HEWLETT-PACKARD JOURNAL MAY 1970 © Copr. 1949-1998 Hewlett-Packard Co.

advertisement

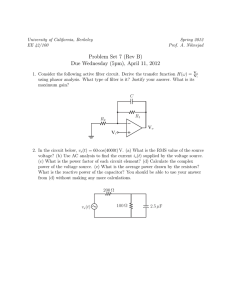

HEWLETT-PACKARDJOURNAL MAY1970 © Copr. 1949-1998 Hewlett-Packard Co. Design and Application of Silicon IMPATT Diodes DC power is converted directly into microwave energy by an IMPATT diode. In X-band, these devices generate higher CW power than any other present-day, solid-state microwave source, clearing the way for new cost-sensitive microwave designs. By A. M. Cowley MICROWAVE POWER GENERATION has been the last major holdout against the solid-state revolution. The smaller size, longer life, and lower power consumption of solidstate circuits could make a host of startling developments possible but, just as vacuum tube designers reached a frequency ceiling with grid-controlled vacuum tubes, solid-state designers are faced with an apparent limit to the capabilities of transistors. Yet, just as vacuum-tube designers succeeded in generating microwave power us ing new concepts in electron beam control, solid-state designers are now generating microwaves by taking ad vantage of certain ways charge carriers behave in semi conductors. One technique for solid-state generation of microwave energy was suggested a dozen years ago by W. T. Read of the Bell Telephone Laboratories.1 Read proposed that the finite delay between an applied voltage and the cur rent generated by avalanche breakdown in a speciallydesigned PN junction device, plus the transit delay as the charge carriers travel through the diode,2 could amount to a total delay of 180° at microwave frequencies. Such a mechanism would thus contribute power to an external circuit. Practical realization of a "Read" diode, however, was not achieved until seven years later3 despite the fact that Read presented a complete and basically correct analysis of the device. The problem was largely thermal: how to remove the heat generated in the device. Since microwave applications require very small devices for practical im pedance levels, and since operation in avalanche break down at the required current densities means extremely high power densities — as much as 10s watts per cubic centimeter — , a method had to be found to extract large quantities of heat efficiently to prevent destructively high temperatures. A successful thermal design was achieved by inverting a mesa-type PN junction diode and bonding the top of the mesa with heat and pressure directly to a gold-plated copper heat sink, as shown in Fig. 1 (solder wouldn't do here because of its thermal resistance). When all the variables in the thermal-compression bonding process are at the optimum, thermal resistances low enough to permit continuous microwave oscillations are obtained. Cover: Scarcely an eighth of an inch long, IMPATT di odes generate more than one-half watt of microwave power in X band (8-12.4 GHz) when imbedded in a resonant circuit supplied with dc power. The article beginning on this page explains the why's and wherefore's of these mighty Lilliputians. In this Issue: Design and Application of Silicon IMPATT Diodes, by A. Michael Cowl e y Measuring Capacitance Automati cally, by Hitoshi Noguchi, ladeo Shimizu and Koichi Maeda . . O HEWL PRINTED IN U.S.A. © Copr. 1949-1998 Hewlett-Packard Co. page 2 page 14 © Copr. 1949-1998 Hewlett-Packard Co. Fig. 1. IMP ATT diode formed on silicon substrate and thermal-compression bonded to metal heat sink. Dotted lines show shape, mechanically more stable but harder to handle, obtained by etching from both sides of wafer. Dimensions apply to X-band diodes. Thermal-compression bonding, though, takes more time than conventional techniques (e.g., soldering) and it requires extreme care to produce an adequate and re producible bond. In a search for a less expensive and more consistent means of constructing an adequate thermal path, members of the development team at the HP Associates Division of Hewlett-Packard developed a means of electroplating a heat sink on the junction side of a wafer, and then etching mesa diodes directly on the heat sink,4 as shown in Fig. 2. Because the integral heat sink diffuses the diode heat over a relatively wide area, the individual diodes can then be soldered into a package or circuit by conventional techniques. Thermal resistances typically between 14 and 17°C/W are obtained in Hewlett-Packard's X-band diodes made this way. Power output for the two types of HP diodes are shown in Fig. 3. A typical diode can generate 700 mW at 10 GHz with 6.5% efficiency at a junction tem perature of about 200°C. One watt output can be ob tained at a junction temperature of 250 to 260°C. Since burnout does not occur until a junction temperature of 350°C is reached, there is a large margin for safety (until extensive reliability studies are completed, however, con servative operation at junction temperatures below 200°C is recommended). The new HP diodes, in common with most avalanche diodes intended for microwave oscillators, use a simple PN junction in a three-layer P"NN* structure rather than ' This method was proposed independently by Bernd Hoefflinger (see reference [5]). the special four-layer N+PIP+ structure proposed by Read. The three-layer structure has all the microwave oscillation properties of the four-layer structure but is easier to make. Both of these devices are called IMPATT diodes, an acronym derived from IMPact ionization and Avalanche Transit Time. Among the important benefits