Derivation of the bending stiffness from REBO potential

advertisement

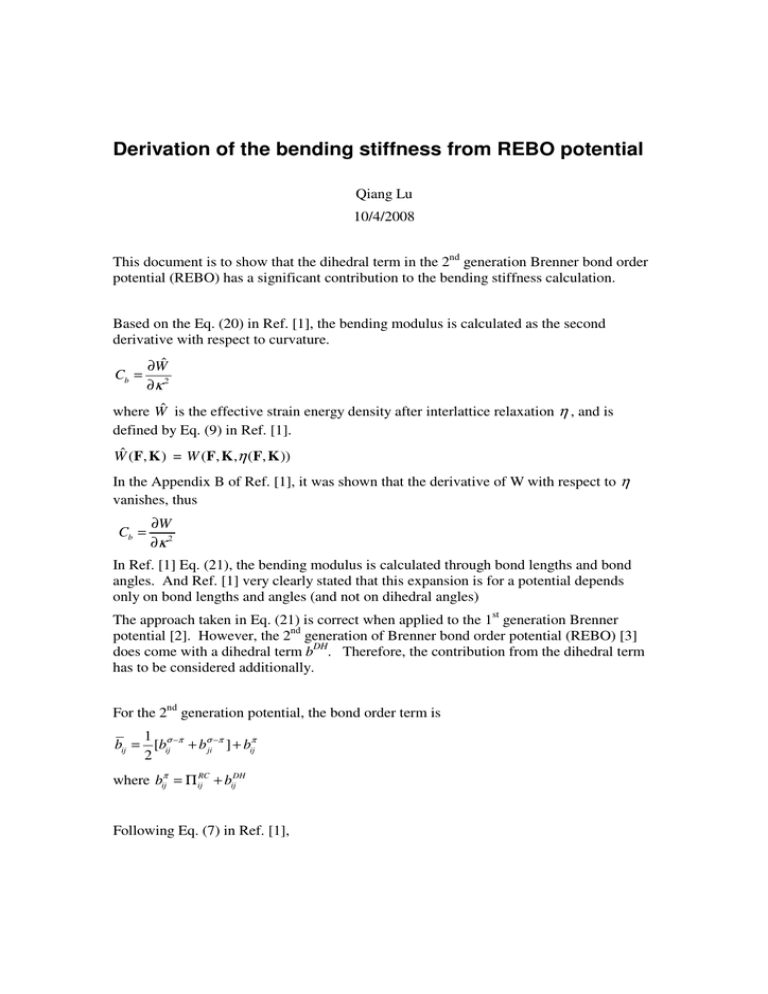

Derivation of the bending stiffness from REBO potential Qiang Lu 10/4/2008 This document is to show that the dihedral term in the 2nd generation Brenner bond order potential (REBO) has a significant contribution to the bending stiffness calculation. Based on the Eq. (20) in Ref. [1], the bending modulus is calculated as the second derivative with respect to curvature. Cb = ∂Wˆ ∂κ 2 where Ŵ is the effective strain energy density after interlattice relaxation η , and is defined by Eq. (9) in Ref. [1]. Wˆ (F, K ) = W (F, K ,η (F, K )) In the Appendix B of Ref. [1], it was shown that the derivative of W with respect to η vanishes, thus Cb = ∂W ∂κ 2 In Ref. [1] Eq. (21), the bending modulus is calculated through bond lengths and bond angles. And Ref. [1] very clearly stated that this expansion is for a potential depends only on bond lengths and angles (and not on dihedral angles) The approach taken in Eq. (21) is correct when applied to the 1st generation Brenner potential [2]. However, the 2nd generation of Brenner bond order potential (REBO) [3] does come with a dihedral term bDH. Therefore, the contribution from the dihedral term has to be considered additionally. For the 2nd generation potential, the bond order term is 1 bij = [bijσ −π + bσji −π ] + bijπ 2 where bijπ = Π ijRC + bijDH Following Eq. (7) in Ref. [1], W ( F , K ,η ) = Cb = 1 S0 3 ∑ [V R − bijVA ] = i =1 1 S0 3 ∑ [V R − bij0VA − bijDH VA ] i =1 1 ∂2 3 ∂W 1 [VR − bij0VA ] − = 2 2 ∑ S0 ∂κ i =1 ∂κ S0 3 ∑ i =1 ∂ 2 (bijDH VA ) ∂κ 2 1 where bij0 = [bijσ −π + bσji −π ] + Π ijRC . The radical term Π ijRC vanishes for solid state 2 structures. Due to the way Eq. (21) was taken, only the contribution from bij0 was calculated. The contribution from bijDH was ignored. Here I show how the dihedral term bijDH makes a contribution to the bending modulus calculation. According to the REBO paper [3], bijDH = Tij ( N it , N tj , N ijconj ) ∑ ∑ (1 − cos 2 (Θijkl ) f ikc (rik ) f jlc (rjl )) k ≠ i , j l ≠i , j where Tij is a constant for solid state structures, Θijkl is the space angle between the bond ik and bond jl, and for moderate deformation, the cutoff functions can be considered as constant 1. Following the same approach taken in the Appendix B of Ref. [1], at ground state, ∂ 2 (bijDH VA ) ∂κ 2 = VA ∂ 2bijDH ∂κ 2 = TijVA ∑ ∂2 ∑ ∂κ 2 [sin 2 (Θijkl )] k ≠i , j l ≠i , j ∂Θijkl ∂Θijkl ∂2 ∂ ∂ [sin 2 (Θijkl )] = [2sin Θijkl cos Θijkl ]= [sin 2Θijkl ] 2 ∂κ ∂κ ∂κ ∂κ ∂κ 2 ∂ 2 Θijkl ∂Θijkl + sin 2 Θ = 2 cos 2Θijkl ijkl ∂κ 2 ∂κ At ground state, Θijkl goes to zero. Thus, ∂Θ ∂2 [sin 2 (Θijkl )] = 2 ijkl 2 ∂κ ∂κ ∂ 2 (bijDH VA ) ∂κ 2 2 ∂Θ = 2TijVA ∑∑ ijkl k l ∂κ 2 The dihedral angles depend on the curvature and the bond directions. Take zigzag nanotube for example, bond ij can be either perpendicular, or π/6 to the circumferential direction. l1 k1 l1 j l2 j i l2 k2 k2 i k1 The dihedral angle can be calculated as a function of curvature from three dimensional geometry. For the bond perpendicular to the circumferential direction, among the four dihedral angles, Θijk1l1 = Θijk2l2 = 0, Θijk1l2 = Θijk2l1 . For the bond π/6 to the circumferential direction, Θijk2l2 = 0, Θijk1l2 = Θijk2l1. Similar observation is taken for armchair nanotube. For the bond