Document 12969715

advertisement

In supercritical fluid chromatography, very high degrees of accuracy are

required for temperature control. On the fluid supply end of the system,

cooling is critical. On the separation end, heating is important. This paper

discusses temperature control in the HP G1205A supercritical fluid

chromatograph.

1,!..%0%( "(1% $.+)0+#.,$5 %/ 0!$*%-1! 0$0

$/ #%*! !,0*! %* 0$! *(50%( $!)%/0.5 ).'!07

,(! / +),(!)!*0 0+ #/ $.+)0+#.,$5 *

(%-1% $.+)0+#.,$5 * 0$! !2!(+,)!*0 +" 0$! /1,!..%0%( "(1% $.+)0+#.,$ %# (!2!.#%*#

+" )&+. +),+*!*0/ ".+) * ,.+ 10/ 3/ ,.%).5 #+( / .!/1(0 +" 0$%/ #+( 0$!.)( )*#!)!*0 %*

0$! /5/0!) 3/ $((!*#! !1/! 0$! +),+*!*0/ 3!.!

*+0 %*0!* ! 0+ +,!.0! %* 0$! 0!),!.01.! .*#! .!-1%.!

"+. +. !4),(! 0$! ,1),%*# )+ 1(! 3/ !/%#*!

0+ ,1), "(1% / 0 .++) 0!),!.01.! 3$%(! "+. "(1% /

+,0%)( !(%2!.5 %/ 0 ° +. (+3!.

+ %"%0%+*/ 3!.! ) ! 0+ 0$! +),+*!*0/ 0+ %*0!#.0!

0$!) %*0+ +*! ,.+ 10 +)! +),+*!*0/ 3!.! +,0%)%6! "+.

$%/ $!(,! 0+ %),.+2! 0$! $.+)0+#.,$% 0!$*%-1!

5 %*+.,+.0%*# *!3 35/ 0+ )*#! * +*0.+( 0!),!.7

01.! $%/ ,,!. !4)%*!/ 0$! !/%#* )+ %"%0%+*/ ) ! 0+

+),+*!*0/ 0+ )!!0 0$! 0$!.)( .!-1%.!)!*0/ "+. 3$%(!

(!2!.#%*# 1..!*0 *(50%( ,.+ 10 +),+*!*0/

* 1*%0 +*/%/0/ +" "+1. )&+. /5/0!)/ "(1% !(%2!.5

,1),/ /!,.0%+* !0!0%+* * 0 +((!0%+* .%!"

!/.%,0%+* +" $.+)0+#.,$5 +),*%!/ 0$%/ .0%(! 0+

,.+2% ! 0$! .! !. 3%0$ * +2!.2%!3 +" 0$! 0!$*+(+#5 /!!

,#! $! ,.+&!0 #+( +" 1/%*# 3$!.!2!. ,+/7

/%(! +),+*!*0/ ".+) (.! 5 ,.+2!* * %*/0.1)!*00%+* .!/1(0! %* .!1/! +" 0$! +2!*

0$! ,1),%*# )+ 1(! 2.%!05 +" +0$ *

!0!0+./ * 0$! $!)00%+* %*/0.1)!*0 +*0.+(

/+"03.! $! )&+. +),+*!*0/ +" 0$! /5/0!) 3%(( *+3 ! !/.%! %* "1.0$!. !0%(

Pumping Module. $! /5/0!) %/ 2%((! / /%*#(!7,1), /5/0!) 1/%*# +. +0$!. "(1% / "+. %0/ /1,!.7

.%0%( )+%(! "(1% +. / 1(7,1), /5/0!) 0$0 ((+3/

)+ %"%!./ 0+ ! ! 0+ 0$! +0$ ,1),/ +*/%/0 +"

.!%,.+0%*# 1( ,%/0+*/ %* /!.%!/ ((+3%*# "+. +*0%*1+1/

.!(%(! * 1*00!* ! ,1),%*# $%/ !(%)%*0!/ 0$! %*+*7

2!*%!*! +" .!"%((%*# /5.%*#! ,1),/ * ((+3/ "+. +*0.+( +"

0$! "(+3 * $*#%*# +" 0$! +),+/%0%+* $! ,1),/ $2!

"!! ' +*0.+( (#+.%0$)/ 0$0 5*)%((5 +),!*/0! "+.

