Organic Frameworks by Tuning the Formations of Metal

advertisement

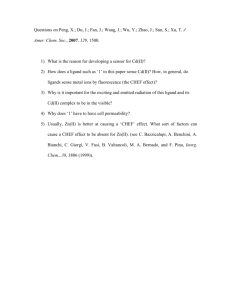

ARTICLE

pubs.acs.org/crystal

Tuning the Formations of MetalOrganic Frameworks by

Modification of Ratio of Reactant, Acidity of Reaction System,

and Use of a Secondary Ligand

Qian Gao,†,‡ Ya-Bo Xie,*,† Jian-Rong Li,‡ Da-Qiang Yuan,‡ Audrey A. Yakovenko,‡ Ji-Hong Sun,*,† and

Hong-Cai Zhou*,‡

†

‡

College of Environmental and Energy Engineering, Beijing University of Technology, Beijing, 100124, P. R. China

Department of Chemistry, Texas A&M University, P.O. Box 30012, College Station, Texas 77842, United States

bS Supporting Information

ABSTRACT: Four porous coordination networks (PCNs), {[Zn 3 O(H2O)3(adc)3] 3 2(C2H6NH2) 3 2(DMF) 3 3(H2O)}n (PCN-131), Zn2(DMA)2(adc)2] 3 2(DMA)}n (PCN-132), {[Zn3O(DMF)(adc)3(4,40 -bpy)] 3 2(C2H6

NH2) 3 S}n (PCN-1310 ), and {[Zn(adc)(4,40 -bpy)0.5] 3 S}n (PCN-1320 ), have

been synthesized by the assembly of anthrancene-9,10-dicarboxylic acid

(H2adc) with Zn(II) under different reaction conditions, including modifications of reactant ratio, acidity variations, and the use of a secondary ligand.

Single-crystal X-ray diffraction studies reveal that PCN-131, obtained from

the dimethylformamide (DMF) solution under acid condition, has a threedimentional (3D) framework structure with one-dimensional (1D) honeycomb channels. PCN-132 isolated from dimethylacetamide (DMA) solution

without adding acid in synthesis is a two-dimensional (2D) layer compound.

By employing 4,40 -bipyridyl (4,40 -bpy) as a secondary ligand, PCN-1310 and

PCN-1320 were synchronously synthesized as a mixture outcome with more PCN-1310 than PCN-1320 . In PCN-1310 , 4,40 -bpy

acting as a secondary ligand is arranged inside the honeycomb channel of the 3D PCN-131, resulting in an effective improvement of

thermal stability of the network, while in PCN-1320 , 4,40 -bpy ligands link 2D layers of PCN-132 to form a pillared-layer 3D

framework. Gas adsorption has been performed for selected materials. The results show that the framework of PCN-131 is thermally

unstable after removing the solvent molecules coordinated to their metal sites. While PCN-1310 is stable for gas uptake, with an

evaluated Langmuir surface area of 199.04 m2 g1, it shows a selective adsorption of CO2 over CH4.

’ INTRODUCTION

Metalorganic frameworks (MOFs) or porous coordination networks (PCNs) have attracted much attention because of their

intriguing structural architectures and topology,1 as well as their

potential applications in many fields such as gas storage,2 gas

separation,3 and drug delivery.4 These materials usually have a threedimensional (3D) open framework constructed from the combination

of multidentate organic ligands with metal ions or clusters also known

as secondary building units (SBUs). The approach of utilizing SBUs

developed by Yaghi et al.5 has been proven to be a powerful strategy in

designing functional MOFs. Inorganic building blocks, such as μ4-oxotetrametal basic carboxylate SBUs ([M4O(CO2)6]), are observed in

several famous MOFs, including MOF-56 and MOF-177,7 μ3-oxotrimetal basic carboxylate SBUs ([M3O(CO2)6]) seen in MIL-1018

and other MOFs,9 and dimetal-paddle-wheel SBUs ([M2(CO)4]).10

Selecting the proper metal ions and ligands, one expects to synthesize

the prospective SBUs and sequentially design and synthesize the

prospective MOFs. However, some metal ions such as Zn(II) can

form multiple possible SBUs with the same ligand; thus, it is difficult to

predict both the SBUs and the structures of its MOFs.

r 2011 American Chemical Society

The formation of MOFs is highly influenced by various

factors, such as the molar ratio of reactant reagents, solvent used,

pH value of the solution, and the selection of a secondary

ligand.11 In these factors, the secondary ligand plays a crucial

role in extending and reconstructing the structure. On the other

hand, 4,40 -bipyridyl (4,40 -bpy) is frequently introduced as a

secondary ligand to extend two-dimensional (2D) sheets into threedimensional networks by displacing coordinated solvent molecules through the “pillar-and-layer” method.12,13 This kind of

method has been proved to be a quite useful strategy. Additionally, 4,40 -bpy can also take part in channel modification to

stabilize the structure and conveniently arrange the surface

features of the channel in some MOFs.14

Gas adsorption selectivity is an important property of

MOFs which has potential applications in gas separation and

purification.3 Gas adsorption selectivity is determined not only

by the pore size and shape, but also by the channel surface feature

Received: August 14, 2011

Revised:

October 23, 2011

Published: November 04, 2011

281

dx.doi.org/10.1021/cg201059d | Cryst. Growth Des. 2012, 12, 281–288

Crystal Growth & Design

ARTICLE

of MOFs. One effective way to increase the gas selectivity of

MOFs is the modification of the inner channel, by changing the

surface polarity and the acidbase property.15 Recent research

has shown that ionic MOFs have a good behavior in selectively

adsorbing high quadrupole moment molecules (for example

CO2) through the electric field in the pores of MOFs.16 In

previous works, our group successfully synthesized a 3D structural complex, PCN-13, and investigated its gas adsorption

properties.9a As a continuing effort of our systematic investigation, we report herein the syntheses, crystal structures, and gas

adsorption of four related MOFs, PCN-131, PCN-132, PCN1310 , and PCN-1320 . The effects of mole ratios of metal ion and

ligand on the formation of SBU, as well as the function of the

secondary ligand for extending and modifying the structures of

these MOFs, are established.

for 2 days, and then cooled to room temperature. Many yellow block

crystals (PCN-1310 ) and a few colorless block crystals (PCN-1320 ) were

obtained with a yield of 46% and 18% based on Zn, respectively. The two

compounds were separated manually. FT-IR (cm1) for PCN-1310 : 3388

m, 3061 m, 2786w, 1617s, 1431w, 815s, 777s, 738w, 674s, 643s, 612s, 581s.

FT-IR (cm1) for PCN-1320 : 3389 m, 3060 m, 2788w, 1618s, 1434w, 815s,

778s, 745w, 673s, 644s, 613s, 582s.

X-ray Crystallography. Single crystal X-ray data were collected on

an Apex-II diffractometer equipped with a low-temperature device.

Single crystals were picked directly from the mother liquor, attached

to a glass loop, and transferred to a cold stream of liquid nitrogen

(163 °C) for data collection. Raw data collection and refinement was

carried out using SMART. Data reduction was performed using SAINT

and corrected for Lorentz and polarization effects.18 Adsorption corrections were applied using the SADABS routine. The structure was solved

by direct methods and refined by full-matrix least-squares on F2 with

anisotropic displacement using the SHELXTL software package.19 Nonhydrogen atoms (except some in coordinated solvents) were refined

with anisotropic displacement parameters during the final cycles.

Hydrogen atoms on carbon were calculated in ideal positions with

isotropic displacement parameters. In PCN-1310 and PCN-1320 , free

solvent molecules were highly disordered, and attempts to locate and

refine the solvent peaks were unsuccessful. The diffused electron

densities resulting from the these residual solvent molecules were

removed from the data set using the SQUEEZE routine of PLATON

and further refined using the data generated.20 The contents of the

solvent region are not represented in the unit cell contents in crystal

data. Attempts to determine the final formula of such compounds from

the SQUEEZE results combined with elemental analysis and TGA data

were not successful because the volatility of the crystallization solvents

during measurements prevented accurate data from being obtained.

Crystallographic data and experimental details for structural analyses are

summarized in Table 1. The selected bond lengths and angles of all

complexes are listed in Table S1 of the Supporting Information.

’ EXPERIMENTAL SECTION

Materials and General Methods. Commercially available reagents were used as received without further purification. H2adc was

synthesized according to a literature procedure.17 Elemental analyses

(C, H, and N) were obtained by Canadian Microanalytical Service Ltd.

1

H NMR data were collected on a Mercury 300 spectrometer. FT-IR data

were recorded on an IRAffinity-1 instrument. TGA data were obtained on

a TGA-50 (Shimadzu) thermogravimetric analyzer with a heating rate of

2 °C min1 under N2 atmosphere. The powder X-ray diffraction patterns

(PXRD) were recorded on a Bruker D8-Focus BraggBrentano X-ray

powder diffractometer equipped with a Cu sealed tube (λ = 1.541 78 Å) at

a scan rate of 0.2 s deg1. Simulation of the PXRD spectrum was carried

out by the single-crystal data and diffraction-crystal module of the Mercury

program available free of charge via Internet at http://www.iucr.org.

ASAP 2020 surface area analyzer was used to measure gas adsorption.

Syntheses of Complexes. {[Zn3O(H2O)3(adc)3] 3 2(C2H6NH2) 3

2(DMF) 3 3(H2O)}n (PCN-131). PCN-131 was prepared by the solvothermal reaction. N,N-Dimethylformamide (DMF, 1.5 mL) solution containing anthrancene-9,10-dicarboxylic acid (H2adc) (26.2 mg, 0.1 mmol) was

mixed thoroughly with DMF (1.5 mL) solution containing Zn(NO3)2 3

6H2O (59.4 mg, 0.2 mmol), and then five drops of HBF4 were added. The

mixture was sealed in a Pyrex tube, heated at 120 °C for 1 week, and then

cooled to room temperature. The light-yellow block crystals were obtained

with a yield of 56% based on Zn. FT-IR (cm1): 3273 m, 2920 m, 2779 m,

1609s, 1428s, 1381w, 1318s, 1280 m, 1091s, 815s, 777 m, 683s, 604s, 581s.

Anal. Calcd for C60.5H73.5Zn3N4.5O25.5: C, 50.95; H, 4.87; N, 4.10. Found:

C, 51.63; H, 4.78; N, 4.15.

{[Zn2(DMA)2(adc)2] 3 2(DMA)}n (PCN-132). Complex PCN-132 was

prepared by the solvothermal reaction. An N,N-dimethylacetamide (DMA,

1.5 mL) solution containing H2adc (26.6 mg, 0.1 mmol) was mixed

thoroughly with a DMA (1.5 mL) solution containing Zn(NO3)2 3 6H2O

(59.4 mg, 0.2 mmol). The mixture was sealed in a Pyrex tube, heated at

60 °C for 3 days, and then cooled to room temperature. Colorless block

crystals were obtained with a yield of 32% based on Zn. FT-IR (cm1):

3278 m, 2921 m, 2781 m, 1607s, 1427s, 1381w, 1319s, 1282 m, 1091s,

816s, 778 m, 683s, 606s, 582s. Anal. Calcd for C48H52Zn2N4O12:

C, 57.21; H, 5.20; N, 5.56. Found: C, 57.34; H, 5.18; N, 5.53.

