SCHOOL OF OCEANOGRAPHY The Rapid-Sampling Vertical Profiler "FRONTS 82"

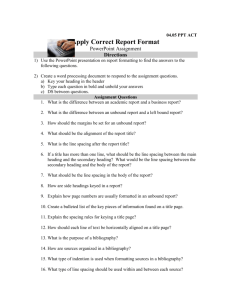

advertisement

C

SCHOOL OF OCEANOGRAPHY

The Rapid-Sampling

Vertical Profiler

Test Cruise, July 1982

"FRONTS 82"

by

OREGON STATE UNIVERSITY

Priscilla A. Newberger

Herve H. Dannelongue

Douglas R. Caldwell

Thomas M. Dillon

Stephen D. Wilcox

James L. Cantey

Reference 83-9

May 1983

I

The Rapid-Sampling Vertical Profiler

Test Cruise July 1982

Priscilla A. Newberger

Herve H. Dannelongue

Douglas R. Caldwell

Thomas M. Dillon

Stephen D. Wilcox

James L. Cantey

School of Oceanography

Oregon State University

Corvallis OR 97331

Page

TABLE OF CONTENTS

I. Introduction . . . . .

I I . Cruise report . . . .

III. FRONTS 82 data plots

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

.

.

.

.

.

.

.

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6

.

.

.

.

.

.

.

.

a) Temperature, salinity and density profiles

.

.

.

.

.

.

b) Plots of isotherms vs depth

6

.

192

226

226

254

266

d) Cable and terminations

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

288

e ) Winch

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

297

f) Onboard analog electronics

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

356

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

356

358

368

371

.

.

.

.

IV. The RAPID SAMPLING VERTICAL PROFILER

a) Electronics

.

.

.

.

.

b) Sensors . . . . . . .

c) Probe mechanical design

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

V. The analog to digital system

a) Hardware . . . . . . . . .

b) The data acquisition program . .

VI. Processing the data . . . . . . .

VII. Equipment and software performance

.

.

345

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

c) Probe mechanical design

d) Cable and termination .

.

.

.

.

.

.

.

.

.

.

.

.

.

374

374

e) Winch

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

375

.

.

.

.

.

.

.

376

377

379

a) Electronics

b) Sensors

.

.

.

.

.

.

.

.

.

.

f) Onboard analog electronics

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

g) Analog to digital system

VIII. References . . . . . . .

371

373

ACKNOWLEDGEMENTS

Assistance with this cruise was provided by Michael Brown and David

Strehlow. Funding for the development of the RSVP , for our

participation in this cruise, and for the preparation of this report

has been furnished by the Oceanic Processes Division of the National

Aeronautical and Space Administration. We especially thank W.

Stanley Wilson for his encouragement.

I. Introduction

In this report we describe a preliminary version of a

temperature/conductivity profiler that combines the

calibration accuracy of a CTD with the vertical resolution

of a microstructure instrument and the ease of deployment of

an XBT. We also describe the results of a test of this

version on a month-long cruise from Honolulu to 42 N and

back in July 1982. This instrument system, which we call the

Rapid-Sampling Vertical Profiler, has two versions. One uses

a Neil Brown conductivity transducer and a fast-tip

thermistor as sensors, and has a vertical resolution of 3 cm

in salinity and temperature. The other has a micro-scale

conductivity sensor, with a fast-tip thermistor. It has a

resolution of less than one millimeter in conductivity,'but

only 3 cm in the thermistor signal so that density

information can still only be acquired on the 3-cm scale.

The system used for this test and described in this

document is only a trial version, definitely not the final

version which is under construction in 1983. We will issue a

report in 1984 which will describe the final version and the

results of a test of it to be conducted as part of the

"Mildex" experiment in October/November 1983.

The probe is designed to be deployed from a ship moving at

speeds to 8 knots, but on this cruise considerations

involved with the other instruments in use kept the ship's

speed at 4.2 knots. The other instruments were the Towed

Thermistor/Conductivity Chain (Clayton Paulson, Oregon State

University) and an Acoustic Doppler Log (Lloyd Regier,

Scripps Institution of Oceanography). The RSVP has been

designed to complement these instruments in producing a

3-dimensional picture of the temperature, salinity, density

and shear fields in the upper ocean, and especially the

spatial distributions of the gradients of these fields. The

same suite of instruments will be used in the "MILDEX"

experiment and in the "TROPIC HEAT" cruises of 1984 and

1986.

2

II. Cruise report

The FRONTS 82 cruise lasted for 23 days from 4 July 1982 to

25 July 1982. During this period the towed thermistor/

conductivity chain (Clayton Paulson, OSU) and the acoustic

doppler log (Lloyd Regier, SIO) were kept in operation

around the clock, but the RSVP was deployed only between

lunch and sunset (7 hours a day), mostly because we were

allotted only three berths. During the cruise the weather was

nice to fair with winds of 0 - 2 knots and swell 0 - 5 feet.

II-1) were tried in order

to determine the effect of design variation and possible

Five versions of the RSVP (Table

interaction among elements. The temperature-measurement

system was the same for all units as was the conductivity

circuitry. Each of

these measurement systems is discussed in

detail in section IV of this report.

In addition to the vertically profiling RSVP, a similar unit

equipped with a microconductivity sensor was modified to

attach to Paulson's towed chain. It was hoped that the

extremely fast response time of this sensor would enable us

to calculate horizontal towed spectra of the temperature

fluctuations. The unit did not work due to electronic and

connector difficulties, but the technique shows great

promise and will be used again.

The RSVP units were deployed during 14 seven hour working

periods. A profile was recorded every 6 minutes, so that

about 65 profiles were recorded each day for a total of 890

profiles. This includes 662 profiles with Neil Brown

conductivity sensor units and 228 with the Michael Head

microconductivity sensor (Table 11-2).

At the

beginning of each working period (and more frequently

if there was any question of the conductivity signal

drifting), a file was recorded with the instrument in a

bucket on deck and a water sample was taken to be analysed

on shore. Additional surface water samples were taken every

two hours throughout the cruise. Thus we are able to monitor

any changes in conductivity calibration.

3

Table II-1. Description of RSVP units

-------------------------------------------------------------------Unit #

1

2

3

4

5

6

CHAIN

-----------------------------------------------------------------9V

POWER

DC/DC

DC/DC

#2

# 3

9V

DC/DC

DC/DC

#3

#1

--------- -------------------------------------------------------BATTERY

PRESSURE

BATTERY

FM

FM

DC

DC

DC

#3

#7

# 10

# 20

# 20

CHAIN

TEMPERATURE

MODULE

# 12

# 13

# 14

# 15

# 15

# 16

SENSOR

FP07

FP07

FP07

FP07

# 73

FP07

# 75

FP14

# 72

FROM

------------------------------------------------------------------

# 77

REPLACED

# 75

# 143

FP14

# 147

-----------------------------------------------------------------CONDUCTIVITY

MODULE

#2

#5

SENSOR

NBIS

NBIS

# 479

# 844

#4

#6

#6

#3

NBIS

MICRO

MICRO

MICRO

# 743

#6

#6

#3

REPLACED

MICRO

#1

-----------------------------------------------------------------VOLTAGE

REGULATOR

#

10

# 11

# 12

# 17

# 17

# 15

REPLACED

# 12

--------------------------------------------------------------------

Unit # 5 was used for one day only to test microconductivity

powered by a dc/dc converter. Unit # 3 was not used after July 18.

