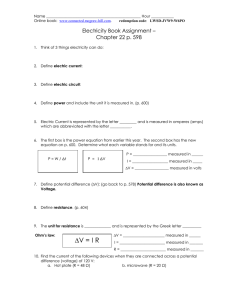

C R

advertisement