Large Deformation Plasticity of Amorphous Solids, with Application and Implementation into Abaqus

advertisement

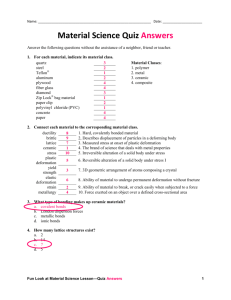

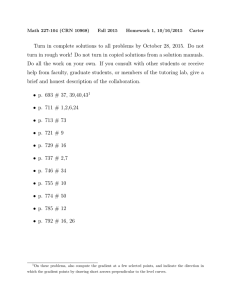

Large Deformation Plasticity of Amorphous Solids, with Application and Implementation into Abaqus Kristin M. Myers January 11, 2007 Plasticity ES 246 - Harvard References: [1] Anand, L., Gurtin, M.E., 2003. “A theory of amorphous solids undergoing large deformations, with application to polymeric glasses.” International Journal of Solids and Structures 40, 1465-1487. [2] Boyce, M. C., Arruda, E. M., 1990. “An experimental and analytical investigation of the large strain compressive and tensile response of glassy polymers.” Polymer Engineering and Science 30 (20), 12881298. [3] Lubliner, J. Plasticity Theory. 1990. Macmillan Publishing Company. (Chapter 8) [4] Abaqus 6.5-4 Documentation “Getting Started with ABAQUS/EXPLICIT.” Hibbitt, Karlsson & Sorensen,INC. Motivation – Examples of Materials • Amorphous Solids – – polymeric and metallic glasses (i.e. Polycarbonate) – Rubber degradation • Biomaterials – Soft Collageneous Biological Tissue (i.e. cartilage, cervical tissue, skin, tendon, etc.) – Engineering Collagen Scaffolds (i.e. skin, nerve, tendon etc.) Material Characteristics: 1. Large stretches – elastic & inelastic 2. Highly non-linear relationships between stress/strain 3. Time-Dependent; viscoplasticity 4. Strain hardening or softening after initial yield 5. Non-linearity of tension & compression behavior (Bauschinger effect) Experimental Results – Polycarbonate From Boyce and Arruda COMPRESSION TENSION • Large deformation regime • Strain-softening after initial yield • Back stress evolution after yield drop to create strain-hardening Kinematics – Multiplicative Decomposition of the Deformation Gradient p e d x F X d l Segment of the “current F X configuration” e F X dl F p X d X Segment of the “relaxed configuration” “Relaxed Configuration”: Intermediate configuration created by elastically unloading the current configuration and relieving the part of all stresses. F y( X , t ) Deformation Gradient FF F Decomposition of deformation gradient into its elastic and plastic components (Kroner-Lee) e p v y ( X , t ) Velocity tensor 1 L grad v F F Velocity Gradient Kinematics – Multiplicative Decomposition of the Deformation Gradient II LL F L F e e p e 1 1 e e e e L F F D W e D sym L e 1 p p p p L F F D W p e D sym L p p W skwL e e W skwL p p • Conditions of Plastic Flow – Incompressible det F 1 p J det F det F tr L 0 p W 0 p p p F D F p – Irrotational L D p p e Principle of Objectivity Principle of Material Frame Indifference Smooth time-dependent rigid transformations of the Eulerian Space: y( X , t ) y ( X , t ) Q(t ) y( X , t ) q(t ) * Principle of Relativity: relation of the two motions is equivalent Q(t ) Relative motion of two observers Eulerian bases g Qg * To be objective (in general): F Q F F Q F e e e T D Q D Q e e * T The relaxed and reference configurations are invariant to the transformations of the Eulerian Space T L Q L Q QQ e G QGQ T F P e e T T W QW Q Q Q D P Principal of Virtual Power • External expenditure of power = internal energy ~e 1 P ~ P ~ ~ Wext t (n) v dA f b v dVt Wint T L J T D dVt dP P Macroscopic Force Balance divT f b 0 P • Internal energy Wint is invariant under all changes in frame * Wint Wint – Microforce Balance Wint T D J 1T P D dVt P e P Dissipation Inequality and Constitutive Framework • 2nd Law of Thermodynamics: The temporal increase in free energy ψ of any part P be less than or equal to the power expended on P J T D T D 0 e P P • Constitutive framework: ˆ ( F , F ) Free energy, stress, and e P ˆ T T (F , F ) internal variables are a function of deformation. T P Tˆ P ( F e , F P , D P , ) e P e P P i h (F , F , D , ) Constitutive Theory – Framework • Frame Indifference – Euclidean Space – Amorphous Solids: material are invariant under all rotations of the Relaxed and Reference Configuration ˆ ( F , F ) (C , B ) e P ˆ T T (F , F ) T F T (C , B ) F P e P P ˆ T T (F , F , D , ) e P P i h (F , F , D , ) T T (C , B , D , ) e P P i h (C , B , D , ) e P P e e P P e P e P P eT P Constitutive Theory – Thermodynamic Restrictions and Flow Rule e P C B e P C B (C e , B P ) e F T 2 J F e C e P ( C , B ) P P T 2symo Y P B 1 S back Energy dissipated per unit volume (in the relaxed configuration) must be purely dissipatative. Dissipative FLOW STRESS: e FLOW RULE: Define: Plug into dissipation inequality (C e , B P ) 2 symo P B Y (C , B , D , ) D 0 P e P P P Y (C , B , D , ) S o S back P e P S 0 2 symo C T e P e e (C e , B P ) 2 symo C e C Constitutive Equations material parameters • Free Energy e GE e e 2 o 1 / 2K tr E e 2 P Constitutive prescription P (P ) • Equations for Stress T 2G E o K tr E 1 e e eT T R TR e e e Te Stress conjugate to Ee T R T R e e eT = Cauchy Stress Constitutive Equations material parameters • FLOW RULE for Plastic STRETCHING P P P F D F F T B P D P 2 e o P o P Constitutive prescription X ,0 1 Effective Stress: 1/ m s p P o 1 2 T B e o P o DP=(magnitude)(DIRECTION) • Evolution of Internal Variables s s ho 1 ~ P s ( ) s 1 P scv g o = evolution of shear resistance (captures strain softening) = change in free-volume from initial state Saturation value: ~ s ( ) scv 1 b(cv ) Micrograph by Roeder et al, 2001 Evolution of the Back Stress: Langevin Statistics undeformed Amorphous polymeric materials: • Wavy kinked fibrous network structure • Resistance of the network in tension • Have finite distensibility (maximum stretch L ) • Once material overcomes the resistance to intermolecular chain motion chains will align w/principle plastic stretch (Bp,λp) •Alignment decreases the configurational entropy creates an internal network back stress Sback Force-stretch relationship: - Initially compliant behavior followed by increase in stiffness as the limiting stretch is approached deformed L 1 (P ) P 3 P P R L P Force L0 2 L Stretch x .... L( ) coth( ) ( ) 1 L Limiting extensibility P L 1 R P L 3 L Parameters: •Rubbery Modulus •Limiting stretch L L0 State Variables in Summary: In VUMAT C********************************************************************** C STATE VARIABLES - Variables that need to be evolved with TIME C STATEV(1) = Fp(1,1) -- PLASTIC DEFORMATION GRADIENT, (1,1) COMP. C STATEV(2) = Fp(1,2) -- PLASTIC DEFORMATION GRADIENT, (1,2) COMP. C STATEV(3) = Fp(1,3) -- PLASTIC