4

Table 11-2. RSVP cast summary

Number of casts

----------------------------------------------------------------DATE

START

END

UNIT

UNIT

UNIT

UNIT

UNIT

LOCAL

LATITUDE

LATITUDE

# 4

# 5

# 3

# 1

# 2

----------------------------------------------------------------27 08' N

27 14' N

2

5

----------------------------------------------------------------7

MOORING

----------------------------------------------------------------8

28 20'

28 44' N

52

----------------------------------------------------------------6

N

9

30 02' N

30 36' N

60

----------------------------------------------------------------10

31 57' N

32 23' N

41

15

-----------------------------------------------------------------

48' N

34 23' N

11

33

12

35 51' N

36 19'

13

37 42' N

38 13' N

N

59

68

73

----------------------------------------------------------------14

39 35'

N

40 05' N

71

----------------------------------------------------------------15

41 30' N

41 59' N

44

25

----------------------------------------------------------------16

42 45' N

42 26' N

11

58

----------------------------------------------------------------17

MOORING

----------------------------------------------------------------18

39 38' N

SURVEY

41

12

----------------------------------------------------------------19

38 09' N

37 43' N

60

----------------------------------------------------------------20

36 13' N

35 39' N

71

----------------------------------------------------------------21

34 01' N

33 41' N

41

----------------------------------------------------------------22

32 18' N

31 44' N

69

----------------------------------------------------------------23

30 21' N

30 15' N

13

-------------------------------------------------------------------

6

III. FRONTS 82 data plots

a) Temperature, salinity and density profiles

The data collected were divided into sequences of

consecutive profiles, one sequence per day unless there was

an extended period with no data taken. There are a total of

19 sequences. An average sequence consists of 60 profiles.

As a rule, profiles are 6 minutes apart. The data were

processed as described in section VI. Twenty centimeter

averages are plotted.

For each sequence, two series of plots are presented:

left-hand

versus depth (in

On the

page, temperature (in degrees Celsius)

meters). Profiles separated by 6 minutes

in

time are offset 3 degrees Celsius. If a profile is missing,

consecutive profiles are 12 minutes apart in time, and

correspondingly separated by 6 degrees Celsius on the plot.

If there

is a 12 minute gap at the end of a page within a

sequence, the first profile on the next page is offset by 3

degrees.

page, a plot of 5 variables versus depth

for a chosen profile of the left hand page. The 3-lines in

On the right hand

the main panel are temperature (T, in degrees Celsius),.

salinity (S, in parts per

thousands) and density (unmarked,

in grams per centimeter cubed). The mark plot in the main

panel is the Brunt-Vaisala frequency, or buoyancy

frequency (in cyles per hour). This frequency is computed

from the potential density on a length scale of 2 meters.

The right-hand panel shows the arc tangent of the stability

ratio versus depth. The stability ratio (Turner,1973) is the

most important external parameter indicating the relative

strength of double-diffusive processes. Ruddick(1981)

suggests that the (four quadrant) arc tangent of this

quantity is a practical indicator of whether these processes

can be important in a region. For values between minus PI/4

and zero double diffusion can occur. The water column is

stable for values between zero and PI/2 while salt fingering

may occur for values between PI/2 and 3PI/4. This parameter

is computed over a 2 meter scale.

The profiles are identified by tape name and tape file

number. The tape name is a string of 8 characteres, 6 for

the GMT date, one for the tape identification (A,B,C...),

and one for the instrument type (N for NBIS conductivity

sensor, M for microconductivity). For the left page, the

tape name(s) is printed above the plot, and the file number

is printed at the top of each profile. Location, wind and

time of the sequence are shown at the bottom of the plot.

7

Following is a list of some of the profiles in which the

problems discussed in section VII can be observed:

-failing conductivity data line (1OJLA file 7, 10JLB file 1,

1OJLB file 10, 1OJLC file 1).

-broken wire in winch connector

(11JLC file 9).

-x 5 on-board gain was too great for the temperature range

observed at the southern stations so that the temperature

profiles are not on scale to the end of the drop (sequences

6, 18).

In addition the data from units 2 and 3 tend to be noisier

because of the voltage regulator oscillation associated with

the dc/dc power.

For unit 4 (microconductivity), right hand page plots have

been replaced by blank pages when the conductivity signal

was unreliable (sequences 6, 11) and all sequences after the

microconductivity sensor was replaced (Table 11-2, section

VII).

9JL82AN

0.

100.

150.

200.

10.

5.

30.

15.

35.

45.

40.

50.

TEMPERATURE ( °C)

SEQUENCE 1

START

TIME

LOCATION.

Profi)e spacing

00:13

28°20'N

800m

PAGE 1

GMT

07/09/82

151 °40'W

WIND

SPEED

6. m/s

DIRECTION

100°

Ship's heading

0°

09JLA FILE 05

11

RRCWN (R)

200

.5

a

'

10.

T °C

32.

S °/O0

20.

1S.

25. -TT

34.

36.

1.025

1.028

I

L. 022 DENSITY

1

1

0.

BV CPH

15.

1

30.

TT

9JL92AN

,

9JL92BN

0.

50.

100.

150.

I

200.

.

i0.

5.

11

I

/. A

15.

20.

SEQUENCE 1

START

TIME

LOCATION

Profile spacing

01:09 GMT

28°29-N

800m

/i

-

I

/1

25.

/30.

1

11

lI

35

L

i

151 °40-W

I

40.

111

45.

I

50.

TEMPERATURE ( °C)

PAGE 2

07/09/82

1

WIND

SPEED

DIRECTION

Ship's heading

6. m/s

1000

00

09JLA FILE 15

13

ARCTAN (R)

,

ops

I

ti

40

I I

6.

AN

r

ON

e a

1

w

120

S

160

%

0

200"

10.

T °C

I

32.

25.-1T

I

S °/°0

1.022 DENSITY

I

0.

20.

15.

BV CPH

34.

36.

1.025

1.028

1

1

15.

30.

n

9JL92BN

0.

5o.

100.

i50.

111

200.

10.

5.

SEQUENCE 1

START

TIME

LOCATION

Profile spacing

30.

15.

07/09/82

28°30-N

151 °40-W

45.

40.

50.

TEMPERATURE ( °C)

PAGE 3

02:03 GMT

800m

35.

WIND

SPEED

6. m/s

DIRECTION

1000

Ships heading

0°

09JLB FILE 07

15

ARCTAN

(R)

! !

f

r

40

80

!

120

ti

160

1

200

10.

32.

f

T °C

20.

15.

S °ioo

34.

25 .-TT

36.

r

1.022 DENSITY

I

0.

BV CPH

1.025

1.028

I

I

15.

30.

1

1

Tt

9JL82BN

,

9JL82CN

35.

SEQUENCE 1

START

TIME

LOCATION

Profile spacing

02:58 GMT

28°35'N

800m

151 °40'W

50.

TEMPERATURE ( °C)

PAGE 4

07/09/82

45.

40.

WIND

SPEED

DIRECTION

Ship's heading

6. m/s

1000

00

09JLC FILE 01

17

ARCTAN

(R)

f

40

f

f f

.

120

160

200

10.

T °C

S °/00

1.022 DENSITY

0.

25.-IT

I

I

32.

20.

15.

BV CPH

34.

36.

1.025

1.028

15.

30.

ri

9JL82CN

200.

10.

5.

15.

20.

SEQUENCE 1

START

TIME

LOCATION

Profile spacing

03:53 GMT

28°35-N

Boom

5.

30.

35.

151 °40-W

50.

TEMPERATURE ( °C)

PAGE 5

07/09/82

45.

40.

WIND

SPEED

DIRECTION

Ships heading

6. m/s

1000

00

09JLC FILE 10

19

ARCTAN (R)

r

r1

s

r

r r

s

r

200

10.

32.

T °C

15.

S °/pp

1.022 DENSITY

25.-IT

34.

36.

1.025

1.028

I

1

0.

20.

BV CPH

15.

30.

0.

9JLe2CN

0.

T--T --- T--1

,

9JLe2DN

TI I

i

n

T

II

1

50.

100

150.

200.

5.

10.

15.

20.

SEQUENCE 1

START

TIME

LOCATION

Profile spacing

04:49 GMT

28°40'N

800m

4-

.