added by the integral heat-sink construction technique are a reduction in fab rication costs and a significant improvement in uniformity from diode to diode. Also, since the PN junction is at the wide base of the mesa, rather than at the narrow top, the slope of the mesa sides reduces the electric field at the junction periphery, lowering the chances of pre mature edge breakdown. Furthermore, the diodes can be passivated by conventional dielectric deposition tech niques while still in wafer form. HP IMPATT diodes made with integral heat sinks are currently priced at $150 each in sample quantities, as compared to the $200-$300 price range of earlier IMPATT's. There is every reason to believe that the price will go down substantially as both demand and production rates for these diodes grow. Hence, the era of solid-state microwave systems is upon us. IMPATT diodes, presently the highest power solid-state source of CW microwave power in X-band, are already being designed into airborne Doppler naviga tion radars, point-to-point microwave communications links, and airborne phased array radars. Besides making Fig. 2. Integral heat sink serves as wafer substrate dur ing manufacture of new HP IMPATT diodes. Chips can be soldered into circuit or package without seriously degrading thermal properties. © Copr. 1949-1998 Hewlett-Packard Co. Fig. 3. Typical performance of HP IMPATT diodes in X-band. Two types are currently offered. possible some rather complex microwave systems, the IMPATT diodes will also contribute to low-cost, com pact systems like radar transponders, navigation beacons, collision avoidance systems, disposable ECM jammers, fuses, automobile radar braking systems, and intrusion alarms. Theory To provide insight into IMPATT diode performance in preference to exact quantitative design theory, several simplifying assumptions are made in the description of diode operation presented in this section. The basic theory was well described by Read in his original paper1 and more recently Sze" and deLoach7 have reviewed the theory in the light of experimental results. A diagram representing a three-layer P+NN+ diode is shown in Fig. 4. The diode is represented as biased into reverse breakdown, which gives rise to a positively charged depletion layer that has a triangular field distri bution, the field maximum being at the PN junction. Breakdown occurs when the electric field is so high that an electron or hole entering the depletion region has a significant probability of ionizing a hole-electron pair. If, on the average, each carrier in the depletion region pro duces just one new hole-electron pair, a sustained ava lanche can exist, in much the same way an electrical dis charge occurs in a gas. The diode can thus support any dc current with essentially a constant voltage Vbd, the breakdown voltage. The probability of ionization is a strongly increasing function of the electric field. For this reason, charge generation in a diode biased into breakdown tends to be localized near the P+N junction, i.e., in the region of highest electric field. In an abrupt silicon P+N junction, this region, known as the avalanche zone (Wa in the diagram), is about 25% of the total depletion layer width. The remainder of the depletion layer is the drift zone, shown as Wd. When the diode is operating, charge is generated throughout the avalanche zone. Under the influence of the high electric field, the charge drifts to the N+ end of the depletion region at constant velocity. It is charac teristic of this mechanism that the charge velocity is independent of electric field levels above 2 x 104V/cm; under typical IMPATT operating conditions, the field is higher than this over most of the depletion region. The resulting charge velocity, known as the saturated velocity, vsat, is about 107cm/s for electrons in silicon. Since diode operation involves the time delay in the avalanche process, we need to consider how charge builds up in response to an applied voltage. From analysis of charge build-up in a thin avalanche zone in a diode biased with a dc voltage just equal to the breakdown voltage Vbd, and with a sinusoidal microwave voltage superimposed, Read arrived at an approximation that shows a sharp pulse occurring just as the total diode voltage drops below the breakdown level, as shown in Fig. 5. The charge pulse occurs in the avalanche region and as the charge moves across the drift zone, it generates a rec tangular current waveform in the external circuit. The © Copr. 1949-1998 Hewlett-Packard Co. Avalanche Generation Takes Place Here Where Field is Highest quency, as explained above. In practice, this is done by careful control of the resistivity and consequently the breakdown voltage of the N-type layer. The N-type re gion, however, should not be much thicker than required to support the depletion layer at breakdown, since "un depleted" material contributes to series resistance. When epitaxial wafer requirements are met, the re maining parameter to be controlled is junction area, since it determines the operating or depletion capacitance, Cd, of the diode. Depletion capacitance is related to junction area, A, and depletion layer thickness, Wsc, by: A pF Ws where A is in cm2 and Wsc is in cm. If Wsc were 4 X 10-4cm (4.0 p.m) and A were 2 X 10-4cm2, Cd would be 0.5 pF. In principle, maximum power output is increased as junction area A is made larger, but diode reactance is reduced. Convenience of circuit