parallel to the circumferential direction, among the four dihedral angles, Θijk1l1 = Θijk2l2 = 0, Θijk1l2 = Θijk2l1. For the bond π/3 to the circumferential direction, Θij1k2l2 = 0, Θij1k1l2 = Θij1k2l1. l1 k2 k1 i j l2 j l1 k2 i l2 k1 The analytical results of the dihedral angles are obtained, but too long to show here. Plots of the dihedral angles and their derivatives are shown in following figures For armchair nanotubes 2.5 2 Parallel, Θ ijk1l2 π/3, Θ ijk1l1 π/3, Θ Dihedral angle ijk1l2 1.5 1 0.5 0 0 2 4 6 Curvature (1/nm) 8 10 The derivatives of the dihedral angles with respect to curvature 2.5 dΘ /dK 2 1.5 1 0.5 Parallel, dΘ /dK ijk1l2 π/3, dΘ ijk1l1/dK /dK π/3, dΘ ijk1l2 0 0 2 4 6 Curvature (1/nm) 8 10 For zigzag nanotubes 2 Dihedral angle 1.5 Perpendicular, Θ ijk1l2 π/6, Θ ijk1l1 π/6, Θ ijk1l2 1 0.5 0 0 2 4 6 Curvature (1/nm) 8 10 Derivative of dihedral angles with respect to the curvature 2.5 Perpendicular, dΘ /dK ijk1l2 /6, d /dK π Θ ijk1l1 /dK π/6, dΘ ijk1l2 dΘ /dK 2 1.5 1 0.5 0 2 4 6 Curvature (1/nm) 8 10 ∂Θijkl The final results of ∂κ at ground state are shown in the table Bond direction dΘij1k1l1/dK Perpendicular 0 π/6 3r0 Parallel 0 π/3 3r0 dΘij1k1l2/dK dΘij1k2l1/dK dΘij1k2l2/dK 3 r0 2 3 r0 2 0 3 r0 2 3 r0 2 0 3 r0 2 3 r0 2 0 3 r0 2 3 r0 2 0 For atom i on an armchair nanotube, among the 3 bonds surrounding it, one is parallel to the circumferential direction, the other two bond are π/3 to it. 3 ∑ i =1 ∂ 2 (bijDH VA ) ∂κ 2 = ∂ 2 (bijDH VA ) ∂κ 2 |0 +2 ∂ 2 (bijDH VA ) ∂κ 2 |π / 3 2 2 ∂Θijkl ∂Θijkl | + 2 |π / 3 = 21TijVA r02 = 2TijVA ∑∑ ∑∑ 0 k l ∂κ k l ∂κ Exactly same result is obtained for zigzag. Therefore, the bending stiffness including the contribution of the dihedral term is ∂W 1 ∂2 3 1 Cb = 2 = [VR − bij0VA ] − 2 ∑ ∂κ S0 ∂κ i =1 S0 3 ∑ ∂ 2 (bijDH VA ) i =1 ∂κ 2 1 d (bijσ −π + bσji −π ) 14 3T V 3VA 2 ij A = − − 4 d cos θ 3 Here S0 is the area of a hexagon. S0 = 3 3 2 r0 2 The first part is directly taken from Ref [1], and the second part is the contribution of the dihedral term. On Brenner’s REBO paper [3], Tij = -0.00809675. In our atomistic simulation, for some reason, Tij is taken as half of this number. In this case, Cb = 2.246 × 10-19 Nm Following is a comparison between our atomistic simulation and the above theoretical analysis. They match exactly. Bending stiffness (10-19Nm) 2.4 Simulation Linear fit Analytical 2.2 2 1.8 1.6 0 0.5 1 Curvature (1/nm) 1.5 2 This is about twice of what Ref [1] gives (1.1 × 10-19 Nm). Ref. [4] took a different approach, but ignored the contribution of the dihedral term for the 2nd generation Brenner potential too. Their result is identical to Ref. [1]. Reference 1. M. Arroyo and T. Belytschko, Finite crystal elasticity of carbon nanotubes based on the exponential Cauchy-Born rule. Physical Review B, 2004. 69(11). 2. D.W. Brenner, Empirical potential for hydrocarbons for use in simulating the chemical vapor deposition of diamond films. Physical Review B, 1990. 42(9485-9471). 3. D.W. Brenner, O.A. Shenderova, J.A. Harrison, S.J. Stuart, B. Ni, and S.B. Sinnott, A second-generation reactive empirical bond order (REBO) potential energy expression for hydrocarbons. Journal of Physics-Condensed Matter, 2002. 14(4): p. 783802. 4. Y. Huang, J. Wu, and K.C. Hwang, Thickness of graphene and single-wall carbon nanotubes. Physical Review B, 2006. 74(24).