Side-by-Side Testing of Water Heating Systems: Results from the 2010 – 2011 Evaluation

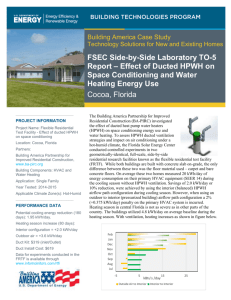

advertisement