30.

35.

151 °40'W

50.

TEMPERATURE ( °C)

PAGE 6

07/09/82

45.

40.

WIND

6. m/s

SPEED

DIRECTION

Ship's heading

00

1000

09JLD FILE 02

21

ARCTAN (R)

,

40

i

80

It

s

120

160

200 L-W-m

10.

T °C

20.

15.

1

32.

S °/pp

1.022 DENSITY

I

0.

25. -IT

1

34.

36.

1.025

1.028

I

BV CPH

15.

30.

0.

TT

9JL82EN

50.

100.

150.

I,

200.

10.

15.

TIME

LOCATION

Profile spacing

22:24 GMT

30°03-N

800m

J

20.

SEQUENCE 2

START

i

I

t

IJ

25.

i/

I

30.

35.

151046-W

50.

TEMPERATURE ( °C)

PAGE 1

07/09/82

45.

40.

WIND

SPEED

DIRECTION

Ship's heading

2. m/s

1000

00

09JLE FILE 05

23

ARCTAN

(R)

!

'

I

40

I

IT

32.

S °/pp

1.022 DENSITY

0.

BV CPH

34.

36.

1.025

1.028

15.

30.

9JL82EN ,9JLe2FN ,1OJLB2AN

0

50.

i00.

150.

200.

10.

5.

15.

20.

SEQUENCE 2

START

TIME

LOCATION

Profile spacing

23:19 GMT

30°07N

800m

25.

30.

35.

151 °46-W

50.

TEMPERATURE ( °C)

PAGE 2

07/09/82

45.

40.

WIND

SPEED

2. m/s

DIRECTION

100°

Ships heading

0°

10JLA FILE 01

25

ARCTAN (R)

40

a

120

160

200 40

10.

T °C

I

32.

20.

15.

I

S °io

34.

1

36.

1

1

1.022 DENSITY

1.025

1.028

1

1

0.

25.-IT

BV CPH

15.

30.

0.

n

10JL82AN

0.

N

c1

50.

100.

150.

I

200.

I

1

1

I

I

1

I/

i0.

5.

1

I

1/

1

I

15.

I/ I

TIME

LOCATION

Profile spacing

00:14 GMT

30°11-N

800m

11 I

20..

SEQUENCE 2

START'

1

1

It

I

25.

1

1 /1

I

30.

I

11

1

1

11

35.

I

I

/1

I

1

151 °47-W

1

1

1

1

45.

40.

1

1

50.

TEMPERATURE ( °C)

PAGE 3

07/10/82

1

WIND

SPEED

2. m/s

DIRECTION

100°

Ship's heading

00

1OJLA FILE 07

ARCTAN

(R)

27

r

40

120

160

r

200

10.

32.

T °C

15.

S °io,

1.022 DENSITY

20.

25 . -TT

34.

36.

1.025

1.028

15.

30.

L

0.

BV CPH

0.

TT

iPJL82AN ,1PJL82BN

SEQUENCE 2

START

TIME

01:09 GMT

LOCATION

30015-N

Profile spacing

800m

TEMPERATURE ( °C)

PAGE 4

07/10/82

151045-W

WIND

SPEED

DIRECTION

Ships heading

2. m/s

1000

00

10JLB FILE 01

ARCTAN (R)

nn

29

qF'

r

r

25.-1T

32.

S 0/pp

34.

36.

I

1. 022 DENSITY

0.

BV CPH

1.025

1.028

15.

30.

0.

1OJL82BN

l l l

TIME

LOCATION

Profile spacing

02:10

GMT

30°19N

800m

30.

35.

07/10/82

151045'W

45.

40.

50.

TEMPERATURE ( °C)

PAGE 5

SEQUENCE 2

START

25.

20.

15.

WIND

SPEED

2. m/s

DIRECTION

1000

Ships heading

0°

IOJLB FILE 1 1

31

ARCTAN (R)

nn

T CZ

czp--

40

80

120

160

200

10.

T °C

32.

S °/pp

20.

1S.

34.

25 .-TT

36.

I

1.022 DENSITY

1.025

1.028

is.

30.

l

0.

BV CPH

TT

1OJLB2CN

0.

I

T--T---F--l

T

r--F---T -T

T

T

r1

m

II

I

I

I

I

I

T-7- r-1

i

1--F--T--T

50.

100.

150.

200.

10.

5.

i5.

20.

SEQUENCE 2

START

TIME

LOCATION

Profile spacing

03:05 GMT

30°23--N

BOOM,

25.

30.

35.

151 °45-W

50.

TEMPERATURE ( °C)

PAGE 6

07/10/82

45.

40.

WIND

SPEED

2. m/s

DIRECTION

1000

Ships heading

00

33

1OJLC FILE 01

ARCTAN (R)

.,

40

ti

ti

120

160

200

10.

T °C

32.

S °/00

I

1. 022 DENSITY

0.

20.

15.

BV CPH

25.-TT

34.

36.

I

I

1.025

1.028

,

,

15.

30.

11

1OJL82CN

10.

15.

20.

SEQUENCE 3

START

TIME

LOCATION

Profile spacing

04:07 GMT

30°27-N

800m

25.

30.

35.

40.

50.

TEMPERATURE ( °C)

PAGE 1

07/10/82

45.

WIND

SPEED

151 °45-W

Ships heading

0. m/s

1OJLC FILE 07

35

ARCTAN

.,

(R)

ti

40

80

120

160

200

10.

32.

T °C

S 0/00

1.022 DENSITY

t

0.

20.

15.

34.

36.

1.025

1.028

1

BV CPH

25.-IT

15.

I

30.

1OJL82DN

0

50.

100.

150.

1

1

1

I

I

I

111119111/1-j

200.

5.

10.

20.

15.

TIME

LOCATION

Profile spacing

22:35

GMT

31 °55-N

800m

25.

30.

35.

Il

I

I

I

I

07/10/82

151043-W

I

I

I

I

I

45.

40.

1

1

50.

TEMPERATURE ( °C)

PAGE 1

SEQUENCE 4

START

I

WIND

SPEED

6. m/s

DIRECTION

280°

Ships heading

0°

1OJLD FILE 06

37

ARCTAN (R)

.

. '

l

it

!

! i

0.

1

32.

S °/oo

i

I

34.

36.

1

1.022 DENSITY

1.025

J

1.028

I

1

0.

I

BV CPH

15.

30.

IT

1OJL82DN

11JL82AN

,

0

50.

100.

150.

1

1

1

1

200.

5.

11

II

1

10.

1

1

1

1

d

15.

I

1

TIME

LOCATION

Profile spacing

23:30 GMT

31 °59-N

800m

1

1

1

20.

SEQUENCE 4

START

1

Ill

1

25.

LI

I

30.

I

I

I11 11

35.

1

I

I

I

151 °43-W

1

1

40.

I

1

45.

1

1

1

I

50.

TEMPERATURE ( °C)

PAGE 2

07/10/82

1

WIND

SPEED

6. m/s

DIRECTION

2800

Ships heading

0°

IOJLD FILE 14

39

ARCTAN (R)

0

40

120

160

200 L

10.

-SR

T °C

20.

15.

t

I

32.

6l

i

S 0/00

34.

25 . -TT

1

36.

I

1.022 DENSITY

I

0.

BV CPH

1.025

1.028

I

I

15.

30.

IT

11JL82AN

0.

50.

100.

150.

I

200.

10.

5.

15.

20.

SEQUENCE 4

START

TIME

LOCATION

Profile spacing

00:24 GMT

32°03-N

800rn

25.

30.

35.

I

I

40.

151043'W

i

1

I

1

45.

-

1

I

50.

TEMPERATURE ( °C)

PAGE 3

07/11/82

1

WIND

SPEED

6. m/s

DIRECTION

280°

Ship's heading

0°

11JLA FILE 08

41

ARCTAN (R)

nn

c

is

i

1

40

'i

120

160

200

10.

a--'

T °C

25.-fl

I

S

/00

1.022 DENSITY

34.

