Efficient Estimation of Fuel Consumption Using Fuzzy Logic Latha P S

advertisement

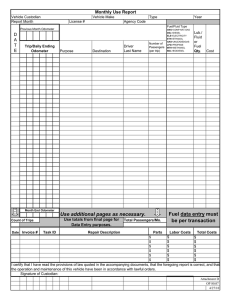

International Journal of Engineering Trends and Technology (IJETT) – Volume 16 Number 1 – Oct 2014 Efficient Estimation of Fuel Consumption Using Fuzzy Logic Latha P S1, Menaga N2, Manjunath T K3 1,2 Asst. Prof. Dept. Of Computer Science And Engineering Mahendra College Of Engineering,Anna University,Tamil nadu ,India Assoc. Prof. 3 Dept. Of Computer Science And Engineering AIeMS,VTU,Bangalore,India. ABSTRACT- Fuzzy logic is a rule based system which is implemented using if then rules. For example two parameters say x & y are varied in order to know which parameter effects the fuel efficiency. This paper explores in particular the use of fuzzy logic in the Efficient estimation of fuel consumption. We present an intelligent Engine Control Unit (ECU) that controls a series of actuators on an internal combustion engine to ensure optimal engine performance. Here, PCA is used to reduce the data collected using reduction algorithm where Principal Component Analysis (PCA) is the best, in the mean-square error sense, linear dimension reduction technique. It is a statistical procedure that uses orthogonal transformation to convert a set of observations of possibly correlated variables into a set of values of linearly uncorrelated variables called principal components. Hence, The fuel efficiency of the vehicle and the efficiency of the driver can be calculated using the sensor data available in the vehicle. Key words: ECU, CAN bus , PCA ,fuzzy logic. I. INTRODUCTION An Engine Control Unit (ECU), now called the Power train Control Module (PCM), is a type of electronic control unit that controls a series of actuators on an internal combustion engine to ensure optimal engine performance. It does this by reading values from a multitude of sensors within the engine bay, interpreting the data using multidimensional performance maps (called lookup tables), and adjusting the engine actuators accordingly. CAN bus (for controller area network) is a vehicle bus standard designed to allow microcontrollers and devices to communicate with each other within a vehicle without a host computer. An on-board instrumentation capable to communicate with the electronic system of the vehicle (OBD/CAN) have been developed to collect all the sensor data available and use them as input for power and consumption models. Here is the proposed reduction Optimization algorithms that either require the data to be sphered, or they converge better for sphere data. Sphering is a linear transformation that maps x into a new variable v with unit covariance matrix: Here we are using Fuzzy logic which is a form of manyvalued logic; it deals with reasoning that is approximate rather than fixed and exact. Compared to traditional binary sets ISSN: 2231-5381 (where variables may take on true or false values), fuzzy logic variables may have a truth value that ranges in degree between 0 and 1. Fuzzy logic has been extended to handle the concept of partial truth, where the truth value may range between completely true and completely false. Furthermore, when linguistic variables are used, these degrees may be managed by specific functions. Irrationality can be described in terms of what is known as the fuzzjective. II. RELATED WORK In the modern society, as the rapid development of automotive industries, environment pollution gradually becomes a challenged problem to which more and more people pay much attention. The increased environment awareness and requirement for drivability have raised the interest and investment in the researches of complicated automotive modeling and control methods. One of the researches concerns on a high power output while still maintaining a good fuel economy. In order to meet the requirements of high fuel combustion efficiency, balanced torque and power output, the performance development of a 1.5L small gasoline engine has been carried out. The technologies for high power and low fuel consumption include optimized combustion system and optimized gas exchange system. During the process of engine development, advanced engine simulation tools were applied to optimize design parameters in order to minimize the experimental iterations. The performance experiment of the engine has been verified. The test results show that the power is 80kW and the maximum torque is136N.m. The brake specific fuel consumption (BSFC) at part load condition of 2000r/min & 2bar is378g/kW/h. The engine performance achieves the development target. Alternative power trains for automotive applications aim at improving emissions and fuel economy. Lack of