Enclosure 4A - Project Summary Form (541) 737-3437

Enclosure 4A - Project Summary Form

NATIONAL FIRE PLAN COMMUNITY ASSISTANCE AND WILDLAND URBAN INTERFACE PROJECTS

Application for Fuels Utilization and Marketing Projects

Applicant

Applicant/Organization:

Office of Sponsored Programs / Oregon State University

Phone:

(541) 737-3437

FAX:

(541) 737-3093

Address (Street or P. O. Box, City, State, Zip) :

312 Kerr Administration Building, Covallis, OR 97331-2140

Email:

Sponsored.Programs@orst.edu

Project Coordinator

Project Coordinator (Name and Title):

Michael R. Milota, Associate Professor, Department of Wood Science and Engineering

Organization/Jurisdiction:

Oregon State University, 136 Richardson Hall, Corvallis, OR 97331-5751

Phone:

(541) 737-4210

FAX:

(541) 737-3385

Email:

Mike.Milota@orst.edu

Project Information

Project Title:

New Drying Technology Demonstration for Lumber Produced From Small-Diameter Logs

Project Start:

July 1, 2002

Project End:

June 30, 2003

Federal Funding Request:

$26,643.00

Total Project Funding:

$33,304.00

Are you submitting multiple projects? If so, please explain and prioritize:

No

Brief Project Description:

There are hundreds of thousands of acres of young, fast-growing ponderosa pine stands in the

Western U.S. Utilization of this for lumber is often uneconomic due to warp. A recent study conducted by OSU, in cooperation with the US Forest Service and Burnt River Forest Products

(Unity, OR), confirmed this problem when approximately 80% of lumber obtained from young, fastgrowing ponderosa pine failed to meet grade due to warp.

We propose to demonstrate that a technology recently developed in New Zealand can be used to produce straight dry lumber from green and dry warped lumber using high temperatures and elevated pressure. The technology is also applicable to difficult-to-dry hardwoods. If a board is held straight during drying, warp is reduced. However, when conventionally dried, the memory in the wood polymer structure can cause warp after drying. The higher temperature and pressure will eliminate this effect.

A report will be prepared documenting warp reduction, necessary operating parameters, and estimated costs. This will be used to design and obtain partners for a precommercial version of the dryer. A nontechnical how-to guide will also be prepared which summarizes the findings.

Project Location:

Corvallis, OR

County:

Benton

If the applicant is an unincorporated area, define the geographic area being represented:

Congressional District:

5

Enclosure 4B (Page 1 of 3) - Project Narrative Description

Applications for funding must include a narrative response that describes the proposal. Please do not submit responses longer than one page, single space, 12-pitch font.

Describe project including, but not limited to:

Address these items as applicable:

project location

project implementation

anticipated outcomes

measures and reporting

partners

project income

project time frames

specify types of activities and equipment used

amount or extent of actions (acres, number of homes, etc)

environmental, cultural and historical resource requirements

Response:

Project Location: OSU, Corvallis, OR. Logs and lumber will come from the Lakeview, OR region.

Project Implementation (includes Activities and Equipment): Ponderosa pine lumber from small-diameter, fast-growing ponderosa pine will be sourced, processed, and delivered to OSU by the Lake County Resources

Initiative. Lumber will be tracked so we will know which pieces came from the what log. A portion of the wood will be dried from green in the pressurized kiln vessel using various combinations of schedules

(temperatures and pressures). Schedules will be designed not only to obtain a significant warp reduction, but to give favorable wood properties such as strength, color, and shrinkage. A conventional lab kiln using a conventional schedule and stacking techniques will be used to dry control samples which will be paired

(when possible) to the treatment samples by log. Storage and drying will be done in the winter to minimize staining and predrying. Cycling between high and low humidity rooms will be used to establish the permanency of the warp reduction. Dry, warped boards from the conventional dry kiln will be put through the pressurized kiln to demonstrate possible warp reductiono if this system is used in series with a conventional kiln.

Anticipated Outcomes: Demonstration of new drying technology for difficult-to-dry species, such as smallerdiameter, fast-growing ponderosa pine; rough ecomomic projections for commercial scale application; and baseline data for developing pre-commercial scale kiln with private and public partners.

