Drag Brakes Variation for Range Correction of

advertisement

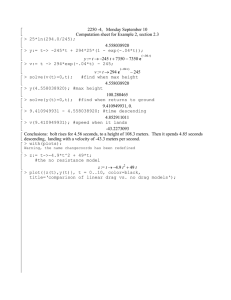

International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 Drag Brakes Variation for Range Correction of Artillery Projectile R. B. Sarsar 1 and S. D. Naik2 Applied Mathematics and Reliability Group, Armament Research and Development Establishment, Pashan, Pune 411021, Maharashtra, INDIA. Abstract Improvement in accuracy of artillery projectile is of prime importance for gun designers. Generally it is associated with range extension. Various methods and modifications in the design are applied to correct the range and deflection of artillery projectile like impulse thruster, pulsejet, drag devices, reciprocating canards. Out of these methods one is drag brake deployment which is analyzed in this paper. A trajectory corrector module consisting of disc is placed at the aft of the fuze. Once deployed, it increases the frontal area and hence the drag which reduces the overshoot range. Analysis has been carried out for increased frontal area, initiation and duration of deployment and optimum range correction with varying diameter of drag brakes using simulation. The model used is six degrees of freedom equations of motion. Keywords: Trajectory correction systems, Drag brakes, range correction, Fuze, Equations of motion, Artillery projectile, Trajectory, Accuracy. Nomenclature ϕ θ ψ α β δ γ Ax Ay Az C-xyz C-tnb m O-XYZ u v w Roll angles in degree Pitch angle in degree Yaw angle in degree Angle of attack in degree Side slip angle in degree Flight path angle in degree Flight yaw angle in degree Rotation matrix about x axis Rotation matrix about y axis Rotation matrix about z axis Body coordinate system Velocity coordinates system Mass of the artillery projectile Inertial coordinate system Velocity component in x direction Velocity component in y direction Velocity component in z direction 1. INTRODUCTION The role of field artillery is to provide fire support to other arms by backing up attacks, providing defensive fire, neutralizing an enemy's gun emplacement. Long and medium-range artillery projectiles are used for indirect fire. These are area weapon and largely suffer from dispersion at impact point if fired against a specific target. Reduction in collateral damage and delivering highly accurate fires, dictates the need for much improved round accuracy. Variations in temperature, wind, the barrel wear of the weapon, and the charge are some of the factors affecting during flight of a projectile. Trajectory correction is defined for a given trajectory to reduce the dispersion at point of impact. It is achieved by applying corrections to the path of the body in flight using different means like drag brakes. Trajectory correction is applied in two directions: along range and perpendicular to range (drift). Such systems are known as two dimensional projectile trajectory corrector systems which include two types of aerodynamic surfaces to be deployed during the flight. The first type of surface provides one-dimensional range correction, which is a drag device that acts as an airbrake. The second type of surface provides the correction in cross range, which affects spin and the normal force of the projectile inflight. These types of surfaces are known as spin device which are also stored within the projectile at launch. The initiation and duration of deployment of the drag devices and spin devices determine the percentage reduction in range and drift. Improving artillery projectile accuracy is very important for designers and lot of work has been carried out in last decade. A simple analytical approach has been studied by C.Grignon et al [1] which talks about deflection correction capabilities Volume 2, Issue 9, September 2013 Page 182 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 obtained with spin control, direct lift and pitch control. C.Grignon et al determines that change in direct lift and pitch characteristics seems to offer significant deflection correction, where as spin control is not efficient enough for primary deflection control even for the minimum spin admitted by the gyroscopic stability criterion. Stockenstrom [2] presented a paper on range dispersion reduction where author has observed that for the ERFB-shaped projectiles, the drag augmentation device needs to impart a drag multiplier factor upto two in the Mach number range 0.9 to 1.6. The design of a canard-controlled mortar projectile using a bank-to-turn concept is presented by