International Journal of Application or Innovation in Engineering & Management... Web Site: www.ijaiem.org Email: , Volume 2, Issue 12, December 2013

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 12, December 2013 ISSN 2319 - 4847

Study of modelling approach on nose prosthesis compared to human smell sensing activity with advanced design technique

Zinkar Das

1

, Moupali Roy

2

, Subham Ghosh

3

, Aniruddha Ghosh

4

and Biswarup Neogi

5

1

M. Tech Scholar, EIE Dept., JISCE, W.B., India

2

Assistant Professor, ECE Dept., NIT, W.B., India

3,4

Assistant Professor, ECE Dept., JISCE, W.B., India

5

Faculty, ECE Dept., JISCE, W.B., India

Abstract

Prosthesis nose is an artificial intelligent nose based on complex computing algorithm. It is not possible for direct human interaction as this appropriate decision is taken by computing algorithm. This is an emerging field of electronic, mechatronics, robotics and even implementation of artificial intelligence. In this paper we discuss about how we can model prosthesis nose using the concept of electronics nose. It outlines the operating principles and fabrication methods of each sensor type as well as the application in which the different sensors have been utilized. It also outlines the advantages and disadvantages of each sensor for application in a cost- effective low power handheld e-nose system.

Keywords: Olfactory bulb, artificial olfaction, prosthesis, electronics nose.

1.

I

NTRODUCTION

Electronic noses have provided a plethora of benefits to a variety of commercial industries, including the agricultural, biomedical, cosmetics, environmental, food, manufacturing, military, pharmaceutical and various scientific research fields. Hence, gas chromatography and mass spectrometry is employed to aid human panels to assess the quality of products through odor evaluation and identification obtaining more consistent results. Electronics nose system utilizes an array of sensors to give a fingerprint response to a given odor and pattern recognition software then performs odor identification and discrimination. The e-nose is a cost-effective solution to the problems associated with sensory panel and with chromatographic and mass-spectrometric techniques and can accommodate real time performance in the field when implemented in portable form. The earliest work on neuromorphic computation for gas sensor arrays was reported by

Ratton et al., who employed a model of olfactory bulb-cortex interactions developed by Ambros- Ingorson et al. to classify data from micro-hotplate metal-oxide sensors [1]. An electronic nose system typically consists of a multisensory array, an information processing unit such as an artificial neural network (ANN), software with digital pattern-recognition algorithms, and reference library data bases. The cross-reactive sensor array is composed of incrementally different sensors chosen to respond to a wide range of chemical classes and discriminate diverse mixtures of possible analysts. The output from individual sensors are collectively assembled and integrated to produce a distinct digital response pattern [2].

This paper presents a detailed characterization of a contrast enhancement model that incorporates two key principles in the early olfactory pathway convergence of sensory inputs and lateral inhibitory circuits. Using E-nose the prosthesis nose comes in this paper where nose (nasal) prosthesis is a type of craniofacial prosthesis used to replace an absent nose [3].

Typically made of polydimethylsiloxane, nose prosthesis is flexible and made to move with the skin. It is retained to the patient daily by using adhesive implants.

2.

S HORT O VERVIEW ON O DOR D ETECTION T ECHNIQUE THROUGH N ASAL A CTION

Odor sensing techniques are still in research. The process that permits the human brain to make a sensation about fragrance from inhaling through nose is not fully tacit. Olfactory bulb has connected with olfactory nerve fibers named cranial nerve I [4], the interior part of human brain and the axons of olfactory sensory neurons has connected with outer layer of the olfactory bulb within small multiple globular structures termed glomeruli. They create an interconnection between the mitral cells and olfactory receptor cells .The olfactory cells has olfactory stimuli named olfactory cilia that binds with receptor protein in the membrane of each cilium [5, 6].

The procedure of human sensation of smell is represented in the fig.1 and illustrated in a nutshell:

I) The odorant chemicals are perceived by the receptors that approach with the air and the human brain locates the odorant based on their identification, perception and state. The odorants bind to receptors in specific functional group or feature.

