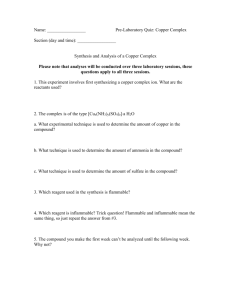

Document 13203354

advertisement