Rogers and Costello [3]. Rogers and Costello used PID control for set of two reciprocating fixed - angle maneuver canards to perform trajectory corrections and PD control for set of two reciprocating fixed-angle roll canards for regulating projectile spin rate to zero and setting the airframe in the desired roll orientation. Corriveau et al [4] used impulse thruster to correct the trajectory of a conventional artillery projectile. Results indicated that locating the impulse thruster at or aft of the center of gravity provides greater drift correction for a given impulse magnitude. Corriveau et al assessed that impulse thrusters with a burning intensity between 15 and 20 Ns would provide adequate course correction for a 105 mm artillery projectile. The work has been continued by Way P et al and gave a novel method for correcting the trajectory of spin- and fin-stabilized projectiles using pairs of impulse thrusters located away from the center of mass [5]. Gupta et al [6] studied a trajectory correction flight control system which consists of a lateral pulsejet ring mounted on the rocket body. Each pulsejet on the ring imparts a single, short-duration, large force to the rocket in the plane normal to the rocket axis of symmetry. A range correction module which is fitted onto a spin stabilized ballistic projectile for correcting range error is designed by Brandon et al [7]. In this work Brandon et al used sixteen semi-circular plates to create a blunt cross sectional area in front of projectile to increase the drag and effectively slow down the projectile. Harkins et al has given a drag-brake deployment method and apparatus for range error correction of spinning gun launched artillery projectiles in [8]. Bar et al has discussed about drag device with different design [9]. In their work, the drag device is placed approximately at half the height of the fuze with flap-shaped sectors. The drag device in launch position forms a radial ring which is closed or has gaps. The work carried out in this paper discusses the effect of change in drag brakes surface area on range correction. The analysis has been carried out for various frontal areas of drag brakes and studied the effect of it on range using six degrees of freedom equations of motion. An optimum design of drag brakes can be obtained using this analysis for required correction in the range. 2. DRAG BRAKE CONCEPT The concept of drag brake with a single deployment scheme has been discussed by Hollis [10]. In addition, Hollis has proposed the requirement of power to deploy the drag brake and suitable DC motor to actuate it. The intent of this paper is to replace standard fuze of conventional artillery projectile with trajectory corrector module, without any changes within the ogive shape of the artillery projectile. Drag brakes are placed at the aft part of fuze as shown in Figure 1. Adaptability of trajectory corrector module is maintained at design level. Figure 1: Artillery Projectile with Drag Brakes The aim of this work is to estimate the effect of change in diameter of fuze on range. When the drag brakes are deployed during the flight, it increases the frontal area of the fuze which indeed increases the drag acting on the projectile and reduces the range. The frontal area of fuze changes with variation in drag brakes diameters. The drag brakes are divided into four parts as shown in Figure 2. (a) (b) Figure: 2 (a) Front view with Drag Brakes deployed (b) Front view without drag brakes The analysis is carried out for the varying drag brakes diameters. The additional parameters considered are point of deployment of drag brakes and deployment duration. Further analysis is carried out for one time deployment of drag brakes during the complete flight and multiple time deployment of drag brakes. Multiple deployments of drag brakes are Volume 2, Issue 9, September 2013 Page 183 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 applied for get the optimum range correction. The simulation is carried out using six degrees of freedom model for projectile motion. 3. MATHEMATICAL MODEL A general mathematical model is developed using Newton’s second law of motion to study the dynamical motion of an artillery projectile. Motion of the projectile is affected due to the forces and moments acting on it. The forces and moments on the projectile are acting in different frames, for example, drag force and lift force are represented in velocity frame and gravity force acts in inertial frame. To generate scalar equations of motion, transformation matrix between each frame is required to be defined. Using transformation matrices, forces and moments can be resolved in particular directions. A solution of equations of motion gives the trajectory of the projectile. 