II) The odorant cells are activated after binding the odorant and generate an electric signal for sending it towards glomeruli.

III) The signals are accepted by glomeruli from olfactory cell via nervous system and detect their features. They send

Volume 2, Issue 12, December 2013 Page 260

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 12, December 2013 ISSN 2319 - 4847 them to mitral cells for further transmission of signal at higher region.

IV) The signals are transmitted to higher region of the brain. The brain distinguishes the odorant came from glomeruli on behalf of their specifications and patterns.

Figure 1 Human odor detection mechanism

Odor concentration is a sensory property that engenders an olfactory response or sensation. Mainly, the odor intensity, the strength of the perceived odor sensation, increases with the odorant concentration. The relationship between odor intensity and concentration is represented in fig.2 [7, 8] and it can be signified as:

I KC n or, log I log K n log C

Here, I = Perceived odor intensity

C = Odorant concentration in milligrams/cubic meter (mg/m3)

K = Proportionality constant (differs for every odorant)

n = Steven’s law exponent (differs for every odorant)

Figure 2 Logarithmic graphical representation of intensity vs. concentration

This is renowned as Steven’s power law [9]. The ranges of ‘n’ depends on the odorant and the odor intensity is expressed in parts per million of butanol [10, 11]. It is exposed that the ranges of ‘n’ is from 0.2 to 0.8. The rating of odor intensity is usually stated that,

Volume 2, Issue 12, December 2013 Page 261

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 12, December 2013 ISSN 2319 - 4847

0= No odor

1= Threshold

2= Very weak

4= Weak

6= Weak-moderate

8= Moderate

10= Moderate-strong

12= Strong

In 2004, Linda B. Buck and Richard Axel won Nobel Prize for unveiling the sense of smell. Several research papers have also been published on odor detection techniques and olfactory organs [12].The quality of code can be automatically measured by checking the presence of code smells and this approach can contribute to automatic code inspection. E.V.

Emden and L. Moonen presented an approach for the automatic detection and visualization of code smells and discussed how this approach can be used in the design of a software inspection tool [13]. Recent work on electronic noses and its numerous practical applications stresses progresses since 1991 makes it an priceless resource for anyone studying electronic noses or machine olfaction[14].‘Chemical imaging’ can be advanced by either using the firm techniques of analytical chemistry or by using a large number of calibrated sensors and sensor systems. The latter are sometimes represented ‘electronic noses’, provide an electronic approach to artificial olfaction which suggests a variety of principal benefits as well as the fact that calibration efforts and sizes can be minimized systematically for precise applications by fine-tuning individual components of the sensor arrangement . Later the pattern recognition between the biological olfactory system and the electronic noses is also inspected. It is shown that the two systems share many connections in their architectures and other properties, such as odor delivery, nonspecific sensor/receptor response and a number of prospects for improving the biological plausibility of electronic nose systems are recommended that may produce an enhancement in performance [15, 16]. . Gardner et al. and P. Bartlett et al. further discussed about the electronic nose and its applications incorporating details about artificial senses [17]. The quick developments in the understanding of the information processing achieved by the biological olfactory system are critically studied, and its significance to recent research in artificial olfaction is also considered. Not only have the preliminary biochemical pathways involved in the transduction of odor stimuli been exposed, but also computational models of the key synaptic circuits have advanced to the point where network simulations are clearly capable of odor discrimination. Later the key processing principles subjugated in the olfactory pathway for overcoming operating restrictions such as sensor drift/degeneration, limited sensitivity, and xenobiotic response are highlighted, so that their integration into the electronic analogue may be explored

[18]. The prediction of organoleptic properties has been moderately successful to date which is further progressed by the concept of electronic nose [19]. From the research on an enzyme electrode and a bio-electronic nose (bio-nose) for methyl mercaptan (MM) contrast between numerous kinds of the MM sensors with isoform FMOs is acquired where the FMO

3

(type 3) immobilized nose appropriate for the measurement of MM vapor because of greater output current than those of other device[20]. Later it is also proved that the bioelectronics sniffer device possessed high selectivity for TMA being attributable to the FMO

3

substrate specificity, uninterrupted measurability, and decent reproducibility in the repetitive measurements (coefficient of variation = 2.41%, n=10) [21]. The selectivity of the bio-sniffer was also investigated and

Acetaldehyde, acetone, benzene, methanol and ethanol (5.0 ppm) was also tested using the bio-sniffer with FALDH [22].