Measures and Reporting: Project will result in a report documenting 1) technical feasibility of using pressurized, all-water vapor environment to reduce warp during drying of smaller, fast-growing pondersoa pine; 2) potential to reduce warp in already-dried lumber, 3) time-temrperature relationships for precommercial kiln design, and 4) rough projections of potential economics. Layperson's version will also be completed.

Partners: OSU, Lake County Resources Initiative (letter attached to same e-mail as proposal), Fremont NF, and Northwest Forest Products (Paisley). Other partners may be added as circumstances require.

Project Time Frame: One Year (1 month; Equipment testing, 2 months; Testing of schedules, 3 months; Warp reduction, 2 months; Humidity cycling, 2 months; Reporting, 2 months).

Amt/Extent of Activities: Limited acreage treated due to requirement at this stage for less than a half truckload of logs. Long-term potential is that drying technology will permit additional acreage to be treated due to improved economics.

Environmental Review Requirements - Will obtain logs from National Forest lands with all environmental documentation completed.

Enclosure 4B (Page 2 of 3) - Project Evaluation Criteria

Applications for funding must include narrative responses that address the following four criteria. Within each criterion, subcriteria are listed in descending order of importance. Limit your responses to the areas provided .

1. Increasing Local Capacity (35 Points)

A.

How would the proposal improve or lead to the improvement of the local economy in terms of jobs and sustainable economic activity? How many jobs are expected to be created or retained and for how long (please distinguish between essentially year-round and seasonal jobs)?

B.

Will biomass or forest fuels be utilized; if so, in what manner and how much?

C.

Which, if any, private businesses will participate?

D.

To what extent will this project be offered to serve as a model for other communities or businesses?

Response:

A: This is a technology demonstration project. It will provide rough economic projections that can be used to estimate mill capital investment requirements and efficiency improvements. Eventual outcome is improvement in mill competitiveness due to increased efficiencies and retention of year-round sawmill jobs.

Results could directly affect all mills processing smaller diameter ponderosa pine and other difficult-to-dry species.

B: LeVan and Livingstone (USDA, FPL in FPJ, Sept, 2001) estimate 20 to 30% of removed material is suitable for high end uses and another 40 to 50% for lumber. Smaller-diameter ponderosa pine exhibits much more warp than similar Douglas-fir and it is unlikely straight lumber can be consistently produced using conventional processes. The technology demonstrated could substantially improve higher-value utilization of smaller ponderosa pine, and probably hardwoods as well.

C: NW Forest Products is participating in procuring and processing the logs. Other companies will be recruited for proto-type kiln design and funding if results are as expected.

D: Project will be model of technology demonstration and transition to next logical phase for commercial use.

2.

Reducing fire risk. (30 points )

A.

Describe how the proposal promotes reduction of risk in high hazard areas and communities.

B.

Describe how the proposed project benefits resources on federal land or adjacent non-federal land, or how it protects the safety of communities.

C.

To what extent does the project implement or create a cooperative fuels treatment plan or community fire strategy (include evidence of the plan if it already exists)?

D.

Explain how the proposal (a) leads to, enhances or restores a local fire-adapted ecosystem, and/or (b) mitigates or leads to the mitigation of hazardous fuels conditions.

Response:

A.: Proposal addresses one of most difficult issues of fuels treatment involving ponderosa pine, and that is how to manufacture economically feasible, value-added products from smaller-diameter, faster-growing trees.

Successful demonstration will eventually help subsidize treatment costs in a variety of locations, including high hazard areas and communities.

B: Proposal will demonstrate technology to obtain higher-value-added products from ponderosa pine (and other difficult-to-dry species) removed as part of fuels treatments on public and private lands.

C: Utilization of smaller-diameter material is a part of many community economic development and fuels reduction plans.

D: Proposal will demonstrate technology to add value to ponderosa pine removed as part of fuels reduction projects. Additional value derived will enable treatment of more acres of hazardous fuels.

Enclosure 4B (Page 3 of 3) - Project Evaluation Criteria

3.

Increasing interagency and intergovernmental coordination. (15 Points)

A.

To what extent have interested people and communities been provided an opportunity to become informed and involved in this proposal?

B.

Describe the extent of local support for the project, including any cost-sharing arrangements

C.

What are the environmental, social and educational benefits of the project?

Response:

A: A prestudy was done with a private cooperator in Eastern OR to dry smaller diameter ponderosa pine in a vacuum/superheated steam kiln. The report was widely distributed and there was much interest in the recommendation to demonstrate use of a pressure/superheated steam process instead of the vacuum.