3.1. Coordinate System: The vector equations obtained from Newton’s second law are resolved in three directions with the help of three reference frames as shown in Figure 3. 1. Inertial Frame (O – XYZ) 2. Body Frame (C – xyz) 3. Velocity Frame (C – tnb) Figure 3: Coordinate System The relations between these frames have been developed using transformation matrices obtained by applying Eulerian rotations sequentially. Transformation matrices are developed with the assumption that anticlockwise sense is positive. Transformation matrix from Inertial frame to Body frame is denoted by AIB. It consists of three rotations and hence is obtained as product of three rotation matrices [11]. AIB Ax Ay Az cos cos AIB sin sin cos cos sin cos sin cos sin sin cos sin cos cos sin sin sin cos sin sin sin cos sin sin cos 1 cos cos where ϕ, θ & ψ are roll, pitch and yaw rotations respectively. ABI is obtained by taking transpose of AIB. Transformation matrix from Inertial frame to Velocity frame is denoted by AIV and defined as AIV Ay Az cos cos AIV sin cos sin cos sin cos sin sin sin 0 2 cos δ and γ are defined as angle of elevation and drift respectively. AVI is transpose of AIV. Transformation matrix from Body frame to Velocity frame is denoted by ABV and defined as ABV Ay Az cos cos ABV sin cos sin Volume 2, Issue 9, September 2013 cos sin cos sin sin sin 0 3 cos Page 184 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 α and β are angle of attack and sideslip angle respectively. 3.2. Equations of Motion: The dynamical motion of the projectile is studied with the help of Newton's second law of motion. The equations of motion are converted in body frame with the help of transformation matrices. The forces taken into consideration are gravity force, drag force, lift force, Magnus force and damping force. The moments considered are Spin damping moment, Spin driving moment, Overturning moment, Magnus moment and Damping moments. The six degrees of freedom model which consists of three scalar equations for linear motion (force equations) and three for angular motion (moment equations) is developed and scalar equations of motion are given below [11] - [12]: 1 gravityx (drag x DBx ) lift x coriolisx magnusx damp x m 1 v gravity y (drag y D By ) lift y coriolis y magnusy damp y m 1 w gravityz (drag z D Bz ) lift z coriolisz magnusz damp z m 1 p SD SDr I xx u 4 5 6 7 q 1 OM y MM y DM y I yy 8 r 1 OM z MM z DM z I zz 9 In these equations (u, v, w) denotes velocity of the projectile in x, y and z directions respectively. m is the mass of the projectile. Ixx, Iyy and Izz are moment of inertia in x, y and z directions respectively. All the forces are resolved componentwise to get the scalar equations for transverse motion. SD denotes the spin damping moment, SDr denotes spin driving moment. OM, MM and DM are overturning moment, Magnus moment and damping moment respectively. Scalar equations for angular motion are obtained by resolving these moments in x, y and z directions. Definitions of all the forces and moments could be referred in literature [13]. The drag induced by the drag brakes is denoted by the vector DB and it is defined as follows. DB 0 when drake brake is not deployed 1 DB S1VCd V 2 when drake brake is deployed where ρ is air density, V is velocity of projectile, S1 is surface area of drag brakes ΔCd is additional drag coefficient. A simulation study has been carried out and analysis has been done to study the effect of drag brakes on projectile range. The equations of motion are integrated using forth order Runge – Kutta method. 4. SIMULATION AND ANALYSIS 4.1. Simulation Data: The simulation has been carried out for 155 mm artillery projectile. The initial conditions used for simulation are m = 44.80 Kg, V = 878 m/s, θ = 30 deg, x = y = z = 0. Mass of the projectile includes weight of drag brakes also. It is assumed that the weight of each drag brake is 0.012 Kg. The deployment of drag brakes increase diameter of fuze and the analysis is carried out for the variation of fuze diameter from 60mm to 100mm with the assumption that 50mm being the diameter of fuze without drag brakes. As drag brakes are hosted in the fuze, the deployment of drag brakes with diameter more than 100mm is not possible because of space constrains. The deployment of drag brakes with the diameter of fuze of 60mm increases the frontal area by 1.5 times whereas for 100mm diameter of fuze the frontal area increases by 4 times. It is assumed that projectile will take 4 - 5 seconds for stabilization itself after the muzzle exits and 2 seconds to deploy the drag brakes. 