1.025

36.

1.028

I

I

0.

20.

15.

A

32.

r

6

BV CPH

15.

30.

0.

TT

11JLe2AN

,

11JLe2BN

0.

50.

100.

150.

200.

10.

5.

15.

20.

SEQUENCE 4

START

TIME

LOCATION

Profile spacing

01:18 GMT

32°07'N

800m ,

25.

30.

35.

40.

151 °44-W

50.

TEMPERATURE ( °C)

PAGE 4

07/11/82

45.

WIND

SPEED

DIRECTION

Ships heading

6. m/s

2800

00

11JLA FILE 15

43

ARCTAN

(R)

0

4

40

xp

r

U

120

160

r

200 L-lb-j

10. T °C

l

32.

20.

15.

I

S °/°p

25.-IT

1

34.

36.

1.025

1.028

I

1.022 DENSITY

I

0.

i

BV CPH

15.

J

30.

r

n

11JL82BN

5.

10.

15.

20.

SEQUENCE 4

START

TIME

LOCATION

Profile spacing

02:14 GMT

32011'N

800m

25.

30.

35.

151044'W

50.

TEMPERATURE ( °C)

PAGE 5

07/11/82

45.

40.

WIND

SPEED

6. m/s

DIRECTION

280°

Ships heading

00

1 1 JLB FILE 06

ARCTAN (R)

40

120

160

I

i

200

10.

32.

T °C

15.

S °/00

20.

25.-IT

34.

36.

1.025

1.028

15.

30.

I

1.022 DENSITY

1

0.

BV CPH

s

45

11JLe2CN

0.

50.

100.

150.

200.

35.

SEQUENCE 5

START

TIME

LOCATION

Profile spacing

03:48 GMT

32°17N

800m

40.

151 °45-W

50.

TEMPERATURE ( °C)

PAGE 1

07/11/82

45.

WIND

SPEED

5. m/s

DIRECTION

2500

Ships heading

0°

11JLC FILE 05

47

ARCTAN

(R)

is

I

i i

40

i

80

120

160

i

.

.

200

10.

T °C

32.

S °/oo

1.022 DENSITY

0.

20.

15.

BV CPH

25 .-TT

34.

36.

1.025

1.028

1

I

15.

30.

TT

11JL82CN

50.

100.

150.

200.

35.

.SEQUENCE 5

START

TIME

LOCATION

Profile spacing

04:43 GMT

32021-N

800m

151 °46-W

50.

TEMPERATURE ( °C)

PAGE 2

07/11/82

45.

40.

WIND

SPEED

5. m/s

DIRECTION

2500

Ships heading

0°

1 1 JLC FILE 12

49

ARCTAN (R)

40

.

.

'I.

1

80

.

I

120

.

160

ti

200

10.

32.

T °C

S °/pq

I

34.

25 . -1T

36.

a

1.022 DENSITY

0.

20.

15.

BV CPH

1.025

15.

1.028

30.

TT

r- r- r- r-j- r r-r- r

i

5G

--_L___ I.--I_J -J_-J

l(;R

SEQUENCE 6

START

TIME

LOCATION

Profile spacing

00:06 GMT

33°57'N

800m

TEMPERATURE (°C)

PAGE 1

07/12/82

151 °50-W

WIND

SPEED

6. m/s

DIRECTION

2500

Ships heading

0°

51

I.-_I---J---. r--r-I --

fem.

ri

11a,CJ,

SEQUENCE 6

START

TIME

LOCATION

Profile spacing

01:01 GMT

34°01-N

900m

TEMPERATURE (°C)

PAGE 2

07/12/82

151 °50-W

WIND

SPEED

DIRECTION

Ships heading

6. rn/s

2500

00

53

1- Of -1

..

1

J. 50

f

L._1-,_J

J__1

SEQUENCE 6

START

TIME

LOCATION

Profile spacing

02:00 GMT

34°05-N

900tH

TEMPERATURE (°C)

PAGE 3

07/12/82

151 °50-W

WIND

SPEED

6. m/s

DIRECTION

250°

Ship's heading

0°

55

1<

I

I

._..J I_k "-

`I

t-`

TEMPERATURE ( °C)

SEQUENCE 6

START

TIME

LOCATION

Profile spacing

02:54 GMT

34°091N

900M

PAGE 4

07/12/82

151 °50-W

WIND

SPEED

6. m/s

DIRECTION

2500

Ships heading

00

57

J.

0,

- r r -r-I -

r--T --I

T

T

r

r' i

r

t

r- r

I i; r

1

-.L- lr

r

1

r-1T

r

1

;'

r

r-T-r "

mar'

r

1

f-r

l

L

1 -1-

SEQUENCE 6

START

--,-1

J-j

JJ_l._.__1

lI1._-.___ 1_11.1

r

TIME

LOCATION

Profile spacing

03:48 GMT

34°13-N

900m-

TEMPERATURE ( °C)

PAGE 5

07/12/82

151050-W

WIND

SPEED

6. m/s

DIRECTION

2500

Ships heading

00

59

12JL82EN

0

50.

100.

150.

200.

10.

i5.

20.

SEQUENCE 7

START

TIME

LOCATION

Profile spacing

22:54 GIFT

35°534N

900m

25.

30.

35.

151°52-W

50.

TEMPERATURE ( °C)

PAGE 1

07/12/82

45.

40.

WIND

SPEED

6. m/s

DIRECTION

2800

Ships heading

0°

61

12JLE FILE 07

ARCTAN (R)

40

.

'

80

120

i

160

r

I

i

i

200

5.

T °C

10.

15.

20. -Ti

1

32.

S °/pp

34.

36.

1.025

1.028

15.

30.

I

1.022 DENSITY

0.

BV CPH

TT

13JL82AN

0.

II

50.

100.

150.

200.

.

1

1

.

I

.

.

t

.

I

.

.

1

I

1

.

A

'.

.

1

5.

10.

15.

20.

SEQUENCE 7

START

TIME

LOCATION

Profile spacing

00:00 GMT

35°57N

900m

1

`5.

I

30.

d.

.

.I

I

35.

.

J.

I

.

151 °50-W

.

1

.

I

45.

40.

.

1

1

.

50.

TEMPERATURE ( °C)

PAGE 2

07/13/82

.

WIND

SPEED

6. m/s

DIRECTION

280°

Ships heading

0°

13JLA FILE 05

63

ARCTAN

(R)

40

80

120

I

160

200

5.

32.

T °C

S °ioo

34.

20 . -TT

36.

I

I

1.022 DENSITY

L

0.

15.

10.

8V CPH

1.025

1.028

I

I

15.

30.

IT

13JL82AN

,

13JL82BN

0

1

25.

SEQUENCE 7

START

TIME

LOCATION

Profile spacing

01:06 GUT

36°01-N

900m,

1

Y

1

I

30.

1

1

1

I

I

35.

1

1

1

1\

40.

151049-W

I

1

I

45.

50.

TEMPERATURE ( °C)

PAGE 3

07/13/82

1

WIND

SPEED

DIRECTION

Ship's heading

6. m/s

2800

00

13JLB FILE 02

65

ARCTAN

(R)

40

%

80

120

I

%

160

200

5.

T °C

32.

S °/00

10.

1.022 DENSITY

20. -1T

34.

36.

1.025

1.028

1

1

0.

15.

BV CPH

15.

30.

IT

13J-L82BN

,

13JL82CN

50.

100.

150.

200.

10.

5.

15.

20.

SEQUENCE 07

START

TIME

LOCATION

Profile spacing

02:12 GIFT

36°05-N

900m

25.

30.

35.

TEMPERATURE ( °C)

PAGE 4

07/13/82

151 °49-W

45.

40.

