JOURNAL ^ ^ ^ H HEWLETT-PACKARD

advertisement

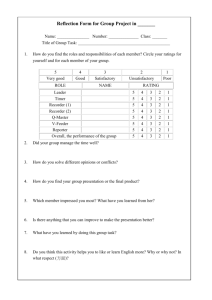

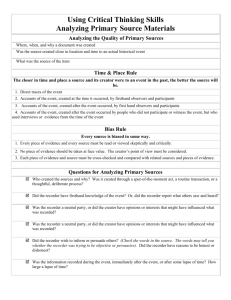

HEWLETT-PACKARD JOURNAL T E C H N I C A L I ^ I N F O R M A T I O N â € ¢ F R O M ^  T H E - d p - · L A B O R A T O R I E S â € Vol. 8, No. 7 ^^^H ¢ LISHED CALIFORNIA THE HEWLETT-PACKARD COMPANY, 275 PAGE MILL ROAD, PALO ALTO, CALIFORNIA MARCH, 1957 A Fast Digital Recorder with Analog Output for Automatic Data Plotting FIG. 1 shows a new digital device which considerably increases not only the speed and amount of information that can be ob tained with electronic frequency counters but also the ease with which it can be obtained. This new instrument is a high-speed digital recorder which converts electronic counter readings into printed form on adding machine tape. The new recorder is distinguished by four special features: 1. It is fast. Print-outs can be made at rates up to 5 lines per second. 2. It has high count capacity: numbers of as many as 11 columns can be printed on each line. This high count capacity enables addi tional data such as time signals or the read ings of more than one counter to be printed simultaneously through use of suitable aux iliary equipment. Fig. 1. New -hp- Model 560 A Digital Recorder prints -Hp- electronic counter readings on paper tape at rates up to 5 lines per second and up to 11 columns per line. An important feature of the instrument is that it provides output voltages proportional to the counter reading so that counter readings can be simultaneously and automatically plotted by strip recorders. P R I N T E D I N 3. It is a slave to the counter. Counter readings are thus reproduced exactly. 4. It has an analog output for operating a con ventional strip-chart recorder. This feature is an outstanding convenience in many ap plications since it means that data can be automatically plotted as it is received by the counter. Further, a scale expansion feature enables the resolution of chart recordings made with this arrangement to be unusually high — if desired, variations as small as 1 unit of the counted quantity can easily be discerned in a typical recording. Where large samples are counted, resolutions up to 1 part in 107 can thus be obtained. Under some cir cumstances resolutions of 1 part in 109 can be obtained. Fig. 2 shows how a typical tape record ap pears as it comes from the new recorder. The second part of the illustration shows how this same information appears when use is made of Fig. 2. (a) Curve of accuracy of power line frequency made by operating strip recorder from analog output of the new •hp- 560A Digital Recorder which oper ated from -hp- 524B counter (measuring 10-period averages), (b) at right shows section of printed tape corresponding to part of plotted curve (j actual size). U . S . A . C O P Y R I G H T © Copr. 1949-1998 Hewlett-Packard Co. 1 9 5 7 H E W L E T T - P A C K A R D C O . 198.300MC 198.200MC Fig. 3. Curve of warm-up characteristic of oscillator operating near 200 me. Curve made by operating. 198.141590 MC strip recorder from new (FROM DIGITAL digital recorder and -hpRECOfiDERTAPE)524B with 525B con verter. 198.200 MC 1MIN the recorder's analog output to make a strip record. In this illustration there are two special features worthy of comment. One is that where only the last two or three places of the measured quantity are varying, a strip record is obtained which is equivalent to that obtainable only by involved arrangements such as heterodyning with a local oscillator to translate small frequency vari ations to a convenient region. The second is that the use of the analog recorder substantially compresses the tape data, since as many as sev eral hundred measurements can be plotted per lineal inch of the strip record. The value of these features is apparent for such work as tele metering, systems records, fuel flow monitoring, frequency drift meas urements, and proof of performance measurements. the counter reading. The whole scanning and printing action is rapid: it requires only 0.2 second. New counts can be made by the counter during the last 20% of this interval, so that print-outs can be made at rates up to 5 lines (55 digits) per second. Although the recorder has been designed to be capable of printing 1 1 columns, this number of columns is seldom needed when a single counter is involved. The recorder is thus normally supplied with cir cuitry for 6 wheels, as described la ter. Where desired, however, the 11column capacity can be used with auxiliary equipment to print the readings of two or three counters simultaneously or to print coded in formation such as time along with a counter reading. RECORDER OPERATION Two sets of analog output ter minals are provided on the recorder so that either