岩 土 工 程 ...

advertisement

第 31 卷

2009 年

岩

第1期

1月

土

工 程

学 报

Chinese Journal of Geotechnical Engineering

Vol.31 No.1

Jan. 2009

Modeling rate-dependent behaviors of soft subsoil under embankment loads

YIN Zhen-yu1, 2, 3, HUANG Hong-wei3, UTILI Stefano1, HICHER Pierre-Yves2

(1. Department of Civil Engineering, University of Strathclyde, Glasgow, G4 0NG, UK; 2. Research Institute in Civil and Mechanical

Engineering, Ecole Centrale de Nantes, Nantes 44321, France; 3. Key Laboratory of Geotechnical and Underground Engineering of

Ministry of Education, Department of Geotechnical Engineering, Tongji University, Shanghai 200092, China)

Abstract: The paper aims to model the rate-dependent behaviors of subsoil under embankment loads using a simple

elasto-viscoplastic model, based on the modified Cam-clay model and Perzyna’s overstress theory, coupled with Biot’s

consolidation theory. A geotextile reinforced embankment is studied. An inverse analysis procedure is proposed to identify the

viscosity parameters of subsoil from the settlements due to the first few loading phases. In order to assess the performance of

the proposed model, numerical predictions using the determined parameters are then compared with those obtained by four

other models. Special attention is given to the effect of reinforcement on delayed deformations and on the stability of the

embankments and foundations. The performance of the proposed inverse analysis procedure is also assessed. Finally, according

to the simulation runs, it can be concluded that the proposed model is easy to be calibrated and suitable for geotechnical projects.

The proposed model can describe the rate-dependent behaviors of soft soil compared with the modified Cam-clay model, with

accuracy using the simple constitutive equations compared with other viscoplastic models.

Key words: clay; embankment; geotextile; rate dependence; elasto-viscoplasticity

CLC number: TU43

Document code: A

Article ID: 1000–4548(2009)01–0109–09

Biography: YIN Zhen-yu(1975– ), male, research fellow in geotechnical engineering. E-mail: zhenyu.yin@gmail.com.

模拟堤坝荷载作用下软土的速率效应特性

尹振宇

1,2,3

,黄宏伟 ,UTILI Stefano1, HICHER Pierre-Yves2

3

(1.英国斯特莱斯克莱德大学,格拉斯哥 G4 0NG 英国;2.法国南特中央大学,南特 44321 法国;3.同济大学地下建筑与工程系

教育部重点实验室,上海 200092)

摘 要:用基于 Perzyna 超应力理论与修正剑桥模型的简单的弹黏塑性本构模型,耦合比奥固结理论,来模拟堤坝荷载

作用下的软土的速率效应特性。以土工织布加固的堤坝为实例,提出从最初几个加载阶段下的沉降数据来确定黏性参

数的反分析法。根据反分析的参数值来模拟,同实测值予以比较,并同文献中使用其他四个不同本构模型的模拟结果

进行比较,比较研究表明:本文建议的模型具有优越性。特别研究了土工织布加固对堤坝下软土的滞后变形和稳定性

的影响。良好的模拟结果反应了所提出的反分析法的可用性,同时展示了所使用的弹黏塑性本构模型在岩土工程中的

实用性:弥补了修正剑桥模型不能模拟速率效应特性的缺点;跟其他黏塑性本构模型比较, 本模型参数确定方法简单,

模拟结果准确。

关键词:软土;堤坝;土工织布;速率效应特征;弹黏塑性

0

Introduction

The construction of embankments on soft natural

soil deposits has become increasingly important in the

last decades, as development occurs more and more on

areas previously considered unsuitable for construction.

Stability of embankments is a major consideration in the

design and construction, while consideration of the

duration of construction is also required. Geosynthetic

reinforcement has been widely used to improve the

bearing capacity of subsoil and then to fasten the

construction, as reported by researchers [1-4]. To simulate

the rate-dependent behaviors of embankments, a suitable

and simple constitutive model is required. This study is

an attempt to use a simple but robust elasto-viscoplastic

───────

Foundation item: Supported by a grant from “Conseil Regional des Pays

de la Loire” in France

Received date: 2007–12–14

110

2009 年

岩 土 工 程 学 报

(EVP) model EVP-MCC, based on the framework of

Perzyna’s overstress theory and the elasto-plastic

modified Cam-clay model, with an inverse analysis

procedure for identifying soil parameters, in order to

describe the rate-dependent behaviors of compressible

subsoils under embankment loads.