WIND

SPEED

6. m/s

DIRECTION

2800

Ships heading

0°

13JLB FILE 12

67

ARCTAN (R)

0

ti

40

80

rd

120

160

r

ral

200

S.

32.

T °C

15.

10.

S °/°0

34.

20. -1T

36.

I

1.022 DENSITY

1.025

1.028

1S.

30.

I

0.

BV CPH

j

R

10JL82CN

0.

50.

100.

150.

200.1 1]

.

I

5.

1

1

i

I

J111111111 111111111

10.

15.

20.

SEQUENCE 7

START

TIME

LOCATION

Profile spacing

03:12 GMT

36009-N

900m.

25.

11

1

1

111

i

1

I

I

151 °49-W

I

I

I

I

45.

40.

30.

I

1

I

50.

TEMPERATURE ( °C)

PAGE 5

07/13/82

1

WIND

SPEED

6. m/s

DIRECTION

280°

Ships heading

0°

13JLC

FILE 07

69

ARCTAN (R)

.,

r

40

120

r

r

r

r

rr

r

160

Wd

5.

32.

T °C

S 0/00

1.022 DENSITY

0.

15.

10.

BV CPH

20.-IT

34.

36.

1.025

1.028

15.

30.

r

0.

i3JL82CN

,

13JL82DN

0

50.

100.

150.

200.

10.

5.

15.

20.

SEQUENCE 7

START

TIME

LOCATION

Profile spacing

04:13 GMT

36013'N

900m

40.

25.

TEMPERATURE

PAGE 6

07/13/82

151 °49-W

45.

WIND

SPEED

6. m/s

DIRECTION

2800

Ship's heading

00

50.

°C)

13JLD FILE 02

71

ARCTAN (R)

40

120

160

200

5.

T °C

32.

S °/.

10.

1.022 DENSITY

20.-U

34.

36.

1.025

1.028

1

1

0.

15.

8V CPH

15.

30.

TT

13JL82DN

T--l

0.

I

I

I

I

T---I

,

-J

I

I

I

50.

100.

150.

200.1

I

I

I

"

I

10.

5.

,

I

ii

i

15.

20.

SEQUENCE 7

START

TIME

LOCATION

Profile spacing

05:19 GMT

36017'N

900m

,

I

25..

30.

35.

40.

PAGE 7

07/13/82

151 °48-W

WIND

I

I

I

I

I

50.

45.

TEMPERATURE ( °C)

SPEED

6. m/s

DIRECTION

2800

Ships heading

if

0°

13JLD FILE 10

73

ARCTAN

(R)

.,

i I

40

120

ti

160

%

NON

5.

T °C

32.

S °ioo

10.

1.022 DENSITY

0.

BV CPH

15.

20.-1T

34.

36.

1.025

1.028

15.

30.

n

13JLB2EN

50.

100.

150.

200.

10.

SEQUENCE 08

START

TIME

LOCATION

Profile spacing

P5.

15.

22:35 GMT

37°43-N

900m

30.

35.

151049'W

50.

TEMPERATURE ( °C)

PAGE 1

07/13/82

45.

40.

WIND

SPEED

DIRECTION

Ships heading

9. m/s

3400

0°

13JLE FILE 06

75

(R)

ARCTAN

.,

.3

r.

40

I

1

ti

:

i

120

I

I

160

., .,

5.

32.

T "C

S 0,

1.022 DENSITY

20 . n

I

i

34.

36.

1.025

1.028

I

L

0.

15.

10.

BV CPH

15.

30.

R

13JLe2EN

,

14JL82AN

T --T

50.

100.

150.

I

200.

10.

5.

15.

20.

SEQUENCE 08

START

TIME

LOCATION

Profile spacing

23:42 GMT

37048N

900M

25.

30.

35.

151 °49-W

I

I

40.

I

I

45.

I

I

I

I

50.

TEMPERATURE ( °C)

PAGE 2

07/13/82

I

WIND

SPEED

9. m/s

DIRECTION

3400

Ships heading

0°

»

14JLA FILE 02

ARCTAN (R)

40

_.

120

.

160

5.

T °C

10.

1

32.

20.-fl

1

S °/pp

1.022 DENSITY

0.

15.

BV CPH

34.

36.

1.025

1.028

15.

30.

14JL82RN

,

14JL82BN

0.

50.

100.

150.

200.

5.

10.

15.

220.

SEQUENCE 08

START

TIME

o0o.48 GMT

37°52,'N

LOCATION,

Profile spacing

9O0rn

25.

40.

30.

151 °49'W

50.

TEMPERATURE ( °C)

PAGE 3

07/14/82

45.

WIND

SPEED

DIRECTION

Ships heading

9. rn/s

3400

00

14JLB FILE 01

79

(R)

ARCTAN

e

e

.

.

r

40

.

rr

N

.

r

.

120

,

160

e

r

a-

200

5.

T °C

10.

32. S 0/pp

1.022 DENSITY

0.

BV CPH

15.

20 . -rr

34.

36.

1.025

1.028

15.

30.

0.

Tt

i4JL82BN

,

14JL82CN

40.

SEQUENCE 08

START

TIME

LOCATION

Profile spocing

oZ. oo GMT

37°561N

900m

PAGE 4

07/14/82

151 °49'W

45.

50.

TEMPERATURE ( °C)

WIND

SPEED

9. m/s

DIRECTION

3400

Ships heading

0°

14JLB FILE 10

81

ARCTAN

(R)

!

i !

f !

%

%

0

20 .-Ti

1

32.

S °i,oo

1.022 DENSITY

0.

BV CPH

i

1

34.

36.

1.025

1.028

15,

30.

0.

Ti

14JL82CN

0

50.

100.

150.

200.

5.

10.

15.

20.

SEQUENCE 08

START

TIME

LOCATION

Profile spacing

03:06 GUT

38°oO-N

900rn

25.

30.

35.

40.

151 °49,,W

50.

TEMPERATURE ( °C)

PAGE 5

07/14/82

45.

WIND

SPEED

DIRECTION

Ship's heading

9. m/s

3400

00

14JLC FILE 06

83

ARCTAN

nn

-r

-+

(R)

cc,

40

N

120

'

160

200

5.

T °C

10.

S °ioo

34.

I

1.022 DENSITY

0.

J

I

I

32.

20. n

15.

BV CPH

36.

-

1.025

1.028

15.

30.

0.

11

14JLe2CN

14JL82DN

,

0

50.

100.

150.

I

1

11

10.

1

I

11

1

1

15.

h

TIME

LOCATION

Profile spacing

04.:43 GMT

38°o4.N

900m

I

20.

SEQUENCE 08

START

1I

I

1

11

1

1

25.

11

I

I

i

30.

1

1

1

I

35.

1

II

1

1

I

151°49-W

I

I

I

I

45.

40.

I

I

1

I

50.

TEMPERATURE ( °C)

PAGE :6

07/11/82

1

WIND

SPEED

9. m/s

DIRECTION

3400

Ships heading

00

14JLD

FILE 02

85

ARCTAN (R)

'

'

%

I

20.-IT

I

32.

S °ioo

34.

1

1. 022 DENSITY

1.025

36.

_J

1.028

1

0.

BV CPH

15.

30.

n

14JL82DN

0

50.

100.

150.

200.

10.

5.

15.

SEQUENCE 08

START

TIME

LOCATION.

Profile spacing

05:119 GMT

38°06"'N

900m

20.

25.

30.

35.

50.

TEMPERATURE ( °C)

PAGE 7

07/14/82

45.

40.

WIND

151 °49-W

Ship,

SPEED

9. m/s

DIRECTION

3400

heading

00

14JLD FILE 10

87

ARCTAN (R)

4

40

80

a,r

120

160

ti

.

16

200

5.

T °C

32.

S o,

10.

1.022 DENSITY

0.

BV CPH

15.

20.-T1

34.

36.

1.025

1.028

15.

