International Journal of Application or Innovation in Engineering & Management...

advertisement

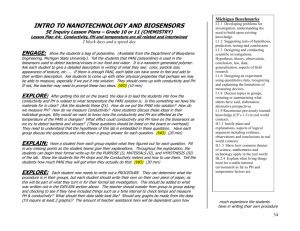

International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 8, August 2015 ISSN 2319 - 4847 A.C conductivity and dielectrical properties of bulk Polyaniline/Ferro Fluid nano composites Salma M. Hassan1, May S.Ibraheem2 , Harith I. Jafaar3 Baghdad University – College of Science – Physics Department, Al-jadiria, Baghdad, Iraq ABSTRACT Polyaniline pure and doped in ferro fluid was prepared in different concentration at room temperatuer. The ac electrical properties were stadied.AC conductivity,σac(ω), is found to vary as ωs in the frequency range(50Hz-15MH),s < 1and increases with the increase of ferro fluid indicating adominat hopping process. The conductivity increased two order with increasing the concentration of ferro fluid, and one order with frequency. The dielectric constant ε1and dielectric loss ε2 have been determined for bulk polyaniline. Both ε1 and ε2 decreases with increasing frequency. Keywords: polyaniline, Ferro fluid, A.C conductivity, Dielectric constant 1. INTRODUCTION Polyaniline has been the subject of considerable scientific inquiry because of its unique electrical behavior and its potential as an environmentally stable conducting polymer.conductivity exhibits a strong dependence on solution PH [1] ,oxidation stat[2] and water content. Polyaniline is synthesised by the electrochemical or chemical oxidative polymerization of aniline and can exist as a number of unique structures, charactrized by the oxidation state, i.e., the ratio of amine to imine nitrogens, and the extent of protonation. These different structures can be interconverted by acid / base or oxidation / reduction treatment[3]-[4] . Polyaniline can be prepared in three major form (LEB) that, Y is one, the half oxidized emeraldin base (EB), Y is 0.5 and for fully oxidized pernigraniline base (PNB),Y is 0 as in Fig.(1)[5]-[6] . Polyaniline is an insulator in each of these forms with a band gap 3.6eV. These polymers can also exist in the corresponding protonated(salt) forms but only emeraldinsalt (ES) has shown high electrical conductivity[7] the structure of the Polyaniline(PANI) chain can be expressed by the general formula [8] . Figure 1 The structure of the polyaniline chain [8]. In the present work, the a.c. conductivity, dielectric constant and dielectric loss measurements have been perfoemed for polyaniline pure and dopeed with (0.5,1,and2)wt% Ferro fluid in bulk form. The measurments have been carried out in the frquency range form 50Hz to 15MHz . 2.EXPERIMENTAL WORK 2.1 synthesis of Fe3 O4 nano particles and Ferro fluid the co-precipitation [9] method was used to synthesize Ferrofluid. The process for the Fe3 O4 nucleation from the salt solution occurs in accordance with the reaction: 2FeCl3 .6H 2O + FeCl2 .4H 2O + 8NH4 OH→ Fe3 O4+8 NH4Cl +20H 2O A solution of FeCl3 and FeCl2 mixed in a molar ratio of 2:1 was prepared in contact with air . An ammonia aqueoues solution (25%) was then quikly charged into the solution with vigorous stirring using a mechanical stirrer, followed by adding more ammonia aqueous solution into the mixture while stirring. The solution was stirred for about one hour. A black precipitate was obtained. Oleic acid 5% v/v was added slowly and intensely stirred at 60°C for 30 min. the precipitate was separated using a magnet and washed with deionised water and methanol several time. The Ferro fluid solution was centrifuged at low temperature for ten minutes. Precipitate was dried at 70°C for 3 hours . 2.2 synthesis of PANI/ Fe3 O4 nano composites. The preparation of (PANI) is based on the oxidation of (0.2M) aniline hydrochloride with (0.25M) ammonium peroxy disulfate in aqueous medium. The pure sample was prepared in distilled water and the doped sample with different Volume 4, Issue 8, August 2015 Page 118 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 8, August 2015 ISSN 2319 - 4847 concentration of Ferro fluid (0.5, 1 and 2Wt. %). The preparation steps was, aniline hydrochloride dissolved in distilled water in volumetric flask to 50ml, ammonium peroxy disulfate is similarly dissolved in to 50 ml of solution both solutions are mixed at room temperature in a rounder, and gently stirred to polymerize the mixture, then it was left to rest to the next day. The (PANI) precipitate is collected on a filter and washed with three 