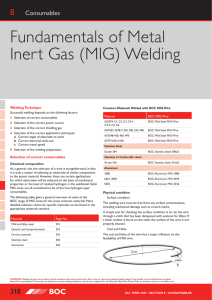

MIG Welding

advertisement

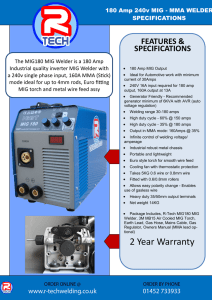

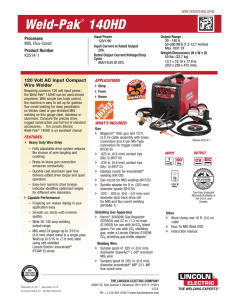

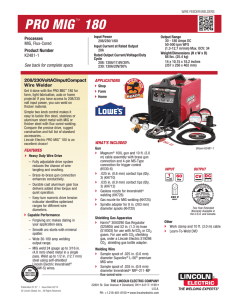

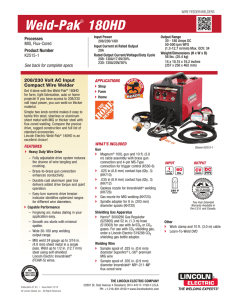

MIG Welding Overview Welding: a process of joining two materials that coalesce at their contacting surfaces through the application of heat. • Advantage: portable, permanent, stronger than the parent materials with a filler metal; the most economical method of joining in terms of material usage and fabrication costs. • Disadvantage: expensive manual labour, highenergy and important safety considerations; does not allow for disassembly, defects can be concealed. MIG welding A continuously fed metal electrode (wire) contacts the base metal and produces heat through an ‘arc’ of electrical current. The arc is shielded by an inert gas to inhibit oxidisation. Typical setup for wire speed • The wire feed rate or speed is set using the dial on the wire controller. This setting increases or decreases the current or heat. This setting is measured in amps. • Ideal settings can be fixed and monitored by the amp meter on the front panel of the welder. • Ideal settings can be found in the wire manufacturer’s data book, related to the appropriate current. Types of joint Butt joint http://www.youtube.com/watch?v=XYBjLvxG5z0 Corner joint http://www.youtube.com/watch?v=sNSHDork_Yw Lap joint http://www.youtube.com/watch?v=JqFp5kCeTA0 T joint http://www.youtube.com/watch?v=NNz_Bbo4Ojg Technique Speed of movement is very important. The angle and direction for a right-handed person. (Left-handed people move to the right, angled to the left.) Method of welding • The following films will show you how to use a MIG welder. Watch and listen very carefully, taking notes, to remember all the tips that are given in each clip. Remember, the best way to learn how to weld is practise, practise and practise some more. • http://www.youtube.com/watch?v=ZNyAzVQTY6Y&feature=re lated • http://www.youtube.com/watch?v=lzBGZaS1apw&feature=rel ated • http://www.youtube.com/watch?v=NCrJWoid9Y&feature=related