An Analysis of Lift and Drag Forces of NACA

advertisement

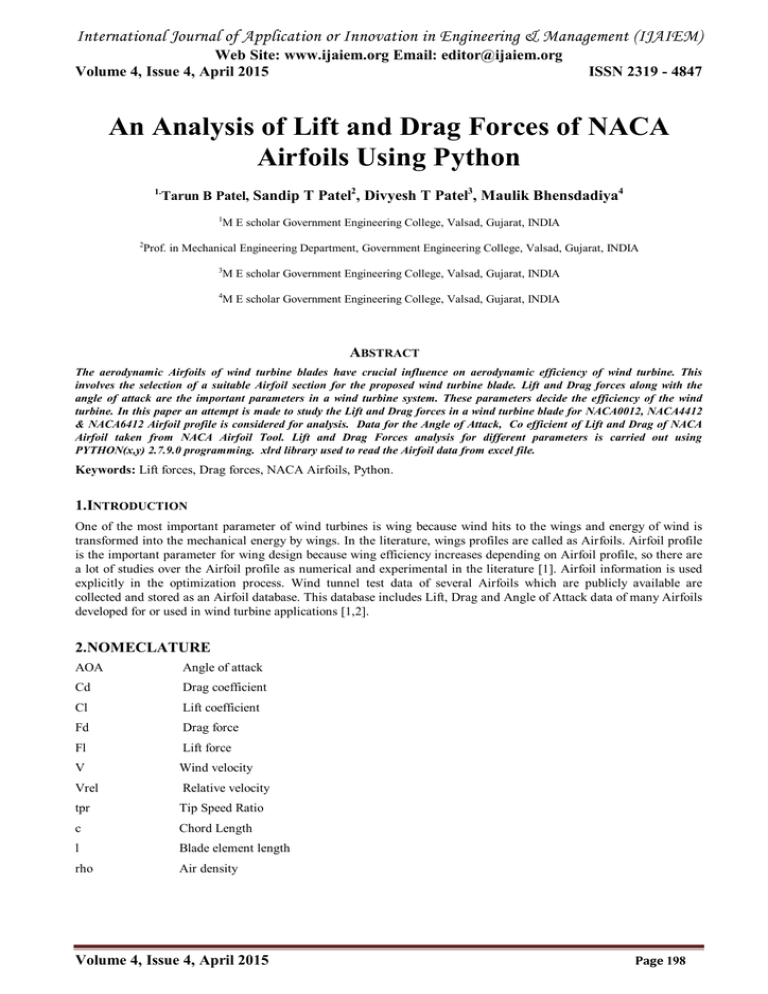

International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 4, April 2015 ISSN 2319 - 4847 An Analysis of Lift and Drag Forces of NACA Airfoils Using Python 2 1. 3 4 Tarun B Patel, Sandip T Patel , Divyesh T Patel , Maulik Bhensdadiya 1 M E scholar Government Engineering College, Valsad, Gujarat, INDIA 2 Prof. in Mechanical Engineering Department, Government Engineering College, Valsad, Gujarat, INDIA 3 M E scholar Government Engineering College, Valsad, Gujarat, INDIA 4 M E scholar Government Engineering College, Valsad, Gujarat, INDIA ABSTRACT The aerodynamic Airfoils of wind turbine blades have crucial influence on aerodynamic efficiency of wind turbine. This involves the selection of a suitable Airfoil section for the proposed wind turbine blade. Lift and Drag forces along with the angle of attack are the important parameters in a wind turbine system. These parameters decide the efficiency of the wind turbine. In this paper an attempt is made to study the Lift and Drag forces in a wind turbine blade for NACA0012, NACA4412 & NACA6412 Airfoil profile is considered for analysis. Data for the Angle of Attack, Co efficient of Lift and Drag of NACA Airfoil taken from NACA Airfoil Tool. Lift and Drag Forces analysis for different parameters is carried out using PYTHON(x,y) 2.7.9.0 programming. xlrd library used to read the Airfoil data from excel file. Keywords: Lift forces, Drag forces, NACA Airfoils, Python. 1.INTRODUCTION One of the most important parameter of wind turbines is wing because wind hits to the wings and energy of wind is transformed into the mechanical energy by wings. In the literature, wings profiles are called as Airfoils. Airfoil profile is the important parameter for wing design because wing efficiency increases depending on Airfoil profile, so there are a lot of studies over the Airfoil profile as numerical and experimental in the literature [1]. Airfoil information is used explicitly in the optimization process. Wind tunnel test data of several Airfoils which are publicly available are collected and stored as an Airfoil database. This database includes Lift, Drag and Angle of Attack data of many Airfoils developed for or used in wind turbine applications [1,2]. 2.NOMECLATURE ΑOA Angle of attack Cd Drag coefficient Cl Lift coefficient Fd Drag force Fl Lift force V Wind velocity Vrel Relative velocity tpr Tip Speed Ratio c Chord Length l Blade element length rho Air density Volume 4, Issue 4, April 2015 Page 198 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 4, April 2015 ISSN 2319 - 4847 3. AIRFOIL Airfoils are structures with specific geometric shapes that are used to generate mechanical forces due to the relative motion of the Airfoil and a surrounding fluid. Wind turbine blades use Airfoils to develop mechanical power. The cross-sections of wind turbine blades have the shape of Airfoils. The width and length of the blade are functions of the desired aerodynamic performance, the maximum desired rotor power, the assumed Airfoil properties, and strength considerations. Fig 1- Terminology of Airfoil. Terminology of Airfoil shows in Fig 1.Air flow over an Airfoil produces a distribution of forces over the Airfoil surface. The flow velocity over Airfoils increases over the convex surface