THE TREATMENT OF WEATHERED GLOBIGERINA LIMESTONE: THE

advertisement

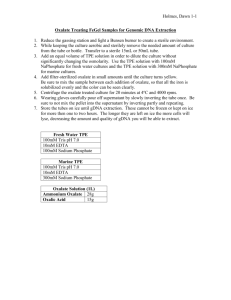

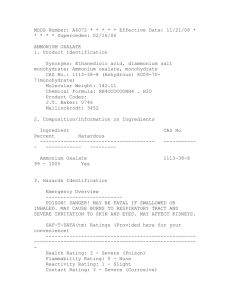

THE TREATMENT OF WEATHERED GLOBIGERINA LIMESTONE: THE SURFACE CONVERSION OF CALCIUM CARBONATE TO CALCIUM OXALATE Tabitha Mifsud Dissertation submitted to the Institute for Masonry Construction and Research in partial fulfillment of the requirements for the Degree of Master of Science in Conservation Technology for Masonry Buildings ABSTRACT This work concerns the investigation of ammonium oxalate treatment on weathered Globigerina Limestone of the “franka” type. To this end, “franka” Limestone samples were subjected to a 5% ammonium oxalate poultice for 5 hours, after which testing took place on both treated and untreated samples. The range of samples included fresh quarry samples, artificially weathered quarry samples and naturally weathered samples. From each group, both desalinated and non-desalinated samples were studied. The non-desalinated samples included sodium chloride as the predominant salt since the presence of this salt in Globigerina Limestone is the most representative of the local scenario. The first part of the investigations included X-Ray Diffraction where the formation of calcium oxalate following ammonium oxalate treatment was verified. It was confirmed that the presence of sodium chloride did not hinder the formation of calcium oxalate in any way. In fact, the non-desalinated samples were found to produce more calcium oxalate than the desalinated samples of the same type. This was attributed to the increased surface area available for reaction with ammonium oxalate in the non-desalinated samples. It was consequently concluded that desalination prior to ammonium oxalate treatment is not imperative. Scanning Electron Microscopy was then used in order to look at the surface morphology which was noted to be more compact in the treated samples. The hardness was then evaluated utilising the Mohs hardness test which in all cases revealed a surface hardness of 4 – equal to the hardness of calcium oxalate - in all of the treated samples. The surface cohesion of the samples during a tape test, where tape was applied and then removed together with any superficial surface material from the surface of the stone, resulted in more material being removed in the untreated samples than in the treated ones for both the desalinated and non-desalinated samples. The possible protection from acid attack as a result of the treatment was examined through acid resistance tests which included 4 different acids – acetic acid (5%), acetic acid (10%), hydrochloric acid (0.5%) and hydrochloric acid (2%). In all cases, the treated samples lost less mass when placed in direct contact with the acids than the untreated samples. In addition, it was observed that during contact with the 5% acetic acid solution, the treated samples underwent “whitening” in colour on the treated faces. This was then used to look at the depth of calcium oxalate formed in the treated samples through total immersion in a 5% acetic acid solution. Any resistance to salt crystallisation that may have been gained due to ammonium oxalate treatment was looked at through artificial weathering using sodium sulphate. A small increase in resistance was registered in all of the treated samples. The water absorption properties were subsequently examined through water absorption test through capillarity. These tests revealed that the treatment did not alter the mode of water absorption through capillarity. Finally, direct comparison between treated and untreated samples within each group and to a Munsell colour chart confirmed that no colour alterations took place following ammonium oxalate treatment. These promising results represent ammonium oxalate treatment on “franka” Globigerina Limestone in a positive light. In practical terms, it was concluded that this treatment could be used in the filed of conservation as a protective treatment, possibly with some consolidating properties, on historic buildings and monuments in the Maltese Islands.