The strain-rate-dependency behaviors of soft

compressible subsoil under a reinforced embankment

load at Sackville in Canada have been studied. Details of

Sackville embankment and field measurements were

reported by Rowe et al.[5-6] used a fully coupled Biot’s

consolidation theory with the modified Cam-clay model

(named MCC in this study) to analyze the reinforced

embankment showing that the elasto-plastic model was

not adequate for accurately predicting the different

features of the embankment behaviors. Rowe &

Hinchberger [7] demonstrated that an EVP model could

better reproduce the strain-rate-dependent behaviors of

the foundation soil using an EVP model with an elliptical

cap yield surface (named EVP-EC in this study).

However, the model has four additional parameters

compared to the Cam-clay model to be identified. A

comparison between different model predictions was

later carried out by Gnanendran et al.[8] Using the MCC,

an EVP model based on the original Cam-clay model and

Perzyna’ overstress theory by Adachi & Oka [9] (named

EVP-OCC in this study), and a constitutive model based

on the critical state theory and secondary compression

coefficient Cαε proposed by Kutter & Sathialingam[10]

(named CREEP in this study). However, their predictions

performed less well than those by EVP-EC model by

Rowe & Hinchberger[7]. Thereby the need for a new

model, the EVP-MCC, capable of taking into account the

rate-dependent behavior of soils with only two additional

parameters in comparison with the MCC model, is

adopted to simulate the subsoil behavior under the

embankment loads.

In the following, first, the EVP model and its

constitutive equations are briefly introduced. Then, the

Sackville reinforced embankment is illustrated. An

inverse analysis procedure is used to identify the

viscosity parameters from the several initial loading

phases.

Settlements,

vertical

and

horizontal

displacements, and excess pore pressures are calculated.

The obtained predictions are compared with field data

and predictions by four other constitutive models to

assess the performance of the models as well as the

performance of the inverse analysis procedure. The

effect of reinforcement is also numerically investigated.

1

Constitutive model

The constitutive model EVP-MCC developed by

Yin et al. (in press), is based on the framework of

Perzyna’s overstress theory[11-12] and the elasto-plastic

MCC[13] model. The elastic behavior in the proposed

model is given by the same expressions as in the MCC

model. The constitutive equations of the proposed model

for normally consolidated clays are derived as follows:

εij =

sij′

2G

+

δ ⎞

⎛ 3s ′

p ′

δ ij + µ φ ( F ) ⎜ ij2 + ( 2 p′ − pcd ) ij ⎟ ,(1)

3K

3 ⎠

⎝M

with

⎛

⎜

⎝

⎡ ⎛ pcd

⎞⎤ ⎞

− 1⎟⎥ − 1⎟ ,

s

⎠⎥⎦ ⎟⎠

⎣⎢ ⎝ pc

µ φ ( F ) = µ ⎜ exp ⎢ N ⎜

(2)

where sij′ is the deviatoric stress tensor ( sij′ = σ ij′ − p′δ ij ;

G is the elastic shear modulus, which is related to the

elastic bulk modulus (K=(1+e) p′ /κ) by assuming a

constant value of Poisson’s ratio ν(G=3(1-2ν)K/2(1+ν));

κ is the slope of the swelling line in the “ e − ln σ v′ ” plane;

δij is the Kronecker delta with δij=1 for i=j and δij=0 for

i≠j; pcs is the static preconsolidation pressure; pcd is the

dynamic preconsolidation pressure corresponding to the

current stress state; M is the slope of the critical state line;

N is the viscosity index; µ is the viscosity coefficient;

p′ is the effective mean stress; q is the deviatoric stress,

relating to the second invariant of deviatoric tensor; <

and > represent the MacCauley´s function.

The proposed model involves the parameters of the

MCC model {ν, κ, λ, e0, M, pc′0 }, and two additional

parameters of viscosity {N, µ}. Details can be found in

Yin et al.[14] and Yin & Hicher [15].

