International Journal of Application or Innovation in Engineering & Management... Web Site: www.ijaiem.org Email: Volume 3, Issue 4, April 2014

advertisement

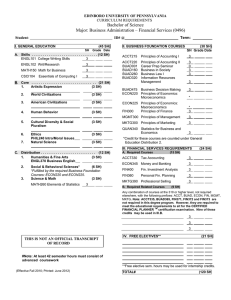

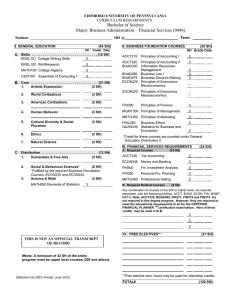

International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 4, April 2014 ISSN 2319 - 4847 Experimental and Numerical Investigation for Structural and Thermal Characteristics of Externally Finned Double Pipe Heat Exchanger 1 Sameer H. Ameen, 2Deyaa Mohammed N. Mahmood, 3 Laith Najim A. Alameer 1,2&3 Institute of preparation technical trainers ABSTRACT The heat exchanger of double pipes was constructed in the present paper from a copper alloy with inclined parabolic fins fixed over the outer surface of its inner pipe with different angles. The experimental part of the current work was carried out and it gave a coefficient of convection equal to 304.5 W/m 2.oC, while the numerical part was achieved using ANSYS PACKAGE. Both structural and thermal investigations were considered in the numerical analysis which required developing a factor was called "thermal to structural performance coefficient" which was maximum at 60o inclination angle among other inclinations, namely, 24.72 W/MN. The Parabolic fins improved the local heat convection to about 2.42 more than pipes without fins. Keywords : structural, thermal, heat exchanger, fin. Nomenclature A Surface temperature of inner pipe ( m2 ). D Outer diameter of inner pipe ( m ). Cp Specific heat at constant pressure ( J/kg.oC ). h heat transfer coefficient ( w/m2.o C ). L Length of double pipes ( m ). mo Mass flow rate ( kg/s ). P Pressure ( Pa ). Q Heat transfer ( W ). Vo Volumetric flow rate ( m3/s ). t Thickness of pipe (m). Tin Inlet temperature ( oC ). Tout Outlet temperature ( oC ). Ts Surface temperature ( oC ). T∞ Fluid temperature ( oC ). σH Hoop stress ( N/m2 ). σL Longitudinal stress ( N/m2 ). ρ Density ( kg/m3 ). ζ Thermal to structural performance coefficient ( W/MN ). 1. INTRODUCTION High performance heat exchangers are widely used in many industries such as petrochemical industry, automotive industry, energetic industry and many others. The name of this kind of heat exchangers is in consistency with their structure. Large heat transfer area leads to high thermal efficiency of the device. Its working principle is to cool rapidly large amount of gaseous or liquid medium. Because of its compact size, it is possible to use it for easy installation in various systems, like the heating, drying, air conditioning and the other systems [1]. The reliability of several compact enhanced heat transfer designs including internally finned bayonet tube, internally and externally finned bayonet tube and CW primary surface sheet was investigated. The results indicate that for the bayonet tube, the high stress is caused by high temperature, while for the thin CW primary surface sheet; it is caused by big pressure difference. The big stress exists in the joint of inner fins and inner tubes, so the welding quality of the joint must be ensured [2]. A finite element solution for the strain as a function of the tube material and geometry was determined for several geometries and a family of design curves for elliptical tubes was created [3]. The inner fin and inner tube should Volume 3, Issue 4, April 2014 Page 201 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 4, April 2014 ISSN 2319 - 4847 not be welded together and the gap between them should be less than 1 mm for considered bayonet tube with 6 mm annulus height according to the coupled consideration of heat transfer and stress performances [4]. The optimization of a finned double pipe with trapezoidal fins augmented to the outer surface of the inner pipe has been carried out by using genetic algorithm and Trust Region Method [5]. The different heights of triangular fins were laminar forced convection in the fully developed flow through the finned annulus subjected to boundary conditions of constant heat transfer rate per unit axial length with uniform peripheral temperature distribution [6]. The four different types of fluids and for different fin heights and location were also can be carried out for heat exchanger [7]. Helical fins were used on inner tube to generate some vortex along the centerline of the helical channel [8]. A longitudinal finned vertical pipe was used to represent the air-heating vaporizer in the CFD model, where nitrogen gas was used as the working fluid inside the vertical pipe to made flow upward [9]. Heat exchanger was numerically analyzed, using ANSYS 14 CFX software, by putting extended surfaces in the annular space and superior pressure drop was obtained with fins [10]. 