design usually dictates a capacitance that gives a reactance around 20 to 30 ohms at the operating frequency. €,,= Neutral (undepleted) Zone Contributes to Rs Fig. 4. Representation of diode with abrupt P*NN* ¡unc tion reverse-biased in avalanche breakdown. Avalanche is generated in W* region where electric field is highest. Charge carriers move at constant velocity through drift region Wd. W!C is total space charge region. duration of the external current waveform is determined by the time T required by the charge to move across the drift zone, and is equal to Wd/vsat. If T equals one-half the ac period, the fundamental Fourier component of the current waveform will be 180° out of phase with the diode voltage. The diode thus delivers ac power to the external circuit or, looking at it from another viewpoint, the diode has negative resistance at this frequency. External Circuit Current Due to Charge (Electrons) Drifting Across Drift Zone Diode Design Fabrication of IMPATT diodes at Hewlett-Packard is described step-by-step in the box on page 8. The wafer is designed so that transit time across the drift region is roughly one-half a period of the desired oscillation fre Fig. 5. Charge builds up in avalanche zone just as micro wave voltage falls below breakdown level. Movement of charge across drift zone causes rectangular current waveform in external circuit. © Copr. 1949-1998 Hewlett-Packard Co. assuming penect spreading in mtinite copper heat sink and ~5 m thickness of silicon Fig. 6. Thermal resistance of HP IMPATT diode vs. ¡unction area. Smaller diodes are closer to ideal than larger ones. Thermal resistance of Hewlett-Packard IMPATT diodes was measured using the dc incremental avalanche resistance technique, a variation of a method originally proposed by Haitz8. Some typical results are shown in Fig. 6. The solid line represents the ideal — the best one can do with a silicon mesa bonded to a copper heat sink. It was calculated from the assumption that the thermal resistance consists of perfect thermal spreading resistance working into a semi-infinite copper heat sink, plus the contribution to thermal resistance of the silicon itself. The diodes with small junction areas come very close to the ideal. The larger area diodes do not come as close because the solder interface with the package assumes greater importance. For the Hewlett-Packard X-band diodes, which have junction areas around 2 XlO~4 cm2, the average measured values of thermal resistance are about 15°C/W, as compared to a calculated value of 12°C/W. More detailed calculations that take into ac count the solder interface are within a few percent of the measured values. P a c k a g e P a c k a g e Inductance J ^ Capacitance Silicon vs. GaAs Use of gallium arsenide (GaAs) for IMPATTs has some potential advantages, among them increased effi ciency (23% theoretical maximum vs. 15% for Si4), and reduced noise. These advantages are offset somewhat by the significantly greater cost of GaAs, and the relatively © Copr. 1949-1998 Hewlett-Packard Co. Fig. 7. Coaxial oscillator circuit designed tor IMPATT diode operation in X-band. Adjusting value of shunt capacitor tunes circuit. Poui(W); f0 = 12.5 GHz ldc = 130 mA Rs = 0.8 « \frm,(Hz); BW = 200 Hz fm = 10 kHz Fig. 8. Power output and noise vs. load resistance for two types of IMPATT diodes (fm is spacing of measured 200-Hz band from oscillator center fre quency). primitive state of GaAs material and device technology compared to that of Si. It is likely that GaAs IMPATT diodes will find their place in those high-performance applications where greater cost can be tolerated; silicon devices are destined to be inexpensive, and hence will appeal to designers of low-cost, high-volume products. Making Cool-Running IMPATT Diodes P-N junction A. Construction starts with highly-doped N silicon wafer of low resistivity (=0.01 il cm). On this, first an N layer (p = 0.5 - 1.0 n cm) and then a P* layer (p = 0.003 il cm) are grown epitaxially. Double epitaxial construction achieves abrupt junction and closely controlled layer widths. B. Wafer is metallized on junction (P*N) side by thin-film techniques. Copper or gold is then electroplated on metallic film to thickness of 0.003 to 0.004 inch. C. Wafer's other side (N*) is thinned mechanically and chemically to reduce wafer thickness to 0.001 to 0.002 inch. This side is then metallized. D. Standard photoresist techniques are used to etch metal into circular pads and to etch silicon mesas (mesa diameter: 0.006 inch). E. Wafer is cut apart. Relatively large metal substrate left with each mesa is soldered to copper stud of HewlettPackard style 41 microwave package. Gold strap or wire is thermal-compression bonded to top of mesa and to top edge of package. Package interior is then filled with inert gas and, finally, Kovar or steel cap is welded to top, forming hermetic seal. © Copr. 1949-1998 Hewlett-Packard Co. Metalization Plating Fig. 8 b. Oscillator Circuit corresponds to constant ac voltage across the diode. The behavior shown in Fig. 8 is qualitatively explained by a simple modification of Read's basic large-signal theory9. RF power output as a function of bias current is shown with R,, as a parameter in Fig. 9. Here, it is seen how small values of RL lead to saturation at relatively low values of I,k. and power output. The output power level at which saturation occurs becomes higher as RL is in creased up to a particular level. Note in Fig. 