2

Sackville reinforced embankment

2.1 Embankment and soil conditions

A full scale test embankment was constructed on

organic silty clays and clayey silts in New Brunswick

(Canada), consisting of a 25 m long unreinforced section

and a 25 m long reinforced section connected by a

reinforced transition (Fig. 2). A number of instruments

was installed and readings taken during construction (see

Rowe et al.[5]).

第1期

YIN Zhen-yu, et al. Modeling rate-dependent behaviors of soft subsoil under embankment loads

The elasto-plastic Mohr-Coulomb model is adopted

for the embankment fill consisting of gravelly silty sand

and clay. The unit weight and parameters of fills are

listed in Table 1.

The geotextile reinforcement is modeled as a series

of linear elastic perfectly plastic bar elements. The

parameters adopted for the reinforcement were: axial

stiffness J = 1920 kN/m, and tensile strength Tf = 216

kN/m (see Rowe et al.[6]). The embankmentreinforcement-soil interface was modeled using nodal

compatibility joint elements, assumed to be rigid plastic

and nondilatant.

Table 1 Parameters of the embankment (after Rowe et al.[6])

Height

γ

E

-3

ν

c'/kPa

ϕ/(°)

Ψ/(°)

kh=kv

/(m·s 1)

-

/m

/(kN·m )

/kPa

0.0~1.3

18.8

10000

0.35

0

43

8

1

1.3~9.6

19.6

15000

0.35

17.5

38

7

1

2.2

Parameter calibration

For the compressible subsoil, the time-dependent

behavior is taken into account by using the EVP-MCC

model. For all the soil layers, the Poisson’s ratio ν is

taken equal to 0.3 as for most clays; the slope of the

critical state line M is taken equal to 1.12 as proposed by

Rowe et al.[6] for the MCC model; the coefficients of

compressibility and the vertical and horizontal

permeabilities are taken by Rowe et al.[6] and Rowe &

Hinchberger [7]; the preconsolidation pressure pc′0 is

determined using the in-situ vertical effective stresses

′ , the coefficient of earth pressure at rest K 0′ and the

σ v0

ratio of overconsolidation OCR reported by Rowe et al.[5]

and Rowe & Hinchberger[6]:

⎡ 3 (1 − K ′ )2

(1 + 2 K0′ ) ⎤

0

⎥ σ v0

′ =⎢

′ OCR .

+

pc0

3

⎢ (1 + 2 K0′ ) M 2

⎥

⎣

⎦

(3)

The viscous index N is taken equal to 10 according to

111

Yin et al.[14]. The parameters adopted for the subsoil of

the embankment are summarized in Table 2.

2.3 Finite element analysis

Plain strain conditions are assumed in the finite

element method analysis (FEM). The modeled range in

vertical direction is 14 m deep and 65 m away from the

embankment centerline horizontally. The displacement

boundary conditions are as follows: at the bottom, both

vertical and horizontal displacements are fixed, while

along the left and right vertical boundaries, only the

horizontal displacements are fixed. The adopted drainage

boundary conditions are as follows: the ground surface is

kept drained while the other boundaries undrained. The

FEM mesh is constituted by 2519 nodes and 1204

triangular elements. Each element has 6 Gauss

integration points. The adopted mesh is proved to be

suitable since analyses run using 2 and 10 times denser

meshes gave rise to closely convergent results.

The construction of the embankment is simulated

by increasing the unit weight of each layer of the

embankment fills linearly over time. Eight phases of

construction are adopted according to the construction

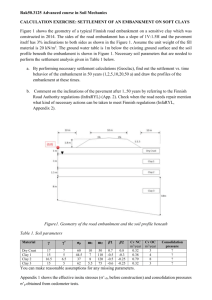

sequence shown in Figure 1. The apparent viscosity is

then identified from the settlements measured during the

initial loading phases by performing inverse analysis.

2.4 Inverse analysis procedure to identify A procedure of inverse analysis is carried out to

obtain the value of µ. The parameter is calibrated by an

optimization procedure. According to this procedure, the

input values of the parameter are iteratively changed

until the calculated results matched the observed data.