30.

IT

14JL82EN

0.

50.

i00.

150.

1

200.

10.

15.

SEQUENCE 9

START

TIME

LOCATION

Profile spacing

22:46

39°36'N

800m

20.

25.

11

a0.

r.

.1.

1

35.

.1.

.

07/14/82

1,510521W

I

I

I

I

45.

40.

I

I

50.

TEMPERATURE ( °°C)

PAGE 1

GMT

l

111

WIND

SPEED

5. m/s

DIRECTION

340°

Ships heading

00

14JLE FILE 06

89

ARCTAN

(R)

I

40

s

m

80

120

rt

I

160

200

5.

T °C

10.

I

I

32.

S

0/00

1.022 DENSITY

0.

15.

BV CPH

34.

20.-IT

I

36.

1.025

1.028

15,

30.

0.

14JL82EN

15JL82AN

,

0

50.

100.

150.

200.

J

5.

I

{

10.

II

,r

15.

SEQUENCE 9

START

TIME

LOCATION

Profile spacing

00:00

40°01 -N

800m

I

I

25.

20.

30.

35.

I I

I

1

I

I

I

07/15/82

151 °52'W

1

1

40.,

1

I

45.

1

I

1

50.

TEMPERATURE ( °C)

PAGE 2

GMT

1

WIND

SPEED

5. m/s

DIRECTION

340°

Ship's heading

0°

15JLA FILE 05

ARCTAN

91

(R)

'

i

'

'

'

i

20. -TT

32.

S °i o

1 .022 DENSITY

0.

BV CPH

34.

36,

1.025

1 .028

15.

30.

0.

TT

15JL82AN

,

15JL82BN

0.

50.

100.

150.

1

200.

30.

5.

SEQUENCE 9

START

TIME

LOCATION

Profile spacing

01:07

40°06'N

800m'

I

35.

It

l

I

1

1

I

07/15/82

151 °52-W

1

I

1

I

1

45.

40.

TEMPERATURE

PAGE 3

GMT

1

WIND

SPEED

DIRECTION

Ship's heading

5. m/s

3400

00

50.

15JLB FILE 02

93

ARCTAN

(R)

0

m

m

®®

40

C

80

m

® >p

to

k®

ti

ii

120

m

S"

160

i

i

m

i

200

5.

T °C

32.

S °/°0

10,

20:TT

34.

36,

.

1 .022 DENSITY

0.

r

BV CPH

1.025

1.028

15.

30.

0.

r

i

15JL82BN

,

15JL82CN

I

10.

5.

15.

SEQUENCE 9

START

TIME

LOCATION

Profile spacing

02:06

40°10'N

800m

I I

20.

I

I

I

I

I

I

I

25.

II

I

30.

I

(

I

I

I

I

35.

l

I

1

II

I

07/15/82

151 °52-W

I

I

I

I

I

45.

40.

1

50.

TEMPERATURE ( °C)

PAGE 4

GMT

I

WIND

SPEED

5. m/s

DIRECTION

3400

Ships heading

0°

15JLB FILE 11

(R)

ARCTAN

f

i

I

rr

.

200 1 %

5.

T °C

I

I

32.

I

S °/°0

34.

I

I

1 .022 DENSITY

I

0.

15.

10.

BV CPH

1.025

20.-IT

I

36.

-1

1.02e

I

I

15.

30.

0.

95

15JL82CN

50.

100.

150.

200.

10.

15.

SEQUENCE 9

START

TIME

LOCATION

Profile spacing

03:12

40014'N

800rn

20.

25.

30.

35.

07/15/82

151 °52'W

50.

TEMPERATURE ( °C)

PAGE 5

GMT

45.

40.

WIND

SPEED

5. m/s

DIRECTION

3400

Ship's heading

0°

15JLC FILE 07

ARCTAN

I'

97

(R)

i

i

i

I i

20.-11

32.

S 0/pp

1.022 DENSITY

0.

BV CPH

34,

36.

1.025

1.028

15.

30.

0

IT

15JL92CN

,

15JL82DN

0

45.

40.

SEQUENCE 9

START

TIME

LOCATION

Profile spacing

04:19

40°18-N

800m

TEMPERATURE ( °C)

PAGE 6

GMT

07/15/82

151°53-W

50.

WIND

SPEED

5. m/s

DIRECTION

340°

Ships heoding

00

15JLD FILE 04

99

ARCTAN (R)

'

i

ti

i

i'

20 . -TT

L

32.

1

S 0/

34,

38.

1.025

1.028

I

1 .022 DENSITY

I

0.

BV CPH

I

I

15.

30.

0

TT

15JL82DN

0

T

I

T--T--T-1

I

T-T-f--T

-F--T--T

I

I

T--T---T--T

50.

100.

150.

200. '-

I

I

I

u

I

5.

III

1

Il I

15.

SEQUENCE 9

START

TIME

LOCATION

Profile spacing

05:25

40°22N

800m

I

20.

1

1

,

I

T

I

I

25.

I

I

I

30.

1

1

1

I

I

T

35.

I

I

I

I

07/15/82

151 °53'W

T

1

40.

1

I

1

45.

I

1

I

50.

TEMPERATURE ( °C)

PAGE 7

GMT

I

WIND

SPEED

5. m/s

DIRECTION

340°

Ships heading

0°

15JLD FILE 13

101

ARCTAN (R)

%

®

i

d in

i

i

IF

16

Ps

20.-TT

I

32.

1

S 0/00

1 .022 DENSITY

I

0.

34.

36.

1.025

1.828

I

BV CPH

15.

I

30.

0.

TT

15JL82EM

50.

100.

150.

200

PAGE 1

SEQUENCE 10

START

TIME

LOCATION

Profile spacing

22:42

41030-M

800m

TEMPERATURE ( °C)

GMT

07/15/82

151 °59'W

WIND

SPEED

3. m/s

DIRECTION

0400

Ship's heading

00

103

15JLE FILE 08

ARCTAN

(R)

0

40

I

80

0

120

N

0

150

1:1

IF

i

200

5.

T °C

32.

S °/.

1.022 DENSITY

34.

1.025

ti

1

0.

15.

10.

BV CPH

15.

20.-U

3E.

1.028

I

30,

0.

TT

15JL82EM

,

1GJL82AM

0.

50.

100.

150.

10.

5.

15.

SEQUENCE 10

START

TIME

LOCATION

Profile spacing

23:54

41 °34'N

800m

25.

20.

30.

35.

07/15/82

152°00'W

50.

TEMPERATURE ( °C)

PAGE 2

GMT

45.

40.

WIND

SPEED

3. m/s

DIRECTION

0400

Ship's heading

00

105

16JLA FILE 06

(R)

ARCTAN

nn

0

c;F

40

0

s

80

0I

of

0

q6

120

160

L-

200

5.

T °C

32.

S °/00

I

10.

15.

34.

20.-IT

36.

I

1.022 DENSITY

0.

BV CPH

1.025

1.028

15.

30.

TT

1GJL82AM

1GJL82BN

,

0.

So.

100.

150.

200.

I

I

1

lI_

I

1

1

1

10.

5.

I

I

1

1

I

15.

I

I

TIME

LOCATION

Profile spacing

01:06

41041,'N

800m

I

I

I

1

1

25.

20.

1

1

I

30.

I

1

35.

40.

GMT

07/16/82

152°00'W

45.

50.

TEMPERATURE ( °C)

PAGE 3

SEQUENCE 10

START

I

WIND

SPEED

3. rn/s

DIRECTION

040°

Ship's heading

0°

107

16JLB FILE 04

ARCTAN

(R)

40

80

120

-. -

160

200

20, -TT

5.

I

32.

S 0/pp

I

I

34.

36.

I

I

1 .022 DENSITY

1,025

1,02e

15.

30.

I

0.

BV CPH

TT

1EJL82BN

1BJL82CN

.