2. THEORETICAL ANALYSIS The heat exchanger considered is of two pipes, each pipe has two pressures ( inside and outside ); therefore from elementary structural analysis which states a pipe is merely a thin tube without fins develop hoop ( at circumferential ) and longitudinal ( along pipe ) stresses under inner pressure only as follows [11] : P.D 2t P.D = 4t H = L (1) (2) The above equations don't give real results due to firstly the pressure loading is not only on the inner surface of the tube but also on the outer surface too; and secondly the effect of fin is not taken into consideration. Generally, elementary solution does not exist and needs more complicated analysis which is the ANSYS PACKAGE. In thermal analysis, the heat transfer is done by convection using the two basic equations as follows : Q = h A ( Ts - T∞ ) (3) Q = mo Cp ( Tout – Tin ) (4) Where, A=ЛDL (5) mo = ρ Vo (6) 3. CASE STUDY The case study of the current work is a double pipe with parabolic fin on the outer surface of the inner pipe that has a cross – sectional area with dimensions as shown in Figure 1. The distance between the two adjacent fins is taken 40 mm in the direction perpendicular to the paper plain with 0.6 mm fin's thickness. The two pipes are made of copper alloy with inner pressure for each pipe of 5 bar. Structural and thermal mechanical properties of the heat exchanger material are listed in Table 1. Figure 1 Dimensions of cross – sectional area of pipes (mm) Modulus of elasticity GN/m2 110 Table 1 : Structural and thermal mechanical properties of copper alloy [12] Coefficient Yield Thermal Poisson's Density Of thermal Stress Conductivity 3 ratio Kg/m Expansion MN/m2 W/m.oC 1/oC 0.34 8300 280 1.8*10-5 401 Volume 3, Issue 4, April 2014 Specific Heat J/kg.oC 385 Page 202 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 4, April 2014 ISSN 2319 - 4847 4. EXPERIMENTAL PART The double pipe heat exchanger, of dimensions shown in Figure 1, is constructed from its main parts as clearly seen in Figure 2 which has 2 m length and 2 mm thickness. Number of fins are 50 fins distributed over pipe length equally by 4 cm spacing distance. The experimental result which is required from the mentioned rig is parameter h, using the equations 3 to 6. The flowing of cold water in the inner pipe has 15oC measured temperature, while the hot water in the outer pipe has 45oC temperature is flown in the opposite direction of the inner pipe. The flow rate of the cold and the hot water is 4 lit/min for both pipes. The outer surface temperature of the inner pipe is measured to be equal to 25oC. By substituting all measured temperatures and dimensions in equations 3 and 4 and after solving them, the convection heat transfer coefficient is determined equal to 304.5 W/m2.oC. Figure 2 Heat exchanger rig 5. NUMERICAL PART 5.1 Structural results The numerical structural results of the inner pipe with 60o inclined parabolic one fin are shown in Figures 3, 4, 5, and 6 for Von – Misses stress, Shear stress, total deformation, and strain respectively. The results are calculated by applying pressure of 5 bar at the inner and the outer surfaces of the inner pipe including surface of parabolic fin. Other, numerical results with different fin's angle ( 90o, 75o, 45o, 30o ) are evaluated and listed in Table 2 in addition to angle 60o . Figure 3 Von-Misses stress for 60o inclined fin (Pascal) Figure 4 Shear stress for 60o inclined fin (Pascal) Volume 3, Issue 4, April 2014 Page 203 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 4, April 2014 