3.

I

NVESTIGATIONAL

A

PPROACH TOWARDS

O

DOR

S

ENSING

T

ECHNOLOGY

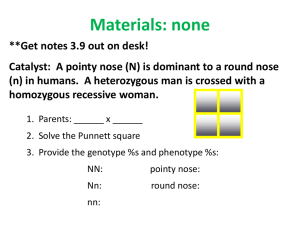

Gas sensor is the key factor in this prosthesis system. In basic gas chromatography analysis method, the used suitable sensors are conductivity type sensor, piezo-electric sensor, field effect sensor, fiber optic sensor presented in fig.3 [23, 24] a) When the volatile organic compounds (VOC) change their resistance values, the response of conductivity type sensor also changes. This type of sensor categorized in two types, such as metal oxide sensor (MOS) and conductive polymer sensor (CP). In e-nose, metal oxide sensor is mostly used; its structure is depicted in fig.3. In this type, the substrate materials are typically silicon, glass, plastic etc. and the response of volatile organic compounds are like tin, zinc, tungsten, titanium and iridium oxide. This sensor works in 200-400°C temperature with presence of heater. The conductive polymer sensors response for conductive polymers like thiophene, indole, furan and other ingredients those reacted with the contact of gas materials. They work in normal ambient temperature. b) Piezo-electric sensor responses on contact of VOC and it are reflected in the change of frequency and it can measure the changes in temperature, pressure, force, acceleration. They are mainly two types, quartz crystal microbalance (QCM) and surface acoustic wave sensor (SAW). For QCM, with increasing the disc quality it responses by absorbing the gaseous molecules with decreasing the resonant frequency. SAW sensor operates in higher frequency than QCM and commonly used in photolithographic techniques of microelectronics industry. c) Another important sensor is metal oxide semiconductor field effect transistor (MOSFET) sensor. VOC with a catalytic material will spread through MOSFET when it comes in contact and generates reaction product. The sensitivity and selectivity of this device change with variation of types and thickness of the metal contact.

Volume 2, Issue 12, December 2013 Page 262

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 12, December 2013 ISSN 2319 - 4847

d) The fiber optic sensor responses by changing the spectral color of its gaseous compounds. When it contacts with

VOC from external light source, it reacts by changing with the polarity of fluorescent dye by changing the fluorescent emission spectra.

Figure 3 Different types of gas sensors

4.

C

ONCEPTUAL

A

RTISTIC

M

ODEL

A

PPROACH ON

N

OSE

P

ROSTHESIS THROUGH

E

LECTRONIC

N

OSE

C

ONCEPT

Prosthesis is an artificialize device that designed to substitute for missing or diseased body parts like ears, eyes, noses, limbs, arms, legs and so on and interfaced them with human brain. The detection process of prosthetic nose is done in two ways, (1) an array of chemical (gas) sensors and (2) signal processing system. Odor recognition is the main mechanism for each sensor lying on the array that has different sensitivity of the measured gas and the pattern recognizer compares the pattern accordance with the measurements to store patterns for the recognized ones in signal processing system.