0

5 0. f-

100.-

150. F-

200.

I

I

5.

I

I

I

I

I

1

10.

I

I

I

I

1

15.

I

TIME

LOCATION.

Profile spacing

02:30

41 °47'N

800m

I

tA

1

1

25.

20.

i

1

I

30.

1

1

1

1

I

35.

1

1

1

1

GMT

07/16/82

152°00'W

I

1

t

1

1

I

45.

40.

1

I

I

50.

TEMPERATURE ( °C)

PAGE 4

SEQUENCE 10

START

1/

I

WIND

SPEED

3. m/s

DIRECTION

0400

Ship's heading

00

16JLB FILE 17

ARCTAN

109

(R)

i

ii

f

i

-

i

0

15,

32,

S

0/00

1.822 DENSITY

0.

BV CPH

34.

36.

1.025

1.028

15.

30.

TT

16JL82CN

0

5o.

100.

150.

I

2 00

I

I

I

.

5.

10.

15.

II

TIME

LOCATION

I)ofile spacing

03:42

41052-N

800m

i

I

i

1

25.

20.

SEQUENCE 10

START

1

i

i

I

30.

1

I

I

I

40.

45.

I

35.

TEMPERATURE ( °C)

PAGE 5

GMT

07/16/82

152°00'W

50.

WIND

SPEED

3. m/s

DIRECTION

040°

Ship's heading

0°

16JLC FILE 07

111

ARCTAN

(R)

40

~

90

'

i

120

'.

160

i

200

5.

T °C

1

I

10.

15.

i

32.

S

/00

1.022 DENSITY

i

0.

BV CPH

20.-TT

1

,

34.

36.

1.025

1.028

I

I

15.

30.

0.

IT

i6JL82CN

,

16JL82DN

0

50.

100.

150.

1

I

1

I'

1

15.

1

I

TIME

LOCATION

Profile spacing

04:54

41 °57'N

800m

I

1

I

1

I

25.

20.

I

1

I

30.

1

1

1

1

I

35.

1

1

i

!

GMT

07/16/82

152°00'W

I

1

I

I

I

45.

40.

1

50.

TEMPERATURE ( °C)

PAGE 6

SEQUENCE 10

START

1

WIND

SPEED

3. m/s

DIRECTION

040°

Ship's heading

00

18JLD FILE 03

ARCTAN

113

(R)

i

s

5.

32.

T °C

10.

S °!°0

i

34.

36.

1

1 .022 DENSITY

I

0.

20.-TT

BV CPH

1.025

1.02e

I

I

15.

30.

0.

TT

i Q:1 L_'_E=i`1

I-

100.

f--

i 50. I-

200

0

j,

START

TIME

LOCATION

Profile spacing

22:36

42°45'N

Boom,

TEMPERATURE ( °C)

PAGE 1

SEQUENCE 11

GMT

07/16/82

WIND

SPEED

0. m/s

152°01-W

Ship's heading

0°

115

i EAL_9 E_f 1

17 Tl._A2 AM

50

100.

150.

lk'JkJ.

L

1

I

_I

I

1_-L _L

__L_I I _1_

I___L

I

I

5

r7

TIME

LOCATION

Profile spacing

23:48

42°49'N

800m

GMT

07/16/82

(71

..

TEMPERATURE ( 0C)

PAGE 2

SEQUENCE 11

START

40

WIND

SPEED

0. m/s

152°01'W

Ship's heading

00

117

i 7TL_R11`fM

1 7.J_1__92 E I'1

511

I

i oo

ti

1

1.

LJ

1_

L_ I

10

k

jr)

QI

45

TEMPERATURE ( °C)

PAGE 3

SEQUENCE 11

START

TIME

LOCATION

Profile spacing

01:00

42°44'N

800m

GMT

07/17/82

WIND

SPEED

0. m/s

152°02'W

Ship's heading

1900

119

i 7JLAH 1-2B N1

1.7.1 L_9 M

50.

girl

SEQUENCE 11

START

TIME

LOCATION

Profile spacing

02:12

42°39-N

800m

,

`

07/17/82

..J'_I

TEMPERATURE ( °C)

PAGE 4

GMT

-

k. I ,.

WIND

SPEED

0. m/s

152°02-W

Ship's heading

190°

,.

121

i.7JL82C:M

i

50.

ti

}

22

00

PAGE 5

SEQUENCE 11

START

TIME

LOCATION

Profile spacing

03:24

42°34'N

800m

TEMPERATURE (°C)

GMT

07/17/82

WIND

SPEED

0. m/s

152°02-W

Ship's heading

1900

123

17JL82DN

0

50.

100.

150.

200.

25.

10.

SEQUENCE 12

START

TIME

LOCATION.

Profile spacing

04:42

42°30'N

800m

30.

35.

40.

07/17/82

50.

TEMPERATURE ( °C)

PAGE 1

GMT

45.

WIND

SPEED

0. m/s

152°04'W

Ship's heading

1900

17JLD FILE 06

ARCTAN

0

125

(R)

'

i

40

80

120

160

200

5.

T °C

10.

I

32,

S

/00

1 .022 DENSITY

0.

BV CPH

15.

20. -TT

I

1

34.

36.

1.025

1 .028

15.

30.

TT

18JL82GN

,

19JL82AN

0

50.

100.

150.

200.

,y

5.

10.

15.

TIME

LOCATION

Profile spacing

23:00

39°35'N

900m,

25.

20.

SEQUENCE 13

START

I

I

30.

II

.

I

35.

II

.

I

.r

07/18/82

152°34-W

I

I

I.

i

45.

40.

I

I£

I

50.

TEMPERATURE ( °C)

PAGE 1

GMT

I

WIND

SPEED

5. m/s

DIRECTION

030°

18JLG FILE 06

127

ARCTAN

(R)

0

'

40

80

s

-

'

s

120

`

'

160

200

5.

32.

T °C

S

10.

/00

34.

I

I

1.022 DENSITY

0.

15.

BV CPH

20:TT

36.

1

1.025

1.028

15.

30.

0.

TT

19JL92AN

0

50.

100.

150.

200.

5.

10.

15.

SEQUENCE 13

START

TIME

LOCATION

Profile spacing

00:06

39°36'N

900m

20.

25.

30.

35.

152°31'W

50.

TEMPERATURE ( °C)

PAGE 2

GMT 07/19/82

45.

40.

WIND

SPEED

5. m/s

DIRECTION

030.°

19JLA FILE 06

ARCTAN

129

(R)

I

15.

I

32.

S °/pp

1.022 DENSITY

I

0.

I

I

34.

36.

I

I

BV CPH

20. -TT

1.025

I

1.028

I

I

15,

30.

0.

TT

19JL82AN

,

19JL82BN

0.

50.

100.

150.

200.

10.

5.

15.

20.

TIME

LOCATION

Profile spacing

01:12

39°37-N

900m

30.

35.

40.

GMT

07/19/82

152°33'W

45.

50.

TEMPERATURE ( °C)

PAGE 3

SEQUENCE 13

START

25.

WIND

SPEED

5. m/s

DIRECTION

030°

19JLB FILE 02

131

ARCTAN

(R)

0

s

'

,

ti

,

0.

32.

S 0/00

1.022 DENSITY

i

BV CPH

34.

36.

1.025

1.028

I

I

15.

30.

rr

19JL82BN

0.

50.

100.

150.

1

200.

1

1

1

5.

(

J

1

1

1

10.

1

1

15.

20.

SEQUENCE 13

START

TIME

LOCATION

Profile spacing

02:18

39°35-N

900m,

25.

30.

35.

40.

07/19/82

152°35-W

50.

TEMPERATURE ( °C)

PAGE 4

GMT

45.

WIND

SPEED

5. m/s

DIRECTION

0300

133

19JLB FILE 11

ARCTAN

(R)

0

40

.

I.

a0

120

.