ISSN 2319 - 4847 Figure 5 Total deformation for 60o inclined fin (Pascal) Figure 6 Elastic strain for 60o inclined fin (Pascal) Angle 90o Table 2 : Structural results of finned inner pipe with different angles Von-Misses stress Deformation Shear stress (MPa) (mm) (MPa) Strain 64.13 2.67 * 10-5 36.16 0.00058298 57.39 2.61 * 10 -5 30.89 0.00052173 3.02 * 10 -5 31.17 0.00050220 -5 39.52 0.00063585 52.68 0.00084173 75 o 60 o 45 o 69.94 4.24 * 10 30o 92.59 6.57 * 10-5 55.24 5.2 Thermal results The temperature distribution , total heat flux, and temperature gradient for the inner pipe with 60o inclination angle of fin are shown in Figures 7, 8, and 9 respectively. Figure 7 Temperature distribution for 60o inclined fin (o C) Volume 3, Issue 4, April 2014 Page 204 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 4, April 2014 ISSN 2319 - 4847 Figure 8 Total heat flux for 60o inclined fin (W/m2) Figure 9 Temperature gradient for 60o fin's angle ( oC/m ) 30 degree 3250 o Temperature Gradient( c/m) The path which is shown in Figure 9 along pipe in z – direction is selected to plot deviation of the temperature gradient and the heat flux over the outer surface as shown in Figures 10 and 11 respectively for all inclinations of fin under study in the current work. The heat flux for the first three adjacent fins at 60o inclination is seen in Figure 12. The investigated thermal to structural performance coefficient ( heat flux to Von-Misses stress ratio ) for all inclinations of fin are calculated and assessed as shown in Figure 13. 45 degree 60 degree 2750 70 degree 90 degree 2250 1750 1250 0 0.5 1 1.5 2 2.5 3 3.5 4 Fin's Pitch (cm) Figure 10 Temperature gradient along fin's pitch ( oC/m ) Heat Flux (W/m 2 ) 1400 1300 30 degree 1200 45 degree 1100 60 degree 70 degree 1000 90 degree 900 800 700 600 500 0 0.5 1 1.5 2 2.5 3 3.5 4 Fin's Pitch (cm) Figure 11 Total heat flux along fin's pitch ( w/m2 ) Volume 3, Issue 4, April 2014 Page 205 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 4, April 2014 ISSN 2319 - 4847 1500 1400 2 Heat Flux (W/m ) 1300 1200 1100 1000 900 800 700 600 500 0 2 4 6 8 10 12 Pipe Length (cm) Coeffecient of Structural to Thermal (W/MN) Figure 12 Total heat flux along pipe length at 60o fin angle ( w/m2 ) 24 22 20 18 16 14 12 10 30 40 50 60 70 80 90 Fin's Angle (degree) Figure 13 Variation of ζ factor to fin's angle (W/MN) 6. DISCUSSION In the current work for structural numerical investigation, four items are evaluated for five different inclination angles of fin to investigate which angle gives a better structural performance of lower stresses and deformation developed in fin. Maximum value is located at the middle near root of fin for Von – Misses stress, shear stress, and strain cases as shown in Figures 3, 4, and 6 respectively; while the maximum deformation is seen on the tip of the parabolic fin as shown in Figure 5. Table 2 clearly shows minimum Von – Misses stress of 55.24 MN/m2 developed in the pipe at 60o fin's angle only which represent lowest value than against angle by about 13.9 %, 3.7 %, 21.0 %, and 40.3 % for 90o, 75o, 45o, and 30o angles respectively. Minimum deformation is located at 90o and 75o fin's inclinations which is approximately equal or slightly more than 2.6 * 10-5 mm, and these values are in increased in sequence with reduction in fin's angle. Maximum shear stress obtained at 30o angle while minimum value was at 60o and 75o angles of fins are about 31 MN/m2. Minimum strain is determined at 60o fin's angle of 0.00050220 which represents the lowest amount among other angles of 90o, 75o, 45o, and 30o by identical percentage reduction as for Von – Misses stress case. Thermal solution for 60o fin's inclination, namely the temperature distribution, the total heat flux, and the temperature gradient are shown in Figures 7, 8, and 9 respectively. Figure 7 shows the maximum temperature at the outer diameter of the pipe of 43o C, while the temperature is 15oC in the inner pipe leaving intermittent temperature at approximately 23oC. The maximum heat flux and the gradient of temperature are located at rounded edges at the root of fin