TTPACKAKD JOURNAL — -» — AUGUST 1975

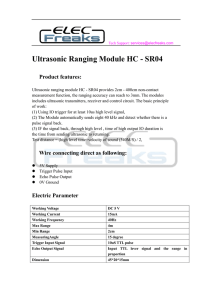

advertisement