substantiate those obtained in the other

mentioned;

Efficiency of Dehydration

'""' "'

......

.,...

e engineering data obtained included (a) pounds of green

per hour; (b) pounds of dry meal per hour; (c) pounds

air passing through the drum per minute, and (d) fuel

per hour. From these data the rat e of evaporamoisture and the amount of water removed p,er unit

consumed could be calculated. The carotene content

dehydrated meal as compared with the fresh material

. also obtained. Table 6 presents the engineering data on

units.

capacity of each unit is best measured by t he rate of

. ... removal. As shown in the table, the capacity ranged

···. 7,675 pounds per hour to 4,860 pounds per hour.

efficiency of each unit is best measured by the ratio of

of gas consumption to the rate of evaporation of water.

t he latent heat of water is 970 B.T.U. per pound and the

value of natural gas is approximately 1000 B.T.U. per

cubic foot, 100 percent efficiency is very close to a

tion of one cubic foot of gas per pound of water evapos ratio actually varied from 1.155 to 1.98, i ndicating

te efficiencies from 50 to 85 percent. This neglects

small heat quantities such as the sensible heat in the

and air leaving the dehydrator, and the sensible heat in

alfalfa, but it is still a good relative index of t he therof the process.

Special Equipment

are some pieces of equipment used in processing and

dehydrated alfalfa which, although not of universal

are of considerable interest. Included are such

blending equipment, pelleting machines, automatic

equipment, automatic sacking equipment, loading

ers for cooling alfalfa meal before sacking, spray

for adding oil to dehydrated alfalfa, shredders for

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

22

KANSAS BULLETIN 3 56

DEHYDRATED ALFALFA

23

stems before dehydration, and numerous other

0

00

"'

00

....

0

0

r;--

"'

0

"'

..,.

0

0

ending equipment is frequently used to combine various

of alfalfa meal to meet certain specific·ations. This type

~·,-~.~~t is quite common, especially where t he operator

sufficient meal t o warrant such operat ions; high

lower grade meal can then be mixed in the correct

to meet the requirements of the buyer. Many types

are in use. Typical of this kind of equipment is

own in Figure 11.

..,.

0

,..;

0

>.0

0

00

operators are using equipment to cool alfalf.a meal

sacking. The meal will average 20 to 30 degrees F. highatmospheric temperature as it leaves the hammer mill.

l oss of carotene caused by the higher t emperabe reduced by coo!ing. Several different types of cool-

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

24

KANSAS BULLETIN 356

DEHYDRATED ALFALFA

ing units are available commercially, and in some cases p

operators have designed their own coolers. One

of a cooling device is shown in Figure 12.

Fig. 12.-Alfalfa meal cooling equipment.

Caple Co., Toledo, Ohio.

Another device commercially available is a shredder

crushes and tears up the stemmy portion of the alfalfa

diately before it enters the dehydrating unit. This device

said to make dehydration of the alfalfa more uniform and

quire less heat because of the relative ease of drying

crushed stems as compared to whole stems. It is claimed

better quality meal results from such operations. The

construction of such a crusher is shown in Figure 13.

Sacking operations have been simplified in many cases

using automatic weighing and sacking equipment. Paper

are also finding use in the industry. Typical of sacking

mentis that shown in Figure 14, while a stack of

alfalfa loaded in a freight car is shown in Figure 15.

Still other variations of equipment are in use.

machines make it possible to handle dehydrated alfalfa

bulk loading equipment when buyers are interested in

14.-A!falfa s a cking equipmen t.

Vermillion, South Dakota.

25

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

26

DEHYDRATED A LFALFA

KANSAS BULLETIN 3 56

27

. expenses, bank credit, dues,. a nd taxes, which they esti$4 to $5 per ton.

estimat es of cost of production are as follows:

Alfalfa

$10.00

Gasoline

2.00

Gas

2.00

Electr icity

2.00

Bags

5.00

Labor

8.00

Repairs

2.00

Depreciation

6.00

Cost per ton

$37.00

(37) estimated the cost of production at a somewhat

He gave as production costs a value somewhere

$15 and $23 per ton, excluding t he cost of alfalfa. If

purchased at $10 a ton the cost would b.e from $25

ton, somewhat below the estimate of Dombrowski and

Fig. 15.-Alfalfa sacked in paper b a gs and stacked in freight

shipmen t. Photo courte3y of the W . J. Small Co., Division of

Daniels-Midland Co.