experience with these relatively new technologies makes them ideal applications for computer-based modeling and simulation studies. There is a variety of configurations, control strategies, and design variable choices that can be made. If mathematical models exist, rigorous optimization techniques can be used to explore the design space. This provides an overview of a design environment for alternative power trains that has these characteristics: modularity, allowing a system to be built by http://www.ijettjournal.org Page 36 International Journal of Engineering Trends and Technology (IJETT) – Volume 16 Number 1 – Oct 2014 combining components, flexibility, allowing different levels of fidelity and different existing codes to be used; and, rigor, since it is based on mathematical methods of decision making. A simple application to a hybrid diesel-electric power train is included. Although the recent technological improvements in engine, fuel and after-treatment devices, road transport is still responsible for air pollution in urban area due to increasing number of circulating vehicles and their relative travelled distances. The actual European type approval procedure for passenger cars and light-duty vehicles fixes standard limits for exhaust pollutants to be respected during the execution of a normalized driving cycle. This kind of procedure is not representative of the real on-road use of vehicles, characterized by a more dynamic speed profile: a fixed driving cycle, equal for all the vehicles penalizes low power weight ratio vehicles that see the driving cycle more hard to execute than vehicles with higher ratios and does not take account for the driving style; the influence of driving style to the emissions in driving the same vehicle is not negligible [1, 2]. In previous years a lot of on-board pollutant measurements at the exhaust of vehicles was carried out in order to assess the real emission and consumption behavior: the high costs of portable emissions analyzers (PEMS), their continuous maintenance and calibrations, the fragility of the components and the weight and the encumbrance do not allows big acquisition campaigns. Microscopic models produce emissions and fuel consumption estimates with higher temporal resolution than other scales of models. Most emissions and fuel consumption models were developed with data from dynamometer testing which are sufficiently accurate for macroscopic level emissions inventories. The primary goal of this project is to improve the microscopic modeling of emission and fuel consumption by integrating detailed vehicle data into the simulation. The proposed approach combines a microscopic traffic simulation model (VISSIM) with detailed emissions and fuel consumption data that is either collected in the field or obtained from an existing emission inventory dataset. The project also examines the possibility of using the vehicle’s On-Board Diagnostic Board (OBD) to record real-time engine and emissions data at a high temporal resolution. The outcome of this project provides transportation operators with a model that is capable of reliably estimating the environmental impact of various traffic management policies at the microscopic modeling and would fill a gap that currently exists in traffic modeling capabilities[8]. There are two basic approaches that may be taken to combine the Environmental Protection Agency (EPA) detailed emissions and fuel consumption data, used in the Motor Vehicle Emission Simulator (MOVES) model, with microscopic simulation tools, such as VISSIM[2]. ISSN: 2231-5381 One alternative is to use the microscopic simulation model vehicle specific power trajectory data as source activity input for a MOVES emissions model. This approach has the potential to improve the quality of source activity input to MOVES project scale analysis, as well as make the process of generating activity input simpler for the user. The second alternative is to use the emissions and vehicle data contained in the MOVES default database to improve the input to the microscopic simulation emissions module to assist users in developing custom emissions profiles in the emission module in order to more accurately represent the vehicle fleet operating in the United States. Full description of the two alternatives as well as a case study to illustrate how EPA MOVES’ data can be integrated into microscopic simulation [6]. In previous years in Europe NEDC(New European Driving Cycle) was designed to know the fuel consumption of vehicles but no consideration is given so far to driving conditions not represented by this cycle. This is a significant limitation of the approach, as the NEDC driving cycle covers