The methodology of the inverse analysis is shown in

schematic form in Figure 2. In the optimization

procedure, the difference between the observed data and

the model predictions is expressed as follows:

Table 2 Values of MCC parameters and permeability for subsoil

Layer

Depth/m

κ

λ

e0

γ/(kN·m 3)

OCR

K′0

ν

M

kh/( m·s 1)

kv/(m·s 1)

Sol6

0~1.1

0.06

0.28

2.2

17.8

3.6

0.68

0.3

1.12

3.0 x10-6

3.0 x10-7

Sol5

1.1~2.7

0.02

0.12

1.31

17.8

3.6

0.70

0.3

1.12

2.0 x10-7

1.0 x10-7

Sol4

2.7~4.4

0.05

0.23

1.39

16.5

1.0

0.75

0.3

1.12

2.0 x10-7

5.1 x10-8

Sol3

4.4~5.8

0.06

0.28

2.3

17.2

1.0

0.80

0.3

1.12

1.0 x10-6

1.0 x10-7

Sol2

5.8~10

0.03

0.15

1.12

17.2

1.2

0.80

0.3

1.12

3.3 x10-8

8.2 x10-9

Sol1

10~14

0.03

0.15

1.12

17.2

1.2

0.80

0.3

1.12

3.3 x10-8

8.2 x10-9

-

-

-

112

岩 土 工 程 学 报

2009 年

Fig. 1 Section of embankment with instrumentation layout and construction sequence (after Rowe et al.[5])

iterative process.

The procedure of parameter identification by

inverse analysis, as presented in Figure 2, is used to

determine the parameter µ from the settlements

measured for plates 8S and 9A during the first loading

Fig. 2 Procedure of identifying parameter by inverse analysis

Fig. 3 Iterative process to identify soil viscosity parameter

Ln ( P ) =

1

tini − tfin

∫

R * ( t ) − R ( µ , t ) dt ,

(4)

where the notation ||…|| represents the scalar norm in the

space variable, tini-tfin is the time of observation, R is the

response of the system, and R*(t)-R(µ,t) is the difference

between experimental and numerical data. Since

measurements are taken at discrete moments, the integral

of the norm can be replaced by a summation and the

length of observation by the number of measurements.

The difference between measured and predicted data is

then expressed as follows:

Ln ( P ) =

1

Mn

Mn

∑(R

i

*

i

− Ri )

2

,

(5)

Ln(P)<ε (ε is a given tolerance) can be used as a

discriminate function to judge the convergence of the

phases up to 5.7 m, assuming that µ is identical for all

subsoil layers. The iterative process to update the

parameter is presented in Figure 3. The optimization

loops (Table 3) are carried out as follows:

(a) First, an interval of acceptable values for the

parameter µ is selected, as shown in the first two lines in

Table 3. The initial value of the parameteris then taken as

the average of the upper and lower bound values.

(b) This value is used in the FE analysis to calculate

the settlements of the points 8S and 9A. Then the

difference between the values determined by FE and the

observed data is calculated. The sign of the difference is

then used to half the range of the parameter for the

successive iteration according to a dichotomy procedure.

If the sign of the difference is positive, the value of the

parameter assumed in the FE simulation becomes the

new upper bound for the successive iteration and

conversely if it is negative, it becomes the new lower

bound. In the former case, the predicted curve will

overestimate the experimental one whereas in the latter

case it will underestimate it. The value adopted in the

successive iteration is taken as the average between the

bounds of the new range as shown in Table 3.

(c) The procedure is stopped when convergence is

achieved that is when the norm of the difference between

第1期

YIN Zhen-yu, et al. Modeling rate-dependent behaviors of soft subsoil under embankment loads

experimental data and predictions become smaller than a

predefined tolerance. In Table 3, the value of the

parameter at the end of the iterative process, µ = 1.07×

10 8 s 1kPa 1, is given.

The final value of the parameter µ is then used in

the FE analysis.

Table 3 Optimization loops for identifying viscosity parameter

Loop of µ

Iteration number

Logµ/(s-1·kPa-1)

Initial

-5

Up

Initial

-10

Low

1

-7.5

Up

2

-8.75

Low

3

-8.125

Low

4

-7.813

Up

5

-7.97

Converge

Final

10

-7.97

113

settlements for locations 10A and 11A from the first

loading phases until the embankment reaches 8.2 m can

be attributed to the presence of a soft zone of soil and the

auger being driven down in the foundation soil by the

surrounding soil as pointed out by Rowe &

Hinchberger [7]. On the other hand, it is found out that the

settlements of the foundation soil decrease with the depth

and the settlement-time responses at different depths are

very similar. This result is reasonable and in general

agreement with the field measurements.