type of product. These devices also serve to r educe labor

by reducing labor requirem ents, but probably increase·

cost due to machine operations. A few instances of eq

for bulk loading alfalfa meal are also known and can be

to reduce costs if the buyer is willing to purchase carload

of alfalfa meal loaded in this manner. The cost of bags

amounts to approximately $8.00 per ton at present quul.4l·•v•~'

Cost of Production

Costs of producing deh ydrated alfalfa vary consid

among various locations in t h e United States as well as

in local areas. The industry is subject to wide variati

production costs due to different methods of manag

different equipment. Many operators are pron e to

with their units. This also tends to produce variation s in

duction costs. The industry as a whole is a new industry

is changing r apidly, which again · tends to make for unLeoual;

production costs.

In spite of difficulties in making accurate estimates,

likely that th e data presented by Dombrowski and Palmer

are as good as any available. They reported a cost-of-pr

tion figure of $37.00 per ton in 1948 as 'being a fairly

estimate. This value did not include storage, sales costs,

~~,,., ....,~~...

and Silker (50) reported a cost estimate, made in

$49.00 per ton. Their data were based on a production

ton of meal per hour, ·operating 20 hours per day

a month a n d 5 mont h s per year.

cost was pla ced a t $49 per ton, broken down as

Raw material

P ower, 130 KWH

Fuel (gas )

Bags, storage,

shipping

Labor (10 men)

Amortization,

interest, taxes

Maintenance,

insurance, misc.

$15.00

2.00

2.00

10.00

10.00

5.00

5.00

$49.00

be seen th at considerable var iation in cost estimates

· made. It must be r emembered, however, that there

fluctuations in the price paid for the alfalfa, l abor

pment costs, etc., which have resulted in con sidern in production costs. The amount of "down time"

inclement weather, etc., are factors which also

the actual cost.

·· example, H onstead and Silker's (50) estimate of the

st s is based on 10 m~n per dehydrator. Present opera-

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

28

KANS AS BULL ETIN 356

tiona l pract ices such as th e use of autom atic

feede rs,

prop elled harv ester s, etc., have elimi nated some

As a resul t Dom brow ski and Palm er have lowe of the

r labor costs

their more recen t estim ate. They also use a

cost of raw

teria l of $10.0 0 a ton rathe r than the $15.00 used

and Silke r. Thes e two facto rs acco unt for most by .L:l.'-'.u"'~""''"

of the diff

ence in the two estim ates.

An estim ate of cost also was made for the

Unite d

Depa rtme nt of Agri cultu re in 1950 by Scho enleb

er and r epo .

in Feed stuff s (83) as total ing $37 per ton.

Costs on

item s inclu ded labor $8.28 , gas $2.20, elect ricity

chine repai rs $2.57. Thes e figures agree close $1.62, and

ly with t hose

Dom browski and Palm er.

I nves tmen ts in plan t and equip ment also

a one- unit plan t the inves tmen t may vary vary wide ly.

from $40,0 00

$190,000, with an avera ge of $95,0 00 _( 82, 83).

Cash . re~

of $10,0 00 to $15,000 per unit are reqm red at

the begm mng .

the seaso n.

Scho enleber also estim ated the typic al cr ew to

numb er

m en, inclu ding on e mill opera tor and fe~de

r, two sacke rs,

field oper ator, two haule rs, a nd one repa1 r man.

Mark et price s on dehy drate d alfal fa also have

varie d

over the past sever al years . P r ices in Kans as

City

have fl

tuate d in one year (1948 ) from $81.2 5 in J a nuar

y

to

$41.50

Augu st. Whe n price s were fixed in 1944- 45

the figur e

$60.30. In 1949 the price dropp ed to $39.5

quota tions (1951 ) have been $73.60 per ton 5.(inR ecen t

Kans as

Thus it can be seen that the plant mana gers

are deali ng

a wide ly fluctuating mark et whic h make s opera

tion at a

or less stabl e marg in almo st im possi ble.

ENG INEE RING RESE ARC H

Rete ntion of Caro tene

One of the m ost impo rtant probl ems the alfal

indus try has is that of prese rving the origi nal fa

ten t of the green alfal fa, both dur in g dehy drati carot ene

on and d

subse quen t stora ge of the alfal fa meal .