{[Zn3O(DMF)(adc)3(4,40 -bpy)] 3 2(C2H6NH2) 3 S}n (PCN-1310 ) and {[Zn(adc)(4,40 -bpy)0.5] 3 S}n (PCN-1320 ) (S = unassigned solvent molecule).

By employing bpy as a secondary ligand, 3D metalorganic frameworks of

PCN-1310 and PCN-1320 were obtained as a mixture. An N,N-dimethylformamide (DMF, 1.5 mL) solution containing H2adc (26.2 mg,

0.1 mmol) was mixed thoroughly with a DMF (1.5 mL) solution containing Zn(NO3)2 3 6H2O (59.4 mg, 0.2 mmol). 4,40 -bpy (15.6 mg,

0.1 mmol) and three drops of HBF4 were added to this solution to give

an acid solution. The mixture was sealed in a Pyrex tube, heated at 120 °C

’ RESULTS AND DISCUSSION

Syntheses and General Characterizations. Besides metal

ions and ligands, the formation of MOFs is highly influenced by

various factors, such as solvent used, pH value of solvent, ratio of

reactants, reaction time, temperature, and so on.2125 In our case,

we try to evaluate the most significant factors that drive the

formation of three primary building units, μ4-oxo-tetrazinc basic

carboxylate, μ3-oxo-trizinc basic carboxylate, and dizinc-paddlewheel carboxylate SBU. In the three SBUs, the ratios of metal and

carboxylate ligand are 2:3, 1:2, and 1:2. In terms of a dicarboxylate ligand, such as adc2‑ herein (the mole ratios of metal and

ligand in complexes are 4:3, 1:1, and 1:1), we can suppose that

the ratio of metal and ligand may be the key factor to control the

formation of different SBUs. In a previous report, a Zn-MOF

named as PCN-139a was constructed with ligand adc2‑. In PCN13, a distorted Zn4O(COO)6 cluster as SBU was observed.

Although this SBU is different from the regular μ4-oxo-tetrazinc

basic carboxylate SBU observed in one of IRMOF series,26 it still

has the same ratio of metal and ligand, 4:3. The unusually

distorted SBU implies the possibility to get some new forms of

Zn clusters with this ligand if the reaction condition changes. On

the basis of the above assumption, we performed a systematic

experiment in the syntheses of Zn(II)adc2‑ MOFs only by

decreasing the mole ratio of metal salt and ligand from 5:1 to 1:1.

Two new MOFs, PCN-131 and PCN-132, were obtained. The

details are shown in the Supporting Information (Table S2 and

Figures S1 and S2). As shown in Figure S1, when the mole ratio

282

dx.doi.org/10.1021/cg201059d |Cryst. Growth Des. 2012, 12, 281–288

Crystal Growth & Design

ARTICLE

Table 1. Crystal Data and Data Collection Parameters for PCN-131, PCN-132, PCN-1310 , and PCN-1320

PCN-131

PCN-132

PCN-1310

PCN-1320

formula

C48H30Zn3O16

C48H52Zn2N4O12

C65H55Zn3N5O14

C21H12ZnNO5

formula weight

1058.83

1007.68

1326.25

423.69

crystal system

trigonal

monoclinic

monoclinic

tetragonal

space group

P31c

P21/n

P21/n

I4/mcm

a, Å

15.58(3)

15.28(11)

15.81

15.44(7)

b, Å

15.58(3)

19.70(14)

26.42

15.44(7)

c, Å

16.52(3)

15.59(11)

16.43

28.03(13)

a, deg

b, deg

90

90

90

90

90

90

90

90

g, deg

120

90

90

90

V, Å3

3472.0(12)

4692.1

6870.0

6680.0

Z

2

4

4

8

D, g/cm3

1.013

1.426

1.283

0.842

μ, mm1

1.076

1.089

1.102

0.752

independent reflections

2265

8693

11168

2451

Rint

R [I/σ(I) > 2]

0.0862

0.0421

0.0696

0.0838

0

0.0635

0.0361

0.0614

Rw [I/σ(I) > 2]

0.1195

0.2162

0.1883

0.2529

goodness-of-fit on F2

1.063

1.050

0.970

1.114

no. of reflection used

2265

8693

11168

2451

no. of parameters refined

103

607

755

77

ΔFmax, e Å3

1.127

4.034

1.458

0.873

ΔFmin, e Å3

0.337

2.023

0.755

0.649

of metal salt and ligand is above 4:1, the PXRD patterns of the

productions match well the simulated pattern (from single crystal

data) of PCN-13. When the ratio reaches 3:1, in PXRD some

new peaks are observed, which indicates a new compound

(PCN-132), except PCN-13 starts to form in this condition.

When the ratio reduced to 2:1, besides the above two compounds, a new compound (PCN-131) can also be obtained.

However, when the ratio is less than 2:1, other unassigned new

phases are formed.

