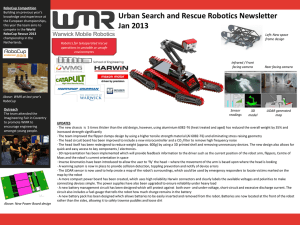

MAIN GROUP REPORT 1

advertisement