Since the destr uctio n of carot ene migh t resul

datio n proce ss, and since aldehydes, which can t from an

agen ts, are produced by poor comb ustio n of t act as

h e fuel, the

of furnace and quali ty of the fuel- air mixture were

in

as facto rs in ca roten e reten tion. This appr

oach seem ed ,

offer real possi biliti es, since the work of Greene,

et al. (35)

show n that t he quali ty of dehy drate d egS?; powd

er

was

materially as the r esult of the adsor ption of

aldeh

ydes

perox ides formed by incom plete comb ustion of

the fuel.

· DEHY DRAT ED AL FALF A

29

ts conducted in a smal l, pilot size, How ard-t

ype

•·•··v'"'"'u.'1"· loane d to the Depa rtme nt of Chem

ical Engi neeri n g

Labo ratories, Inc., failed to produ ce

chan ges in carot ene reten tion · as a resul t of any sigchan ges

of comb ustio n. This fact was verified by carot

ene

tests on alfal fa m eal from Heil dehy drato rs with

furin whic h comb ustio n shou ld be complete, a nd

on meal

ehyd ra tors, such as the H owar d, in which the

in the dryin g space ; thus ever y oppo rtuni ty gas was

was profor the prod uctio n and adso rptio n of aldeh ydes,

perox othe r oxidi zin g mate rials. Agai n, no signi fican

t difwas found .

appro ach to the carot ene reten tion prob

the inactivation of the en,zyme systems. The lem incarot ene could well be the r esult of enzy mic destrucactiv

was made to remo ve this possibility by stea min ity.

g or

u~lJ.Hl.l". t he alfal fa prior to deh ydrat

ion. As shown by Silke r,

and King ( 89), this proce dure work ed

6) when the dehy drati on was cond ucted at ver y well

relatively

--+--

·LSI:

~ -----< ~ ·--- -;

·- --- -

~ -----,

ir- - - - - ,

i

1

f R

STORE D A T 3 ° C·

P-=--~

-- -

-

~ - - -

S TORED AT

D

R"OOM

- -- -

'

·-<b

TEI>tPE RATU Rf

I

2

l»

STORAGE TIME IN MON THS

4

5

6.-Ef fect of blanc hing on t he carotene r etent

ion of alfalf a a ft er

dehy dra tion. Dotte d line, bla

; solid line, unF B, f r esh blanch ed; F, fresh a lfa lfa; D,nched

dehyd ra ted.

eratu r es over sever al hour s. Whe n high temp

eratu re

in t he smal l How ard deh ydrat or was used howucJll1IJ Lii: had n o signi fican t

effec t on carot ene ret~ntion

.

dehy drati on or subse quent stora ge. It has beer:

smce that t?e enzyme syste ms a r e inact ivate

tures to wh1ch the alfal fa is subjected durin g d .by the

the usua l

proce ss.

attem pt t o improve the carotene ret entio n durin

g

subse quen t to dehy drati on invol ved the addit

ion of

u ..,~!un

r ;·

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

30

KAN SAS BUL LET IN 356

DEHYDRATED ALFALFA

anti oxid ants . This was acco mpl ishe

d by dipp ing the a lfalf a

· a dilu te aque ous solu tion of a n anti oxid

ant. A 0.2 perc ent

line pyro gall ol solu tion was used.

The resu lts are show n

Figu re 17. It will be note d that this

trea tme nt incr ease d

31

U)

~

(.!)

0

0

.:::!!)

IJJ ~

2 01-----+-.-.::~.f'>..:?>-.~-+---+-

----1----1

Zoo

w>

i"-r;:

~

<l

u

6

.~

0

10

r---+----r------+--~~+---~~

~---~

0 .!=-----=----+----.J:-----,~,---

----:::-----.1..

'Fig. 17 .-E ffect of dipp ing fresh

solut ion befo re dehy drati on in rotar alfal fa in 0.25 perc ent

y kiln dehy drato r.

( 1 ) Undi pped meal , store d in glass

( 2) Undi pped meal store d in glass jars expo sed to light .

jan wrap ped with black

prev ent pene tratio n of light rays.

( 3) Meal from a lfa lfa dipp ed

in pyro gallo l solut ions a nd store

d

glass jars expo 3ed to light .