Figure 4 Block representation of electronic nose

The fig.4 [23] is represented here an electronic nose system containing chemical sensor array, sensor pre-processing, array pre-processing and pattern recognizer, digital display device and knowledge base. Chemical sensor comprises two basic functional units: a receptor part and a transducer part. The receptor part transforms the information of chemical compounds into a form of energy that implies on the transducer part to convert the signal into an electrical signal in voltage or current form. Here, the individual chemical components of concentration C

1

, C

2

… C n

interact with an array of chemical sensors to produce a vector of sensor responses R

1

, R

2

…R n

. The sensor response is in an analogues form are transformed into digital form by sensor pre-processing. The outputs from this part are arranged in an array form by array pre-processing for next operation. After completing this function it is compared with the standard patterns by pattern recognizer are stored in the knowledge base of the system. Recognizing the correct signal pattern, the final decision of odor representation is taken by this intelligent system and it is displayed in digital display device. [25]

A concept of an artistic model of prosthesis nose is represented in the fig.5. The air with various chemical particles are inhaled by nose and filtered by filters depends on the particle sizes. Then the existing chemical particles are detected by chemical sensor array and converted into electric signal in pre-described procedure. The signal is compared with pre- allocated knowledge base signal determined for every objects and the suitable signal pattern is recognized by pattern recognizer for identification of smell of the particular objects.

Volume 2, Issue 12, December 2013 Page 263

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 12, December 2013 ISSN 2319 - 4847

Figure 5 Artistic model of an artificial nose

There are numerous advantages of prosthetic nose are clarified in brief

• Quality classification of stored grain

• Detection and diagnosis of pulmonary infections

• Identification of source and quality of coffee

• Monitoring of roasting process

• Identification of spilled chemicals in commerce.

• Diagnosis of ulcers by breath tests.

• Bacterial growth on foods such as meat and fresh vegetables.

• Process control of cheese, sausage, beer, and bread manufacture.

In this techno-scientific era, the prosthesis takes an important part not only in biomedical engineering domain also in medical science. The prosthetic nose has wide applications in human body transplant operation. The concept of prosthetic nose comes from electronic nose that use mainly in bomb squad region for identifying the explosives, odor detection, different chemical hazardous and so on.

5.

C ONCLUSION

The application of prosthetic nose using the electronics nose is now developed. Still the nose in reality is a challenge and problem of interfacing. The prosthetic nose can be utilized to reach the goal effectively and accurately. The mapping between these types of artificial nose with electrical nose is a challenge and to quantify the benefits of the model, we have proposed a novel statistical reparability measure that provides the necessary trade-off between concentration-invariant recognition and concentration sensitivity.

Acknowledgement

Authors are acknowledged the Technical Education Quality Improvement Program (TEQIP) for the support to precede the publication. In addition, authors wish to thank to Sayanti Roy for her composing approach.

References

[1] K. Arshak, E. Moore, G. M. Lyons, J. Harris, and S. Clifford, “A review of gas sensors employed in electronic nose applications,” Sensor Review, vol. 24 issue 2, pp.181-198, 2004.

[2] Alphus D. Wilson and Manuela Baietto , “Applications and advances in Electronics Nose technologies,” Sensors, vol. 9, no. 7, pp. 5099-5148, 2009

[3] B. Raman, T. Yamanaka, and R. Gutierrez-osuna , “Contrast enhancement of gas sensor array patterns with a neurodynamics model of the olfactory bulb,” Sensors and Actuators, vol. 119, pp. 547-555, 2006

[4] Morris, H., & Schaeffer, J. P., The Nervous system-The Brain or Encephalon. Human anatomy; A Complete

Systematic Treatise, 11th ed., New York: Blakiston , pp.1218-1219, 1953

[5] Dale Purves, George J Augustine, David Fitzpatrick, Lawrence C Katz, Anthony-Samuel LaMantia, James O

McNamara, and S Mark Williams., Neuroscience, 2nd edition, Sunderland (MA): Sinauer Associates, 2001.

[6] David Bradley, ‘How we smell’, Science Spot, Available: http://sciencespot.co.uk/how-we-smell.html.

[7] Charles M. McGinley, and Michael A. McGinley, “Odor Intensity Scales for Enforcement, Monitoring, and Testing”,

Annual Conference on Air and Waste Management Association, pp. 1-13, 2000.

