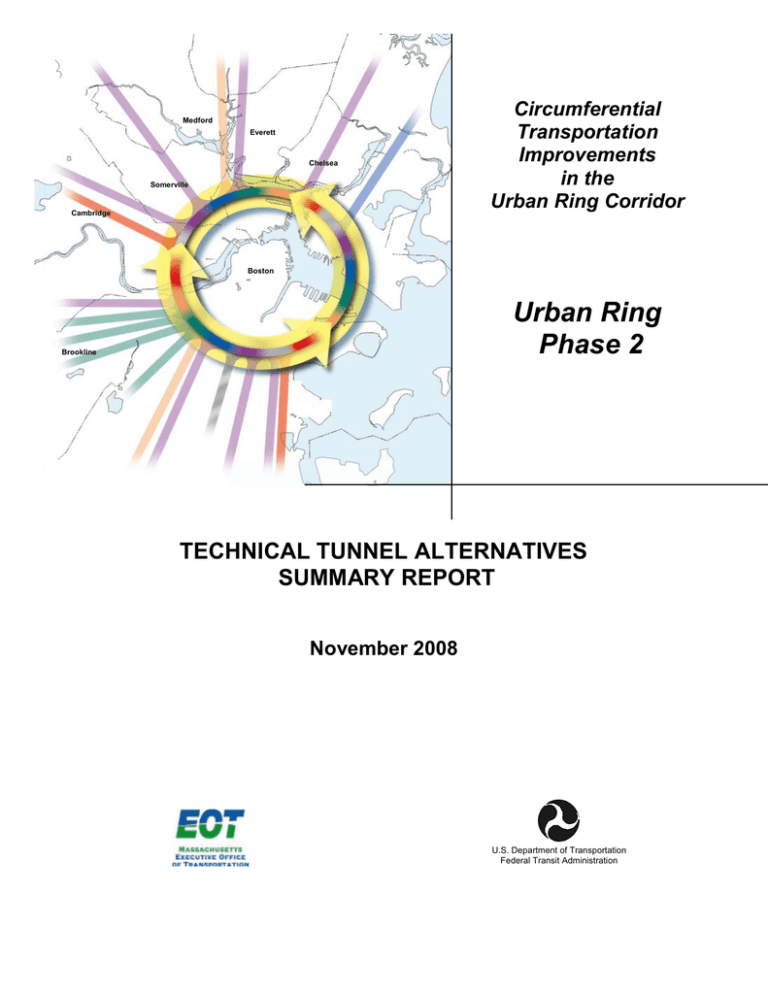

Urban Ring Phase 2 TECHNICAL TUNNEL ALTERNATIVES

advertisement