9 that in each case, the diode voltage at saturation is about the same: Â¥2 V,,,,. It should be emphasized that this is not a thermal effect — it is purely electrical. (The diode used for the data in Fig. 9 is typical of some of the better diodes obtained during our development program: for RL = 2.2n, 0.8W was obtained at a junction temperature of 195°C with 10W input; for RL == 2.6Q, LOW was obtained at T¿ = 240°C and 12.7W input). The oscillator circuit used to obtain results reported here is shown in Fig. 7. It is simply a length of 7 mm coaxial line with the diode mounted at the end in a clamp for good heat sinking. Inductive loading is provided by the diode package inductance and by the length (1) of line between the shorted end and the shunt radial capac itor CL. This circuit also transforms the 5 On line imped ance to an impedance of 1 to 3 ohms as seen by the diode. The circuit is tuned by inserting appropriate dielectric shims between the two parts of capacitor CL. To load an X-band diode properly, the value of CL lies typically be tween 1 and 3 pE The equivalent circuit shown in Fig. 7b is trans formed into an equivalent series-load circuit in Fig. 7c. The values of RL and XL in Fig. 7c were calculated and have also been measured with the Hewlett-Packard Model 8542A Automatic Network Analyzer. It was found that RL and XL could be calculated within 10% of the measured values. Power output and noise as a function of RL are plotted for two diodes in Fig. 8. These show behavior typical of all diodes tested: as RL is reduced from a relative high value, say 3 ohms, the power increases slowly until "satu ration" a self-limiting effect, takes place. Saturation oc curs when the peak value of the applied ac waveform, VD sin wt, reaches a value equal to one-half the diode break down voltage, VM. The power then drops linearly as a function of a further drop in RL. This linear dependence Noise When voltage saturation occurs or is imminent, the RF spectrum becomes noisy, and under certain conditions bias current oscillations can occur. This situation is shown in the frequency spectra illustrated in Fig. 10. Here, a low value of RL was chosen so that saturation would occur at a relatively low power, 0.4 watt. The photos show that as the bias current is increased beyond the saturation level, the spectrum degrades rapidly. 9 © Copr. 1949-1998 Hewlett-Packard Co. Fig. 9. Typical power output as a function of bias current with load resistance as a parameter. 1 Power limits when VD = — - vbd. Measuring IMPATT Diode Thermal Resistance vs Vrt, at Constant Temperature (Slope = 1/Rsc) Thermal resistance measurements made during this study relied on the fact that the breakdown voltage Vbd of silicon PN junctions is almost an exact linear function of tempera ture. For example, the abrupt P-N ¡unctions in HP IMPATT diodes have a breakdown voltage vs. temperature charac teristic aVbd/ST sr 1.17Vbd mV/°C. If Vbd were 70 volts at 25°C, Vbd would thus increase 82 mV for each degree of temperature rise in the junction. With reference to the diagram, the junction voltage Vdo can be considered as having three components: Vbd(T0), -^i AT, and IdcR.c. VM(To) is the room-temperature break3T AT is the increment in Vbd caused by down voltage, oT junction heating, and ldcRSc is the voltage drop in the junc tion space charge resistance, Ric. Rie, a purely electronic effect, can be measured by straightforward pulse techniques. With R!C known, deter mination of the thermal resistance « is simply a matter of accurately measuring the junction voltage and current. Derivation of 9 from these quantities is as follows: A7 = T - T, = e .) + V* = g - (T - T,) + = 37 V d c / * This method is fast, reliable, and accurate. It has a further advantage in that 9 is determined under actual op erating conditions. 10 © Copr. 1949-1998 Hewlett-Packard Co. X-317A-30 400 600 1000 Fig. 9b. In Fig. lOd, a resonant circuit had been connected from the bias port to ground. With the oscillator operat ing above the saturated power level the bias circuit oscil lated, introducing AM and FM modulation on the RF output, as shown by the sidebands in the frequency spectrum. The noisy behavior accompanying power saturation appears to be characteristic of IMP ATT diode opera tion. For quiet operation, then, an IMPATT diode should be operated well below the saturation level, i.e., with RL somewhat larger than the value that obtains maximum power. Values of FM and AM noise measured in diodes operated this way are plotted in Fig. 1 1 . In view of the circuit Q's employed, these are respectable noise per formances. At the time of writing there has been no concerted effort to characterize FM noise in circuits with higher Q. Isolated measurements, however, in cavities with Q's on the order of 100 to 200 at 350 mW power levels, have shown FM less than 7 Hz (rms) in a 100-Hz bandwidth in X-band. This figure is competitive with reflex klystrons and better than that of BWO's found in typical laboratory signal generators. Modulation Amplitude modulation of IMPATT diodes can be achieved by directly modulating the diode's bias current. This method also produces some frequency modula tion simultaneously. Frequency modulation can also be achieved with YIG or varactor circuits, or by modulating the frequency of an external injection-phase-locking sig nal. This technique is especially suitable when an injec tion-locking scheme is already included for frequency stabilization. A typical application is in microwave telecommunication systems where an injection-locked IMPATT oscillator serves as the transmitter. Conclusions The IMPATT diode has been shown to be a practical source of CW microwave power in X-band. The funda mentals of IMPATT circuit design are well understood in terms of simple large-signal equivalent circuits. New manufacturing techniques produce diodes reliably at rea sonable cost, pointing the way to large-scale use of these devices in microwave systems design. Future plans at the HP Associates Division of Hewlett-Packard include de velopment of diodes for operation at frequencies both above and below X-band, from C band through Ku band, and further applications work focused on those areas which appear especially suitable for IMPATT diodes. 