DEFORMATION GRADIENT, (1,3) COMP. C STATEV(4) = Fp(2,1) -- PLASTIC DEFORMATION GRADIENT, (2,1) COMP. C STATEV(5) = Fp(2,2) -- PLASTIC DEFORMATION GRADIENT, (2,2) COMP. C STATEV(6) = Fp(2,3) -- PLASTIC DEFORMATION GRADIENT, (2,3) COMP. C STATEV(7) = Fp(3,1) -- PLASTIC DEFORMATION GRADIENT, (3,1) COMP. C STATEV(8) = Fp(3,2) -- PLASTIC DEFORMATION GRADIENT, (3,2) COMP. C STATEV(9) = Fp(3,3) -- PLASTIC DEFORMATION GRADIENT, (3,3) COMP. C C STATEV(10)= Internal variable S - shear resistance C C STATEV(11)= dFp(1,1) -- incre in PLASTIC DEFORMATION GRADIENT, (1,1) COMP. C STATEV(12)= dFp(1,2) -- incre in PLASTIC DEFORMATION GRADIENT, (1,2) COMP. C STATEV(13)= dFp(1,3) -- incre in PLASTIC DEFORMATION GRADIENT, (1,3) COMP. C STATEV(14)= dFp(2,1) -- incre in PLASTIC DEFORMATION GRADIENT, (2,1) COMP. C STATEV(15)= dFp(2,2) -- incre in PLASTIC DEFORMATION GRADIENT, (2,2) COMP. C STATEV(16)= dFp(2,3) -- incre in PLASTIC DEFORMATION GRADIENT, (2,3) COMP. C STATEV(17)= dFp(3,1) -- incre in PLASTIC DEFORMATION GRADIENT, (3,1) COMP. C STATEV(18)= dFp(3,2) -- incre in PLASTIC DEFORMATION GRADIENT, (3,2) COMP. C STATEV(19)= dFp(3,3) -- incre in PLASTIC DEFORMATION GRADIENT, (3,3) COMP. C C STATEV(20)= Internal variable eta: eta=0 at virgin state of the material, C and change in free volume with time evolution C C********************************************************************** Material Parameters in Summary: In VUMAT C---------------------------------------------------------------------C MATERIAL PARAMETERS C C Elastic Properties C EG = elastic shear modulus C EK = elastic bulk modulus C Langevin Properties (Statistical Mechanics) C MU_R = rubbery modulus C LAMBDA_L = network locking stretch C C D0 = reference (initial) plastic shear-strain rate C m = plastic strain rate dependency (m=0; rate independent) C ALPHA = coefficent of pressure dependency C Internal Variable S coefficients (s monitors the isotropic resistance to deformation C H0 = initial hardening rate C SCV = equilibrium hardening strength C SO = initial resistance to flow (yield point) C Coefficients for ETA - free volume C G0 = coefficent of plastic dilantancy C b = coefficient for evolving eta C NCV = equilibrium value for free volume C---------------------------------------------------------------------- • • • • VUMAT Program F_t = F at start of step F_tau = F at end of step U_tau = U at end of step For the first time step – – – – – – – – • Initialize state variables Fp_tau = 1 Fe_tau=F_tau Calculate Ce_tau Calculate Ee_tau Calculate Te_tau Calculate T_tau Rotate Cauchy stress to Abaqus Stress and update Abaqus stress variables For other time steps – – – – – – – – – Get state variables from last step Calculate Fp_tau Normalize Fp Calculate Fp_tau_inv Calculate Fe_tau Calculate Ce_tau Calculate Ee_tau Calculate Te_tau Calculate pressure – Calculate Tmendel; Mendel stress – Calculate μ Bp_tau_dev; Back Stress (USE LANGEVIN) – Calculate Tflow; Flow Stress – Calculate tau: Equivalent Shear Stress – IF tau is not ZERO THEN • • • • EVOLVE DP; calculate ANUp; EVOLVE dFp EVOLVE S EVOLVE eta – IF tau is ZERO • Do not evolve state variables – Update Fp, F, C, U, T – Update state variables – Update Abaqus stresses