'

'

.'

a

160

.

200

5.

T °C

32.

S 0/

1.022 DENSITY

0.

15.

10.

BV CPH

20.-IT

34.

36.

1.025

1.028

15.

30.

19JL92CM

cl

0

TTT T

1

50.

100.

150.

1

1

1

1

5.

1

11

1

1h

10.

I

III

I

I

15.

111

I

20.

TIME

LOCATION

Profile spacing

04:15

39°36'N

900m

1

1' 1

25.

1

1

11

30.

1

1'1

I

35.

1i1

1

I

I

GMT

07/19/82

152°34-W

1

1

I

I

I

45.

40.

1

I

1

I

50.

TEMPERATURE (°C)

PAGE 1

SEQUENCE 14

START

111

WIND

SPEED

5. m/s

DIRECTION

030°

Ship's heading

1900

135

19JL92DN

T--f

0.

i

-r-T --T

rT

I

I -II

T--T---j

T

TTT

1

I

i

i

50.

100.

150.

200.

,ii

5.

10.

11/11/11

15.

SEQUENCE 15

START

TIME

LOCATION

Profile spacing

23:12

38°08'N

900m

11111h

25.

20.

I

[

I

I

I

ill

30.

I

I

I

I

35.

I

I

I

I

I

152°02-W

I

I

I

I

45.

40.

I

I

I

50.

TEMPERATURE ( °C)

PAGE 1

GMT 07/19/82

I

WIND

SPEED

7. m/s

DIRECTION

070°

Ship's heading

1900

19JLD FILE 08

137

ARCTAN

0

(R)

'

40

I

m

m

80

r-M

m

ap

120

an-

m

0

S

'r

i

160

'

r®

200

1

WO

5.

T °C

10.

I

32.

S 0/00

15.

t

1

34.

36.

1

1.022 DENSITY

0.

BV CPH

20. -IT

i

1.025

1.028

15.

30.

TT

20JL82AN

0.

50.

100.

150.

200.

35.

SEQUENCE 15

START

TIME

LOCATION

Profile spacing

00:00

38°03'N

900m

07/20/82

153°05'W

50.

TEMPERATURE ( °C)

PAGE 2

GMT

45.

40.

WIND

SPEED

7. m/s

DIRECTION

070°

Ship's heading

190.°

139

20JLA FILE 05

ARCTAN

(R)

.

,

. ,

ti

,.

20 . -TT

32,

S 0/pp

I

1.022 DENSITY

0.

BV CPH

34.

36.

I

1

1.025

15.

1.028

30.

0.

r

20JL82AN

,

20JL92BN

0.

50.

100.

150.

I

200.

9

1

201

1

SEQUENCE

START

01:00

LOCATION

37°58'N

Profile spacing

'900m,

30.

35.

40.

GMT

07/20/82

153°06'W

45.

50.

TEMPERATURE ( °C)

PAGE 3

15

TIME

25.

_

WIND

SPEED

7. m/s

DIRECTION

070°

Ship's heading

190°

141

20JLA FILE 15

ARCTAN

on

0

(R)

SF

40

90

k

120

160

p

200

I

I

32.

15.

10.

5.

S

0/00

20.-TT

I

34.

36.

1.025

1.029

15.

30.

I

1.022 DENSITY

0.

BV CPH

IT

2DJLe2BN

35.

TIME

LOCATION

Profile spacing

02:00

37°53'N

900m

GMT

07/20/82

153°07-W

45.

TEMPERATURE ( °C)

PAGE 4

SEQUENCE 15

START

40.

WIND

SPEED

7. m/s

DIRECTION

070°

Ship's heading

1900

143

20JLB FILE 11

ARCTAN

nn

(R)

SF

40

80

120

160

e

s

200

5.

32,

T °C

S

°/00

1.022 DENS TTY

0.

15,

10.

BV CPH

20. -TT

34.

36 .

1.025

1.02e

15.

30.

17

20JL82CN

0.

50.

100.

150.

200.

10.

5.

15.

20.

TIME

03:00

LOCATION

37°48'N

Profile spacing

900m

30.

35.

GMT

07/20/82

153°07'W

45.

40.

50.

-TEMPERATURE ( °C)

PAGE 5

SEQUENCE 15

START

25.

WIND

SPEED

7. m/s

DIRECTION

070°

Ship's heading

190°

2OJLC FILE 06

145

ARCTAN

z

0

41

1

e®

40

80

120

160

mw

6I

vN

200

5.

32.

T °c

S °/pp

I

34.

1

1.022 DENSITY

0.

is.

10.

BV CPH

20.-IT

36.

1

1.025

1.028

is.

30.

(R)

20JLB2CN

200.

5.

10.

20.

15.

SEQUENCE 15

START

TIME

04:00

LOCATION. 37°43-N

Profile spacing

900m

25.

30.

35.

07/20/82

153008-W

50.

TEMPERATURE ( °C)

PAGE 6

GMT

45.

40.

WIND

SPEED

7. m/s

DIRECTION

070°

.

Ship's heading

1900

20JLC FILE 13

147

(R)

ARCTAN

''

S

0

El;

m

m

m

40

80

'

®1

I

-

120

m

MM

m

.

1w

160

200

5,

T °C

I

32.

1

S 0/

34.

-

I

1.022 DENSITY

0.

20 . -TT

10

BV CPH

1

J

36,

I

1.025

1, 028

15,

30.

TT

2OJL82DN

0

50.

100.

150.

200.

1

I

1

5.

t

1

1

1

1

II

10.

1

1

15.

20.

TIME

LOCATION.

Profile spacing

22:30

36°09-N

900m

30.

35.

GMT

07/20/82

153°35-W

45.

40.

50.

TEMPERATURE ( °C)

PAGE 1

SEQUENCE 16

START

25.

WIND

SPEED

5. m/s

DIRECTION

055°

Ships heading

2000

2Z,; -D FILE 06

ARCTAN (R)

Sp

22

r

m

u

m

IN

I

25 AT

34.

32.

Z22D SI i

I

36.

:.025

x.828

i.5

30.

149

20JL92DN

,

21JL82AN

a

0

Il

A

11

5

T

50.

100.

150.

200. ''1

5.

20.

10.

SEQUENCE 16

START

TIME

LOCATION

Profile spacing

23:30

36°06'N

900m

PAGE

GMT

30.

25.

07/20/82

153038-W

35.

45.

40.

50.

TEMPERATURE ( °C)

2,

WIND

SPEED

5. m/s

DIRECTION

055°

Ship's heading

2000

151

20 LD FILE 15

ARCTAN

SF

DD

0

(R)

IN

Iml

40

w

90

120

» IN

[1

160

IN

N

200 r W M

10.

32,

20.

15.

°i0,

I

1.022 DENSITY

Z.

r

I

T °C

BV L.RH

Iz

25.-Tf

I

j

34.

36.

I

I

1.025

4.028

15.

30.

IT

21JL82AN

50.

100.

150.

200.

10.

5.

15.

20.

TIME

00:30

LOCATION

36°03'N

Profile spacing

900m

30.

35.

GMT

07/21/82

153039-W

45.

40.

TEMPERATURE (

PAGE 3

SEQUENCE 16

START

25.

WIND

SPEED

5. m/s

DIRECTION

0554

Ship's heading

2000

50.

°C)

21 JLA

FILE 10

153

ARCTAN (R)

Dn

0

40

to

80

a

120

0

0

IEO

0

a

m

200

10 .

I

32,

T "C

is.

20.

25.-IT

1

S 0/

l

1.022 DENSITY

0.

I

BV C* H

34.

38.

I

j

1.025

1.028

15.

30.

H

21JL82BN

45.

40.

PAGE 4

SEQUENCE 16

START

TIME

LOCATION

Profile spacing

01:30

35°59N

900m

TEMPERATURE

GMT

07/21/82

153°40-W