only a small portion of the vehicle engine operation in both load and speed. Just to give an indication, while a typical passenger car sold today can accelerate from idle to 100 km/h at a rate of 2.8 m/s2, the NEDC imposes an acceleration of only 0.74 m/s2.while using NEDC many costumers recognize that the officially reported fuel consumption does not reflect the fuel consumption they experience as referenced in [10]. The previous work’s collected the vehicle data in real time and then the data is clustered into five groups. A scientific approach is conducted for the clustering using k-means algorithm and two driving features including average velocity and variance of velocity [7]. The hybrid regression models that predict hot stabilized vehicle fuel consumption and emission rates for light-duty vehicles and light-duty trucks are presented below. Key input variables to these models are instantaneous vehicle speed and acceleration measurements. The energy and emission models described in this work utilize data collected at the Oak Ridge National Laboratory that included fuel consumption and emission rate measurements (CO, HC, and NOx) for five light-duty vehicles and three light-duty trucks as a function of the vehicle’s instantaneous speed and acceleration levels. The fuel consumption and emission models are found to be highly accurate compared to the ORNL data with coefficients of determination ranging from 0.92 to 0.99. Given that the models utilize the vehicle's instantaneous speed and acceleration levels as independent variables, these models are capable of evaluating the environmental impacts of operational-level projects including Intelligent Transportation Systems (ITS). The models developed in this study have been incorporated within the INTEGRATION microscopic traffic simulation model to further demonstrate their application and relevance to the transportation profession. http://www.ijettjournal.org Page 37 International Journal of Engineering Trends and Technology (IJETT) – Volume 16 Number 1 – Oct 2014 Furthermore, these models have been utilized in conjunction with Global Positioning System (GPS) speed measurements to evaluate the energy and environmental impacts of operationallevel projects in the field are referenced in [11]. III. PROPOSED WORK The proposed system makes use of the sensors present in the automobiles i.e., the different sensor values are collected from the automobiles and the collected data is fed to a reduction algorithm. The algorithm reduces the M*N data to M*1 data. The reduced data is fed to the model prepared. The model calculates the fuel consumption of the driver. The model makes use of fuzzy logic to calculate the fuel consumption. Fuzzy logic is a rule based system it is implemented using if then rules. For example two parameters say x & y are varied in order to know which parameter effects the fuel efficiency. Transform an N x d matrix X into an N x m matrix Calculate the d x d co-variance matrix : Eigen vectors The scheme is composed of four phases. Ci,j(diagonal) is the variance of variable i Ci,j(off-diagonal) is the covariance between variables i and j Calculate the eigenvectors of the covariance matrix (orthonormal) Select m eigenvectors that correspond to the largest m eigenvalues. If A is a square matrix, a non-zero vector v is an eigenvector of A if there is a scalar λ (eigenvalue)such that =λv. If we think of the squared matrix as a transformation matrix, then multiply it with the eigenvector do not change its direction. Fig. 1 Four Phases 1. Phase -1 Data Extraction 3. Phase -3 Develop Logic There are various sensors in the automobiles and they are connected to different ECU’s these ECU’s are intern connected to the OBD port via the CAN bus. Develop logic is the program that will calculate the fuel efficiency of the driver. The develop logic code is developed based upon the fuzzy logic. Fuzzy logic is a rule based system it is based upon the if then rules. 2. Phase -2 Feature Extraction Feature extraction is a special form of dimensionality reduction. When the input data to an algorithm is too large to be processed and it is suspected to be notoriously redundant (e.g. the same measurement in both feet and meters) then the input data will be transformed into a reduced representation set of features (also named features vector). Transforming the input data into the set of features is called feature extraction. If the features extracted are carefully chosen it is expected that the features set will extract the relevant information from the input data in order to perform the desired task using this reduced representation instead of the full size input. Principle Component