low-impedance or high-impedance type strip recorders can be used. A special feature of these outputs is that the voltages provided are proportional to the total represented by any three adja cent columns or the right-hand two columns of the print-out. This fea ture permits much higher resolution to be obtained in a typical strip re cording than with other methods since it gives an expanded scale type recording. Consider, for example, a The printing mechanism in the new recorder operates from the volt age staircases developed in each dec ade unit (display column) of -hpfrequency counters. These staircases are applied to comparison circuits in the recorder which in turn control the angular positions of each of eleven print wheels. Along their periphery these wheels contain type faces for the numerals 0 through 9 as well as blank positions. During the counter's display time each wheel turns rapidly to its new print ing position. This position is deter mined by the staircase step at which the wheel's corresponding decade unit in the counter has stopped. A print bar in the recorder then presses the combination of the paper tape and an inked ribbon against the print wheels to give a printed impression which is identical with ANALOG OUTPUTS 200.200MC 10,008,228 10,008,255 10,008,240 10,008,261 10,008,252 10,008,260 etc. When recording data of this na ture by using an analog recorder with the digital recorder, the ability of the digital recorder to supply a voltage that is proportional only to the final two or three places of each number is of considerable value, since it gives the full resolution of the counter to the analog record. If the counted sample is large, as in the above example, resolutions in the order of 1 part in 107 can be obtained in the strip record with this feature. If higher frequencies in the order of 10s are counted with the 10-second gate of the -hp- Model 524B counter operating with the Model 525 con verter, resolutions in the order of 1 part in 10C will be obtained in the chart. A further feature of this sys tem is that the strip recorder will never go off scale, as will be shown later. The voltages for the strip recorder outputs are obtained from staircase voltages (separate from the counter staircases) which are generated by print wheel brushes running against a commutator. When the print wheels come to rest to make a print, the voltage step corresponding to the wheel position is applied to a selector switch. This switch applies the voltages from any three adjacent wheels or the right-hand two wheels to a resistive network which adds the voltages in a 90%-9%-0.9% re lation. This combined voltage is then applied to the output terminals. During the next scan time, when the Fig. 4. Sample record made by frequencymodulating 200 me os cillator at slow rates with various wave forms and measuring and plotting fre quency change with recorder-counter com bination. 200.300MC 5 MIN © Copr. 1949-1998 Hewlett-Packard Co. series of readouts like the following frequency drift data in which only the last few digits are varying. •? Fig. 5. Slide switch on recorder panel selects desired adjacent columns for ana log output. wheels are turning to a new position, the voltage at the output terminals is stored in a capacitor so that no interruption of the output level will occur. Even though the analog output is a step-type voltage, steps normally do not appear in a strip record when the 3-column analog output is used. The reason for this is that the counter typically samples enough points that the voltage change be tween points from the recorder's an alog output is small. Voltage incre ments from this output can be as small as 0.1% of full scale (1 unit in the third place). At typical strip recorder lineal speeds these plotted points overlap or blend together so that steps do not appear. Figs. 3 and 4 are records which illustrate this feature. Steps are more likely to be ob servable when the right-hand 2column output is used for operating a strip recorder, since the minimum voltage increments available are then 10 times as large as in the 3column case. ALWAYS ON-SCALE CHARACTERISTIC Since the analog output is ob tained by combining staircase volt ages, the external analog recorder can not go off scale at any time. This characteristic occurs because the staircase voltages always lie between two limits. If the counted quantity advances beyond 999, the staircases will go through their maximum value and rest at the next reading which will be an intermediate value. Similarly, if the counted quantity decreases through 000, the staircases will go through their minimum value and rest at an intermediate value. Within the limits of the counter capacity the strip record will thus always be contained on the chart, regardless