1#1/0 !3(!007'. +1.*(

Fig. 1. /1,!..%0%( "(1% $.+)0+#.,$5 /5/0!)

+,0%)1) "(1% +),.!//%%(%05 * )%*%)%6! 0$! ,.!//1.!

.%,,(! +" 0$! .!%,.+0%*# ,%/0+*/

$! )+ %"%!. ,1), !/%#* ,.((!(/ 0$! ,1), (+/!(5 /%*! +0$ .! %*0!* ! 0+ ,1), %*+)7

,.!//%(! (%-1% / $%/ %/ *+0 0$! /! 3%0$ 0$! /1,!..%0%(

"(1% ,1), 3$%$ .!-1%.! )+.! !40!*/%2! )+ %"%0%+*/

+ ,1), +),.!//%(! "(1% / (%'! !""%%!*0(5 0$!

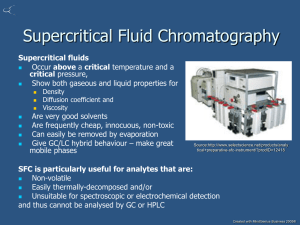

The choice of which chromatographic method to use depends on the compounds

being analyzed. In gas chromatography (GC), the mobile phase that carries the

sample injected into the system is a gas. GC is generally a method for volatile and

low molecular weight compounds. High-performance liquid chromatography

(HPLC) is primarily used for analysis of nonvolatile and higher molecular weight

compounds. A combination of desirable characteristics from both of these methods

can be obtained by using a supercritical fluid as the mobile phase. A supercritical

fluid is a substance above its critical point on the temperature/pressure phase

diagram (see Fig. 2). Above the critical point, the fluid is neither a gas nor a liquid,

but possesses properties of both.

The advantage of SFC is that the high density of a supercritical fluid gives it the

solvent properties of a liquid, while it still exhibits the faster physical flow properties of a gas. In chromatographic terms, supercritical fluids allow the high efficiency and detection options associated with gas chromatography to be combined

with the high selectivity and the wider sample polarity range of high-performance

liquid chromatography. Applications that are unique to SFC include analysis of

compounds that are either too polar, too high in molecular weight, or too thermally

labile for GC methods and are undetectable with HPLC detectors. Another benefit

of SFC over LC is the reduction of toxic solvent use and the expense associated

with solvent disposal. This aspect has become increasingly important as environmental awareness becomes a larger issue.

Liquid

Pressure

Chromatography is a process in which a chemical mixture, carried by a mobile

phase, is separated into components as a result of differential distribution of the

solutes as they flow over a stationary phase. The distribution is the result of differing physical and/or chemical interactions of the components with the stationary

phase. On a very basic level, chromatography instrumentation consists of (1) a

delivery system to transport the sample within a mobile phase, (2) a stationary

phase (the column) where the separation process occurs, (3) a detection system

that identifies or distinguishes between the eluted compounds, and (4) a data

collection device to record the results (see Fig. 1).

Pc

Supercritical

Fluid

Region

Solid

Critical

Point

Gas

Temperature

Tc

Fig. 2. Phase diagram with critical point and supercritical region.

Hewlett-Packard developed and manufactured its first SFC instrument in 1982. For

the past decade, SFC has primarily been used in R&D laboratories. The market

has now expanded to include routine analysis for process and quality control as

SFC is continuing to gain acceptance as a complementary technique to GC and

LC.

Connie Nathan

Barbara Hackbarth

Development Engineers

Analytical Products Group

Sample

Injection

Pump

Detector

Column

Data Handling

&(#%%' ( #( # (&' "" '" "*%

' #%'(%& '% ""! *& &' "% '& ! &"!'! $(' ! % "#%'"! '"!+ '

'% !'& #%") #%& ' #%'(% "!'%"

! ,! #( # "* !"& ! "*! "% (%'

" #%&&'+ " #!&'"!

Separation Phase. "( ! & *% ' '( &#%'"!

" " #"!!'& "(%& (!$( !'%'"!& " ' " #"(!& *' )! &''"!%+ #& ' %'! "!'"!&

Fig. 1. Basic components of a chromatographic system.

%&('& ! %!' ('"! ' & %" ' "( ! &+&' ! (& *' #%+ !%%"* "% "%

# "( !& &"&'+ " &(#%%' ( & ' &'

"! "%% " !'( % '! ' )&"&'+ ! ' &"(& &'' (' & "! '" '*" "%%& " !'( && '!