= 1.07×10- 8 s- 1.kPa- 1

Remarks: up – Upper bound value; low – Lower bound value.

3

Results

3.1

Settlements at 6S, 7S, 8S, and 9A, 10A, 11A

The comparison between measured and calculated

settlements for different positions beneath the

embankment and at different depths in the subsoil is

shown in Figure 4. The evolution of the settlements with

time generally agrees with the field measurements. For

all positions investigated but 11A, settlements are

overestimated so long as the embankment height reaches

5.7 m. From that point of construction onwards, good

agreement is achieved so long as the embankment height

reaches 8.2 m except for positions 6S and 10A. But, in

the last phase of the embankment construction, a

significant

discrepancy between analysis and

observations is found. Rowe et al.[5] reported that a large

increase of settlements was observed at location 8S

during this phase of construction because of the rupture

of the geotextile, perhaps due to horizontal

non-uniformity of the foundation shear strength. On the

contrary, the geotextile does not reach the failure

condition because of the assumptions of soil

homogeneity made in the FE analysis. The calculated

settlement at location 6S is greater than the measured

one. This may be due to the presence of a zone of soft

soil that is not spotted by soil investigations. The

difference between the measured and calculated

Fig. 4 Measured and predicted settlements

In the following, the predictions obtained by the

selected five models for locations 7S and 8S are

compared with the field observations as shown in Figure

5. Considering the first construction phases of the

embankment, up to the height of 4.2 m, the predictions

by the EVP-EC model capture well the settlements

whereas other models overestimate them. Considering

the subsequent two loading phases, the predictions by the

proposed model, EVP-MCC, result to be better than the

others. Finally considering the last phase, from end of

construction onwards, the settlements predicted by the

elasto-plastic model (MCC) become stable after a while

whereas those predicted by the four elasto-viscoplastic

models increase indefinitely over time as observed in the

field.

A similar comparison is carried out for plates 9A

and 11A, as shown in Figure 6. For 9A (Fig. 6(a)),

considering the first construction phases of the

embankment up to the height of 5.7 m, the predictions by

EVP-MCC overestimate the settlements while the other

four models give better results. For the subsequent

114

岩 土 工 程 学 报

loading phases, the predictions by EVP-EC and the

proposed model are closer to the field observations than

those by MCC, EVP-OCC and CREEP models. For 11A

(Fig. 6(b)), all predicted settlements are lower than the

field observations, whereas predictions by EVP-MCC

are better than those obtained by the other models.

2009 年

deformation at the embankment toe, as noted by Rowe &

Hinchberger[7].

Fig. 5 Settlements by different models for (a) 7S and (b) 8S

Fig. 7 Vertical displacements by different models

Fig. 6 Settlements by different models for 9A and 11A

3.2 Vertical displacements at 1H, 2H, 3H and 4H

The comparison between the measured and

calculated vertical displacements at the heave plates 1H,

2H, 3H and 4H is shown in Figure 7. A good agreement

is achieved up to an embankment height of 5.7 m.

However, for the last two loading phases, the calculated

displacements are greater than the measured ones. Rowe

et al.[4] observed significant “thrust faulting” in the heave

zone at a fill height of 8.2 m, while the present method of

analysis does not account for this type of discontinuous

Figure 7(b) shows a comparison between

predictions by the EVP-EC and the proposed EVP-MCC

model for plates 1H and 4H. Both of them well capture

the evolution of vertical displacements up to the fill

height of 5.7 m. Considering the subsequent phase, the

rate of displacements calculated by EVP-EC is different

from that by the proposed model, while the final

displacements predicted by the two models are close to

each other.