100 ml of (0.2M) HCl, and 150ml of acetone. Polyaniline (emeralidin) hydrochloride powder is dried in air for about one hour then in vacuum oven about (80 ºC) for 6 hours, the average yield is (1.85)gm. The a.c. electrical measurements are used to investigate polyaniline samples doped during polymerization with various concentration of Ferro fluid. The polyaniline powder was thoroughly grounded in a mortar to obtain very fine particles, and then it was compressed under a pressure 7 tone in the form of a pellet. The resulting pellet has a diameter of 1.0cm and thickness of 1.35 -1.5mm). A computerized sensitive impedance analyzer type (Avcitive Awia, Agilent 4294A was used for the a.c. measurements at room temperature. The sample was placed in a holder specially designed to minimize stray capacitance. The range of frequency was 50Hz -15MHz.for the sample under investigation, the specimen capacitance, C, dissipation factor, D, and resistance, R, has been measured .The total conductivity was calculated from the following equation: σt(ω) = (1) where d is the thickness of the sample and A is the cross-section area. The a.c. conductivity σac(ω) was calculated by using the relation: σac( ω) = σac(ω) + σdc(ω) (2) where σdc is the d.c. conductivity. The dielectric constant, ε1, was calculated from the equation: ε1 (3) where εο is the permittivity of free space. The dielectric loss, ε2, was calculated from the equation: ε2 = ε1 tanδ (4) Where δ =90 – φ, φ is the phase different angle. 3. RESULTS AND DISCUSSION The a.c. conductivity for the common polymer is changes with the frequency according of the following formula: σac(ω)=σt – σd.c =Aωs [10] (5) Where A is a constant independent on temperature, ω =2*π*f, and s is the frequency exponent. Fiq. (2) Shows the frequency depended of the measured total conductivity σt for polyaniline pure and doped with different Ferro fluid concentration (0, 0.5, 1and 2 wt %) samples at room temperature. It was observed that the σt, increased with the angular frequency .the variation of conductivity with frequency reveals that the charge transport mechanism can be considered to be semiconductor[11] and with increasing the concentration of Ferro fluid the behavior was not systematic ,σac , is obtained by subtracting the d.c. conductivity, from the measured total conductivity according to Eq.(5). Fig. (3) Shows the dependence of a.c. conductivity on frequency at different concentration. It is clear from the figure that σa.c increases with the increase in frequency. The frequency exponent s, can be calculated from the slope of the straight lines in figure 3, the value of exponent s is listed in table 1. Figure 2 total conductivity as a function of frequency for different concentration of PANI/Ferro fluid. Volume 4, Issue 8, August 2015 Page 119 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 8, August 2015 ISSN 2319 - 4847 Figure 3 a.c. conductivity for a. pure PANI, b. PANI/0.5g Ferro Fluid, c. PANI/1g Ferro Fluid and d. PANI/2g Ferro Fluid nano composite. Table (1): list of the value S Samples (S )exponent factor PANI 0.696 0.5 Ferro 0.965 1.0 Ferro 0.972 2.0 Ferro 1.426 From the table, the exponent s was found to be less than unity for all powder nanocomposites except the sample of 2.0 Ferro fluid. The behavior of A.C.() with the frequency can be explained in terms of polarization effect and hopping i.e., polarization effect in low frequency region is slightly changed and D.C. is dominating, but at higher and high frequencies the polarization is increased gradually, and the conductivity here can be related to the hopping of the charge carrier over a small barrier height [12]. The conductivity in PANI increases because of contribution of polaron, which is moving along smaller and smaller distances in polymer chain. Volume 4, Issue 8, August 2015 Page 120 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 8, August 2015 ISSN 2319 - 4847 3.1 Frequency dependence of dielectric constant Figure 4 Frequency dependence of dielectric constant for PANIpure and PANI/ Ferro Fluid at different concentration. The dielectric constant was calculated from the measured value of capacitance in the range of frequency 40Hz-15MHz. The frequency dependence of ε1 is shown in Fig. 4 It is clear from the figure that ε1 decreases with the increase in frequency. The dielectric constant shows at low frequency and the variation is small at high frequencies. The decrease of ε1 with frequency can be explained as follows: at low frequencies, ε1 for polar materials is due to the contribution of multi-component of polarizability, deformational polarization (electronic, ionic, orientational, and interfacial) [13, 14]. When the frequency is increased, the dipole will no longer be able to rotate sufficiently rapidly. So, their oscillation being to lag behind those of the field. As the frequency is further increased, the dipole will be completely unable to follow the field and the orientation stopped, so ε1decreases at a higher frequency approaching a constant value due to the interfacial polarization [15]. 