! ' $( &'' & '%!&'& !'" #%&&(% %"# %"&&

' "( ! '' & '! ' & %'% *' '! ' &

*' "*% )&"&'+ " "*& "!% "( !& * + ''% &#%'"! " "&+ %' " #"(!&

((&' *''-% "(%!

$+$"3(5(38 1$%$12 3. 3'$ 2$+$"3(5$ /'82("."'$,(" + (-3$1 "3(.-2

!$36$$- 3'$ 2 ,/+$ ".,/.-$-32 -# 3'$ ".+4,- - 3'$ 2$+$"3(5(38 .% ".,/.4-#2 (2 #)423$# !8 "' -&(-& 3$,:

/$1 341$ ,.!(+$ /' 2$ #$-2(38 -#.1 ".,/.2(3(.- .%

##$# ,.#(%($12 '$2$ ".-31.+ / 1 ,$3$12 1$ ".,!(- 3(..% 3'.2$ 5 (+ !+$ (- $(3'$1 /41$ .1 /41$ //+(" :

3(.- '$ ".+4,- (2 (-23 ++$# (- 3$,/$1 341$:".-31.++$#

$-5(1.-,$-3 3'$ .5$-

Detection. -.3 .-+8 24//.132 !.3' " /(++ 18 -# / "*$#

".+4,-2 !43 +2. 5 1($38 .% -# #$3$"3.1 ./3(.-2

$3$"3.12 1$ #$5("$2 3' 3 2$-2$ 3'$ /1$2$-"$ .% 3'$ #(%%$1$-3

".,/.4-#2 $+43(-& %1., 3'$ ".+4,- -# ".-5$13 3'(2 (-%.1:

, 3(.- (-3. - $+$"31(" + 2(&- + $+$"3(.- .% 6'("' #$3$"3.1

3. 42$ #$/$-#2 .- 2$5$1 + % "3.12 (-"+4#(-& 3'$ 38/$ .% (-%.1:

, 3(.- -$$#$# %1., 3'$ - +82(2 3'$ 2$-2(-& +$5$+ 1$04(1$#

-# 3'$ ".,/+$7(38 .% 3'$ ".,/.4-#2

#$3$"3.12 3' 3 1$ 5 (+ !+$ (- 1$ 3'$ %+ ,$ (.-(9 :

3(.- #$3$"3.1 3'$ -(31.&$- /'.2/'.142 #$3$"3.1 -# 3'$

$+$"31.- " /341$ #$3$"3.1 '$ $+$"31.- " /341$ #$3$"3.1 (2

' +.&$-:2$-2(3(5$ #$3$"3.1 /1(, 1(+8 42$# (- /$23("(#$ - +8:

2(2 '$ %+ ,$ (.-(9 3(.- #$3$"3.1 (2 4-(5$12 + #$3$"3.1 %.1

6(#$ 5 1($38 .% .1& -(" ".,/.4-#2 '$ -(31.&$- /'.2/'.:

142 #$3$"3.1 (2 2$+$"3(5$ #$3$"3.1 %.1 ".,/.4-#2 ".-3 (-(-&

-(31.&$- -# /'.2/'.142 -# (2 +2. 42$# %.1 /$23("(#$ -#

"+(-(" + //+(" 3(.-2 -$6 #(,$-2(.- 3. #$3$"3(.- " / !(+:

(38 (2 , #$ /.22(!+$ 6(3' 3'$ 42$ .% ,.#(%($12 6(3' 3'$ $+$":

31.- " /341$ -# -(31.&$- /'.2/'.142 #$3$"3.12 '$ %+ ,$

(.-(9 3(.- #$3$"3.1 -# 3'$ -(31.&$- /'.2/'.142 #$3$"3.1

1$04(1$# #$2(&- "' -&$2 %.1 42$

#$3$"3.12 5 (+ !+$ (- (-"+4#$ 3'$ ,4+3(/+$ 6 5$:

+$-&3' #$3$"3.1 3'$ 5 1( !+$ 6 5$+$-&3' #$3$"3.1 -# 3'$

#(.#$ 11 8 #$3$"3.1 '$2$ ".5$1 //+(" 3(.- -$$#2 %.1 '(&'

2$-2(3(5(38 -# 2$+$"3(5(38

Data Acquisition System. '$ # 3 "04(2(3(.- 2823$, 2.132

-# $7$"43$2 3'$ , -8 #(%%$1$-3 2(&- +2 %4-"3(.-2 -# ".,:

, -#2 .1 $7 ,/+$ 3'$ %(123 3'(-& 3'$ (-2314,$-3 -$$#2 3.