( 4 ) Meal from alfal fa dipp ed in

pyr ogall ol solut ions a nd store d in

dark (as in 2).

caro tene reta ined by over 50 perc ent duri

The expe nse of such an ope ratio n madng 4 mon ths of

e furt her

imp ract ical .

c:! Tr\T"<>·cn•

Frac tion atio n of Deh ydra ted Alfa lfa

The poss ibili ty of sepa ratin g the fibro

us, stem my part s

dehy drated alfa lfa from the f.iner le~f

frac tion , whi ch is rich .

i n both prot ein and caro tene , was

·

desi rabl e beca use the sma ller bulk inve stig ated . This

of the rich er co.ml>OileiHS.,

coul d be stor ed und er refr iger atio n ,

at less cost than the tota l mea l. Theor in an iner t atm osp

high qua lity mea l so

duce d then coul d be blen ded with othe

caro tene con tent up to desi rabl e leve r mea l to brin g the

ls.

The ungroun d, dehy drat ed alfa lfa cam

e from the pilo t

hyd rato r in liz-i nch leng ths. The se

wer

e

fed to a sma ll

mon d air sepa rato r whi ch separate d the

on the basi s of dens ity and part icle size mea l into two

tion of the air sepa rato r, the prop ortio . By vary ing the

ns of the mea l foun d

CAROTE

PROTEIN

20

40

so

eo

100

PERCENT CA RO TENE OR PROTE

IN IN

FIN E FRACTION

.-Fra ction ation of ungr ound, dehy

drate d altal fa by a ir sepa -

'"'''"H''ll coul d be con troll ed. The resu lts

of

show n in Figu re 18 in whi ch the percthis frac tion aent

frac tion is plot ted agai nst the perc ent by wei ght

of the tota l

or t otal caro ten e, foun d in the fine

frac

tion

. Thu s a

can be prod uced cont aini n g 80 perc ent

of the caro tene

con tain ing 65 perc ent of the weig ht.

This mea ns

qua lity mea l cont aini ng 200,000 I. U.

p er pou nd coul d

ted into two frac tion s, the larg er

of

ch wou ld

con tent of 246, 000 I. U. per pou ndwhi

and

con tain

of the mea l. The sma ller frac tion

wou ld hav e a

. con tent of 114,000 I. U. per pou nd

and

the mea l. This latte r frac tion is still con tain 35 pere mar ket spec ifica tion s for a gua rant good mea l· and

.·.. 00,000 unit s. This coul d be plac ed eed caro tene conon the mar ket im' and only the high caro tene mea l

stor ed for late r

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

32

KANSAS BULLETIN 3 56

sale. Since the cost of storage is an important item,

placed in storage should have as high a carotene

possible.

The wide variation in the quality of alfalfa meal

by commercial dehydrators indicated the need for

mental studies on the· fac tors affecting the

of

alfalfa. T o t h is end, a sma ll rotary drum

for measuring temperatures throughout its l

trolling as many variables as possible was

Department of Chemical Engineering. This

shown in Figure 19.

Fig. 19.-Experimental pilot plant alfalfa dehydrator at

College, Ma nha ttan.

Drum Rotation Rate

One of the most important variables in this type o ·

tor is the rate of rotation of the drum. ·A study of

therefore was conducted in the pilot plant d

Koegle (56) . While the rate of feed to the

flow through the dehydrator, and the outlet temp

held constant, the rate of revolution of the drum

between 12 and 39 revolutions per minute.

It was expected that, as the rat e of revolution

alfalfa would p:·ogress through the dehydrator

This, in effect, shortens the time of drying and

.·

in higher moisture content for the product. At the

the gas temperature at the inlet to the drum

·

through the drum should be higher as the rate of

DEHYDRATED ALFALFA

33

about because the actual amount of water

but slightly for a considerable change

content. In order to remove this water

driving force for the drying process must

would be manifested by the increased tem...... <""""v••cu above.

found to be true between rotation rates of

.. ns per minute. Between 30 and 39 revolu·..··. however, the moisture content of the product

. · temperature gradient through the drum also

observed at the same time that there was

· ··· .alfalfa to pile up in the front end of the drum.

· · interpreted to mean that between 30 and 39

UJ.J..u.u. ~c. the centrifugal force developed held the

of the drum. The rate of revoshould occur can be calculated from theo.

for a smooth drum with no flights. This

··· •..8.2 revolutions per minute for the small 2. used. The flights in the drum, which were

· e o'f 15° to the radii, would tend to reduce

.·.·.· ·. to produce this effect.

installations have drums 8 feet in diameter.

required to hold the alfalfa along the

was calculated to be 19.2 r.p.m., while

ng to the limiting value of 30 r.p.m. f ound

drum would be about 15 r.p.m.