3.2 Frequency dependence of dielectric loss The dielectric loss, ε2, was measured as a function of frequency. Fig.5 shows the dependence of ε2 on the frequency. It is observed from the figure that ε2 is found to decrease with the increase in frequency. The origin of the dielectric losses are the conduction losses [16]. As the frequency increases σa.c increases and the electrical conduction losses increase and hence increase the value of the dielectric loss. Figure 5 Frequency dependence of dielectric loss for PANIpure and PANI/ Ferro Fluid at different concentration. 4.CONCLUSION A.C. conductivity of prepared pure and doped with different concentration of Ferro fluid at room temperature was measured as a function of frequency in compressed pellet , the a.c. conductivity was found to vary as ωs in the frequency range 50Hz-15MHz. ,the frequency exponent ,s, was less than unity accept the sample with 2.0 Ferro fluid, the value of conductivity increased with increasing of Ferro fluid around two order from 2.9x10-4 S/cm to 2.18x10 -2 Volume 4, Issue 8, August 2015 Page 121 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 8, August 2015 ISSN 2319 - 4847 S/cm indicating a dominant barrier hopping mechanism, the variation of conductivity with frequency increased one order for the sample, the conductivity for PANI increased from (2.9x10 -4 S to 9.2x10 -3 ) S/cm, reveals that the charge transport mechanism can be considered to be semiconductor. Both ε1, and ε2 was found to decrease with the increase in frequency and not systematic. REFERENCES [1] Jagadeesh Babu Veluru , Satheesh K.K., Journal of Engineered fibers and Fabrics, Vol.2,Issue2-2007. [2] S.C.Kmisra, Maneesha yadav, Prafull Mathur, Thin Solid Films Vol.514, pp.272-277, 2006.G.A Rimbu, I.Stamatin, C.L.Jackson, K.Scott, Journal of Optoelectronic and Advanced Materials. Vol. 8, No.2, pp.670-674, 2006. [3] A.J.Motheo.J.R.Santos Jr, E.C. Venanico and L.H.C.Mattoso, Polymer Vol.39, No.26, pp.6977-6982, 1998. [4] J. Stejskal, R.G. Gilbert "Pur Appl. Chem., Vol.47, N0.5,PP.857-867,2002. [5] Z. Opilsk, T. Pusteiny, E. Maciak,M. Bednorz, A.Stolarezy and M. Jadamiec, technical Sciences, Vol. 53, No.2 ,pp.151-156,2005. [6] Huber.Trisha “Conducting Polymers as Radar Absorbing ”DRDC Atlantic TM, , P014, 2003. [7] Medhat Ibrahim and Eckhard Koglin, Acta Chim. Slov. Vol.52, pp.159-163, 2005. [8] Pryanka, Simran, Adarsh Singh, Vivek Verma, International Journal of Engineering Research&Technology ,Vol. 2 Issue 4, pp.1321-1324, 2013. [9] A.N.Papathanassiou,J,Phys. D:Appl Phys. Vol.35, L88-L89, 2002. [10] Safaa K. El-Mahy, M.Dawy and E.Abd El-Aziz, Journal of Applied Sciences Research, Vol.9 (4), pp.2918-2926, 2013. [11] T.T.Al-Dhhan,C.A.Hogarth. Int.J. Electron.Vol.63, p.707, 1987. [12] A.M.Farid,A.E Bekheet,Vacuum Vol.59,p. 932, 2000. [13] K.Gupta,G.Chakraborty,P.C.Jana and A.K.Meikap , Journal of Physical Sciences,Vol.13, pp.251-260, 2009. [14] S.c.Racavendra, Syed Khasim, M.Revanasiddappa, Bull.Mater .Sci., Vol.26,No7,pp.733-739, 2003 [15] M.M.El-Nahass, A.M. Farid, K.F.Abd El-Rahman, H.A.M.Ali, Physica B Vol.403, pp.23331-2337, 2008. AUTHORS Salma M. Hassan (born in Baghdad in Julay ,1 972). Received a B.Sc (1994) M Sc (2001), and Ph.D. (2010)in material physics from Baghdad university . she was a lecture at the material lab of the physics DepartmentCollege of Science of Baghdad university. Her research interest in material physics field, and she has many published research in conjugated polymer and polymer blends. May S. Ibraheem ((born in Baghdad in December,1989). Received a B.Sc (2011) in physics department\ collage of science\ university of Baghdad and now she is student, she is publishing this paper as a required part to get MSc in material physics from Baghdad university. Volume 4, Issue 8, August 2015 Page 122