Because PCN-13, PCN-131, and PCN-132 were simultaneity

produced at the same reaction conditions, additional experiments were carried out for clarifying the particular synthetic

conditions of the three compounds. In this case, the mole ratio of

metal/ligand is kept at 2:1 and just changes the acidity of the

solvent system. The results showed that PCN-131 is the only

product obtained in acid condition (by adding 48% HBF4 in

water). Under low acidity conditions, the crystal size formed

is too tiny to determine its structure by a single-crystal X-ray

crystallographic study (the PXRD results showed that the product is still PCN-131), while in high acidity the crystal quality is

very good. The results were confirmed by the PXRD patterns

shown in Figure S2 (Supporting Information). The PXRD

patterns show all samples have a slightly front shift of the peaks

after 15° for 2θ that is probably due to the unstableness of PCN131 without solvent. It is interesting that when two drops of

HBF4 acid were added to the system, some new peaks can be

observed in the PXRD pattern (green) and the new shape

crystals are found in the system. Those new shape crystals were

manually picked up and their unit cell parameters were checked

out several times by the single-crystal diffraction. The results

show that they are all PCN-131. The new shape crystal is just a

little bit of a twin crystal to the old one, which may cause the

differences shown in PXRD patterns. However, pure phase of

PCN-132 was found at the temperature of 60 °C without any

HBF4 acid added.

In order to extend layered PCN-132 into 3D networks, bpy

acting as a secondary ligand was introduced in the synthesis

process using the “layer and pillar” method. However, two new

compounds, PCN-1310 and PCN-1320 , were found in the same

reaction system. Pure PCN-1310 can be obtained under

optimized conditions of metal salt mole ratio (6:5:3) of

H2adc and 4,40 -bpy. Unfortunately, we could not get a pure phase

of PCN-1320 either by changing the pH value of the solvent or by

using different solvent systems or even by modifying the ratios of

reagent.

In the IR spectra of all complexes, the peaks at 29212787 cm1

belong to the CH3 stretching of solvent molecules. The Deacon

Philips rule is helpful to determine the coordination mode between

carboxylate groups and center metal ions, by calculating the

frequency separation (Δν) between the asymmetric (νas) and

symmetric stretching (νs) modes of the carboxylate unit.27 The Δν

for PCN-131 provides an indication of the bridging coordination

mode [Δν = 181 cm1 < 200 cm1, νas(COO) = 1609 cm1,

νs(COO) = 1428 cm1]. Similar characteristics are also observed in PCN-132 [Δν = 180 cm1 < 200 cm1, νas(COO) =

1607 cm1, νs(COO) = 1427 cm1), PCN-1310 (Δν = 186 cm1

< 200 cm1, νas(COO) = 1617 cm1, νs(COO) = 1431 cm1]

and PCN-1320 [Δν = 184 cm1 < 200 cm1, νas(COO) =

1618 cm1, νs(COO) = 1434 cm1]. For PCN-131, TGA

studies show that a mass loss of 8.36% corresponds to the leaving

of uncoordinated and coordinated water molecules (calcd 8.01%)

in a temperature range of 6394 °C, while a mass loss of 13.17%

corresponds to the leaving of uncoordinated DMF molecules

(calcd 13.49%) in a temperature range of 157241 °C.

283

dx.doi.org/10.1021/cg201059d |Cryst. Growth Des. 2012, 12, 281–288

Crystal Growth & Design

ARTICLE

Figure 2. (a) SBU structure of PCN-132. (b) The 2D square-grid net

structure of PCN-132. (c) The packing style of PCN-132. (d) The

hydrogen bonds between adjacent layers.

direction (Figure 1b). PLATON calculations indicate that the

effective volume for solvent molecules is 1757.4 Å3 per unit cell,

which is 50.6% of the crystal volume.28

{[Zn2(DMA)2(adc)2] 3 2(DMA)}n (PCN-132). PCN-132 crystallized in monoclinic space groups P21/n with two Zn ions, two

adc ligands, two coordinated DMA solvent molecules, and two

free DMA molecules in the asymmetric unit. Each Zn2+ ion is

coordinated by five O atoms with four from the adc ligands and

one from the coordinated DMA solvent molecule. Four carboxylate groups bridge two Zn2+ to form a distorted Zn2(CO2)4

paddle-wheel SBU as a square-planar four-connected node

(Figure 2a). The distance of Zn 3 3 3 Zn in the paddle-wheel cluster

is 2.979 Å, which is similar to those found in another dizinc

paddle-wheel SBUs.29 The bond distance of ZnO (solvent) is

1.982 Å and ZnO (adc) bond distances range from 2.039 to

2.059 Å. The ligand adc bridges dizinc paddle-wheel SBUs to form

a two-dimensional sheet (Figure 2b). There exist three kinds of

CH 3 3 3 O hydrogen bonds between adjacent layers. The first

one is formed between the methyl H atoms of the coordinated

DMA solvent molecules and the carboxylic O atoms of ligands

from adjacent layers. The second one is formed between H atoms

of the anthrancene rings and O atoms of the free DMA solvent

molecules. And the last one is formed between the methyl H

atoms of free DMA solvent molecules and the carboxylic O atoms

of ligands. These hydrogen bonds link the complex with an

“ABAB” packing fashion, resulting in a nonporous structure

(Figure 2c,d). The hydrogen-bond parameters are presented in

Table S3 (Supporting Information).

{[Zn(adc)(4,40 -bpy)0.5] 3 S}n (PCN-1320 ). PCN-1320 crystallized in tetragonal space group I4/mcm with one-half of a Zn2+

ion, one adc ligand, and one-quarter of a 4,40 -bpy in the

asymmetric unit. The zinc ion adopts a similar coordination

geometry to that of PCN-132 with 4,40 -bpy replacing the axial

Figure 1. (a) SBU structure of PCN-131 and (b) 3D structure of PCN131 with 1D channels.

This compound starts to decompose at ca. 310 °C (see Figure S3,

Supporting Information). For PCN-132, TGA studies show that a

mass loss of 17.18% corresponds to the loss of uncoordinated

DMA molecules (calcd 17.27%) in a temperature range of

84151 °C, and the other mass loss of 17.79% corresponds to

the leaving of coordinated DMA molecules (calcd 17.27%) in a

temperature range of 262343 °C. The complex starts to

decompose at ca. 350 °C (see Figure S4, Supporting Information).