resulting in lower average pressure on the ‘suction’ side of the Airfoil compared with the concave or ‘pressure’ side of the Airfoil. Meanwhile, viscous friction between the air and the Airfoil surface slows the air flow to some extent next to the surface. Lift force – defined to be perpendicular to direction of the oncoming air flow. The lift force is a consequence of the unequal pressure on the upper and lower Airfoil surfaces. Drag force – defined to be parallel to the direction of the oncoming air flow. The drag force is due both to viscous friction forces at the surface of the Airfoil and to unequal pressure on the Airfoil surfaces facing toward and away from the oncoming flow. Fig 2 shows the Lift and Drag Forces on Airfoil. Fig 2- Lift and Drag forces. The lift and drag forces are calculated by the following formula. Lift = (1/2)*rho* CL*c*l*Vrel² Drag = (1/2)*ρ* CD*c*l*Vrel² Where rho – density of air - 1.2 kg/m³ c – Chord length in meter l – Length of the blade element Vrel – relative velocity of air in m/s = V (1+ (tpr) ²)0.5 Volume 4, Issue 4, April 2015 Page 199 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 4, April 2015 ISSN 2319 - 4847 4.NACA AIRFOIL The NACA Airfoils are Airfoil shapes for aircraft wings developed by the National Advisory Committee for Aeronautics (NACA). The shape of the NACA Airfoils is described using a series of digits following the word “NACA”. The parameters in the numerical code can be entered into equations to precisely generate the cross-section of the Airfoil and calculate its properties. 4.1NACA 4 digit Airfoil specification This NACA Airfoil series is controlled by 4 digits e.g. NACA 2412, which designate the camber, position of the maximum camber and thickness. If an Airfoil number is NACA e.g NACA 2412 MPXX M is the maximum camber divided by 100. In the example M=2 so the camber is 0.02 or 2% of the chord P is the position of the maximum camber divided by 10. In the example P=4 so the maximum camber is at 0.4 or 40% of the chord. XX is the thickness divided by 100. In the example XX=12 so the thickness is 0.12 or 12% of the chord. 5.ANALYSIS USING PYTHON Python is a widely used general-purpose, high-level programming language. Its design philosophy emphasizes code readability, and its syntax allows programmers to express concepts in fewer lines of code than would be possible in languages such as C++ or Java. The language provides constructs intended to enable clear programs on both a small and large scale. Python(x,y)2.7.9.0 is used for the programming. xlrd library used for the read the excel file which contain data for different NACA Airfoils. The Airfoil profiles selected for the analysis are NACA0012, NACA4412 and NACA6412. The database contains Airfoils that are designed or used for wind turbine applications. The lift and drag coefficients of the Airfoils, that are based on wind tunnel test, are listed for various angles of attack and Reynolds numbers. Data are taken from the Airfoil tool. Fig 3-5 shows the NACA profile and Table 1-3 shows the data of each. 5.1NACA001 (Max thickness 12.2% at 22.5% chord. Max camber 0% at 0% chord) Fig 3- NACA0012 Airfoil (Source “NACA Airfoil Tool”) Table 1- Sheet1 data NACA0012 Cl & Cd for AOA Reynolds No = 50000 AOA Cl Cd 1 -0.017 0.2162 2 0.3527 0.01992 3 0.4357 0.0225 4 0.5252 0.02594 5 0.6109 0.03079 6 0.6828 0.03762 