B. A cooperator in the local area, Lake County Resources Initiative, with relationships to Sustainable NW and its network of rural communities, will be selecting, processing, and delivering the raw material, and will also assist in disseminating the findings and recommendations.

C. Environmentally, the wood resource is extended. Socially, this drying technology may help retain jobs in rural areas. An educational benefit will be seen in the plain-language guide to the process. This will be of greater assistance to rural communuties than a technical publication or the final project report.

4.

Increasing interagency and intergovernmental coordination. (20 Points)

A.

Explain the level of cooperation, coordination or strategic planning among federal, state, tribal, local government and community organizations in developing this proposal. List the cooperators.

B.

Describe how this project implements a local intergovernmental strategy or plan, or creates such a plan. Describe the plan if it already exists.

Response:

A. Previous work was done as noted above. In addition, the acquisition or construction of a fully-operating pressure kiln was discussed and considered with the U.S. Forest Service and OECDD. It was decided that this option was too expensive ($250,000 after transportation from New Zealand and testing). The possibility of shipping some of the small-diameter material to New Zealand was also considered. This was ruled out because of the high risk of stain and decay and the import regulations that would apply to undried wood. To complete this project at a substantially reduced cost/risk ratio, it was decided that an existing treatment vessel could be converted into a small dryer to provide some initial data. Then, if the results are promising, an equipment manufacturer can be brought on board for a larger project. This would provide for a professional design and an easy pathway to commercialization.

B. Proposal supports many rural community and intergovernmental strategies and plans by addressing the issue of how to add value to smaller-diameter trees removed for fuels treatment and watershed restoration projects.

Tasks

Start Up - Set up schedule for delivery of wood. Identify and order parts to allow airflow in treatment vessel.

Enclosure 4C - Project Work Form

1 months

Time Frame

OSU

Responsible Party

Modification of treating vessel.

Installation of fans.

Acquisition of wood

2 month

Drying of green wood in vessel and controls

Set up humidity cycling schedule to test permanancy of warp reduction

3 months

Testing of dry wood to remove warp

Continue humidity cycling

3 months

Continue humidity cycling

Analysis of demonstrated effectiveness

2 months

Final report proparation

Plain-language guide preparation

1 month

OSU

Lake County Resourses Initiative

OSU

OSU

OSU

OSU

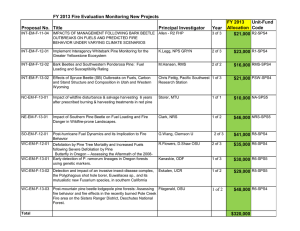

Cost Category

Description

Personnel

Subtotal

Fringe Benefits

Subtotal

Travel

Subtotal

Equipment

Subtotal

Supplies

Subtotal

Contractual

Subtotal

Other

Subtotal

Total Costs

Project (Program) Income 1

Enclosure 4D - Project Budget

Federal

Agency

$6,158.00

$8,281.00

$14,439.00

$2,094.00

$3,727.00

$5,821.00

$600.00

$600.00

$0.00

$1,300.00

$1,300.00

$0.00

$4,483.00

$4,483.00

$26,643.00

Partner 1

$933.00

$933.00

$327.00

$327.00

$408.00

$408.00

$0.00

280

$280.00

$0.00

$0.00

$1,948.00

Applicant

$0.00

$0.00

$0.00

$0.00

$0.00

$0.00

$4,713.00

$4,713.00

$4,713.00

Total

$0.00

$0.00

$0.00

$0.00

$0.00

$1,580.00

$0.00

$1,580.00

$0.00

$0.00

$0.00

$0.00

$9,196.00

$0.00

$0.00

$9,196.00

$33,304.00

$0.00

$7,091.00

$8,281.00

$0.00

$15,372.00

$327.00

$2,094.00

$3,727.00

$6,148.00

$0.00

$1,008.00

$0.00

$1,008.00

Partner 2

$0.00

$0.00

$0.00

$0.00

$0.00

$0.00

$0.00

$0.00

1 Program income is the gross revenue generated by a grant or cooperative agreement supported activity during the life of the grant. Program income can be made by recipients from fees charged for conference or workshop attendance, from rental fees earned from renting out real property or equipment acquired with grant or cooperative agreement funds, or from the sale of commodities or items developed under the grant or cooperative agreement. The use of Program Income during the project period may require prior approval by the granting agency.