11 © Copr. 1949-1998 Hewlett-Packard Co. ldc = 55 m A; P0 = 176 mW f0 = 8.2 GHz RL = 1.0 n b ldc = 90 mA; P0 = 395 mW c ldc = 95 mA; P0 = 400 mW I = 90 mA; (RESONANT BIAS CIRCUIT) Fig. with Spectra of IMPATT diode oscillator operated at 8.2 GHz with 1.0 n load. Vertical scale is 10 dB/cm. Horizontal scale is 1 MHz/cm in a, b, and c; 30 MHz in d. Acknowledgments understanding of IMPATT diode noise behavior. Val uable insight into the large-signal diode operation was contributed by Zvonko Fazarinc and Chu Yen of the Hewlett-Packard Laboratories. Finally, during the devel opment stage diodes could never have been made without the skills and perseverance of R. C. Patterson, M. R. Gavette, G. Horn, M. Bryan, and E. Petherbridge. S Overall guidance and direction through most of the IMPATT diode development program was provided by Robert A. Zettler. The simple coaxial cavity oscillator design was suggested by Robert D. Hall. Steven H. Ham ilton participated in the later stages of circuit develop ment and also made significant contributions to an 12 © Copr. 1949-1998 Hewlett-Packard Co. References [1 ]. W. T. Read. Jr., 'A Proposed High-Frequency, NegativeResistance Diode; Bell System Technical Journal, Vol. 37, No. 2. March 1958. [2]. W. Shockley, 'Negative Resistance Arising from Transit Time in Semiconductor Diodes; Bell System Technical Jour nal, Vol. 33, No. 4, July 1954. [3]. R. L. Johnston, B. C. deLoach, Jr., and B. G. Cohen. 'A Silicon Diode Microwave Oscillator; Bell System Tech nical Journal, Vol. 44, No. 2. February 1965. [4]. R. A. Zettler and A. M. Cowley. 'Batch Fabrication of Integral Heat Sink IMPATT Diodes; Electronics Letters, Vol. 5, No. 26, December 27, 1969. [5]. B. Hoefflinger, 'Recent Developments on Avalanche Diode Oscillators; Microwave Journal, Vol. 12. No. 3. March 1969. [6]. S. M. Sze, 'Physics of Semiconductor Devices; Chapter 5. Wiley-Interscience, New York. 1969. [7]. B. C. deLoach. in 'Microwave Semiconductor Devices and their Circuit Applications; H. A. Watson. Ed.. McGrawHill, New York, 1969. [8]. R. H. Haitz, H. L. Stover. N. J. Tolar, 'A Method for Heat Flow Resistance Measurements in Avalanche Diodes; IEEE Transactions on Electron Devices, Vol. ED-16, No. 5, May 1969. [9]. A. M. Cowley, Z. Fazarinc. R. D. Hall, S. H. Hamilton. C. Yen. R. A. Zettler. The Singly-Tuned IMPATT Oscilla tor; presented at the IEEE Solid-State Circuits Conference, Philadelphia, February, 1970. A. M. Cowley Mike Cowley earned BSEE and MSEE degrees at Notre Dame (1959 and 1961) anda PhD in electrical engineering at Stanford in 1965. Along the way he taught electrical engineering at the University of California at Santa Barbara and worked as a consultant in physical electronics. He joined HP in 1965, where he has been concerned with Schottkybarrier diode technology and with microwave oscillators using avalanche effects in silicon and the Gunn effect in gallium arsenide. Mike is presently manager of the Applied Research Section of the HP Associates R and D Laboratory. He is a member of the IEEE, Tau Beta Pi, Sigma Xi, and the American Physical Society. Staunch members of the Sierra Club, Mike and his wife enjoy backpacking in the high Sierras with their two sons, aged 1 and 21/2 years, usually with the help of a not-too-stubborn burro. 13 © Copr. 1949-1998 Hewlett-Packard Co. Measuring Capacitance Automatically Completely automatic multifrequency bridge measures capacitance from 0.001 pF to 1.2 fjiF, conductance and dissipation factor. By Hitoshi Noguchi, Takeo Shimizu and Koichi Maeda VALUES OF CAPACITANCE USED IN CIRCUIT DESIGN range from less than 1 pF to 1 F. To measure capacitance and loss factor over this wide range, designers most often use the frequencies 1 20 Hz, 1 kHz or 1 MHz to drive a capacitance bridge. Large capacitors (greater than l,uF) and electrolytics are usually measured at the lowest frequency. Capacitors less than 1 ^F down to several hundred pF are mea sured at 1 kHz, and capacitors less than about 1000 pF are commonly measured at 1 MHz. Most capacitance bridges use a single frequency — either 1 kHz or 1 MHz — for capacitance and loss measurements. Efficiency in capacitor measurement can be improved with automatic methods of measurement. Measurements at several frequencies rather than a single frequency also allow complete evaluation of frequency sensitive devices. The new HP Model 4270A Automatic Capacitance Bridge, Fig. 1, automatically measures capacitance and loss at four frequencies between 1 kHz and 1 MHz. It measures capacitance from 0.001 pF to 1.2 /.iF in six automatically selectable ranges. The loss component is measured as either parallel conductance or dissipation factor. The loss (G) can be measured down to 0.1 nanomhos. The instrument has an internal, continuously variable dc bias supply to 200 volts to measure param eters of such devices as varactor diodes. Balancing the Bridge A bridge measurement, obviously, is valid only when the bridge is balanced. Various types of bridges are balanced in different ways. The best bridge design bal ances quickly with relatively simple operation. Ideally, the null detector should control bridge operation during balancing. 