7 0.7446 0.04637 8 0.7173 0.06535 Volume 4, Issue 4, April 2015 Page 200 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 4, April 2015 ISSN 2319 - 4847 5.2NACA4412 (Max thickness 12% at 30% chord. Max camber 4% at 40% chord) Fig-4 NACA4412 Airfoil (Source “NACA Airfoil Tool”) Table 2- Sheet2 data NACA4412 Cl & Cd for AOA Reynolds No = 50000 AOA Cl 1 0.3166 2 0.4299 3 0.5279 4 0.635 5 0.7094 6 0.7723 7 0.843 8 0.9309 9 1.2725 10 1.3248 11 1.3527 12 1.4092 13 1.381 14 1.2403 Cd 0.03657 0.04014 0.04426 0.04832 0.05375 0.06012 0.07193 0.04155 0.03991 0.03091 0.04742 0.05796 0.07194 0.09792 5.3NACA6412 (Max thickness 12% at 30.1% chord. Max camber 6% at 39.6% chord) Fig-5 NACA6412 Airfoil (Source “NACA Airfoil Tool”) Table 3- Sheet3 data NACA6412 Cl & Cd for AOA Reynolds No = 50000 AOA Cl 1 0.3871 2 0.4843 3 0.5632 4 0.6138 5 0.6602 6 0.7021 7 0.6765 8 0.721 9 0.7932 10 0.8434 Volume 4, Issue 4, April 2015 Cd 0.04738 0.05252 0.05831 0.06554 0.07377 0.08387 0.09828 0.10767 0.11926 0.13017 Page 201 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 4, April 2015 ISSN 2319 - 4847 5.4Python Programme to find the Lift and drag forces for NACA Airfoils. Fig 6 shows the screen layout of Python(x,y) 2.7.9.0 programming and its output. Excel file read by the xlrd package for the Python. Fig 6 - Python programming and output. 6.RESULTS The Lift and Drag forces are find out here for different parameter which is shown in Table 4-7.There behavior shown in Fig 7-12. 6.1Lift and Drag forces for the tpr=5, V=8m/s , c=2m & various AOA Table 4- Lift and Drag forces for various AOA AOA NACA0012 NACA4412 NACA6412 Fl Fd Fl Fd Fl Fd 1 -33.9456 431.7082 632.1869 73.02298 772.9613 94.60838 2 704.2714 39.77626 858.4243 80.15155 967.0502 104.8719 3 870.0058 44.928 1054.111 88.37837 1124.598 116.4334 4 1048.719 51.79699 1267.968 96.48538 1225.636 130.8703 5 1219.845 61.48147 1416.53 107.328 1318.287 147.3039 6 1363.415 75.11962 1542.129 120.0476 1404.953 167.4716 7 1486.817 92.59162 1683.302 143.6298 1350.835 196.2455 8 1432.305 130.4909 1858.821 82.96704 1439.693 214.9955 9 …….. …….. 2540.928 79.69229 1583.862 238.1384 10 …….. …….. 2645.361 61.72109 1684.101 259.9235 11 …….. …….. 2701.071 94.68826 ……. ……. 12 …….. …….. 2813.891 115.7345 ……. ……. 13 …….. …….. 2757.581 143.6498 ……. ……. 14 …….. …….. 2476.631 195.5267 ……. ……. Volume 4, Issue 4, April 2015 Page 202 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 4, April 2015 ISSN 2319 - 4847 Fig 7- NACA0012 Lift & drag forces for AOA Fig 8–NACA4412 Lift & drag forces for AOA Fig 9-NACA6412 Lift & drag forces for AOA Volume 4, Issue 4, April 2015 Page 203 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 4, April 2015 ISSN 2319 - 4847 6.2Lift and Drag forces for the tpr=5, AOA=70 and c=2m & Varying V Table 5- Lift and Drag forces for various V Velocity NACA0012 NACA4412 NACA6412 Fl Fd Fl Fd Fl Fd 5 580.78 36.1686 657.54 56.1054 527.67 76.6584 6 836.3347 52.08278 946.8576 80.79178 759.8448 110.3881 7 1138.344 70.89046 1288.778 109.9666 1034.233 150.2505 8 1486.817 92.59162 1683.302 143.6298 1350.835 196.2455 9 1881.753 117.1863 2130.43 181.7815 1709.651 248.3732 10 2323.152 144.6744 2630.16 224.4216 2110.68 306.6336 Fig 10-NACA Airfoil Lift & drag forces for Wind velocity. 