*-.6 (2 '.6 (3 (2 ".-%(&41$# .-$ /4,/ 36. /4,/2 6'("'

#$3$"3.12 (-)$"3(.- ,$3'.# $3" .,, -#2 1$ &(5$- 3.

./$1 3$ 3'$ 2823$, 3 / 13("4+ 1 ".-#(3(.-2 %+4(# %+.6 1 3$

/1$2241$ 3$,/$1 341$ $3" +$"31.-(" 2(&- +2 %1., 3'$ #$:

3$"3.12 1$ ".++$"3$# -# ".-5$13$# 3. 42$%4+ "'1., 3.:

&1 /'(" (-%.1, 3(.- - +83(" + 1$24+32 1$ 23.1$# -# + 3$1

/1$2$-3$# (- ,$ -(-&%4+ 1$/.13 %.1, 3 #$3$1,(-$# !8 3'$

42$1 '$ 2.%36 1$ /+ 3%.1, %.1 3'$ 6 2

+$5$1 &$# %1., $7(23(-& '$,3 3(.- /+ 3%.1,2 .1*(-&

3'1.4&' ("1.2.%3 (-#.62 2 3'$ ./$1 3(-& ".-31.+ 282:

3$, (3 " - ,4+3(3 2* 6(3' .3'$1 //+(" 3(.-2 -# -$36.1*

6(3' .3'$1 # 3 2823$,2

'$ 1$, (-#$1 .% 3'(2 13("+$ %."42$2 .- 3'$ 3'$1, + #$2(&.% 3'$ /4,/ -# .-$ .% 3'$ #$3$"3.12

'$ /4,/ ,.#4+$ (2 - /4,/ ./3(,(9$# 3. ./$1 3$ 6(3'

24/$1"1(3(" + %+4(#2 3 +.6 3$,/$1 341$2 -# '(&' /1$2241$2

4/$1"1(3(" + %+4(#2 24"' 2 1$ /4,/$# 3'1.4&' 3'$ 282:

3$, 3 1 3$2 2 '(&' 2 ,(++(+(3$12 /$1 ,(-43$ -# /1$2241$2

2 '(&' 2 ! 12 '$ (-(3( + //1. "' 6 2 3. 42$ "18.&$-("

3. "..+ 3'$ /4,/ 241% "$ '$ /1./.2$# #$2(&- 6 2

"' --$+ .% ,$3 + 34!(-& 6(3' "18.&$-(" %+.6(-& 3'1.4&'

(3 2(-& -$36.1* .% "' --$+2 3'$ "18.&$-(" (2 $5$-+8

4&423 $6+$33: "* 1# .41- +

Electrical Insulation

(Good Heat Conductor)

ÎÎÎÎÎÎÎÎÎÎÎ

ÏÏÏÏÏÏÏ

ÎÎÎÎÎÎÎÎÎÎÎ

ÏÏÏÏÏÏÏ

ÏÏÏÏÏÏ

ÏÏÏÏÏÏ

ÎÎÎÎÎÎÎÎÎÎÎ

ÏÏÏÏÏÏ

ÏÏÏÏÏÏ

ÎÎÎÎÎÎÎÎÎÎÎ

Body to Be Cooled (Heat Source)

n-type

Semiconductor

Electronic

Carriers

Moving Heat

to the Heat

Sink

p-type

Semiconductor

Heat Sink

DC Source

Fig. 2. '$1,.$+$"31(" $+3($1 "..+$1

#(231(!43$# 3'1.4&' 3'$ /4,/ -# /1.5(#$2 - $%%("($-3

,$3'.# .% "..+(-& '$ #$2(&- ".4+# !$ %413'$1 ./3(,(9$#

!8 42(-& , 3$1( +2 6(3' '(&' 3'$1, + ".-#4"3(5(38 %.1 3'$

/4,/ '$ # 3. (,/1.5$ 3'$ $%%("($-"8 -# $-' -"$ 3'$ "..+:

(-&

'$ 24/$1"1(3(" + %+4(# $731 "3.1 (-31.#4"$# ( 42$# 2(,(+ 1 //1. "' '$ 42$2 24/$1"1(3(" +

%+4(# 3. $731 "3 3'$ 2 ,/+$ -# /1$/ 1$ (3 %.1 - +82(2 '$

/4,/ +(*$ 3'$ /4,/ ,423 !$ "..+$# 18.&$-("

3'1.4&' 2(-&+$ 23 (-+$22 23$$+ 34!$ (2 42$# 3. "..+ 3'$

241% "$ .% 3'$ /4,/ '$ # +3'.4&' 3'(2 #$2(&- ,$3 3'$

%4-"3(.- + .!)$"3(5$ (3 1$04(1$# - ##(3(.- + 2.41"$ .% 4/$1"1(3(" + %+4(# &1 #$ (2 -.3 42$# %.1 "18.&$-(" /41:

/.2$2 !$" 42$ (3 (2 ,.1$ $7/$-2(5$ -# /41$1 %.1, .% %+4(#

. , *$ 3'$ /1.#4"3 ,.1$ ".,/ "3 -# 2$+%:".-3 (-$#

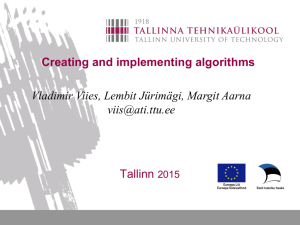

3'$1,.$+$"31(" $+3($1 #$5("$ 6 2 (-5$23(& 3$# '$1,.$+$":

31(" "..+(-& /1.5(#$2 .-$ .% 3'$ 2(,/+$23 ,$ -2 .% 1$%1(&$1 3:

(-& $+$"31.-(" $04(/,$-3 6(3'.43 42(-& ".,/1$22.12 .1 +(0:

4(# 1$%1(&$1 -32 3'$1,.$+$"31(" #$5("$ (2 '$ 3 /4,/ 3' 3

./$1 3$2 $+$"31.-(" ++8 '$ #$5("$ (2 , #$ %1., 36. 2$,(:

".-#4"3.12 424 ++8 !(2,43' 3$++41(#$ 3' 3 $(3'$1 ' 5$ $7"$22 - 38/$ .1 #$%("($-"8 / 38/$ .% $+$"31.-2 411$-3

/ 22$2 3'1.4&' 3'$ #(22(,(+ 1 ".-#4"3.12 "1$ 3(-& 3$,/$1 :

341$ #(%%$1$-3( + "1.22 3'$ #$5("$ $ 3 $-$1&8 (2 31 -2%$11$#

%1., 3'$ ".+# 2(#$ !.#8 3. !$ "..+$# 3. 3'$ '.3 2(#$ '$ 3

2(-* -# #(22(/ 3$# '(2 (2 *-.6- 2 3'$ $+3($1 $%%$"3 (&

(2 2"'$, 3(" #( &1 , .% 3'$1,.$+$"31(" #$5("$ !+$ /1.5(#$2 ".,/ 1(2.- .% 3'$1,.$+$"31(" '$ 3 /4,/ 6(3'

.3'$1 38/$2 .% 1$%1(&$1 -3 "..+(-& 2823$,2

- //+8(-& 3'$1,.$+$"31(" 3$"'-.+.&8 24""$22%4++8 3'1$$

#$2(&- (224$2 3. !$ ".-2(#$1$# 1$

• '$ ./$1 3(-& $-5(1.-,$-3

• .6 3. #(22(/ 3$ 3'$ '$ 3 $%%("($-3+8

• 23(, 3$# ,.4-3 .% '$ 3 3'$ #$5("$ -$$#2 3. 1$,.5$

. , (-3 (- ° ./$1 3(-& 3$,/$1 341$ 3'$ %(- + #$2(&2$$ (& (-"+4#$2 2$5$1 + 3'$1,.$+$"31(" #$5("$2 2 -#:

6("'$# !$36$$- - +4,(-4, '$ 3 2(-* -# ".//$1 ".+#

/+ 3$

1$+(,(- 18 1$24+32 2'.6$# 3' 3 3'$ 3'$1,.$+$"31(" #$5("$

".4+# , (-3 (- 3$,/$1 341$ .% ° 3 3'$ /4,/ '$ # 241:

% "$ % 3'$ '$ 3 2(-* 1$ "'$2 3'$ 3$,/$1 341$ .% 3'$ '.3 2(#$

Table I

Refrigerant Cooling Comparison

Thermoelectric

Cryogenic Fluids

-30!#

- *'/3'" !--*,2

#/3'0#1 *'/3'"

!--*,2 1-30!#

#+.#0230#

.#02',%

,%#

, !!-++-"2#

2#+.#0230#

#620#+#1

° 2- °

0-4'"#1 !--*',%

-,*7

.#02'-,

*#!20-,'!**7

!-,20-**#"

-4',% !-+.-,#,21

-0 4*4#1 2- !-,20-*

$*3'" $*-5

&71'!*

220' 32#1

-"3*0 ,"

!-+.!2

3*)7 5'2& #620

&0"50# 4*4#1

2,)1 #2!

-$ 2&# #*2'#0 "#4'!# 2&#, 2&# &#2 1',) *-,# !,,-2 #$$#!9

2'4#*7 "'11'.2# 2&# &#2 -6#0 $, 2 2&# 0#0 -$ 2&# .3+.

!--*1 2&# &#2 1',) &# ',2#0$!#1 #25##, 2&# #*2'#0

!--*#0 2&# &#2 1',) ," 2&# !-*" 1'"# -$ 2&# .3+. &#"

0# 1#!30#" 5'2& 1!0#51 ," #.-67 2- +','+'8# 2&#0+*

*-11#1 ," .0-4'"# %--" 2&#0+* !'0!3'2

302&#0 #$$-021 2- -.2'+'8# 2&# "#1'%, ',!*3"#" 2&# 1#*#!2'-,

-$ +2#0'*1 5'2& &'%& 2&#0+* !-,"3!2'4'27 ,'!)#* &#2

#6!&,%#0 5'2& .-0-31 1',2#0#" ,'!)#* '1 ',!-0.-02#" ', 2&#

"#1'%, 2- !--* 2&# !-,"3!2'4#*7 #$-0# '2 #,2#01 2&# 1719

2#+ &# 2#+.#0230# -$ 2&# 1 '2 #,2#01 2&# .3+. '1

,#0 0--+ 2#+.#0230# &# &#2 #6!&,%#0 '1 ', 2&#0+*

!-,2!2 5'2& 2&# !-*" .*2# &# !-*" 2#+.#0230# '1 !-,9

"3!2#" ',2- 2&# &#2 #6!&,2#0 2- *-5#0 2&# $*3'" 2#+.#09

230# 2- °

&# 2&#0+-#*#!20'! "#4'!# !-+ ',#" 5'2& !-,"3!2'4# ,"

!-,4#!2'4# !--*',% 2#!&,'/3#1 **-51 2&# .3+. +-"3*# 2# 1#*$9!-,2',#" ," +-"3*0 &'1 ..0-!& 0#/3'0#1 ,#62#0,* 1-30!# $-0 !07-%#,'! !--*',%

1 "#1!0' #" -4# 2&# 1#.02'-, ," "#2#!2'-, +-"3*#

',!*3"#1 !&-'!# -$ !-*3+,1 ," "#2#!2-01 &# $*+# '-,9

'82'-, "#2#!2-0 '1 2&#0+**7 -.2'+'8#" $-0 2 '1 +-3,2#"

2- 2&# 2-. -$ 2&# -4#, 5&'!& !-,20-*1 2&# 2#+.#0230#

-$ 2&# !-*3+, 2&2 !-,2',1 2&# 1+.*# &# $*+# '-,'82'-,

Aluminum Heat Sink

"#2#!2-0 &1 25- 1#.02# 2#+.#0230#9!-,20-**#" &#2#"

8-,#1 &# 1# -$ 2&# "#2#!2-0 .0-203"#1 ',2- 2&# -4#, &#

2-. -$ 2&# "#2#!2-0 2&# !-**#!2-0 '1 !-,20-**#" 8-,# #69

.-1#" 2- 0--+ 2#+.#0230# &# -4#, ," "#2#!2-0 1#

-2& -.#02# 2 2#+.#0230#1 3. 2- ° 5'2& *#11 2&,

° 40'2'-,1

$*+# '-,'82'-, "#2#!2-0 '1 12',*#11 12##* *-!) 5'2& (#2 12',*#11 23 # 22!&#" 2- '2 #2 '1 ..*'#" 7 0-"