14 © Copr. 1949-1998 Hewlett-Packard Co. Fig. measure grounded new HP Model 4270 A Automatic Capacitance Bridge can measure grounded cables L- input capacitance of amplifiers with the LOW terminal grounded. In LGROUND operation, the instrument still retains the guarded feature. AC bridges often use phase detectors as null detectors. It is a characteristic of ac bridges that the bridge output waveform inverts as the bridge output passes through the null.1 Thus, the phase detector can provide informa tion about the direction of balance. In the Model 4270A, this information through logic circuits, directly controls the balancing operation. In the Model 4270A, the output of the phase detector is integrated. Detector sensitivity is a function of the ingration time interval. When the bridge is far off null, the integrating time is short (1 millisecond) for rapid ap proach to the null. But detector sensitivity is lowered. As the null is approached, integrating time is automatically increased to about 20 milliseconds, and detector sensitiv ity is increased. Thus the bridge is balanced in the fastest possible time. The traditional, manually-operated bridge uses a very sensitive null detector. The detector, however, shows only the magnitude of the unbalanced voltage or current, but does not indicate the direction necessary to achieve bal ance. Satisfactory control of the bridge depends largely upon the operator's experience. Basic Operation The Model 4270A Bridge is balanced by adjusting attenuators in the C and D,G arms (Fig. 2). Digital signals operate transistor switches in each attenuator, Fig. 3. When the proper value of attenuation is reached, the currents ix, k-, and iD or i0 equal zero and the bridge is balanced. (The capacitance and loss displays indirectly 15 © Copr. 1949-1998 Hewlett-Packard Co. FUNCTION • CAPACITANCE • D.G S W I T C H D I S P L A Y D I S P L A Y C , D , G SWITCHING • REVERSIBLE • REVERSIBLE CONTROL B COUNTER & • COUNTER & D R I V E R D R I V E R CURRENT DETECTOR PHASE â € ¢ TIMING PULSE GENERATOR C Balance D.G Balance E r r o r Signals DIGITAL LOGIC CIRCUIT Fig. 2. capacitance logic circuits control range and balance functions of the capacitance bridge. indicate attenuator resistance values.) During balancing, the phase detector output, through the logic circuitry, operates the reversible counter and driver in the direc tion necessary to achieve balance. Balance Equations Null detector current i(1 is the sum of current ix through the unknown, current Lr through the C measurement arm, and current iD or iG through the D, G measurement arm. From the block diagram, Fig. 2, ix = (Gx + ¡<»Cx)ex = (Gx + joCx)Axe0. Since the gain Ax of operational amplifier Cx has been selected to be 1, then = (Gx + j<oCx)e0 Fig. 3. Transistor switches in the attenuator (51, etc.) ground resistances to keep noise low. (1) 16 © Copr. 1949-1998 Hewlett-Packard Co. play digit through the reversible counter is opened. Whether the counter runs forward or reverse depends upon the po larity of the comparator output. Digital signals from the counter change the attenuators and operate the display once during each integrating interval. When the integrator output polarity changes (which means that the signal is off null in the other direction) the gate to the next digit is opened, and the counter reverses. Attenuators are operated, and each digit actuated in sequence by repeating this process. If the integrator output drops below the reference level while sequencing through the C display, or when the last C digit is reached and integrator output polarity changes, the "parameter change" circuit switches to D,G. Each D,G digit is then actuated in sequence by repeating the same process. If the integrator output drops below the reference level while sequencing through the D,G display, the null circuit stops the measurement. Otherwise the measurement stops after the last digit has been actuated. Logic Circuits The logic circuits are the control circuits that balance the bridge. They switch the standards and digitally select values of attenuation so that balance is reached and maintained. When a measurement is started, the gates that operate the C$ and Gs relays (through the range selector) are opened in the "Auto Range" mode. The "parameter change" circuit switches to C. The signal from the phase detector is integrated as de scribed in the text. From the integrators, the signal goes to comparators that determine its polarity and compare its level with a reference voltage. Polarity is an indication of which direction the signal is off null; level is an indication of how close the signal is to the null. Two gate controls, one for C and one for D,G are actuated by the comparator output. The gate controlling the Cs and G, relays is closed, and the gate to operate the first C dis Digital Signals For Cs Attenuators And C Display Digital Signals For G8 Attenuators And D,G Display Control Signals For Cs, G5 Relay PARAMETER CHANGE CIRCUIT 'Bridge Balanced' Signal Stops Measurement 17 © Copr. 1949-1998 Hewlett-Packard Co. Similarity Ã- c = jiaCsec = j<aCaAce0 lo = Gse0 = GsAUi0e0 (2) At bridge balance, id = 0. Then i<, = ix + ic + ÃG = 0. T h u s C x - â € ” A C C S GX = — AD¡GGS To measure dissipation factor D, the slide switch on the front panel is moved to D. Substituting source voltage e'o (see Fig. 2) for source voltage e,,, I'D = GseD = GsAD¡Be'0 = G,AüiGAi,er (3) Since id = ix + ic + ÃD = 0, from equations (1), (2) and (3), _ GX — GsAutoADAr' Gs ¿ ^ o)C.