•.·.· . · the desirable operating range will lie below

trifugal force becomes important. In this

.. · in the drier will be proportional to the

.. .. of revolution, if the a ir velocity is held

·.total time spent in the dehydrator, however,

riding around the circumference of the drum

t of the drum, and part is spent in falling from

.stream to the low point of the drum. The

. effective than the former, because of the

the alfalfa and the hot gases.

it seemed desirable to investigate a decontact between the alfalfa and the

......,...o"""'~·~ possible efficiency. This requirement

so-called pneumatic type drier.

·. · s

Type Alfalfa Drier

also known as pneumatic conveyor dryor Flash Drying", is the removal of

material as th·e material is being

under the impulse of hot gases. Usually

~., ...uJ,..,.,.,.,

of Combustion Engin eerin g Com pan y, lnc., New Y ork.

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

KANSAS BULLETIN 3 56

the duct in which drying occurs is vertical; hence, by

design and operation, a considerabl e degree of

can occur according to density, shape, and size of the disp

particle. Sirice a decrease in moisture content is often a<.:'\:V.Lll'

panied by a correspond ing decrease in density without a

responding change in the physical dimensions of the disp

particle, the drying column may be so shaped that the

par~icle will be automatica lly retained in the drying co

unt1l dry and then expelled.

Although artificial drying itself has been practiced for

ries, the commercia l application of the principle of pncu.uH:t.~"

drying dates back only to about 1930. Several comm

makes of driers are available for gen·eral purchase.

drying of chopped grasses, alfalfa, sugar beet tops, etc.,

been claimed for units of .foreign manufactur e, among

are the Pherson (Sweden), Bamag (Great Britain), V

Broek (Holland), and Buttner (Germany) . The use of the

mond Flash Drier manufactur ed by Combustion

Company in the United States has been confined mainly

drying materials such as pulverized coal, chemical salts,

age sludge, and the like. Material which has a tend

cake must be disintegrate d before introductio n into the

column.

De Lorenzi (23) lists four fundamenta l factors which

the rate of moisture r emoval from a dispersed particle

a pneumatic drier. They are:

1. Moisture distribution

2. Temperatu re differential

3. Agitation

4. Particle size

A material in which the moisture is close to the surface

· be dried rapidly to low moisture levels without heat

This rapid rate is possible because the major portion of

is evaporated under a condition such that the rate of

movement from the internal portion of the solid to the s

is sufficiently high to supply water to· the surface as

as it is evaporated. During this period of drying, known

"constant-r ate period" of drying, the rate of evaporation

the particle is independen t of t he structure of t he particle,

the particle as a whole remains at the wet-bulb temp

of the hot gas stream if adiabatic drying conditions~'' pr

A.t some value of moist\'..re content of the solid, known

"critical moisture content," the rate of moisture mi

the surface begins to diminish and the temperatur e of

face of the particle being dried begins to rise.

~Adiab atic.

drying condi tions h eat e n e:rgy f or drying available

dec rease m the s ens tb le heat content o f the h o t gas s tream .

DEHYDRATE D ALFALFA

35

period following this point is the "falling-rat e ·p eriod"

during which the rate of moisture removal diminaccelerated pace, while the surface temperatur e of

a nd the particle as a whole approaches the dryture of the hot gas stream. Unless precautiona ry

are taken to reduce the hot gas temperatur e or to

the material being dried from the hot gas stream,

or "burning" can occur. The critical moisture conof drying during the falling-rate period, and the

at which heat damage occurs are influenced prithe internal structure of the particle and by the

and humidity of the hot gas str eam.

that a high rate of drying be maintained , a broad

differential between the dry-bulb temperatur e of

and the surface of the particle from which moisng evaporated must be maintained . During the conperiod, the temperatur e difference is established

the dry-bulb temperatur e and wet-bulb temperatur e

gas. The t emperature difference during the

period is of secondary importance , however, as the

is controlled almost entirely by the rate of moisture

. . or "diffusion" to the surface. In other words tem. · • and humidity of the gas stream tend to fix th~ rate