of how much the count increases or decreases. Even though the strip recorder will always be on scale, the total amount of change in the measured quantity is still easily determined from the strip record. Fig. 3, for example, shows a recording in which the measured frequency has drifted downward beyond the full-scale value of the chart. The total drift is obtained merely by adding the val ues of the second curve section to the first. The always on-scale feature has at least three distinct advantages. First, recordings can be run unat tended since they can never go offscale. Secondly, data in which a wide (Cont'd on P. 4) OPERATION OF THE DIGITAL RECORDER The new digital recorder has a simple and straightforward mechanism which consists of identical sections for each print wheel. A representation of one of these sections is shown in Fig. 1. The fol lowing describes how the section operates. When the recorder is interconnected with a counter, the staircase output of each decade unit in the counter becomes connected to a comparison circuit in the recorder. At the same time a staircase voltage associated with the print wheel is also applied to the comparator. During the sampling interval or gate time in which the counter is accumulating its count, the comparator circuit is dis abled. During this time, also, the print wheel is locked in its last printing position so that it applies only a fixed step of its staircase to the comparator. When the counter gate time is com pleted, the decade unit staircase from the counter will rest at a step corresponding to the count remaining on the decade. As the gate time ends, the counter applies to the recorder a command pulse. This com mand pulse causes three nearly simultan eous actions within the recorder. First, the pulse causes a main clutch to engage, and this causes a shaft on which all print wheels are mounted to begin rotating. The print wheels themselves can not yet rotate, however, because they are locked in position by a pawl. Second, the re corder applies an override signal back to the counter so that the counter can not begin a new count while the print ing action is in process. The third action that occurs from the command pulse is that the comparator circuit is activated. If the step applied to the comparator from the decade staircase is then not equivalent to that applied from the wheel staircase, the comparator energizes a solenoid which releases the pawl from the print wheel. This permits a friction clutch on the individual print wheel to begin rotating the wheel. When the wheel rotates to its proper position, such that the two staircase steps applied to the comparator now correspond, the © Copr. 1949-1998 Hewlett-Packard Co. COMMUTATOR Fig. 1. Basic operating arrangement of print wheel. comparator de-energizes the solenoid. The pawl then locks the wheel in its new position. This same action has simultan eously been occurring with each of the other wheels. At a pre-determined inter val after the command pulse and after the wheels are positioned, a cam on the main shaft presses the print bar, ribbon and paper against the print wheels, trans ferring the counter reading to the paper. The staircase associated with the print wheel is obtained with a brush and com mutator arrangement in which each com mutator segment is connected to a tap on a fixed resistor. The brush is carried by the print wheel. When the wheel is in a locked position, the brush thus supplies the comparator with a single voltage level which corresponds to the angular position of the wheel. When the wheel rotates, the brush supplies the comparator with step voltages until the coincident condition prevails. The two staircases applied to the com parator have been designed to be the in verse of one another. Where the stair case from the decade unit in the counter descends from a higher to a lower voltage as the count increases from 0 through 9, the staircase from the brush and commu tator increases as the wheel rotates from 0 through 9. This arrangement makes (Cont'd on P. 4) SIX-DIGIT RECORDER THE DIGITAL RECORDER (Cont'd from P. 3) Fig. 6. Drawer is provided in recorder to receive accordion-folded paper tape. change may occur such as in warmup curves can be run without danger of incorrectly anticipating the re quired full-scale value to which the recorder should be initially set. Thirdly, quite rapid variations in the measured quantity can be plot ted: the speed is limited mainly by variations that are sufficiently de fined by 5 plotted points per second, i.e., variations in the order of i — 1 cycle per second. PAPER AND RIBBON The new recorder is arranged so that it prints on conventional 3inch adding machine tape and is further arranged so that two types of tape can be used. One type