S7.2 Y. Men, Y. Wang, Y. Lu, Z. Jiang semicrystalline polymers

advertisement

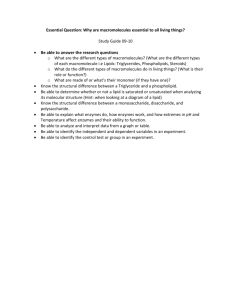

S7.2 Nano-structural evolution during tensile deformation of semicrystalline polymers Y. Men, Y. Wang, Y. Lu, Z. Jiang State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, Renmin Street 5625, 130022 Changchun, P.R. China (men@ciac.ac.cn) Abstract Two competing processes could occur during stretching a semi-crystalline polymer, namely shear yielding and cavitation. Often, both processes occur simultaneously. Stretching a semi-crystalline polymer transforms the originally isotropic spherulitical structure into a highly oriented fibrillar one (a process often referred to fibrillation). The underlying mechanism of such transition has been extensively debated. On the one hand, inter- and intra-lamellae slips have been considered to be responsible [1]; whereas on the other hands a process of stress induced melting of the original crystallites and recrystallization of the freed polymeric chain segments along the stretching direction has been also proposed [2]. Based on true stress-strain determination and recovery property investigation on a set of polyethylene of different crystallinity, in case cavitation is restrained Strobl et al. concluded that intra-lamellar crystalline block slips are activated at small strains whereas stress induced crystalline lamellae disaggregation-recrystallization starts to occur at a strain larger than yield strain [3]. This critical strain marking the onset of fibrillation is related to the state of amorphous entangled network and the stability of crystalline blocks but has no dependency on the number of tie molecules [4]. The findings directed a global understanding of the mechanical properties of semi-crystalline polymers as considering them as composed of two interpenetrated networks of hard crystalline skeleton and soft amorphous entanglements. This two phase model is meaningful only if the system possesses truly interpenetrating networks such as in high density polyethylene, poly(ε-caprolactone) and polybutene-1 [5-8]. In case when a polyethylene copolymer with low crystallinity is considered, the two phase model becomes no longer valid. A new phase in between stacks of crystalline lamellae has to be introduced yielding a more general three phase model for understanding the mechanical behaviour of semi-crystalline polymers [9]. The three phase model returns to a two phase one when dealing with systems of higher crystallinity. The mechanism of cavitation in semi-crystalline polymers is much more complicated due to partly technical difficulties to investigate the structural parameters of the cavities. Cavities normally have a size over few hundred nanometers resulting in a global strainwhitening of the samples when cavitation occurs. We have utilized symchrotron ultrasmall angle X-ray scattering technique to follow the process of cavitation in polybutene-1 as a function of stretching temperature and crystalline lamellar thickness. The results yield interesting dependencies of cavitation behaviour on these parameters. Two different modes of cavitation have been identified where the occurrence of cavitation in crystalline phase was confirmed [10]. 41 WMG_PolymerSymposiumAbstract-inners2.indd 41 25/11/2014 16:16 Acknowledgement This work is supported by the National Natural Science Foundation of China (21134006). References 1. Bowden, P.B.; Young, R.J. J. Mater. Sci., 9 (1974) 2034. 2. Flory, P.J.; Yoon, D.Y. Nature, 272 (1978) 226. 3. Hiss, R.; Hobeika, S.; Lynn, C.; Strobl, G. Macromolecules, 32 (1999) 4390. 4. Men, Y.; Rieger, J; Strobl, G. Phys. Rev. Lett., 91 (2003) 095502. 5. Jiang, Z.; Tang, Y.; Men, Y.; Enderle, H.-F.; Lilge, D.; Roth, S.V.; Gehrke, R.; Rieger, J. Macromolecules, 40 (2007), 7263. 6. Jiang, Z.; Tang, Y.; Rieger, J.; Enderle, H.-F.; Lilge, D.; Roth, S.V.; Gehrke, R.; Heckmann, W.; Men, Y. Macromolecules, 43 (2010), 4727. 7. Jiang, Z.; Fu, L.; Sun, Y.; Li, X.; Men, Y. Macromolecules, 44 (2011) 7062. 8. Wang, Y.; Jiang, Z.; Wu, Z.; Men, Y. Macromolecules, 46 (2013) 518. 9. Sun, Y.; Fu, L.; Wu, Z.; Men, Y. Macromolecules, 46 (2013) 971. 10. Wang, Y.; Jiang, Z.; Fu. L.; Lu, Y.; Men, YPLoS ONE 9 (2014), e97234. Short Biography Yongfeng Men studied applied physics and graduated from Southeast University Nanjing, China in 1995, he received his MSc degree from Changchun Institute of Applied Chemistry (CIAC) in 1998, and obtained his doctor degree at the Physikalisches Institut der Albert-Ludwigs-Universitaet, Freiburg, Germany in 2001. In 2002, he joined the Polymer Research at BASF AG (now BASF SE) as a postDoc and Physicist. At the end of 2004, he accepted a professor position at CIAC. His main research interest focuses on the structuring process in polymeric systems (mainly polyolefins and polymeric latex dispersions) using small angle X-ray scattering technique. 42 WMG_PolymerSymposiumAbstract-inners2.indd 42 25/11/2014 16:16