4.2. Simulation Results: The analysis is carried out for deploying the drag brakes at various stages of trajectory and once the drag brakes are deployed it will remain open throughout the trajectory. Deploying drag brakes in early stage of trajectory results in maximum range correction. As the diameter of drag brakes increases, it improves the correction in the range. Hence maximum range correction is observed for maximum diameter of drag brakes deployed at the earliest. With fuze diameter of 60mm deployed at 10 seconds during the flight corrects the range by 219m whereas the same drag brakes gives the correction of only 3m if deployed at 50 seconds. Deployment of drag brakes of 100mm fuze diameter gives maximum correction of 1347m (Figure 4). Volume 2, Issue 9, September 2013 Page 185 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 1400 Fuze dia 60mm Fuze dia 70mm Fuze dia 80mm Fuze dia 90mm Fuze dia 100mm C o rrectio n in R a n ge ( m ) 1200 1000 800 600 400 200 0 10 15 20 25 30 35 Drag Brake opening Time ( s ) 40 45 50 Figure 4: Effect of deployment time on range The simulation analysis has been carried out for deployment duration with deployment start at 10 second of flight time. It is observed (Figure 5) that long duration deployment of drag brakes results into large correction in range. Deployment of drag brakes of fuze diameter 60mm at time of 10 seconds gives correction of 125m whereas deploying same fuze diameter for completer time of flight gives range correction of 219m. Similarly for 100mm fuze diameter, deployed for 10 seconds starting from flight time of 10 seconds gives 820m range correction whereas for complete flight time deployment1347m. 1400 1200 60mm 70mm 80mm 90mm 100mm Co rrectio n in R a n g e ( m ) 1000 800 600 400 200 0 10 15 20 25 30 35 Deployment duration ( s ) 40 45 50 55 Figure 5: Drag brakes deployment duration Ctrl start time (s) 10 Table 1: Drag Brakes deployed for 10 seconds Correction Correction Correction Correction 60mm Fuze 70mm Fuze 80mm Fuze 90mm Fuze dia (m) dia (m) dia (m) dia (m) 125 271 437 619 Correction 100mm Fuze dia (m) 820 20 56 120 194 277 367 30 23 53 85 124 163 40 10 22 37 54 73 50 2 8 11 18 23 It is observed that deployment of drag brakes early for small duration gives maximum range correction whereas deploying for small duration in later stage of trajectory gives less correction in range. Table 1 shows deploying drag brakes with 60mm fuze diameter at 10 second of time for 10 seconds duration gives 125m correction in range but deploying at 50 second of time for 10 seconds duration gives 2m correction only. 5. CASE STUDY FOR MULTIPLE DEPLOYMENTS One time deployment results into the range correction and increase the diameter is dictated by the required correction in the range. In case if the range correction required does not lead to the exact increase in the diameter of drag brakes then multiple deployment may be the solution for it. In this case depending on the correction required, the variation in the diameter can be calculated and applied at each step. An algorithm has been developed for the same in terms of velocity and applied for a particular case. The selection of fuze diameter is based on following algorithm. a. Calculate the ideal trajectory for exact range. Volume 2, Issue 9, September 2013 Page 186 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 b. Select the time of deployment of drag brakes. c. Calculate the difference between the actual velocity of the projectile and ideal velocity. d. Select the drag brakes such that the difference of velocities becomes zero or closer to zero. e. Deploy the drag brakes for one second. f. Repeat the step b to d for remaining time of flight. 