Crystal

Structures. {[Zn3O(H2O)3(adc)3] 3 2(C2H6NH) 3 2

(DMF) 3 3(H2O)}n (PCN-131). X-ray single crystal diffraction

analyses revealed that PCN-131 crystallizes in trigonal space

group P31c. In the asymmetric unit of PCN-131, there are

one-sixth of a μ3-O atom, one-half of a Zn2+ ion, a H2O

molecule, the adc2‑ ligand and one third of C2H6NH2+.

Uncoordinated C2H6NH2+ part is an NH2(CH3)2+ cation

(dimethylammonium) which is formed by the decomposed

DMF molecules during heated. For the whole framework structure, PCN-131 is built on a μ3-oxo-trizinc basic carboxylate SBU

[Zn3O(COO)6] (Figure 1a) and the adc ligand, with a Znμ3O distance of 2.003 Å and adjacent Zn 3 3 3 Zn distance of 3.470 Å,

which is isorecticular to PCN-19 (Ni-MOF).9c In this SBU, three

Zn2+ ions and a μ3-O atom are on the same plane, forming a sixconnected node. Each pair of adjacent Zn2+ ions are bridged by

two carboxylate groups from two different adc ligands, and the

coordination geometry of each Zn2+ ion is octahedral with the

ZnO (μ3-O) at a distance of 2.110 Å and ZnO (adc) bond

distances ranging from 2.071 to 2.077 Å. Each trizinc SBU

connects to six adc ligands and each adc ligand binds two SBUs

to enclose a honeycomb one-dimensional channel along the c axis

284

dx.doi.org/10.1021/cg201059d |Cryst. Growth Des. 2012, 12, 281–288

Crystal Growth & Design

ARTICLE

Figure 3. (a) SBU structure of PCN-1320 , and (b) 3D structure of

PCN-1320 .

direction coordinated solvent molecules to form an octahedral sixconnected node instead of a square-planar four-connected node

(Figure 3a). It is interesting that the attendance of 4,40 -bpy relieves

the crowding among anthracene rings and breaks the weak

intermolecule interactions, forming a typical dizinc paddle-wheel

SBU with a ZnO (adc) bond distance of 2.046 Å, a ZnO (bpy)

bond distance of 2.022 Å, and a Zn 3 3 3 Zn distance of 2.925 Å,

which is shorter than that of PCN-132. With the linkage of 4,40 bpy PCN-1320 adopts a pillaredlayered structure with the

formula of {[Zn(adc)(4,40 -bpy)0.5] 3 S}n (S = unknowable solvent

molecule) (Figure 3b). However, 4,40 -bpy is disordered in this

structure due to its rotation along the symmetry axis. Compared

with PCN-132, the “layer” structure packs in an “AA” fashion,

resulting in a “pillar” effect in PCN-1320 . Unfortunately, there are

no pores in c direction because of the bulkiness of the anthracene

rings, and finally only 2D channels form in PCN-1320 . PLATON

calculations indicate that the effective volume for solvent molecules

is 3575.3 Å3 per unit cell, which is 53.5% of the crystal volume.28

Figure 4. (a) SBU structure of PCN-1310 . (b) The structure of 1D

channel and connection mode of decrated bpy. (c) The 3D packing style

structure of PCN-1310 .

{[Zn3O(DMF)(adc)3(4,40 -bpy)] 3 2(C2H6NH2) 3 S}n (PCN-1310 ).

PCN-1310 crystallizes in monoclinic space group P21/n with three

Zn2+ ions, one μ3-O atom, one 4,40 -bpy three adc ligands, one

coordinated DMF molecule, and two C2H6NH2+ cations

[C2H6NH2+ is an NH2(CH3)2+ cation (dimethylammonium)

which is formed by the decomposed DMF molecules during

heated.] in the crystallographically asymmetric unit. It is one of a

285

dx.doi.org/10.1021/cg201059d |Cryst. Growth Des. 2012, 12, 281–288

Crystal Growth & Design

ARTICLE

few cases of using 4,40 -bpy to “arrange” a channel in a MOF.14

The Zn(II) adopts a similar coordination geometry to that of

PCN-131, with bpy replacing two coordinated water molecules,

breaking the symmetry in the μ3-oxo-trizinc carboxylate SBU to

form an eight-connected node instead of six-connected node

(Figure 4a). In PCN-1310 , the honeycomb framework maintains

the linking relationship while it exhibits significant expansion along

the diagonal of two perpendicular directions a and b, as evidenced

by the large variations in channel size parameters, from 1.66 1.66

1.66 nm to 1.74 1.59 1.56 nm (Figure 4b). This is also the

reason why only two molecules of solvent can be replaced. The

third one is just sitting along the expansion direction out of the

reach of bpy. The “arrangement” of 4,40 -bpy not only changes the

shape of the channel from honeycomb to rectanglular channel but

also increases the stability of the whole framework (Figures 4c and

5). PLATON calculations indicate that the effective volume for

solvent molecules is 2712.0 Å3 per unit cell, which is 39.5% of the

crystal volume.28

Gas Adsorption. To characterize the porosity of PCN-131

and PCN-1310 , the samples were first soaked in MeOH for

3 days and then in CH2Cl2 for 3 days. However, the different

stabilities of these compounds do not allow using the same

activation conditions. Under high vacuum, PCN-131 has already

been decomposed only by 3 h at room temperature, while the

structure of PCN-1310 has remained stable even after heating to

80 °C for 10 h. This means that PCN-131 is unstable without the

support of solvent molecules, and conversely, PCN-1310 is

stable. It is also confirmed that the arrangement of 4,40 -bpy

inside the channel can effectively increase the stability of the

frameworks. Although PCN-131 is isorecticular to PCN-19,

which is mentioned above, two MOFs have totally different

stabilities after activation. The possible reason is that PCN-19 is a

nickle-based MOF while PCN-131 is a zinc-based MOF, and the

differences between the central metal ions cause different

stabilities of their MOFs. Adsorption isotherms for N2, H2, O2,

and Ar at 77 K and CO2 and CH4 at 195 and 273 K were

measured. No adsorption was observed for PCN-131, which

means that the framework collapsed after activation, as confirmed by PXRD pattern (Figure S5, Supporting Information).

