Tribological Properties Of Epoxy/Al o Nanocomposites

advertisement

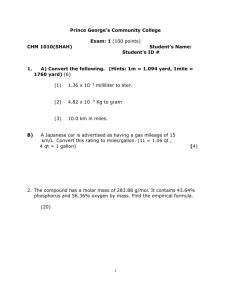

International Journal of Engineering Trends and Technology (IJETT) - Volume4Issue5- May 2013 Tribological Properties Of Epoxy/Al2o3 Nanocomposites Sudheer Kumar.N 1, Venkateswara Rao.K2*, Chakraverti.G1, Shilpa Chakra.CH2 1 Department of Mechanical Engineering Mahaveer Institute of Science and Technology, Hyderabad 2 Center for Nano Science and Technology, IST, JNTU Hyderabad Andhra Pradesh, India Abstract— Tribology is the science and technology of friction, wear and lubrication of interacting surfaces in relative motion. The sliding wear performance of Epoxy composites filled with nano-sized Al2O3 particles was studied in this paper. For this study, Al2O3 nanoparticles were synthesized by solution combustion process and size was found to be 28nm from X-ray Diffraction (XRD) and Morphology of Al2O3 nanoparticles by Scanning Electron Microscopy (SEM). Epoxy/ Al2O3 nano composite were synthesized by Al2O3 nanoparticles and resin with different hardeners like K-6, K-47 with appropriate amounts like 1 wt% of Al2O3 nanoparticles. The wear performances were studied by using pin-on-disc wear testing machine. Keywords— Epoxy/Al2O3nanocomposites, XRD, SEM, and Pinon-Disc set up I. INTRODUCTION In any high-tech structural application, strength, stiffness, durability and light weight are required, epoxy resins are seen as the minimum standard of performance for the matrix of the composite. This is why in aircraft and aerospace applications, as well as offshore racing boats, epoxies have been the norm for years [1]. Epoxy resins have been widely used in many industrial applications such as construction materials, composite adhesives, laminates, and coatings owing to their excellent mechanical properties, low cost, ease of processing, fine adhesion to many substrates, and good chemical resistance [2]. Over the last 10 years, epoxy nanocomposites have been attracted considerable attention from both fundamental research and application point of view. Resin B-47 (3221) is a modified liquid resin of low viscosity used in this study. It can be suitably formulated into high strength adhesives, solvent free coatings and floor toppings. These formulations are generally used as room temperature curing systems and it appearance clear pale yellow liquid. Epoxy Hardeners like K6, K-46 (5107) are added to the resin at a ratio of 100:10,100:50 and these acts as curing agent. ISSN: 2231-5381 The most common material used as a matrix in nanocomposites are polymers (e.g. epoxy, nylon, polyepoxide, polyetherimide, etc.,), ceramics (e.g. alumina, glass, porcelain, etc.,), and metals (e.g. iron, titanium, magnesium, etc.,). Polymers and their composites form a very important class of tribo-engineering materials and were invariably used in mechanical components such as gears, cams, bearings, bushes, bearing cages, etc. where wear performance in non-lubricated condition was a key parameter for the material selection [3]. II. EXPERIMENTAL DETAILS A. Materials The material used in this study to produce epoxy resin specimens were resin B-47 (3221) and the hardeners K-6 and K-46 (5107) from Allied Agencies. The epoxy resin system is widely used in practice and has an advantage of low viscosity at room temperature. For this study, aluminium oxide is prepared by solution combustion process (diameter 28 nm). B. Synthesis of Al2O3 nanoparticles Aluminium oxide is prepared by solution combustion process. Stoicheiometric amount of aluminium nitrate and urea are taken into beaker and stirred it for 30 minutes on a magnetic stirrer and placed it on a hot plate (~1000°C). Heating rapidly the solution contains redox mixture boils, frothing and smouldering, flaming, fumes and catches fire and burns with an in candescent flame to yield Al2O3 with evolution of large amount of gases like carbon dioxide, hydrogen oxide in the form of flames. This procedure was done in open air instead of doing it in closed vessel. C. Synthesis of Epoxy/Al2O3 Nanocomposites: Synthesis of Epoxy/Al2O3 nanocomposites are prepared by mixing resin type B-47(3221) with different Epoxy hardeners (K-6, K-46(5107)) of ratio 100:10, 100:50 for 1 wt% of Al2O3nanoparticles. For preparing nanoAl2O3/Epoxy composites, both the resin and filler with desired http://www.ijettjournal.org Page 2095 International Journal of Engineering Trends and Technology (IJETT) - Volume4Issue5- May 2013 proportion were carefully mixed under magnetic stirrer for 30 min and ultra-sonication for another 30 min and then pour in a prepared wooden mould of 60x6mm length and diameter and cure it for one day, it taken out from the mould and post cure it for another one day, then the wear specimens are cut as per the dimensions. The above fabrication process is carried for 1 wt% of treated Al2O3 nanoparticles. The treated Al2O3 nanoparticles are reinforced with 1 wt% of Al2O3 nanoparticles to study the influence of Al2O3 nanoparticles. Fig.1(a): Sample (k-6) Fig.1(b): Sample (k-47) The above figure 1(a) and 1(b) shows synthesized Epoxy/Al2O3 nanocomposites with different hardeners like K6, K-47. It is very hard to remove the samples from the wooden mould. D. Wear Experimental Procedure Wear Experiments have been conducted in the Pinon-disc type friction and wear monitor (DUCOM; TL-20) with data acquisition system, (Figures 2(a) and 2(b)) which is used to evaluate the wear behaviour of the composite, against hardened ground steel disc (En-32) having hardness of 65 HRC and surface roughness (Ra) of 0.5µm. It is versatile equipment designed to study wear under