with magnitude of 4.84 GW/m2 and 103120 o C/m as seen in Figures 8 and 9 respectively. Figures 10 and 11 represent the values of the temperature gradient and the heat flux along the pipe ( as seen the path in Figure 9 ) starting from root of fin for all combination of fin's angles under consideration. Clearly, figures show also that existing fin in general improve and increase both items mentioned before to higher amounts from 563 W/m2 heat flux, for 60o fin's angle, to about 1365 W/m2 with enhancement factor of 2.42. First three adjacent fins affect the performance of heat exchanger convection and that is seen in Figure 12 for the same angle of previous figure. The thermal to structural performance coefficient ( which is equal to total heat flux to Von – Misses stress ) at the root of fin as shown in Figure 13 with maximum value of 24.72 W/MN at 60o inclination angle of fin. 7. CONCLUSIONS The major points concluded from present work are listed as follows : 1) All combinations of fin's angle have enhanced performance of heat exchanger concerning the heat flux and the temperature gradient to about 2.42. 2) Heat exchanger inner pipe which has 60o fin's angle has proved to be the best among other angles due to its higher ζ factor of 24.72 W/MN for both structural and thermal analyses. Volume 3, Issue 4, April 2014 Page 206 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org Volume 3, Issue 4, April 2014 ISSN 2319 - 4847 References [1] L. Hector Juarez, " Fluid Dynamics, Computational Modeling and Applications", ISBN 978-953-51-0052-2, Publisher InTech, February, 2012. (book style) [2] Ting Ma, Linxiu Du, Dongjie Zhang, Yanpeng Ji, Min Zeng, Qiuwang Wang, " Study on Reliability of high Temperature Heat Exchanger ", Key Laboratory of Thermal Science and Engineering of MOE, Xi’an Jiaotong University, Xi’an, 710049, China, 2010. (journal style) [3] Nawras H. Mustafa, Qusay R. Al-Hagag, " Structural and Thermal Analysis of Heat Exchanger with tubes of Elliptical Shape ", the Iraqi Journal For Mechanical And Material Engineering, Vol. 8, No.3, 2008. (journal style) [4] Ting Ma, Yitung Chen, Min Zeng, Qiuwang Wang, " Stress analysis of internally finned bayonet tube in a high temperature heat exchanger ", Applied thermal Engineering Journal, Vol. 43, pp. 101-108, 2012. (journal style) [5] K.S. Syed, Z. Iqbal, M. Ishaq, " Optimal Configuration of Finned Annulus in a Double Pipe with Fully Developed Laminar Flow ",Applied Thermal Engineering Journal, Published by Elsevier Ltd, 2011. (journal style) [6] M. Ishaq , Khalid S. Syed, Z. Iqbal, A. Hassan, A. Ali, " DG - FEM based simulation of laminar convection in an annulus with triangular fins of different heights ", Intentional Journal of Thermal Sciences, Vol. 72, pp. 125146, 2013. (journal style) [7] N. Dinler, N. Yucel, " Flow and heat transfer in a pipe with a fin attached to inner wall ", Heat Mass Transfer Journal, Vol.43, pp. 817-825, 2007. (journal style) [8] Li Zhang, Hongmei Guo, Jianhua Wu, Wenjuan Du, "Compound heat transfer enhancement for shell side of double – pipe heat exchanger by helical fins and vortex generators", Heat Mass Transfer, Springer publisher, Vol.48, pp. 1113- 1124, 2012. (journal style) [9] Hyo M. Jeong, Young H. Lee, Myoung K. Ji, Kang Y. Bae, Han S. Chung, "Natural convection heat transfer estimation from a longitudinal finned vertical pipe using CFD", Journal of Mechanical Science and Technology, Springer publisher, Vol. 23, pp. 1517-1527, 2009. (journal style) [10] Harshit S. Patel and Reena N. Makadia, " Performance evaluation and CFD analysis of industrial double pipe heat exchanger ", International Journal of emerging trends in engineering and development, Vol.4, issue 3, PP. 112 – 116, 2013. (journal style) [11] Er. R. K. Rajput, " Strength of materials ", Fifth revised edition, S. Chand & Company LTD., India, 2010. (book style) [12] Frank P. incropera, David P. Dewitt, Theodore C. Bergman, and Adrienne S. lavine, " Foundations of heat transfer ", Sixth edition, John Wiley & Sons Singapore Pte. Ltd., International student version, 2013. (book style) Volume 3, Issue 4, April 2014 Page 207