Analysis Principal Component Analysis (PCA) is a useful statistical technique that has found application in fields such as face recognition and image compression, and is a common technique for finding patterns in data of high dimension. It is a statistical procedure that uses orthogonal transformation to convert a set of observations of possibly correlated variables into a set of values of linearly uncorrelated variables called principal components. Steps Involved in PCA The following are the steps involved in PCA: ISSN: 2231-5381 Here two parameters say X and Y are varied to see the effect of those parameters on the fuel efficiency of the car. Suppose when we vary parameter X and find that the fuel efficiency is affected then we say that the parameter X is responsible for fuel consumption. Fuzzy Logic Fuzzy logic is a form of many-valued logic; it deals with reasoning that is approximate rather than fixed and exact. Compared to traditional binary sets (where variables may take on true or false values), fuzzy logic variables may have a truth value that ranges in degree between 0 and 1. Fuzzy logic has been extended to handle the concept of partial truth, where the truth value may range between completely true and completely false. Furthermore, when linguistic variables are used, these degrees may be managed by specific functions. Irrationality can be described in terms of what is known as the fuzzjective. The term "fuzzy logic" was introduced with the 1965 proposal of fuzzy set theory by Lotfi A. Zadeh. Fuzzy logic has been applied to many fields, from control theory to artificial intelligence. Fuzzy logics had, however, been studied since the 1920s, as infinite-valued logics - notably by Łukasiewicz and Tarski. http://www.ijettjournal.org Page 38 International Journal of Engineering Trends and Technology (IJETT) – Volume 16 Number 1 – Oct 2014 The described procedure to learn Fuzzy rules from training data is a straight forward method to capture functional interrelations between relevant parameters. It enables the user to constrain the size of the generated rule base and the resolution of the resulting approximation by the number of input Fuzzy Sets. This resolution can be adjusted specifically to the current problem by the form and position of the Fuzzy sets. Additionally this procedure allows it to complete, extend and/or modify the generated function approximate locally by adding or changing certain rules. Classical logic only permits propositions having a value of truth or falsity. The notion of whether 1+1=2 is an absolute, immutable, mathematical truth. However, there exist certain propositions with variable answers, such as asking various people to identify a color. The notion of truth doesn't fall by the wayside, but rather a means of representing and reasoning over partial knowledge is afforded, by aggregating all possible outcomes into a dimensional spectrum. Both degrees of truth and probabilities range between 0 and 1 and hence may seem similar at first. For example, let a 100 ml glass contain 30 ml of water. Then we may consider two concepts: empty and full. The meaning of each of them can be represented by a certain fuzzy set. Then one might define the glass as being 0.7 empty and 0.3 full. Note that the concept of emptiness would be subjective and thus would depend on the observer or designer. Another designer might equally well design a set membership function where the glass would be considered full for all values down to 50 ml. It is essential to realize that fuzzy logic uses truth degrees as a mathematical model of the vagueness phenomenon while probability is a mathematical model of ignorance. Classical logic only permits propositions having a value of truth or falsity. The notion of whether 1+1=2 is an absolute, immutable, mathematical truth. However, there exist certain propositions with variable answers, such as asking various people to identify a color. The notion of truth doesn't fall by the wayside, but rather a means of representing and reasoning over partial knowledge is afforded, by aggregating all possible outcomes into a dimensional spectrum. Both degrees of truth and probabilities range between 0 and 1 and hence may seem similar at first. For example, let a 100 ml glass contain 30 ml of water. Then we may consider two concepts: empty and full. The meaning of each of them can be represented by a certain fuzzy set. Then one might define the glass as being 0.7 empty and 0.3 full. Note that the concept of emptiness would be subjective and thus would depend on the observer or designer. Another designer might equally well design a set membership function where the glass would be considered full for