\ [n the Model 4270A, Fig. 4. Feedback admittance in the current detector is adjusted automatically to maintain constant bridge sensi tivity over the operating range. - is selected to be ^— and AD = — 27T resistance is thus kept constant, regardless of the attenua tor setting. Stray capacitances can cause differences in the time constant between the attenuator resistors. This appears as error in measuring dissipation factor or conductance especially at 1MHz. In the Model 4270A, the attenua tors are shielded, and the highest value resistors have adjustments so that time constant differences can be kept below 1 00 picoseconds. 10 ' Thus, D x — A o, G (4) At balance then, Cx = — AcCs, Gx = — AD,0G8 and Dx = — AD, Q. As mentioned previously, the front panel readouts are an interpretation of attenuator settings, which set the gains AC and ADj0 in the above equations. Three-terminal measurements reduce errors introduced by stray capacitance. In a conventional ac bridge, a transformer isolates the source voltage so that threeterminal measurements are possible. But transformers have limited frequency range. Therefore, another scheme was used in the Model 4270A to cover the 1 kHz to 1 MHz frequency range with only one bridge network. In the Model 4270A, each measurement arm consists of a resistance attenuator and an operational amplifier. All of the amplifiers have identical frequency and phase characteristics. All use low-impedance elements to reduce effects of stray capacitance at high frequencies. All components in the resistance attenuator are like wise low-impedance elements. The resistance attenuators are a form of digital-to-analog converter. Digital signals actuate the switching transistor, adding or removing re sistances, and producing an analog output voltage. Switching transistors are in series with the standard resistors in the attenuator. It is possible to compensate for any deviation in each resistor by adjusting the base current of its switching transistor. Switching is so ar ranged that unused resistances are grounded. The output Current Detector When using the guarded three-terminal method of measurement, terminal-to-ground capacitance will de crease the sensitivity of a voltage sensitive null detector. With a phase sensitive null detector, this capacitance causes phase shift which also reduces the detection capa bility. A solution to this problem, used in the Model 4270A, is the current sensitive detector and preamplifier with low input impedance. The detector has a feedback circuit, Fig. 4, consisting of an adjustable capacitor and resistor. Values of the feedback capacitance and resistance are adjusted to (1) maintain constant detector sensitivity, (2) maintain a con stant phase relationship between the bridge driving volt age e(J and the detector voltage ed, and (3) maintain a low input impedance to the detector preamplifier. This as sures stable bridge operation and reduces problems asso ciated with phase detection. Because the input impedance to the detector preampli fier is low. the voltage at that point is low. Thus the effect of stray capacitance is negligible. Also, the low input 18 © Copr. 1949-1998 Hewlett-Packard Co. SPECIFICATIONS HP Model 4270A AUTOMATIC CAPACITANCE BRIDGE MEASURING CIRCUIT: FLOAT: Guarded terminals of unknown are floated from ground. L-GROUND: One side of unknown terminals is grounded, guard is re tained. STANDARD CAPACITANCE: PARAMETERS MEASURED: Capacitance, equivalent parallel conduct ance and dissipation factor. MEASURING FREQUENCY: 1 kHz, 10 kHz, 100 kHz and 1 MHz, ±1%. AVAILABLE FULL SCALE RANGES: CAPACITANCE CONDUCTANCE 10 kHz 100 kHz 1 MHz 18.000pF 999. 9n 180.00pF 18.000pF 9.999ii 1800. OpF 1 8 0 . 0 0 p F 1 8 . 0 0 0 p F 99.99^ 18.000nF 1800.0pF 180.00pF 999. 9ft ISO.OOnF 18.000nF 1200.0pF 9.999m DISSIPATION FACTOR 0.9999 REPEATABILITY: ±2 digits at NORMAL TEST VOLTAGE, ±8 digits at LOW TEST VOLTAGE. RANGE MODE: AUTO: Range selection and balance performed automatically. HOLD: Range is held on fixed position determined by previous AUTO and can be selected manually by stepping RANGE STEP. Balance begins with fourth digit from right. TRACK: Range held on fixed position, balance begins with last digit. BALANCING TIME: Typically 0.5 s. MEASURING RATE: Measurement cycle equals balance time plus dis play time. Balance time typically 0.5 s. Display times selected by MEAS RATE are 70 ms, 2 s, 5 s, and MANUAL. RESET: Bridge is reset and new balance operation started automatically (at MEASURING RATE), or manually by RESET pushbutton, or re motely by contact closure. If the unknown changes value during the balance operation, or other changes shift the unknown outside of the balance range, the bridge resets to rebalance after 2 seconds. TEST VOLTAGE ACROSS UNKNOWN: NORMAL: 500 mV rms constant, at capacitance units displayed in pF or nF, 100 mV rms constant at /iF. LOW: 100 mV rms constant