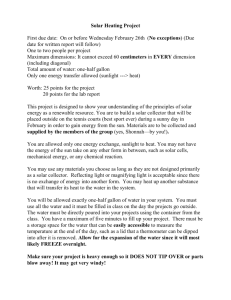

Comparison of Solar Hot Water Systems Simulated in

advertisement