&#2#0 2 2&# 2'. -$ 2&# $*+# '-,'82'-, "#2#!2-0 (#2 $*+#

'1 .0-"3!#" 7 2&# !-+ 312'-, -$ &7"0-%#, ," '0 &# 1+9

.*# #*32#1 ',2- 2&# $*+# ," '-,'8#1 &# "#2#!2-0 %#,#02#1

1'%,* 2&2 0#.0#1#,21 2&# +-3,2 -$ !0 -, ', 2&# 1+.*#

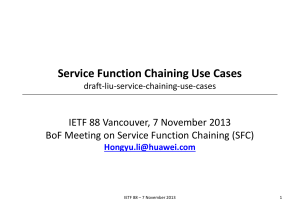

'% !-+.0#1 ," $*+# '-,'82'-, "#2#!2-01 &#

2#+.#0230# -$ 2&# 8-,# (312 #*-5 2&# (#2 '1 !0'2'!* *'%&2

!&,%#1 ', 2&# 2#+.#0230# $$#!2 2&# 0#.0-"3!' '*'27 -$ 2&#

0#13*21

&# $*+# '-,'82'-, "#2#!2-0 51 #4*32#" $-0 .-2#,2'*

31# 5'2& &# "#2#!2-0 &1 *-,% &#2#" 8-,# 5'2&

0#+-4 *# (#2 .-1'2'-,#" -4# 2&# 8-,# 1 1&-5, ', '%

2#+.#0230# %0"'#,2 #6'121 #25##, 2&# &#2#" *-!)

," 2&# (#2 2'. -$ 2&# $*+# '-,'82'-, "#2#!2-0 #!31#

-$ 2&# .-1'2'-, -$ 2&# &#2#0 ," 1#,1-0 ," 2&# *-!2'-, -$

2&# (#2 0#*2'4# 2- 2&# &#2#0 &#, 2&'1 "#1'%, '1 31#" $-0

1.')',% ," $*+#-32 -!!30 .')',% '1 $*3!232'-, ',

2&# 1'%,* 2&2 1&-51 3. ', !&0-+2-%0+ 2 '1 2&# 0#13*2

-$ 2&# '!',% *+#-32 -!!301 '$ 2&#0# '1 2-- +3!& $*-5',% 2&0-3%& 2&# (#2 *-,% &#2#" 8-,# *1- !31#1 3,9

"#1'0 *# "#,1'27 "0-.1 ', 2&2 **-5 2&# 1+.*# 2.0#!'.'22#

312-+#01 $+'*'0 5'2& $*+# '-,'82'-, "#2#!2-01 #6.#!2 2&#

0#13*21 2- # !*#0 ," 0#.0-"3!' *# &# .0'+07 "#1'%,

!-,1'"#02'-, $-0 -.2'+'82'-, -$ 2&# $*+# '-,'82'-, "#2#!9

2-0 $-0 51 2- 1-*4# 2&# .0- *#+1 1##, 5'2& 2&# "#9

1'%, 2&2 '1 2- +','+'8# "#,1'27 "0-.1 ," #*'+',2# 1.')',%

," $*+#-32

1&-02#0 &#2#" 8-,# $*+# '-,'82'-, "#2#!2-0 51 "#9

1'%,#" &# (#2 '1 , ',2#%0* .02 -$ 2&# &#2#" 8-,# '2 '1

.&71'!**7 08#" 2- 2&# 8-,# 2- #,130# 2&2 2&#0# '1 ,2&#0+* 0#) #25##, 2&# 8-,# 1# ," 2&# (#2 &# &#2#0

," 1#,1-0 0# .-1'2'-,#" !*-1# 2- 2&# (#2 &# 2#+.#0230#

%0"'#,2 '1 +','+'8#" &# (#2 -0'$'!# 1'8# '1 -.2'+'8#" 2.0#4#,2 $*+#-32 2 &'%& $*-5 02#1 1#!-," &#2#"

8-,# '1 ""#" 2- 2&# $*+# '-,'82'-, "#2#!2-0 2- #*'+'9

,2# .0- *#+1 -$ 1.')',% ," !-,"#,12'-, -4# 2&# (#2

Fan

Thermoelectric

Peltier Cooler

Copper Cold

Plate

CO2

Tank

Nickel Heat

Exchanger

Pump Drive Assembly

Pump Head

Tank Valve

Fig. 3. )#2!& -$ 2&# .3+.