[8] J.C. Stevens, and S.S. Stevens, “Brightness Function: Effects of Adaptation,” Journal of the Optical Society of

America, vol. 53, issue. 3, pp. 375–385, Mar. 1, 1963

[9] Matti Huotari, Vilho Lantto, “Power Law Estimates of Odour Thresholds”, Available: www.umad.de/infos/cleanair13/pdf/full_488.pdf .

[10] Guidelines on odour pollution & its control, Central Pollution Control Board, Govt. of India, pp. 13-14, May 2008.

Volume 2, Issue 12, December 2013 Page 264

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 12, December 2013 ISSN 2319 - 4847

[11] Zinkar Das, Nilotpol Manna, Dr. Biswarup Neogi, “Model Representation and Study of Essence Effect Creation through Internet Technological Aspect,” Innovative Systems Design and Engineering, ISSN 2222-1727 (Paper) ISSN

2222-2871 (Online), vol.4, no.13, pp. 25-33, 2013.

[12] Linda B. Buck, “Unraveling The Sense of Smell,” Nobel Lecture, December 8, 2004

[13] E. van Emden and L. Moonen, “Java quality assurance by detecting code smells,” Proc. 9th Working Conference on

Reverse Engineering, IEEE Computer Society Press, pp. 576-585, October 2002.

[14] J. W. Gardner and P. N. Bartlett, Electronic Noses Principles and Applications, Oxford University Press, Oxford,

UK, 1999.

[15] T. C. Pearce, “Computational parallels between the biological olfactory pathway and its analogue ‘the Electronic

Nose’: Part II. Sensor-based machine olfaction,” BioSystems, vol. 41, no. 2, pp. 69–90, 1997.

[16] W. Gopel, “Chemical imaging: I. Concepts and visions for electronic and bioelectronic noses,” Sensors and Actuators

B: Chemical, vol. 52, issue: 1-2, pp. 125–142, 1998.

[17] J. Gardner and P. Bartlett, “A Brief History of Electronic Noses,” Sensors and Actuators B: Chemical, vol. 18, issue.

1-3, pp. 211–220, 1994.

[18] T. C. Pearce, “Computational parallels between the biological olfactory pathway and its analogue ‘the Electronic

Nose’: Part I. Biological olfaction,” BioSystems, vol. 41, no. 1, pp.43–67, 1997.

[19] Michael C. Burl, Brett J. Doleman, Amanda Schaffer and Nathan S. Lewis, “Assessing the ability to prdicthumanpercepts of odour quality from the detector responses of a conducting polymer composite-based electronic nose,” Sensors and Actuators B: Chemical, vol. 72, issue 2, pp. 149-159, 2001.

[20] K. Mitsubayashi and Y. Hashimoto, “Bioelectronic nose for methyl mercaptan vapor using xenobiotic metabolizing enzyme: flavin-containing monooxygenase,” Sensors and Actuators B: Chemical, vol. 83, issue. 1-3, pp. 35–40,

2002.

[21] K. Mitsubayashi and Y. Hashimoto, “Bioelectronic sniffer device for trimethylamine vapor using flavin containing monooxygenase,” IEEE Sensors Journal, vol. 2, pp. 133–139, 2002.

[22] K. Mitsubayashi, G. Nishio, M. Sawai, T. Saito, H. Kudo, H. Saito, K. Otsuka, T. Noguer and J. Marty, “A biosniffer stick with FALDH (formaldehyde dehydrogenase) for convenient analysis of gaseous formaldehyde,” Sensors and Actuators B: Chemical, vol. 130, issue 1, pp. 32–37, 2008.

[23] Mahdi Ghasemi-Varnamkhasti, Seyed Saeid Mohtasebi, Maryam Siadat and Sundar Balasubramanian, “Meat

Quality Assessment by Electronic Nose (Machine Olfaction Technology),” Sensors (Basel), vol. 9, no. 8, pp. 6058-

6083, 2009.