6.3Lift and Drag forces for the V =5, AOA=70 and c=2m & Varying tpr. Table 6- Lift and Drag forces for various tpr tpr NACA0012 NACA4412 NACA6412 Fl Fd Fl Fd Fl Fd 5 1486.817 92.59162 1683.302 143.6298 1350.835 196.2455 6 2115.855 131.765 2395.469 204.3963 1922.342 279.2724 7 2859.264 178.0608 3237.012 276.2112 2597.76 377.3952 8 3717.043 231.479 4208.256 359.0746 3377.088 490.6138 Fig 11-NACA Airfoil Lift & drag forces for Tip speed ratio. Volume 4, Issue 4, April 2015 Page 204 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 4, April 2015 ISSN 2319 - 4847 6.4Lift and Drag forces for the tpr = 5 and c=2m & Varying AOA & V. Table 7- Lift and Drag forces for Varying AOA & V Wind velocity AOA 5 NACA0012 NACA4412 NACA6412 Fl Fd Fl Fd Fl Fd 1 -13.26 168.636 246.948 28.5246 301.938 36.9564 6 2 396.1526 22.37414 482.8637 45.08525 543.9658 58.99046 7 3 666.0982 34.398 807.0535 67.66469 861.0202 89.14433 8 4 1048.719 51.79699 1267.968 96.48538 1225.636 130.8703 9 5 1543.866 77.81249 1792.796 135.837 1668.457 186.4315 10 6 2130.336 117.3744 2409.576 187.5744 2190.552 261.6744 11 7 2811.014 175.056 3182.494 271.5501 2553.923 371.0267 12 8 3222.685 293.604 4182.347 186.675 3239.308 483.739 Fig 12-NACA Airfoil Lift & drag forces for varying Wind velocity & Angle of Attack. 7.CONCLUSION 1. Python is programming tool which can be used for the analysis of wind energy. 2. Cl and Cd increased as increasing AOA up to maximum limit then after decreased. For NACA0012 max AOA 70 NACA4412 max AOA 140 NACA6412 max AOA 100 3. Increasing wind velocity For AOA=7, tpr=5, c=2, Fl and Fd increased. 4. Increasing tpr For AOA=7, V=5, c=2, Fl and Fd increased. 5. As V and AOA increased for tpr=5 c=2, Fl and Fd increased. Maximum Lift Forces obtain for the NACA4412.Drag forces eobtain for NACA6412 is higher than other profiles. REFERENCES [1] Michael S. Selig and Bryan D. McGranahan ” Wind Tunnel Aerodynamic Tests of Six Airfoils for Use on Small Wind Turbines” January 31, 2003. [2] Eke G.B., Onyewudiala J.I. “Optimization of Wind Turbine Blades Using Genetic Algorithm”Global Journal of Researches in Engineering 22 Vol. 7 (Ver 1.0), December 2010. [3] Arvind Singh Rathore, Siraj Ahmed ,“ Aerodynamic Analyses of Horizontal Axis Wind Turbine By Different Blade Airfoil Using Computer Program”, IOSR Journal of Engineering (IOSRJEN, Vol. 2 Issue 1, Jan.2012, pp. 118-123. [4] Dr. Eng. Ali H. Almukhtar, “Effect of drag on the performance for an efficient wind turbine blade design”, Energy Procedia 18 ( 2012 ) 404 – 415. [5] www.Airfoiltool.com Volume 4, Issue 4, April 2015 Page 205 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 4, Issue 4, April 2015 ISSN 2319 - 4847 AUTHOR Tarun B Patel1 ME scholar in Energy engineering from Government engineering College, Valsad, Lecturer in Government Polytechnic, Valsad Gujarat , B E Mechanical from SVNIT Surat year 2004, Gujarat, INDIA. Prof. Sandip T Patel2 Professor in Mechanical Department , Government Engineering College, Valsad, Gujarat. B E SVMIT Bharuch year 2004 , M.Tech in CAD/CAM SVNIT, Surat year 2009. Divyesh T Patel3 ME scholar in Energy engineering from Government engineering College, Lecturer in Government Polytechnic Valsad, B E Mechanical from LDCE Ahmedabad year 2005, Gujarat, INDIA. Maulik Bhensdadiya4 ME scholar in Energy engineering from Government engineering College, Valsad, Gujarat B.Tech Mechanical from Ganpat University year 2013, Gujarat, INDIA. Volume 4, Issue 4, April 2015 Page 206