The N2 adsorption of PCN-1310 represents a typical type I

isotherm (Figure 6). Its BET surface area is 442.20 m2 g1(Langmuir surface area is 496.85 m2 g1), and the total pore

volume is 0.177 cm3 g1. The PXRD pattern after gas adsorption

of PCN-1310 is still matches well with the simulated pattern,

showing that the framework structure of this material is still

stable (Figure S6, Supporting Information).

Figure 5. The channel structures of PCN-131 and PCN-1310 .

Figure 6. N2 adsorption isotherms of PCN-131 and PCN-1310 at 77 K

(solid symbols stand for adsorption and open ones for desorption.

Figure 7. (a) H2 adsorption isotherm of PCN-1310 measured at 77 K and (b) N2, O2 and Ar adsorption isotherm of PCN-1310 measured at 77 K.

286

dx.doi.org/10.1021/cg201059d |Cryst. Growth Des. 2012, 12, 281–288

Crystal Growth & Design

ARTICLE

Figure 8. (a) CO2 and CH4 adsorption isotherm of PCN-1310 measured at 195 K and (b) CO2 and CH4 adsorption isotherm of PCN-1310 measured

at 273 K.

The H2 sorption isotherm was measured at 77 K; as shown in

Figure 7a, PCN-1310 can absorb 0.84 wt % (excess) without any

hysteresis at 77 K and 800 Torr. Although the presence of bpy

reduces the porous volume, it effectively enhances the stability of

1D channel compound, and its hydrogen uptake is still comparable to that of the similar complex (PCN-199c) without bpy. The

O2 and Ar uptake was also carried out at 77 K (Figure 7b). In

addition, PCN-1310 exhibits a selective gas adsorption to CO2

over CH4 both at 195 and 273 K, as shown in Figure 8, which

is similar to several reported MOFs.16,30

’ CONCLUSIONS

Two porous coordination networks (PCNs), PCN-131 and

PCN-132, were synthesized by solvothermal reactions of Zn(II)

nitrate with anthrancene-9,10-dicarboxylic acid (H2adc) through

tuning the mole ratio of mental salt and ligand from 5:1 to 1:1.

The studies still show that PCN-131 is the only product under

acid environment. By introducing 4,40 -bpy acting as secondary

ligand, into reaction system, PCN-1310 and PCN-1320 were

obtained. Pure PCN-1310 is the primary product and can be obtained with a mole ratio of metal salt, H2adcd, and 4,40 -bpy of

6:5:3. Through the smart synthetic design, the 1D honeycomb

channel of PCN-131 was “rearranged” and modified by use of

4,40 -bpy, resulting in PCN-1310 , which is stable for gas adsorption. By use of 4,40 -bpy as secondary ligand, the 2D sheet of

PCN-132 is pillared to form a 3D framework, PCN-1320 . In

summary, judiciously tuning metalligand mole ratio could be

an effective way to form different SBUs so as to affect the

structural formation of complexes, and bpy as a good candidate

of secondary ligand not only can extend structural dimension of

complexes through the pillaredlayered method but also can

modify the structures and enhance the stability of frameworks.

’ AUTHOR INFORMATION

Corresponding Author

*Y.-B.X.: fax, +86-10-67391983; tel, +86-10-67392130; e-mail:

xieyabo@bjut.edu.cn (Y.-B.X.). H.C.Z.: e-mail: zhou@mail.chem.

tamu.edu (H.-C.Z.).

’ ACKNOWLEDGMENT

This work was supported by National Natural Science Foundation of China (No.21075114, 21076003, 20851002), the National

Basic Research Program of China (973 Program 2009CB930200),

the Special Environmental Protection Fund for Public Welfare

project (201009015), the Funding Project for Academic Human

Resources Development in Institutions of Higher Learning under

the jurisdiction of the Beijing Municipality (PHR 201107104), the

Ninth Technology Fund for Postgraduates of Beijing University of

Technology (ykj-2011-5406), and U.S. Department of Energy

(ARPA-E: AR0000073 and EFRC: DE-SC0001015).

’ REFERENCES

(1) (a) Yaghi, O. M.; O’Keeffe, M.; Ockwig, N. W.; Chae, H. K.;

Eddaoudi, M.; Kim, J. Nature 2003, 423, 705. (b) Huang, X.-C.; Lin,

Y.-Y.; Zhang, J.-P.; Chen, X.-M. Angew. Chem. Int. Ed. 2006, 45, 1557.

(c) Natarajan, S.; Mahata, P. Chem. Soc. Rev. 2009, 38, 2304. (d) Li,

J.-R.; Timmons, D. J.; Zhou, H.-C. J. Am. Chem. Soc. 2009, 131, 6368.