. during the constant-ra te period, while the character

. terial being dried tends to fix the rate of drying during-rate period. Time, not temperatur e, is the most

controlled variable during the falling-rate period of

of agitation or turbulence is also frequently deough not always essential to the successful func• a pneumatic drier. The rate of drying during the

period is related directly to the fundamenta l

steady-stat e heat transfer by conduction which

.the rate of heat transfer to a surface is proportiona l

·

ture difference, the extent of t he particle surface,

coefficient of heat transfer." The film coefficient

represents the rate at which heat is t ransa hypothetica l stagnant film composed of a

vapor and dry, hot gas surroundin g the parof the particle in t he hot gas stream or turbugas stream has a marked effect in increasing

transfer for a given temperatur e differential

.·. resistance to h eat transfer. As the critical

and the possibility of heat damage during

..are functions of the rates of heat tran.sfilm separating the particle surface

• the hot gas stream may often be adshould be subjected to extreme

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

33

KANSAS BULLETIN 3 56

turbulenc e during the early part of the constant- rate

followed by a quiescent region extending from the latter

tion of the constant- rate period to some point of withdra

of the dried material within the falling-ra te period.

Particle size, particle shape, and particle density are clos

r elated in any considera tion of pneumati c drying theory.

size and shape are an index of the surface-to-volume

high exposed surface-to -volume ratio for a materia l being

is desirable in that the geometry favors minimum

migration of internal moisture to the surface; and,

low values of critical moisture content and favorable la.J.HJ.JL6 -.:.

rate periods of dryin g occur. The particle s hape a nd pa~ticle

density t ogether determine the relative movemen t between the

particle and the hot gas stream. This movemen t, in turn, ·

rectly influence s the value of the film coefficien t o.f heat

fer and the height of drying column r equired for a given

service. Material having the shape of a flake is ideally

to drying to low-mois ture values in a pneumati c-type drier

cause of short distances for moisture migration .

Experime ntal Drier

With meager design informati on an experime ntal pneuma

drier was set up in the chemical engineeri ng departme nt

Kansas State College for the purpose of learning of its

use as a pre-drier to boost the capacity of commerc ial

type driers used for alfalfa drying. This first unit,

during th e summer of 1949, was never successful because

insufficie nt drying capacity and extravaga nt use of heat.

Profiting from the experien ce of the first attempt, the

neers construct ed a · new column with th e purpose of (a)

creasing the time of contact of the particle with the hot

(b) providing greater opportun ity for flotation and

tion of the dispersed particles, and (c) providing a col

.

from which data might be obtained for the more rational d •

sign of future pneumatic drying columns.

The exp erimental drier finally used consisted of a

furnace, blower, drying column, and cyclone separator .

arrangem ent of these units and oth er details are shown

matically in Figure 20. As noted, the drying column

cylindrica l metal duct 24 feet in length and 16 inches in

ter, with a tapered transition section at the lower end.

vation windows and thermocouple connectio ns for

gas temperatu res were suitably placed along the wall

ins ulated column. A stem separator was included in the

ition section to r emove large stems from t he field-ch

alfalfa before appreciab le drying occurred.

Details of furnace, blower, feeder, a nd cyclone

are omitted here, since they were auxiliary equipmen t to

DEHYDRA TED ALFALFA

37

column under study. The blower could be installed to

suction on the cyclone separator, thereby avoiding operaat excessive temperatu res.

each test, samples of alfalfa were collected every

minutes from the feed to the column, from the stem separa-

E XHAUST

GASES

DRYING

COLUMN

DRlFO ALFALFA

PF.OOUCT

STEM

DISCHAR '?E

VENT\.Ri FEED

SECTION

20. -Diagram of experiment al, verti cal drying unit a t K ansas State

Manhattan.

from the top of the pneumati c drying column, and from

product withdraw n from the cyclon e separator. In

on, temperatu res of the hot gases entering and leaving

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

38

KANS AS B ULLET IN 356

DEHY DRAT ED ALFA LFA

t h e test secti on were recor ded, togeth er

nece ssary

for deter minin g the alfal fa f eed rate, thewith

rate of stem

draw al from the sepa rator , t h e hot conv

- a-a s r at e and

hum~dity of_ th_e co~veying gas. Thes e .eyino

da ta"' ; ere an~lyzed

provide a n msight m t o t h e drying oper ation

.

10.0

90

80

\

70

\1

60

so

\

40

1\l

30

1\

20

:

.

\

'

I

~

10

;

9

1\

8

\

'

'

7

1\

6

5

\

4

\

Wo:Mo iatuuo n Feed , ID./Ib . bone drtAif

ol~

Wo: Moistu re ia Produc t, lb./lb. boae 6ryAifa

lfa .