at pF or nF. 20 mV rms constant at ¡if. Other test voltages are available. ACCURACY: CAPACITANCE, CONDUCTANCE AND DISSIPATION FACTOR: DC BIAS: INTERNAL or EXTERNAL to ±200 V, in HOLD and TRACK mode. INTERNAL BIAS at FLOAT measurement: VOLTAGE: 0 to 20 V de; O to 200 V dc; continuously variable on front panel, monitored on rear panel. DIAL ACCURACY: ±5% of full scale. SOURCE RESISTANCE: 100 kfl. POLARITY: LOW unknown terminal (-), HIGH unknown terminal ( + ) in FLOAT position of MEAS CKT control. REMOTE: Programmable by resistor with 250 Ã.VV rate at 20 V range, 25 fi/V rate at 200 V range. REMOTE ACCURACY: ±2% of full scale. INTERNAL BIAS at L-GROUND: An additional connection using a blocking capacitor and a coaxial cable is necessary for INTERNAL source. DATA OUTPUTS: (If unknown in FLOAT) CODE: Positive 4 line BCD (1-2-4-8), 13 columns consisting of decimal location, overrange, units, 5 digits of capacitance and 4 digits of conductance or dissipation factor. '1' LEVEL: +5 V, open circuit, source Impedance 7.5 kSi at all data except at 10« digit of C data and OVER-RANGE. +4V, open circuit, source impedance 7.5 k2 at 10' digit of C data and OVER-RANGE. '0' LEVEL: Ground. PRINT COMMAND: DC coupled, print level + 5 V, print holdoff level 0V. INPUTS: TRIGGER HOLD OFF LEVEL: Level must be between -10 V and -15 V. REMOTE PROGRAMMING: Eight front-panel functions can be remotely controlled by external contact closure to ground with impedance less than 400 Q. Programmable functions are RESET, FREQUENCY, RANGE MODE, TEST VOLTAGE, LOSS MEASUREMENT, RANGE STEP, DC BIAS RANGE, BIAS VERNIER. OPERATING TEMPERATURE: 0°C to 50°C. POWER REQUIREMENTS: 115 or 230 V ac ±10%, 50 to 60 Hz, approx. 110 W. WEIGHT: 34 Ib (15.5 kg). PRICE: $4825.00. NOTE: Cs = internal standard capacitor. Cx = capacitance measured. Dx = dissipation factor measured. FREQUENCY: ±1%. MANUFACTURING DIVISION: YOKOGAWA-HEWLETT-PACKARD LTD. 9-1, Takakura-cho Hachioju-shi Tokyo, Japan © Copr. 1949-1998 Hewlett-Packard Co. impedance nearly eliminates noise induced by electro static coupling, mainly power line noise. Capacitance introduced by connecting cables may be balanced out with an available option. Applications For development of new components, circuits or sys tems, the Model 4270A can be operated as an indepen dent lab-type instrument. It can be used to measure discrete capacitor values, cable capacitance and loss, input and output capacity, strays, junction capacitance and other non-linear capacitances. Other areas using the instrument alone include quality assurance, production or incoming inspection. The HP Model 4270A has been designed for use with other instruments, computers or in systems. Data out puts (measured value, multiplier and units) are available in BCD form. Signals for remote programming are sup plied to the bridge through a rear-panel connector. All major functions can be controlled individually. Thus, the Model 4270A finds application in quality control, reliability analysis, and statistical analysis of products. Users are able to make comparison checks, environmen tal classification, sorting and inspection. In-process testing of integrated circuits is another important application. There are also applications where capacitance itself is not the main parameter being measured, but ca pacitance is monitored to derive other information. For example, in process control, dielectric or capacitance variation may be monitored. Changes in capacity or loss indicate changes in other physical parameters. Acknowledgments The authors wish especially to acknowledge the con tributions of the following people: Giichi Yokoyama, who proposed the original idea of 4270A; Hiroatsu Kohno who did the mechanical design; and Kazunori Shibata who handled the industrial design phase of the project. Other contributors include Masakatsu Shida, Arimichi Nakagiri and Saburo Sugihara. S Reference [1]. K. Yoshimoto, 'A New Universal Impedance Bridge; Hewlett-Packard Journal, Sept. 1966. Hitoshi Noguchi Hitoshi Noguchi obtained a BSEE degree from Akita University in 1961. He then joined Yokogawa Electric Works as an R and D engineer, working on the development of signal generators. Hitoshi joined Yokogawa HewlettPackard in 1964, working on the design of the Model 4260A Universal Bridge, and then on the design of the Model 4270A as the project leader. Takeo Shimizu Takeo Shimizu received his BSEE degree from Fukui University in 1961, and joined Yokogawa Electric Works as an R and D engineer, working on the development of a dc potentiometer, dc bridge, and mechanical strain measure ment. Takeo joined YHP as a senior field engineer in 1964. In 1966 he transferred to the R and D section and developed logic section circuitry for the HP Model 4270A. Koichi Maeda Koichi Maeda received his BSEE from Waseda University, Tokyo, in 1 963. After a year of working at Yokogawa Electric Works as an R & D engineer, he joined YHP in 1964. At YHP he worked on oscillator devel opment, specifically on the design of the Model 4204A Digital Oscillator. He designed the bridge section circuitry for 4270A. HEWLETT-PACKARDJOURNAL_©MAY1970volume21•Number9 TECHNICAL CALIFORNIA FROM THE LABORATORIES OF THE HEWLETT-PACKARD COMPANY PUBLISHED AT 1501 PAGE MILL ROAD. PALO ALTO. CALIFORNIA 94304 Editor: Danielson A Jordan Editorial Board: R. P. Dolan, H. L. Roberts, L. D. Shergalis Art Director: Arvid A Danielson Assistant: Maridel Jordan © Copr. 1949-1998 Hewlett-Packard Co.