(e) Tranchemontagne, D. J.; Mendoza-Cortes, J. L.; O’Keeffe, M.; Yaghi,

O. M. Chem. Soc. Rev. 2009, 38, 1257. (f) Deng, H.; Doonan, C. J.; Furukawa,

H.; Ferreira, R. B.; Towne, J.; Knobler, C. B.; Wang, B.; Yaghi, O. M. Science

2010, 327, 846. (g) Zheng, S.-T.; Zuo, F.; Wu, T.; Irfanoglu, B.; Chou, C.;

Nieto, R. A.; Feng, P.; Bu, X. Angew. Chem. Int. Ed. 2011, 50, 1849. (h) Meek,

S. T.; Greathouse, J. A.; Allendorf, M. D. Adv. Mater. 2011, 23, 249.

(2) (a) Eddaoudi, M.; Kim, J.; Rosi, N.; Vodak, D.; Wachter, J.;

O’Keeffe, M.; Yaghi, O. M. Science 2002, 295, 469. (b) Rosi, N. L.;

Eckert, J.; Eddaoudi, M.; Vodak, D. T.; Kim, J.; O’Keeffe, M.; Yaghi,

O. M. Science 2003, 300, 1127. (c) Murray, L. J.; Dinca, M.; Long, J. R.

Chem. Soc. Rev. 2009, 38, 1294. (d) Huang, S.-H.; Lin, C.-H.; Wu, W.-C.;

Wang, S.-L. Angew. Chem. Int. Ed. 2009, 48, 6124. (e) Wang, Z.; Tanabe,

K. K.; Cohen, S. M. Chem.—Eur. J. 2010, 16, 212. (f) Guo, Z.; Wu, H.;

Srinivas, G.; Zhou, Y.; Xiang, S.; Chen, Z.; Yang, Y.; Zhou, W.; O’Keeffe,

M.; Chen, B. Angew. Chem. Int. Ed. 2011, 50, 3178.

(3) (a) Pan, L.; Parker, B.; Huang, X. Y.; Olson, D. H.; Lee, J. Y.; Li, J.

J. Am. Chem. Soc. 2006, 128, 4180. (b) Ferey, G. Chem. Soc. Rev. 2008,

37, 191. (c) Li, J. R.; Kuppler, R. J.; Zhou, H. C. Chem. Soc. Rev. 2009,

38, 1477. (d) Li, Y. S.; Liang, F. Y.; Bux, H.; Feldhoff, A.; Yang, W. S.;

’ ASSOCIATED CONTENT

bS

Supporting Information. PXRD patterns of complexes

prepared through changing the ratio of metal and ligand, PXRD

patterns of PCN-131 obtained under different acidity in the

synthesis, TGA results of PCN-131 and PCN-132, PXRD results

of PCN-131 and PCN-1310 (after the gas adsorption), and

complete crystallographic details (CIF file). This material is

available free of charge via the Internet at http://pubs.acs.org.

287

dx.doi.org/10.1021/cg201059d |Cryst. Growth Des. 2012, 12, 281–288

Crystal Growth & Design

ARTICLE

(27) Deacon, G. B.; Phillips., R. Coord. Chem. Rev. 1980, 33, 227.

(28) Spek, A. L. PLATON, A Multipurpose Crystallographic Tool;

Utrecht University: Utrecht, The Netherlands, 2001.

(29) (a) Chun, H.; Moon, J. Inorg. Chem. 2007, 46, 4371. (b) Jiang,

H.-L.; Liu, B.; Xu, Q. Cryst. Growth Des 2010, 10, 806.

(30) (a) Kondo, A; Chinen, A.; Kajiro, H.; Nakagawa, T.; Kato, K.;

Takata, M.; Hattori, Y.; Okino, F.; Ohba, T.; Kaneko, K.; Kanoh, H.

Chem.—Eur. J. 2009, 15, 7549. (b) Botas, J. A.; Calleja, G.; SanchezSanchez, M.; Orcajo, M. G. Langmuir 2010, 26, 5300. (c) Babarao, R.;

Eddaoudi, M.; Jiang, J. W. Langmuir 2010, 26, 11196.

Caro, J. Angew. Chem., Int. Ed. 2010, 49, 548. (e) Li, J.-R.; Ma, Y.;

McCarthy, M. C.; Sculley, J.; Yu, J.; Jeong, H.-K.; Balbuena, P. B.; Zhou,

H.-C. Coord. Chem. Rev. 2011, 255, 1791. (f) Li, J.-R.; Tao, Y.; Yu, Q.; Bu,

X.-H.; Sakamoto, H.; Kitagawa, S. Chem.—Eur. J. 2008, 14, 2771.

(4) (a) Horcajada, P.; Serre, C.; Vallet-Regí, M.; Sebban, M.; Taulelle,

F.; Ferey, G. Angew. Chem., Int. Ed. 2006, 45, 5974. (b) Horcajada, P.; Serre,

C.; Maurin, G.; Ramsahye, N. A.; Balas, F.; Vallet-Regí, M.; Sebban, M.;

Taulelle, F.; Ferey, G. J. Am. Chem. Soc. 2008, 130, 6774. (c) Horcajada, P.;

Chalati, T.; Serre, C.; Gillet, B.; Sebrie, C.; Baati, T.; Eubank, J. F.;

Heurtaux, D.; Clayette, P.; Kreuz, C.; Chang, J. S.; Hwang, Y. K.; Marsaud,

V.; Bories, P. N.; Cynober, L. Nat. Mater. 2010, 9, 172.

(5) Kim, J.; Chen, B.; Reineke, T. M.; Li, H.; Eddaoudi, M.; Moler,

D. B.; O’Keeffe, M.; Yaghi, O. M. J. Am. Chem. Soc. 2001, 123, 8239.

(6) Li, H.; Eddaoudi, M.; O’Keeffe, M.; Yaghi, M. O. Nature 1999,

402, 276.