2

1000

I I JI

I J 1111 1'

ISOO

20 00

2500

W;ASS VELOC ITY T hrough Prt i noColu mn

lb./hr. -

sq. ft.

Fig. 21.-Relatio nsh ip betwe en drying gas

rate and initial and

a lfalfa moist ure con tent.

Experime nta l R esult s

of the data obtai ned f or a tota l of 63 sepa r ate

dr ying

alfal fa of wide ly diffe rent initial m oistur e conte

nt

the dryin g rate was influ enced prim arily by

the ve. and temp eratu r e of the hot conv eying gas,

a nd the mois. · cont ent and rate of the alfal fa feed. For

inlet hot gas

eratu res of over 720° F., the reduc tion in mois

.. ··. of the a lfalfa durin g dryin g in t h e expe rime ture conntal colum n

d t o be a funct ion of the mass velocity (lb./ h r.sq. ft.)

gas flow throu gh the cross -sect ion of t he dryin

g colum n.

the m ass veloc ity of the gas inste ad of t he veloc

ity of

(whi ch is sensi tive to temp er at ure becau se of

the terneffec t on the dens ity), a grou p ( W 0 - 1 ) was

correW,

(F ig. 21 ), wher e Wo is t he moist ure conte

W, is the moist ure conte nt of the prod uct,nt of the

both exas lb./ lb. of alfal fa (moisture-free ) . The temp

erature

f the hot gas strea m was r educe d by this

m ethod of

becau se of the inter rela tion sh ip of temp

, and veloc it y of the ga s strea m a t any cross eratu re,

colum n, an d becau se of the temp eratu re, dens -sect ion

ity, and

gr adien t t hrou gh t he colum n.

a lfalfa was fed to the expe rime ntal dryin g colum

n

of only 200 lb./h r., much high er feed rates a r e

possi ble

• a suita ble feedi ng syste m. F or an assum ed

val

t (wet basis ) for the a lfalfa feed, and 6 p er ue of 70

cent (wet

for the dr y leaf leavi n g the dryin g secti on,w

o -1 equals

.

.·.·cor respo nding to a hot gas rate of 1950 wl

· in itial gas t empe ratur e to the drying lb./ hr.-s q. ft.

secti on were

.··.. F a nd the dryin g gas were exha ust ed at 250

°

. ;b.eat ener gy woul d be abou t 680,000 BTU / F, the availhr.-s q.

colum n cross -sect ion. This h eat energ y woul ft. of

to a mois ture r em oval from t he alfal fa of 680d corre This mois ture remo va l rate indic ates a feed rate lb./ h r .of wet alfalf a per h our per squar e foot, andof 1000

r a te of 300 lb./ hr .-sq. ft. F or a drier of t h is type,a dry

heat

not exceed 25 p ercen t of the avail able hea t energ

y

; therefore, the final colum n woul d have

capacity of 750 lb./h r. of wet a lfalfa for each an apsqua re

· ·.·col umn cross -sect ion area.

pract ice may requi r e that t his figur e be reduc

ed some e t h e prese nce of a more dens e suspe nsion

of a lto pr oduc e high er linear gas veloc ities. S ince

t he

city must be caref ully contr olled to prop erly

"floa t"

a gr eater alfa1fa feed r ate tends to reduc e the

al-

j

I

i

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

40

KANSAS BULLETIN 3 56

Iowable mass velocity together with the heat energy

capacity of the gas.

The height of the drying column in the floating bed

pneumatic drier is not critical, provided that 'it exceeds a

tain minimum for practical operation. Theoretically, an ~··~...,.

leaf should remain in a drying section, regardless of

until sufficient moisture has been lost to allow it to be exp

Actually, however, a minimum height of column is set by

distance required to reduce the velocity of the wet alfalfa

injected upward into the column to the settling velocity in

hot gas stream. A height of 24 feet was found to be sati

tory, although higher columns are recommended for ultlU~Ll

installations. Short columns are undesirable in that the alfa

is virtually thrown from the inlet to the point of egress,

lowing very little time for drying. This is especially true

the feed is composed of alfalfa containing many coars

chopped stems.

The pneumatic-typa drier shows promise in the fiel d of

ficial a1falfa drying. A drier of this type may be

from energy balance considerations and experimental

presented. Further work is required to determine the

degree of field chopping and control features to yield a

product of consistently uniform quality.