1&-5',% 2&# +(-0 !-+.-,#,21

," 2&# 2&#0+-#*#!20'! #*2'#0

"#4'!#

3%312 #5*#229!)0" -30,*

Collector

Heated

Zone

Collector

Air In

Jet

Air In

Jet

Detector Block

Heated Zone

Heater

Heater

Hydrogen In

Hydrogen In

Detector Block

Heated Zone

(a)

(b)

Condensation forms from the combustion of hydrogen and

air when the detector block temperature is below 100°C.

Table II is a comparison of the GC and SFC detectors.

Table II

Comparison of SFC and GC Flame Ionization Detectors

SFC Detector

GC Detector

Physical Size

6 mm thick, compact

with jet permanently

attached

25 mm thick with jet

a separate part

Temperature

Gradient

1°C from sensor to

jet tip

17°C from sensor to

jet tip

Problem

Area

No spiking or

flameout

Spiking and flameĆ

out when used as an

SFC detector

Collector

Heated collector

zone

Collector not

actively heated

The SFC flame ionization detector is insulated from the oven

so that the heat from the oven has minimal effect on it. The

SFC detector's minimum operating temperature is the oven

temperature plus 10°C because of convection and conduction

of heat from the oven.

To achieve temperature stability, the SFC flame ionization

detector heated zone required changes in the temperature

control parameters. The controller uses the ZieglerĆNichols

algorithm1 to obtain the proportional (P), integral (I), and

derivative (D) terms in the control algorithm. This algorithm

defines the PID constants such that the object reaches its

desired steadyĆstate temperature without large offsets or

deviations. The PID controller is designed for larger masses

such as the GC heated detector zones. Although it takes

longer for larger masses to heat up, the oscillations are miniĆ

mal and therefore it is easier to dampen the response and

bring temperature under control. The SFC flame ionization

detector is 1/4 the size of the GC design, so it heats up very

quickly. Using the GC PID constants, large oscillations were

seen because of poor temperature control. New initial values

for the PID parameters for the SFC detector were derived

using the ZieglerĆNichols tuning algorithm. A trial and error

method was then applied to fineĆtune the PID parameters to

eliminate oscillations.

Fig. 4. Sketches of the SFC (a)

and GC (b) flame ionization deĆ

tectors. Note the difference in the

heated block size and the locaĆ

tion of the jet.

August 1994 HewlettĆPackard Journal

The major result was the introduction of an HP G1205A SFC

system in May 1992 that meets its performance goals. It was

a challenge to reuse existing components that were not deĆ

signed with SFC in mind. In SFC, control of temperature in

different regions of the system is critical to the success of the

chemical analysis and the performance of the instrument. To

make components perform under conditions for which they

were not originally designed was a major success for the

team. Another tangible result was the reduction of product

cost by consolidation and reuse of components. The product

is a compact modular design and maintains the integrity of

the existing designs it leverages. The introduction of a therĆ

moelectric PeltierĆcooled pump head provides an advantage

over designs that use a second source of CO2 to cool the

pump head. Other HP analytical products have incorporated

the Peltier device. The SFC flame ionization detector, with its

shortened zone, has improved the quality of the analytical

results.

The work described in this paper is the result of several

years of development efforts by the R&D project team. SpeĆ

cifically, Hans Georg Haertl is responsible for successfully

incorporating the Peltier device into LC pump design. Hans

Georg was an engineer on loan to the site from the HP

Waldbronn Division in Germany. The other members of the

project team included Chris Toney (project manager), Elmer

Axelson (software), Paul Dryden (firmware), Bill Wilson

(chemist), Terry Berger (chemist), Mahmoud AbdelĆRahman

(firmware and hardware), and Joe Wyan (hardware). Our

success must also be shared by several other functional

groups (manufacturing, marketing, purchasing, and adminisĆ

trative support) which were instrumental in the release of the

product. Without the combined efforts of these individuals,

the SFC would not have met its targeted release date.

1. G.K. McMillan, Instrument

Society of America, 1990, Chapter 1.

Microsoft is a U.S. registered trademark of Microsoft Corporation.

Windows is a U.S. trademark of Microsoft Corporation.