Figure 7(c) shows a comparison of predictions by

the five models for plate 2H. The proposed model and

EVP-EC can well reproduce the evolution of vertical

displacements as long as the embankment height of 5.7

m is reached, while the other models overestimate the

displacements. For the subsequent phase, the predicted

第1期

YIN Zhen-yu, et al. Modeling rate-dependent behaviors of soft subsoil under embankment loads

displacements by EVP-EC are higher than those

predicted by other models. Concerning 3H (Fig. 7(d)),

the predictions by MCC, EVP-OCC and CREEP models

are better than those by the proposed model as long as

the embankment reaches the height of 5.7 m, and much

lower than those by the proposed model for the

subsequent phase. The lack of agreement in this case can

be attributed to the “thrust faulting” described by Rowe

et al.[4] and Rowe & Hinchberger[7].

3.3 Horizontal displacements

A good agreement between the measured and

calculated horizontal displacements at the embankment

toe by the proposed model and EVP-EC is achieved as

long as an embankment height of 8.2 m is reached, as

shown in Figure 8.

Fig. 8 Horizontal displacements by different models

Figure 9 presents the comparisons of horizontal

displacements at inclinometers 22I and 23I for different

models with observations. For both inclinometers,

considering t = 449 h, the predictions by the proposed

model are close to the field data and to the predictions by

other models up to a depth of 5 m, whereas they

overestimate displacements at greater depth. Considering

22I at t = 473 h (Fig. 9(b)), the proposed model

underestimates displacements until a depth of 2 m and

115

then overestimates them resulting to be less accurate than

the other ones. However, the predictions are quite similar

for all models. Based on the simulation run, it can be

stated that any model is able to well predict some

features of the horizontal displacements at some times,

but none of them can capture all the curves. Rowe &

Hinchberger [7] indicated the many difficulties associated

with the prediction of lateral deformations beneath

embankments due to: difficult estimation of Poisson’s

ratio for the foundation soil, anisotropy and

non-homogeneity

of

the

foundation

soil,

three-dimensional effects, etc. In conclusion, the general

magnitude and profile of lateral displacements beneath

the embankment can be determined with reasonable

accuracy using the proposed EVP-MCC model.

3.4 Excess-pore pressure in the foundation soil

Figure 10 presents the comparison between the

measured and predicted excess pore pressure for

different positions and depths (from 2 to 10 meters) in

the foundation soil. The predictions by the proposed

model are in reasonable agreement with the measured

values for all phases of construction. It is worth noting

that the predictions for locations 12 (Fig. 10(b)) and 19

(Fig. 10(c)) by MCC, EVP-OCC and CREEP models are

overestimated.

3.5 Reinforcement effect

A calculation for the case of embankment without

reinforcement is carried out. In this case, the pore

pressure dissipation is a little faster but similar to the

case of reinforced embankment (Fig. 11). Settlements

and displacements are much greater than in case of

Fig. 9 Horizontal displacements by different models

116

岩 土 工 程 学 报

2009 年

Fig. 10 Excess-pore pressures in the foundation soil

Fig. 11 Comparison of the calculated results at different loading phases for the embankment with and without reinforcement

reinforced embankment as shown in Figure 11 for a fill

height of 9.5 m; therefore the reinforcement can increase

the stability of the embankment. As described by

Leroueil & Rowe[2], the reinforcement serves two

primary functions: it resists some or all of the earth

pressure that develops with the embankment; it also

resists the lateral deformations of the foundation that

would otherwise occur in response to the applied vertical

load.

Figure 12 presents the comparison of settlements at

plates 7S, 8S, 9A, 10A and 11A with and without

reinforcement. The settlement increases far more rapidly

and more significantly at lower depths for un-reinforced

embankments, while for deep depths (for plate 10A), the

effect of reinforcement is small. It is worth remarking

that the reinforcement by geotextile makes it possible to

reduce the construction duration of an embankment on

compressible soils.

4

Conclusions

The rate-dependent behaviors of the foundation soil

under an embankment reinforced by geotextile are

simulated using an elasto-viscoplastic model, EVP-MCC,

coupled with the Biot´s consolidation theory, with an

inverse analysis procedure to identify the viscosity

parameter.

The soil parameters are determined from laboratory

tests with the value of µ identified by the inverse

analysis from the settlement curves of several initial

phases of embankment loads. The predictions by

theproposed model are compared with the field data, as

well as with the predictions by other four constitutive

models:a good performance is achieved for the proposed

model and for the proposed procedure of inverse analysis.