[24] “Principles and Techniques Introduction of electronic nose sensors”, Novaking blog, Montag, Nov. 26, 2012.

Available : http://novaking.twoday.net/stories/principles-and-techniques-introduction-of-electronic-nose-sensors/

[25] Corrado Di Natale, Fabrizio A.M. Davidea, Arnaldo D'Amicoa, Paolo Nellib, Silvio Groppellib, and Giorgio

Sberveglieri, “An electronic nose for the recognition of the vineyard of a red wine,” Sensors and Actuators B:

Chemical, vol. 33, issues 1–3, Pages 83–88, July 1996.

AUTHORS

Zinkar Das is a final year M. Tech Scholar and teaching assistant at Applied Electronics and Instrumentation

Department of JIS College of Engineering, Kalyani, W.B., India. He has completed his B. Tech degree in

Microprocessor, Microcontroller based on embedded systems and Instrumentation domain. He has started his project work under the guidance of Dr. Biswarup Neogi. He has published five International and National papers.

Electronics and Instrumentation department from Greater Kolkata College of Engineering and Management,

Baruipur, W.B., India at 2012. His area of interest belongs to Prosthesis, Control theory, Artificial organ,

Mrs. Moupali Roy is engaged with Narula Institute of Technology, Kolkata, W.B., India as a Faculty member. She has received her M. Tech degree in Mobile Communication and Network Technology from JIS

College of Engineering in 2012 under WBUT. Before that She obtained B. Tech in ECE from Murshidabad

College of Engineering and Technology in 2010 under WBUT. She was working as a guest faculty in ECE

Dept, at Abacus Institute of Engineering & Management. She has been engaged as a successful examiner of WBUT curriculum. She has initiated her PhD (engineering) under the supervision of Dr. B. Neogi. Her research interest includes

Control Theory, Process control, Biomedical Engineering etc.

Subham Ghosh is an Assistant Professor of ECE Dept. at JIS College of Engineering, Kalyani, Nadia, W.B,

India. Subham Ghosh finished his M.Tech from JISCE, WBUT, W.B., India in 2011. His area of specialization is Mobile Communication & Network Technology.

Volume 2, Issue 12, December 2013 Page 265

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com

Volume 2, Issue 12, December 2013 ISSN 2319 - 4847

Aniruddha Ghosh is an Assistant Professor of ECE Dept. at JIS College of Engineering, Kalyani, Nadia,

W.B., India. Aniruddha Ghosh finished his M.Tech from C.U., W.B., India in 2011. His area of specialization is Radio – Physics & Electronics.

Dr. Biswarup Neogi –Asst. Prof., ECE Dept., JIS College of Engineering, Kalyani, W.B, India. Dr. Biswarup

Neogi is awarded PhD (Engineering) from Jadavpur University, India. He received M.Tech degree in ECE from Kalyani Govt. Engg. College in 2007. Before that He obtained B.E in ECE from UIT, The University of

Burdwan in 2005.He has an experience on various project of All India Radio attached with the Webel

Mediatronics Ltd, Kolkata. He was a lecturer in ECE Dept, Haldia Institute of Technology. WB, India. He was working as a faculty in ECE Dept, Durgapur Institute of Advanced Technology & Management. Currently he is engaged with JIS College of Engineering, Kalyani as a Faculty member and flourished R&D related activity. Recently he is also engaged as a consultant executive engineer of YECOES Ltd, Hooghly, and attached as an advising body of different Engineering College under WBUT. His research interest includes Prosthetic Control, Biomedical Engineering,

Digital Simulation, Microcontroller based Embedded System. He is guiding five PhD theses in this area. He also engaged with various Govt. sponsored project works like DST, AICTE and so on as a personnel investigator. He has published more than fifty several papers in International and National Journal and Conference conducted both in India and abroad.

Additionally, he attached as a reviewer of several journals and yearly conference.

Volume 2, Issue 12, December 2013 Page 266