sliding condition only. Sliding generally occurs between a stationary pin and a rotating disc. Fig.2(a): Pin on disc set up The disc rotates with the help of a D.C. motor having speed range 0-2000 rev/min with wear track diameter 50 mm180 mm, which could yield sliding speed 0 to 10 m/sec. Load is to be applied on pin (specimen) by dead weight through pulley string arrangement. The system has a maximum loading capacity of 200N. Dry sliding tests were conducted at ambient conditions of temperature and humidity with different normal loads (5N, 10N) and sliding velocity 640 RPM. Prior to each test, the composite specimens was rubbed over a Sic abrasive paper upto 166-grade to ensure proper intimate contact between the sliding face of the specimen and stainless steel counter face. Also before each test, the wear track on the disc was refreshed by pressing on abrasive paper (silicon carbide water proof, grade 800) for few minutes to ensure same initial condition. E. Characterization Techniques Al2O3 nanoparticles were characterised by X-Ray Diffraction (XRD) to find the average crystalline size. Scanning Electron Microscopy (SEM) is used to find the morphology of Aluminium Oxide. Pin-on–Disc wear testing machine is used to find the friction force, coefficient of friction and wear properties of Epoxy/Al2O3 nanocomposites. III RESULT AND DISCUSSION A. X-Ray Diffraction of Al2O3: In the XRD pattern of the Al2O3 nanoparticles, the peaks are observed at 25.560, 35.140, 37.770, 43.340, 52.560, 57.480 and 68.180 the (h k l) values of the peaks are (0 1 2), (1 0 4), (1 1 0), (1 1 3), (0 2 4), (1 1 6) and (3 0 0) respectively. These results are coincided with JCPDS card number 77-2135, and it shows that the Al2O3 nanoparticles having the rhombohedra structure. The average crystalline size is measured by using Debye-Scherer’s formula [4]. Fig.2(b): Pin on disc Fig.3: XRD Pattern of Al2O3 Nanoparticle ISSN: 2231-5381 http://www.ijettjournal.org Page 2096 International Journal of Engineering Trends and Technology (IJETT) - Volume4Issue5- May 2013 According to the Debye-Scherer’s equation: approximately in both the cases and the wear rate increases gradually in K-6 hardener compared to K-46 hardener as shown in the graph below. Where D – Average size of the particle (nm) --Wavelength of the radiation (A°) θ –Diffraction angle (degree) B – Full width half maximum (FWHM) of the peak (radians) From the above formula we obtained the average crystalline size is 28nm. The lattice parameter a = b = 4.760 A°, c = 12.994 A°. B. Scanning Electron Microscopy of Al2O3: Scanning Electron graphs were taken with a HITACHI S3400NS SEM operated at 15KV. It shows different surface properties at different magnification as shown in the figure below. The Al2O3 nanoparticles are formed like sheet structure because the combustion of Al2O3 nano particles was done in open air, instead of doing in closed vessel. This is the reason why it appears sheet like structure. Fig. 5(a): Wear loss of k-6 hardener Fig. 5(b): Wear loss of k-46 hardener Finally we conclude from the figure 6 that the mass loss of K-6 hardener is better compare to K-46 hardener in both the cases. Especially the mass loss of K-46 hardener at 7.5KN is twice that of the K-6 Hardener as shown in the figure below 6. Fig. 6: Wear volume of composites as a function of loads IV. CONCLUSIONS Fig. 4 : SEM images of Al2O3 Nanoparticle C. Wear Performance: In general, the friction and wear properties always describe the whole tribological system rather than a material property alone [5]. Sliding speed of the disc is 0.52 m/sec and also calculated the sliding distance from the data is 942.6 meters. Initially the test was conducted at 2KN with 250rpm on En-31 Steel Disc of hardens 65 Rc, track diameter of 40mm and surface roughness of 0.4µm it shows no mass loss in the composites. The second test was conducted at 5KN with same parameters, then ultra- soincate the sample for 5 minutes. The weight is measured to know the mass loss of the composites. The frictional force and coefficient of friction remain constant ISSN: 2231-5381 Filling of nano Al2O3 particles in epoxy changed the microstructure of epoxy and prevented the destruction of epoxy banded structure during the friction process which might be one of the anti-wear mechanisms of nano Al2O3. The improvement and the best tribo-performance of the epoxy/1wt% of Al2O3 nanocomposites attributed to the agglomerations of nano Al2O3 particles in epoxy composite have been avoided. Epoxy Hardener K-6 shows better Wear performance compared to K-46 hardener at different loading conditions. The mass loss of the hardener K-46 is twice that of K-6 hardener at 7.5KN. XRD pattern reveals that the Al2O3 Nanoparticles contains the Rhombohedra Structure and average crystalline size measured to be 28nm.Morphology of http://www.ijettjournal.org Page 2097 International Journal of Engineering Trends and Technology (IJETT) - Volume4Issue5- May 2013 Al2O3 nanoparticles shows sheet like structure because of the combustion was done in open air. REFERENCES [1] Gurit, the Advantages of Epoxy Resin versus Polyester in Marine Composite Structure. [2] WalidNaous, Xiao-Yanyu, Qing-Xin Zhang, Kimiyoshinaito, Yutakakagawa, Journal of polymer science: Part B: Polymer Physics, 44 1466-14732006. [3] Hutchings I.M., Tribology, Friction and Wear of Engineering Materials.CRC press, London 1992. [4] Vineet Singh, Pratima Chauhan Chalcogenide Letters 6 421 2009 [5] Naga Raju B., Ramji K.and Prasad V. S. R. K.,ARPN Journal of Engineering and Applied science vol. 6, no. 6, June 2011. ISSN: 2231-5381 http://www.ijettjournal.org Page 2098