Based on the simulations performed for both cases of

reinforced and unreinforced embankment, it is possible

to conclude that the use of reinforcement with geotextile

can significantly reduce the creep deformation of the

foundation soil and therefore improve the stability of the

embankment and underlying foundation. It is found that

the reinforcement affects the effective stress state, thus

affects the velocity field of subsoil. The presence of the

第1期

117

YIN Zhen-yu, et al. Modeling rate-dependent behaviors of soft subsoil under embankment loads

reinforcement significantly delays both horizontal and

vertical displacements in the part of the embankment

opposite to the berms.

[4] ROWE R K, LI A L. Behavior of reinforced embankments on

soft rate-sensitive soils[J]. Géotechnique, 2002, 52(1): 29–

40.

[5] ROWE R K, GNANENDRAN C T, LANDVA A O,

VALSANGKAR A J. Construction and performance of a

full-scale geotextile reinforced test embankment, Sackville,

New Brunswick[J]. Can Geotechnical J, 1995, 32(3): 512–

534.

[6] ROWE R K, GNANENDRAN C T, LANDVA A O,

VALSANGKAR A J. Calculated and observed behavior of

reinforced embankment over soft compressible soil[J]. Can

Geotechnical J, 1996, 33(2): 324–338.

[7] ROWE R K, HINCHBERGER S D. Significance of rate

effects in modeling the Sackville test embankment[J]. Can

Geotechnical J, 1998, 35(3): 500–516.

[8] GNANENDRAN C T, MANIVANNAN G, LO S C R.

Fig. 12 Comparison of the calculated settlements for the

embankment with and without reinforcement

A good agreement between the measured and

predicted settlements, displacements and excess pore

pressures is achieved. So it can be concluded that FE

analyses with fully coupled EVP-MCC model and the

Biot’s consolidation theory can adequately describe the

rate-dependent behaviors of the foundation soil under a

reinforced embankment compared with the modified cam

clay, with accuracy using the simple constitutive

equations compared with other viscoplastic models. All

the simulation runs demonstrate that the proposed model

can be easily calibrated and used in geotechnical

projects.

Influence of using a creep, rate, or an elastoplastic model for

predicting the behavior of embankments on soft soils[J]. Can

Geotechnical J, 2006, 43(2): 134–154.

[9] ADACHI T, OKA F. Constitutive equations for normally

consolidated clay based on elasto-viscoplasticity[J]. Soils and

Foundations, 1982, 22(4): 57–70.

[10] KUTTER B L, SATHIALINGAM N. Elastic-viscoplastic

modeling of the rate-dependent behavior of clays[J].

Géotechnique, 1992, 42(3): 427–441.

[11] PERZYNA P. The constitutive equations for work-hardening

and rate sensitive plastic materials[C]// Proc Vibration

Problems, 1963, 3: 281–290.

[12] PERZYNA P. Fundamental problems in viscoplasticity[M].

Advances in Applied Mechanics, Academic Press, 1966: 243

–377.

[13] ROSCOE K H, BURLAND J B. On the generalized

References:

[1] HUMPHREY D N, HOLTZ R D. Reinforced embankments: a

review of case histories[J]. Geotextiles and Geomembranes,

[2] LEROUEIL S, ROWE R K. Embankments over soft soil and

Geotechnical

535–609.

[14] YIN Z Y, ZHANG D M, HICHER P Y, HUANG H W.

1987, 6(4): 129–144.

peat.

stress-strain behavior of wet clay[J]. Engrg Plasticity, 1968:

and

geoenvironmental

engineering

handbook[M]. Springer Kluwer Academic Publishers, 2001:

463–500.

Modeling of the time-dependent behavior of soft soils using a

simple

elasto-viscoplastic

model[J].

Chinese

J

of

Geotechnical Engrg, 2008. (in Chinese)

[15] YIN Z Y, HICHER P Y. Identifying parameters controlling

[3] LI A L, ROWE R K. Combined effects of reinforcement and

soil delayed behaviour from laboratory and in situ

prefabricated vertical drains on embankment performance[J].

pressuremeter testing[J]. International Journal for Numerical

Can Geotechnical J, 2001, 38(6): 1266–1282.

and Analytical Methods in Geomechanics. (in press).