all values down to 50 ml. It is essential to realize that fuzzy logic uses truth degrees as a mathematical model of the vagueness phenomenon while probability is a mathematical model of ignorance. ISSN: 2231-5381 4. Phase -4 Auto Tuning If the efficiency of the driver is less than 50% then we indicate the driver that the person driving is inefficient. Even after the indication from the intelligent ECU if the driver doesn’t change the driving style then the ECU can control the engine inputs such that engine gives better performance. CAN Interface CAN is a multi-master broadcast serial bus standard for connecting ECUs. Each node is able to send and receive messages, but not simultaneously. A message consists primarily of an ID (identifier), which represents the priority of the message, and up to eight data bytes. The improved CAN (CAN FD) extends the length of the data section to up to 64 bytes per frame. It is transmitted serially onto the bus. This signal pattern is encoded in non-return-to-zero (NRZ) and is sensed by all nodes. The devices that are connected by a CAN network are typically sensors, actuators, and other control devices. These devices are not connected directly to the bus, but through a host processor and a CAN controller. Bit timing Each node in a CAN network has its own clock, and no clock is sent during data transmission. Synchronization is done by dividing each bit of the frame into a number of segments: synchronization, propagation, phase 1 and phase 2. The length of each phase segment can be adjusted based on network and node conditions. The sample point falls between phase buffer segment 1 and phase buffer segment 2, which helps facilitate continuous synchronization. Continuous synchronization in turn enables the receiver to be able to properly read the messages. Fig. 2 Bit Timing of a CAN Message Frame A CAN network can be configured to work with two different message (or "frame") formats: the standard or base frame format (described in CAN 2.0 A and CAN 2.0 B), and the extended frame format (only described by CAN 2.0 B). The only difference between the two formats is that the "CAN base frame" supports a length of 11 bits for the identifier, and the "CAN extended frame" supports a length of 29 bits for the identifier, made up of the 11-bit identifier ("base identifier") and an 18-bit extension ("identifier extension"). The http://www.ijettjournal.org Page 39 International Journal of Engineering Trends and Technology (IJETT) – Volume 16 Number 1 – Oct 2014 distinction between CAN base frame format and CAN extended frame format is made by using the IDE bit, which is transmitted as dominant in case of an 11-bit frame, and transmitted as recessive in case of a 29-bit frame. The sample data’s collected using the OBD2 tool from different cars are as shown in the Fig. CAN has four frame types: Data frame: a frame containing node data for transmission. Remote frame: a frame requesting the transmission of a specific identifier. Error frame: a frame transmitted by any node detecting an error. Overload frame: a frame to inject a delay between data and/or remote frame. To overcome the drawbacks of the existing system another system is introduced here. The proposed system makes use of the sensors present in the car i.e., the different sensor values are collected from the car and the collected data is fed to a reduction algorithm. The algorithm reduces the M*N data to M*1 data. The reduced data is fed to the model prepared. The model calculates the fuel consumption of the driver. The model makes use of fuzzy logic to calculate the fuel consumption. Fuzzy logic is a rule based system it is implemented using if then rules. For example two parameters say x & y are varied in order to know which parameter effects the fuel efficiency. Fig. 5 Unsorted Data The values collected from a car driven by different drivers are given in Fig. 4. These values vary from each other it shows that fuel consumption of the same car differs from one driver to another. The collected values are jumbled as shown Fig. 5. we have to sort them. After sorting the data is as shown below. The block diagram of the proposed system is as shown below Fig. 6 Sorted Data After applying PCA the reduced data will be as shown below Fig. 3 Proposed System IV. EXPERIMENTAL RESULTS AND COMPARISONS The data can be collected from the car using an OBD tool which is connected to the OBD port as shown in the Figure 3 Fig. 7 Reduced Data After Applying PCA Fig. 4 Data Collection ISSN: 2231-5381 http://www.ijettjournal.org Page 40 International Journal of Engineering Trends and Technology (IJETT) – Volume 16 Number 1 – Oct 2014 The snapshots below show the results of