is the standard rolled tape, and the second is accordion-folded tape (Fig. 6). The second type is often preferred be cause it offers convenient access to any portion of a record. The re corder is arranged with a drawer which will accumulate this tape as it is printed. Either type of tape is available from -hp-. The recorder uses a standard type writer ribbon (medium heavy inked) on an Underwood-type ribbon spool. USE WITH -hp- COUNTERS To interconnect the new recorder with -hp- counters, a special multiconductor cable is supplied with the recorder. The counter must then be modified somewhat to receive this cable and to make the internal con nections, but this is easy to do. Modi fication kits are available for all -hpcounters now in production at nom inal cost. The standard Model 560A re corder is supplied with eleven print wheels. Since all of these printing positions may not be required, how ever, the recorder is normally sup plied with only six comparator cir cuits which activate the wheels. The comparators are constructed in plugin form and extra plug-in units to activate additional wheels can be ob tained at extra cost. RECORDER OPERATION (Cont'd from P. 3) for high reliability since the grids of the comparator tube always see coinci dence at the same absolute voltage ACKNOWLEDGMENT Many members of the -hp- engi neering department have contrib uted to the design of the new re corder. Besides the undersigned, the electrical team included Duane Mar shall of the -hp- counter group, while the mechanical team included con sulting engineer Harold F. Elliott, and Francis Berry, Carl J. Clement, Jr., Everet J. Penn, and Ted Pichel. —Alan S. Bagley and Ed A. Hilton SPECIFICATIONS -hp- MODEL 560A DIGITAL RECORDER Accuracy: Identical to that of counter used. Printing Rote: Controlled by counter; 5 lines/sec, max. Printing Capacity: 1 1 columns/line. (See Price). Required Driving Source: Parallel entry stair case voltages such as those derived from • hp- or Dynac, Inc. digital frequency count ers. Staircase descends from +135 V to -f-55 V as the count progresses from 0 to 9. Internal impedance of the staircase source should be approximately 700,000 ohms. Paper Required: Standard 3" roll or folded paper. Line Spacing: Single or double, adjustable. Analog Output: Output is proportional to the count indicated by any three adjacent col umns or by the right-hand two columns of the print-out in the form of a 1000 step staircase. Desired columns may be selected by analog output selector. For example, if selected adjacent digits were 3, 8, and 6, output voltage would be 38. ó millivolts (or .386 ma from galvanometer output); and 99.9 millivolts if adjacent columns were 999. Output Available: 1 ma for galvanometer strip-chart recorders. 100 mv for potentio meter strip-chart recorders. Power Requirements: 105-125 volts, 60 cycles, 250 watts. Dimensions: Cabinet Mount: 203/4" wide, 12'/2" high, I6'/2" deep. Rack Mount: 19" wide, 10'/2" high, 16Vj" deep. Weight: Cabinet Mount: 60 Ibs., approx. Rack Mount: 55 Ibs., approx. Price: -hp- Model 560A Digital Recorder, in cludes cable for connecting to -hp- counters and 6 plug-in comparators. Cabinet Mount: $1265.00 Rack Mount: $1250.00 Additional plug-in comparators: $25.00 MODIFICATION KITS (Adapt -hp- counters for use with -hp- 560A Digital Recorder) For: -hp- 521A/C: $35.00; -hp- 522B: S35.00; -hp- 523B: $35.00; -hp- 524B: $125.00. Factory Installation on New Counters-hp- 521A/C: $45.00; -hp- 522B: $45.00; -hp- 523B: $45.00; -hp- 524B: $150.00. Prices f.o.b. Pato Alto, California. Data subject to change without notice. © Copr. 1949-1998 Hewlett-Packard Co. Fig. 2. Relative time relations of opera tions in recorder. level, a situation that would not occur if both staircases progressed in the same direction. OPERATING CYCLE Fig. 2 shows the time relation of the various operations within the recorder. When the counter gate closes, the counter sends the command pulse (B) to the re corder. This pulse causes the main clutch to engage, the override signal to be ap plied to the counter, and the comparator circuit to be activated (C,D,E). If the comparator does not see coincidence be tween the two staircases, it energizes (F) the wheel solenoid. The wheel then ro tates to its proper position. After the main shaft has rotated approximately 8/10 of a revolution, the cam actuates the printer bar (G) and then advances the paper and ribbon. The whole cycle re quires only 0.2 second, after which the recorder is prepared for another cycle. If the counter is set for minimum display time, it will have completed another count in the last 40 milliseconds of the 0.2 second cycle, so that another printing cycle can begin immediately. A maximum of 5 printed lines per second can thus be obtained.