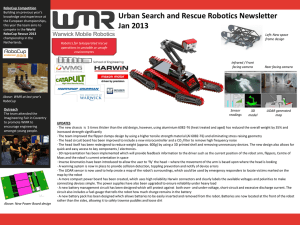

Warwick Mobile Robotics: Urban Search and Rescue Robot ES410 Group Project Technical Report

advertisement