the driver’s fuel consumptions for drivers driving for every second in liters per second. The X axis shows the fuel consumption and the Y axis shows the time in seconds. The car was driven for one minute by each driver. The data collected from the driver as shown: Driver name: Rohith R Time : 19:10 Distance : 400 mts Place : Vijaynagar service road Fig.10 Fuel consumption/sec v/s Time for Driver3 Below Fig. 10 the comparison between the fuel efficiency of the drivers mentioned above. The graph also shows the frequent changes in fuel economy of the different drivers throughout the driving period of one min. Fig. 8 Fuel consumption/sec v/s Time for Driver1 Driver name: Priyadarshan M.P Time : 19:20 Distance : 400 mts Place : Vijaynagar service road Fig. 11 Comparison Of Fuel Consumption Of Different Drivers IV.CONCLUSION The fuel efficiency of the vehicle and the efficiency of the driver can be calculated using the sensor data available in the vehicle. In the present work the sensor data are collected using the OBD tool and we are analyzing the dimension reduction algorithms. Fig. 9 Fuel consumption/sec v/s Time for Driver2 Driver name: Varun.V Time : 19:30 Distance : 400 mts Place : Vijaynagar service road ISSN: 2231-5381 The instantaneous power supplied by the engine and the consumption can be calculated using the sensors that vehicles themselves have installed onboard. In the present work, an instrumentation able to communicate with the electronic system of vehicles has been used to collect sensors data from spark ignition and diesel vehicles, and models to calculate power and consumption have been developed. To calculate the consumption if there is not the specific parameter from OBD that supplies directly that value, intake airflow and air/fuel ratio are needed. If both values are not available models have been developed to calculate them. In future work even after the indication from intelligent ECU if the driver does not stop pressing the accelerator http://www.ijettjournal.org Page 41 International Journal of Engineering Trends and Technology (IJETT) – Volume 16 Number 1 – Oct 2014 unnecessarily the ECU may stop supplying the fuel or it may calculate the amount of fuel to just keep the engine running. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] Alessandrini A., F. Orecchini, F. Ortenzi, F. VillaticoCampbell,"Drive-style emission testing on conventional and hybrid vehicles to measure real road transport emissions", European Transport Research Review: Volume 1, Issue2 (2009). F. Ortenzi, R. Ragona, F. Villatico Campbell, F. Zuccari, "Experimental measurements of the environmental impact of a Euro IV vehicle in its urban use", SAE 2007-01-0966. D.Y.C. Leung, D.J. Williams, “Modelling of Motor Vehicle Fuel Consumption and Emissions Using a Power-Based Model”, Environmental Monitoring and Assessment, 65:21-29,2000. COPERT III,” Computer program to calculate emissions from road transport Methodology and emission factors (Version 2.1)”, Technical report No 49. J Van Mierlo, G Maggetto, E Van De Burgwal and R Gense, “Driving style and traffic measures—influence on vehicle emissions and fuel consumption”. Imola K. “A survey of dimension reduction techniques. FodorCenter for Applied Scientific Computing”, Lawrence Livermore National Laboratory. Andreas A. Malikopoulos, Dennis N. Assanis, and Panos Y. Papalambros. “Optimal Engine”. 2008-01-1367. Real-world driving cycles for measuring cars pollutant emissions – Part A: The ARTEMIS European driving cycles. M. Montazeri-Gh and M. Naghizadeh, “ Development of car drive cycle for simulation of emissions and fuel economy Systems Simulation and Control Laboratory”. Dennis N. Assanis, “ Development of real-world driving cycle”. Zhen Dai, Deb Niemeier, PhD, PE Douglas Eisinger, PhD, “ Driving cycles”. M. Zamalloayz, “dimensionality reduction through For faster speaker recognition” K. Naab, G. Reichart: Driver Assistance Systems for Lateral and Longitudinal Vehicle Guidance.Proceedings of the International Symposium on Advanced Vehicle Control, Tsukuba. Japan, Oct. 25. - 28. 1994, pp. 449 - 454. P. Protzel, R. Holve, J. Bernasch and K. Naab: Fuzzy Distance Control for Intelligent Vehicle Guidance.Proc. of the 12th Annual Meeting of the North American Fuzzy Information Processing Society, Allentown PA, Aug. 22- 25, 1993, 87-91. J. K. Runde, “Modelling and Control of an Automatic Transmission,” Department of Mechanical Engineering, M.I.T., M .S. thesis, 1986. D.Y.C. Leung, D.J. Williams, “Modelling of Motor Vehicle Fuel Consumption and Emissions Using a Power-Based Model”, Environmental Monitoring and Assessment, 65:21-29,2000. ISSN: 2231-5381 http://www.ijettjournal.org Page 42