Storage of Dehydrated Alfalfa

Dehydrated alfalfa frequently is s.tored before being sold

used in mixed feeds, since production in Kansas is limited

about a six-month period, while peak use occurs during

winter." Frequently it is advantageous to store high

meal produced early in the season and use it for blending

tions later. Market pr;ces are also a factor in storage

tions.

Dehydrated alfalfa has been commonly packaged in

bags each containing 100 pounds of meal. R ecently

operators have shifted to paper bags. These are usually

pound bags. Silker, Schrenk, · and King (91) previously

shown that such packaging had no deleterious effect on

meal. The paper bags help · eliminate some of the dust

ciated with packagin g and also with storage, thus

value in the warehouse. The burlap bags have salvage

while paper ones have none.

Some alfalfa meal is pelleted after passing through the

mer mill. The most common size is 3/16 inch in diameter.

pellets are produced as large as 1fz inch in diameter.

problem is not as troublesome with pellets, but an addi

operation is r equired. Pelleted m eal can be handled with

weighing and loading equipment, and bulk shipment is possibl "

DEHYDRATED ALFALFA

41

requires careful control of moisture if the pellets

be satisfactory. The pressure of pelleting also produces

ble heating. The extra heat of pelleting is usually

in a storage hopper before the pellets are weighed

ed into freight cars or trucks or placed in storage.

pellets are produced without the use of hammer mill

~·"''·""~''~o the dry chops. These pellets usually are consumed

industry and apparently are quite satisfact ory for

use.

alfalfa meal has certain advantages. The dust

is diminished, l~ss volume is required, and bulk loadhandling are quite satisfactory.

manufacturers have experimented with a small amount

material in the pellets. One such additive, bentonit e,

of clay, has been used in quantities of l ess than 2 per.. This binding material, contrary to some reports, had

on 't he stability of carotene in t he alfalfa.

usually is dried to a moisture level of 6-8 percent on

t basis. This level is lower t han the normal equivalue for moisture in the meal and the average vapor

of the moisture in the atmosphere. As a result, dealfalfa meal usually will pick up moisture from t he

. The gain in w eight, due t o moisture, may be as

2-4 pounds per 100 pounds of alfalfa during even a

short period of storage. Schrenk and King (85)

the vapor pressure of water adsorbed on dehydrated

and have indicated that excessive drying is an addi. cost of operation.

must be continued, however, until all stemmy rnasufficiently dry to pass through the hammer mill

. It appears likely that with present t ypes of deunits the maximum moisture level that will permit

tion of the hammer mill would be most desirable.

may vary with different grades of alfalfa, but an

figure appears to be in t he neighborhood of 8-19 peradditional advantage to be gained is in the extra proafforded the car otene content of the alfalfa, since

Schrenk, and King (91) pointed out t hat increasing the

content of alfalfa resulted in slowing down the deof carotene in the meal during storage.

··· dust hazard in storage is also eliminated in part by the

· · small amount of oil added to the meal. This procedure

··.to have no effect on carotene or other nutrients in al. does tend to eliminate dust. Schoenleber (83 ) has

the cost of adding oil to the meal a t $1.50 per ton.

has no stabilizing effect on the carotene in alfalfa.

This publication from the Kansas State University Agricultural Experiment Station and Cooperative Extension Service

has been archived. Current information is available from http://www.ksre.ksu.edu.

42

'

;.·.

KANSAS BULLETIN 3 56

Fire Hazards

Alfalfa storage is also hazardous from the standpoint of

Alfalfa, sackP.d as it comes from the hammer m ill, will ha

a temperature 20° to 30° F. above the atmosphere. Sin ce it

finely divided the meal insulates itself well. 'The net result

that the center of a sack of meal cools very slowly. If

foreign part icles are in the meal, small rocks, metal, etc.,

m ay start a slow fire in the interior of t h e bag which may b

unnoticed for considerable time. Care, therefore, should b

.·

exerted to r emove all such foreign substances from

m eal before sacking. Electromagne ts are frequentiy used

remove particles of magnetic substances.

The temperature differ ential of alfalfa in a bag also caus

carotene losses to be uneven. The greatest loss of

takes place in t he center of the ba g wher e temperatures

highest. This requires that care be exercised in sampli

stored alfalfa meal wh en blending operations a re carried

·