(7) Chae, H. K.; Siberio-Perez, D. Y.; Kim, J.; Go, Y. B.; Eddaoudi,

M.; Matzger, A. J.; O’Keeffe, M.; Yaghi, O. M. Nature 2004, 427, 523.

(8) Ferey, G.; Mellot-Draznieks, C.; Serre, C.; Millang, J. D.; Surble,

S.; Margiolaki, I. Science 2005, 309, 2040.

(9) (a) Ma, S.; Wang, X. S.; Manis, E. S.; Collier, C. D.; Zhou, H. C.

Inorg. Chem. 2007, 46, 3432. (b) Jia, J.; Lin, X.; Wilson, C.; Blake, A. J.;

Champness, N. R.; Hubberstey, P.; Walker, G.; Cussen, E. J.; Schr€oder,

M. Chem. Commun. 2007, 840. (c) Ma, S.; Simmons, J. M.; Yuan, D.; Li,

J.; Weng, W.; Liu, D. J.; Zhou, H. C. Chem. Commun. 2009, 4049.

(10) (a) Dai, F.; He, H.; Gao, D.; Ye, F.; Qiu, X.; Sun, D.

CrystEngComm 2009, 11, 2516. (b) Maniam, P.; Stock, N. Inorg. Chem.

2011, 50, 5085.

(11) (a) Wang, J.; Hu, S.; Tong, M.-L. Eur. J. Inorg. Chem. 2006,

10, 2069. (b) Ma, L.; Lin, W. J. Am. Chem. Soc. 2008, 130, 13834. (c) Su,

Z.; Fan, J.; Okamura, T.; Sun, W.-Y.; Ueyama, N. Cryst. Growth Des.

2010, 10, 3515. (d) Liu, J.-Q.; Wang, Y.-Y.; Zhang, Y.-N.; Liu, P.; Shi,

Q.-Z.; Batten, R., St. Eur. J. Inorg. Chem. 2009, 1, 147.

(12) (a) Maji, T. K.; Uemura, K.; Chang, H.-C.; Matsuda, R.;

Kitagawa, S. Angew. Chem. Int. Ed. 2004, 43, 3269. (b) Pichon, A.; Fierro,

C. M.; Nieuwenhuyzen, M.; James, S. L. CrystEngComm 2007, 9, 449.

(13) (a) Bo, Q. B.; Sun, G. X.; Geng, D. L. Inorg. Chem. 2010,

49, 561. (b) Seo, J.; Matsude, R.; Sakamoto, H.; Bonneau, C.; Kitagawa,

S. J. Am. Chem. Soc. 2009, 131, 12792.

(14) (a) Tian, H; Jia, Q. X.; Gao, E. Q.; Wang, Q. L Chem. Commun.

2010, 46, 5349. (b) Park, H. J.; Cheon, Y. E.; Suh, M. P. Chem.—Eur. J.

2010, 16, 11662.

(15) (a) Zhang, S.-M.; Chang, Z.; Hu, T.-L.; Bu, X.-H. Inorg. Chem.

2010, 49, 11581. (b) Chen, Z.; Xiang, S.; Arman, H. D.; Li, P.; Zhao, D.;

Chen, B. Eur. J. Inorg. Chem. 2011, 14, 2227.

(16) (a) Babarao, R.; Jiang, J.; Sandler, S. I. Langmuir 2009, 25, 5239.

(b) Kondo, A.; Chinen, A.; Kajiro, H.; Nakagawa, T.; Kato, K.; Takata,

M.; Hattori, Y.; Okino, F.; Ohba, T.; Kaneko, K.; Kanoh, Hi. Chem.—

Eur. J. 2009, 15, 7549.

(17) Jones, S.; Atherton, J. C. C.; Elsegood, M. R. J.; Clegg, W. Acta

Crystallogr. Sect. C 2000, C56, 881.

(18) Bruker-AXS SAINT Software Reference Manual, Bruker: Madison,

WI, 1998.

(19) Sheldrick, G. M. Acta Crystallogr., Sect. A 2008, 64, 112.

(20) Spek, A. L. J. Appl. Crystallogr. 2003, 36, 7.

(21) (a) Zhong, R. Q.; Zou, R. Q.; Du, M.; Yamada, T.; Maruta, G.;

Takeda, S.; Xu, Q. Dalton Trans. 2008, 2346. (b) Ma, L. F.; Wang, L. Y.;

Huo, X. K.; Wang, Y. Y.; Fan, Y. T.; Wang, J. G.; Chen, S. H. Cryst.

Growth Des. 2008, 8, 620.

(22) Zhang, J. J.; Wojtas, L.; Larsen, R. W.; Eddaoudi, M.; Zaworotko,

M. J. J. Am. Chem. Soc. 2009, 131, 17040.

(23) Khan, N. A.; Jun, J. W.; Jhung, S. H. Eur. J. Inorg. Chem.

2010, 1043.

(24) Zhang, L.; Zhang, J.; Li, Z. J.; Qin, Y.-Y.; Lin, Q.-P.; Yao, Y. G.

Chem.—Eur. J. 2009, 15, 989.

(25) Urko, G.-C.; Oscar, C.; Javier, C.; Monica, L.; Antonio, L.;

Sonia, P.-Y.; Pascual, R.; Daniel, V.-S. Inorg. Chem. 2010, 49, 11346.

(26) Hausdorf, S.; Baitalow, F.; Boehle, T.; Rafaja, D.; Mertens, F. O.

R. L. J. Am. Chem. Soc. 2010, 132, 10978.

288

dx.doi.org/10.1021/cg201059d |Cryst. Growth Des. 2012, 12, 281–288