5.1. Case Study: The case study is carried out for the data given in section 4.1. It is observed that the uncontrolled projectile achieved 25180 m range with total time of flight is 63.8 seconds and vertex is achieved at 28.75 seconds. The remaining velocity at time of impact is 346 m/s when fired at a target on 25000m. It means that a correction of 180m is needed to hit the target. The analysis is carried out for multiple deployments of drag brakes during the flight get the maximum of 180m correction in range. At the time of drag brakes deployment, calculate the impact point using current trajectory data and find the overshoot distance. Depending upon overshoot distance the suitable drag brakes are opened to correct the range. It is observed that deploying the drag brakes just after the vertex height gives 100% correction in range. Figure 7 shows the requirement of fuze diameter for drag brakes once it is deployed at flight time of 31 seconds. It is observed that initially only 60mm fuze diameter drag brakes is required and in later stage of trajectory requirement of drag brakes is varies between 80mm to 100mm to achieve the optimum range correction. 0.1 0.095 F u ze dia ( m ) 0.09 0.085 0.08 0.075 0.07 0.065 0.06 0.055 30 35 40 45 Time ( s ) 50 55 60 65 Figure 7: Fuze diameter during flight 6000 w/o drag brakes with drag brakes 5000 A ltitu de ( m ) 4000 3000 2000 1000 0 0 0.25 0.5 0.75 1 1.25 1.5 Range ( m ) 1.75 2 2.25 2.5 2.75 4 x 10 Figure 8: Trajectory Figure 8 shows the effect of drag brakes on the trajectories of uncontrolled and controlled artillery projectile. The differences in velocities due to drag brakes are shown in Figure 9, it is observed that deployment of drag brakes throughout the flight reduces the remaining velocity by 11m/s which give the required correction in range. Further analysis is carried out for given projectile data and study suggests that a DC motor of the power 300W is required to extract and retract the drag brakes during the flight [10]. Figure 9: Effect of drag brakes on velocity Volume 2, Issue 9, September 2013 Page 187 International Journal of Application or Innovation in Engineering & Management (IJAIEM) Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 9, September 2013 ISSN 2319 - 4847 6. CONCLUSION Range correction using drag brakes is studied in this work. The effect of varying drag brakes frontal area on projectile range has been analyzed. One time deployment of drag brakes at early stage of flight gives maximum range correction. To increase the accuracy artillery projectile multiple deployment scheme can be used. The result shows that deploying drag brakes early for small duration also gives sufficient correction in range. The deployment time can be predefined depending on required correction of range. Optimum correction in range is possible with the help of multiple deployments algorithm. References [1] Grignon C, Cayzac R, Heddadj S., "Improvement of Artillery Projectile Accuracy", 23rd International Symposium on Ballistics, Tarragona, Spain, pp 747 – 754, 2007. [2] Stockenstrom A, “A Simplified Approach to Range Dispersion Reduction”, 20th Int. Symposium on Ballistics, pp 180 - 186, 2002. [3] Rogers J, Costello M, “Design of a Roll-Stabilized Mortar Projectile with Reciprocating Canards”, Journal of Guidance, Control, and Dynamics, Vol. 33, No. 4, July – August 2010, P. No. 1026 - 1034. [4] Corriveau D, Berner C, Fleck V, "Trajectory Correction Using Impulse Thrusters For Conventional Artillery Projectiles" 23rd International Symposium on Ballistics, Tarragona, Spain, pp. 639 – 646¸2007. [5] Wey P, Corriveau D , Berner C, "Thrusters Pairing Guidelines for Trajectory Corrections of Projectiles", Journal of Guidance, Control, And Dynamics, Volume 34, Number 4, pp 1120 - 1128, 2011. [6] Gupta S K, Saxena S, Singhal A, Ghosh A K, " Trajectory Correction Flight Control System using Pulsejet on an Artillery Rocket", Defence Science Journal, Vol. 58, No. 1, pp 15-33, 2008. [7] Brandon F J, Hollis M S L, “Drag Control Module for Range Correction Of A Spin Stabilized Projectile”, US Patent no. 5,826,821, 1998. [8] Harkins T E, Bradford S D, “Drag-Brake Deployment Method and Apparatus for Range Error Correction of Spinning, Gun Launched Artillery Projectiles”, US Patent no. US 6,345,785 B1, 2002. [9] Bar K, Bohl J, Kautzsch K, “Spin-Stabilized Projectile With A Braking Device” US Patent no. US 6,511,016 B2, 2003. [10] Hollis M S L, "A Report on Preliminary Design of a Range Correction Module for an Artillery Shell", Army Research Laboratory, Report number ARL-MR-298, 1996. [11] R L McCoy, “Modern Exterior Ballistics”, Schiffer Publication, 1999. [12] Sarsar R B, Mukhedkar R J, Naik S D, “Study on Extending Range of Artillery Rocket Using Control Surfaces”, Volume 63, Number 2, Journal of Aerospace Science and Technologies, Bangalore, pp No. 153 – 157, 2011. [13] Anonymous, Text Book of “Ballistics and Gunnery”, Her Majestic Stationary Office, Volume I, pp 476 – 483, 198. Volume 2, Issue 9, September 2013 Page 188